Patents

Literature

31 results about "Air changes per hour" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Air changes per hour, abbreviated ACPH or ACH, or air change rate is a measure of the air volume added to or removed from a space (normally a room or house) divided by the volume of the space. If the air in the space is either uniform or perfectly mixed, air changes per hour is a measure of how many times the air within a defined space is replaced. In many air distribution arrangements, air is neither uniform nor perfectly mixed.

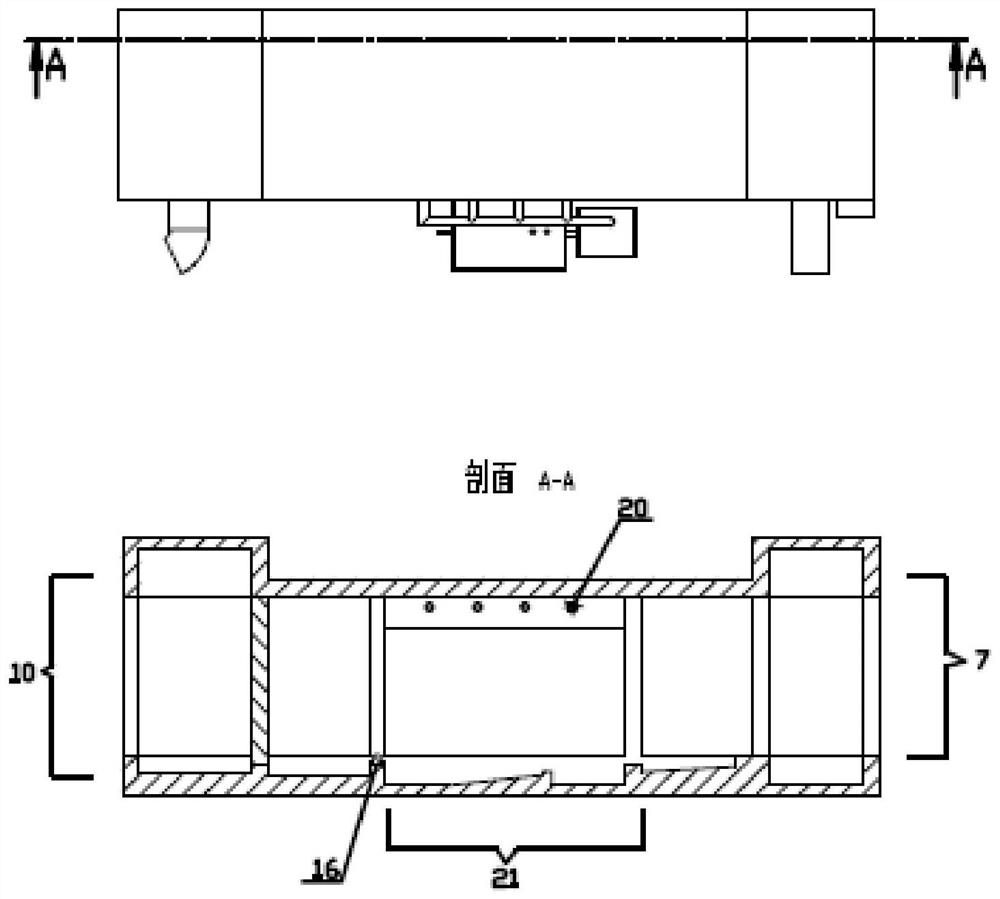

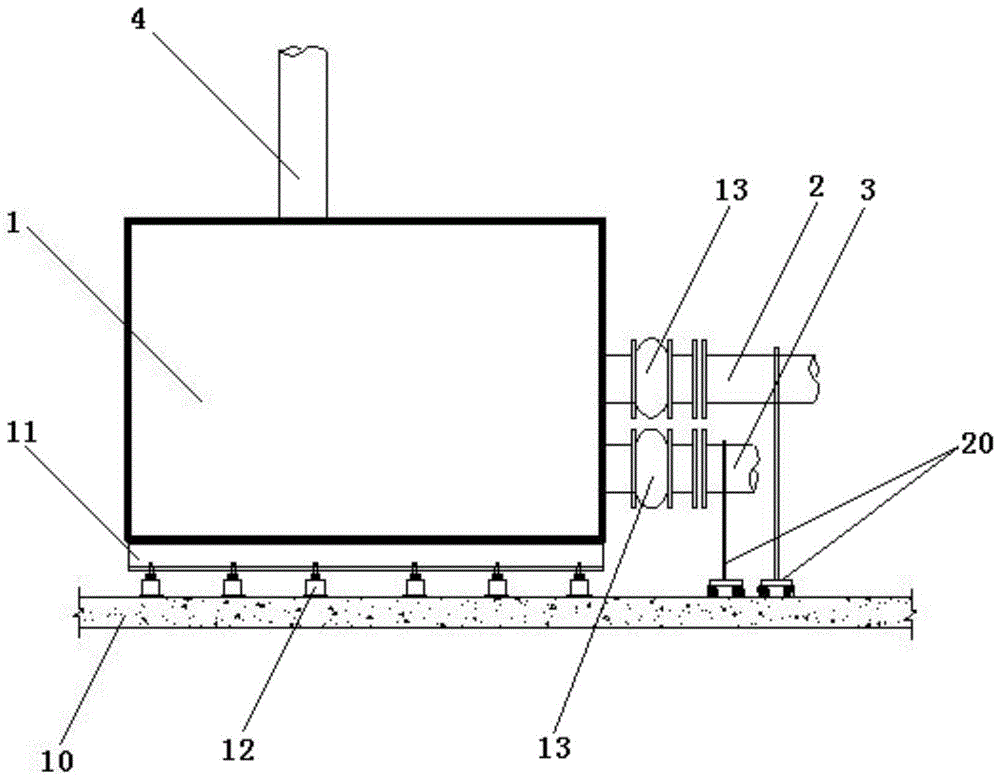

UV air cleaning and disinfecting system

InactiveUS6855295B2Increase exposureEffective radiationCombination devicesMechanical apparatusUV Radiation ExposureAir filter

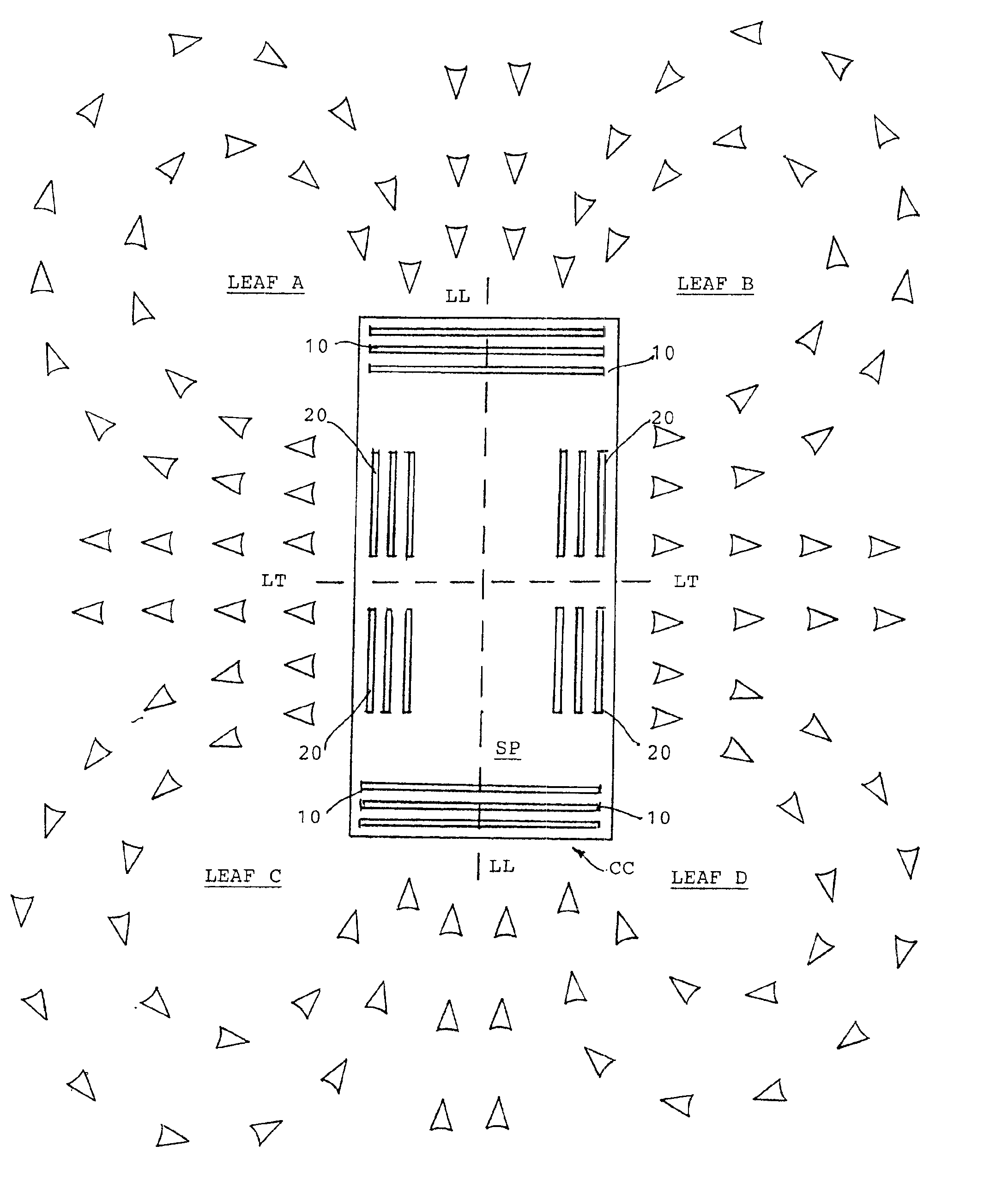

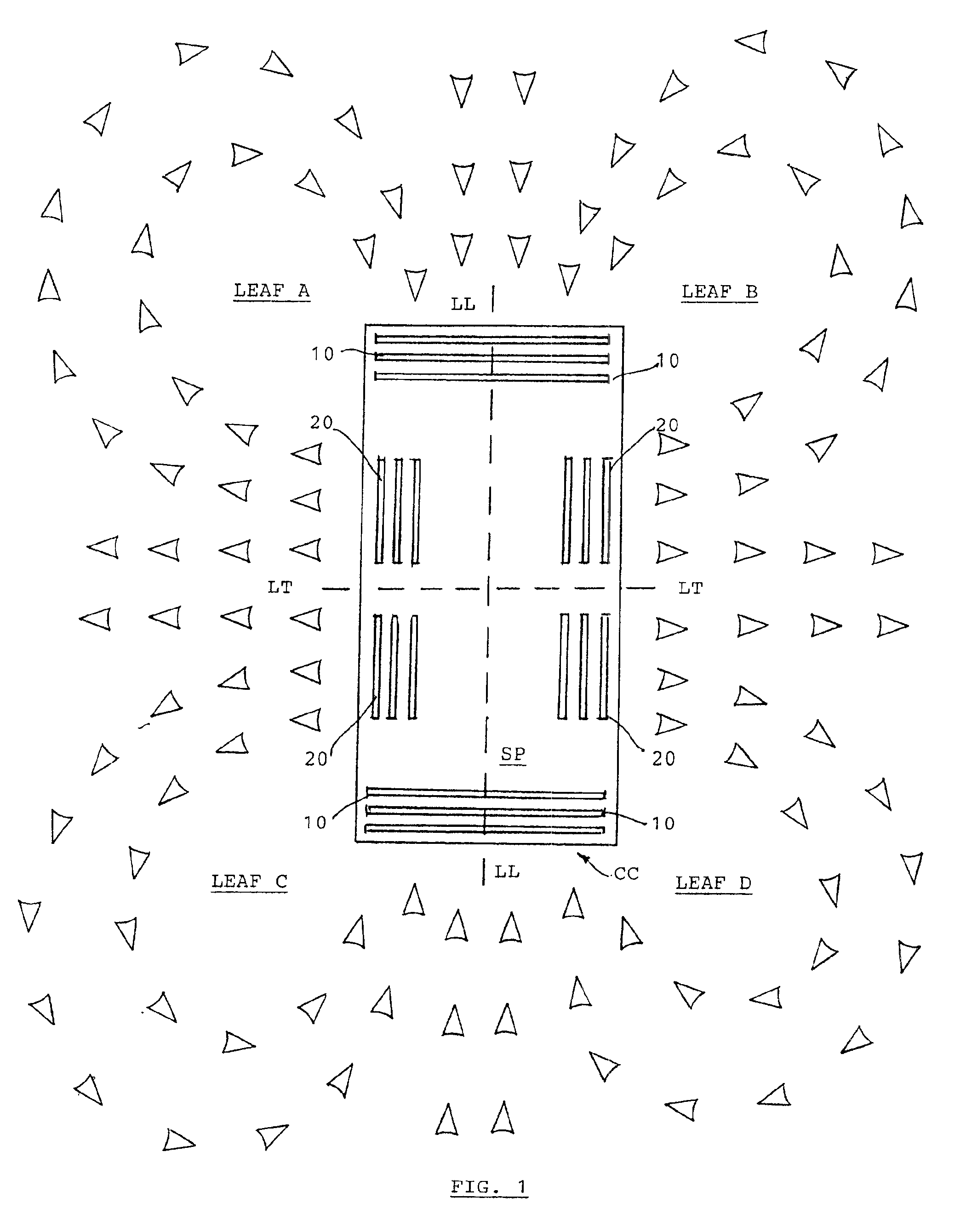

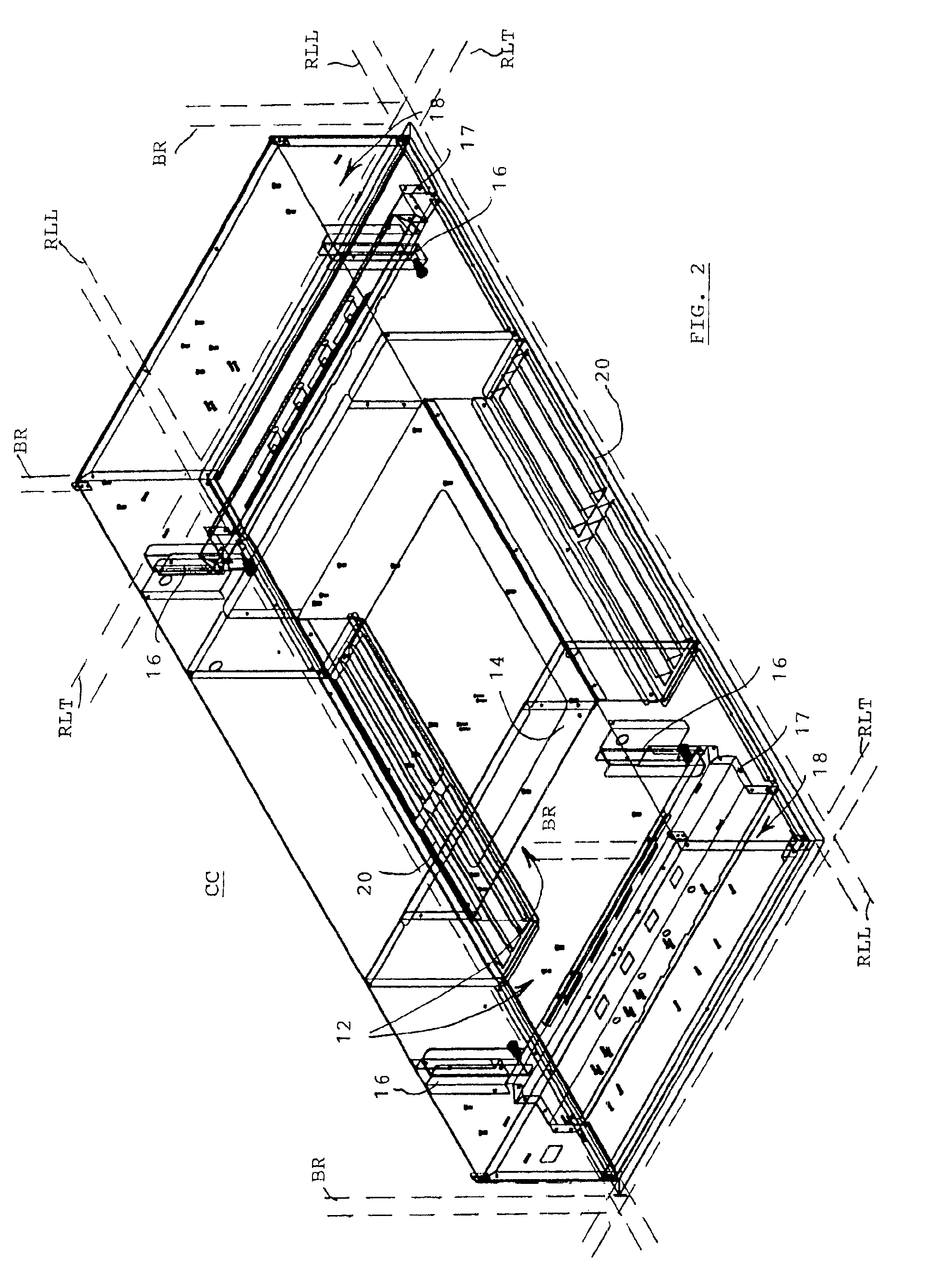

A UV air cleaning and disinfecting system has an enclosed chassis with an inlet / outlet surface panel on one planar side thereof, and the chassis is mounted in the space behind a drop ceiling with its surface panel coplanar with the ceiling surface and facing into the room space. The surface panel has a pair of inlet vent arrays on opposite longitudinal sides of the surface panel from each other, and a pair of outlet vent arrays on opposite latitudinal sides of the surface panel from each other. Arranged in the chassis are an air blower unit and an array of UV lamps. The positioning of the inlet and outlet vent arrays establish four mutually circulating air streams in a four-leaf-clover pattern in the room space, which obtains a high-efficiency throughput of air handled by the system. The UV lamp array is arranged longitudinally across the chassis between the inlet ventsat a lower elevational position of the chassis. A pair of air filters is arranged at intake chambers separated by UV-blocking baffles at opposite longitudinal sides of the main chamber housing the air blower in the center of the chassis at an upper elevational position from the array of UV lamps. The upward and downward movement of the air through the filters and over the UV lamps toward the center causes swirling movements which enhance the exposure of pathogens in the air to UV radiation exposure. The surface panel is formed with a series of cascading door sections to allow wide access across the center of the chassis for maintenance of the UV lamps, with a first door section connected to an interlock switch for cutting off electrical power to the UV lamps and fan when the first door section is opened. The UV-blocking baffles have an angled shape and slits at an upper flange thereof covered with fused silica shields. The system's chassis is dimensioned to fit on ceiling rails spaced at standard 4 foot length and 2 foot width intervals. The system can provide 99% or higher inactivation of pathogens in the air with 2 to 7 or more air changes per hour for standard sized rooms.

Owner:KULP JOHN C

Pest control system

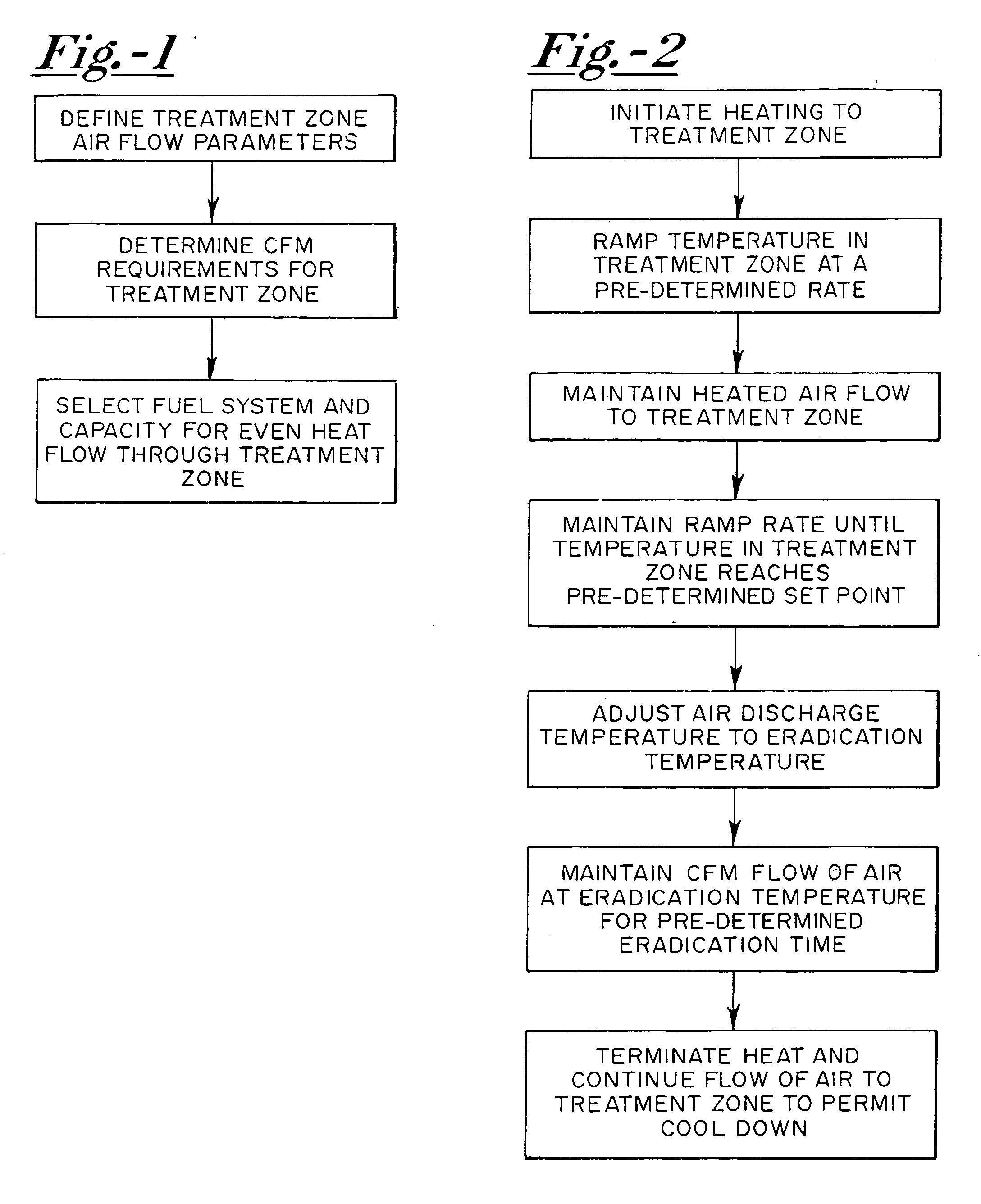

InactiveUS20070023980A1Maintain structural integrityReduce impactHeatInsect catchers and killersControl systemEngineering

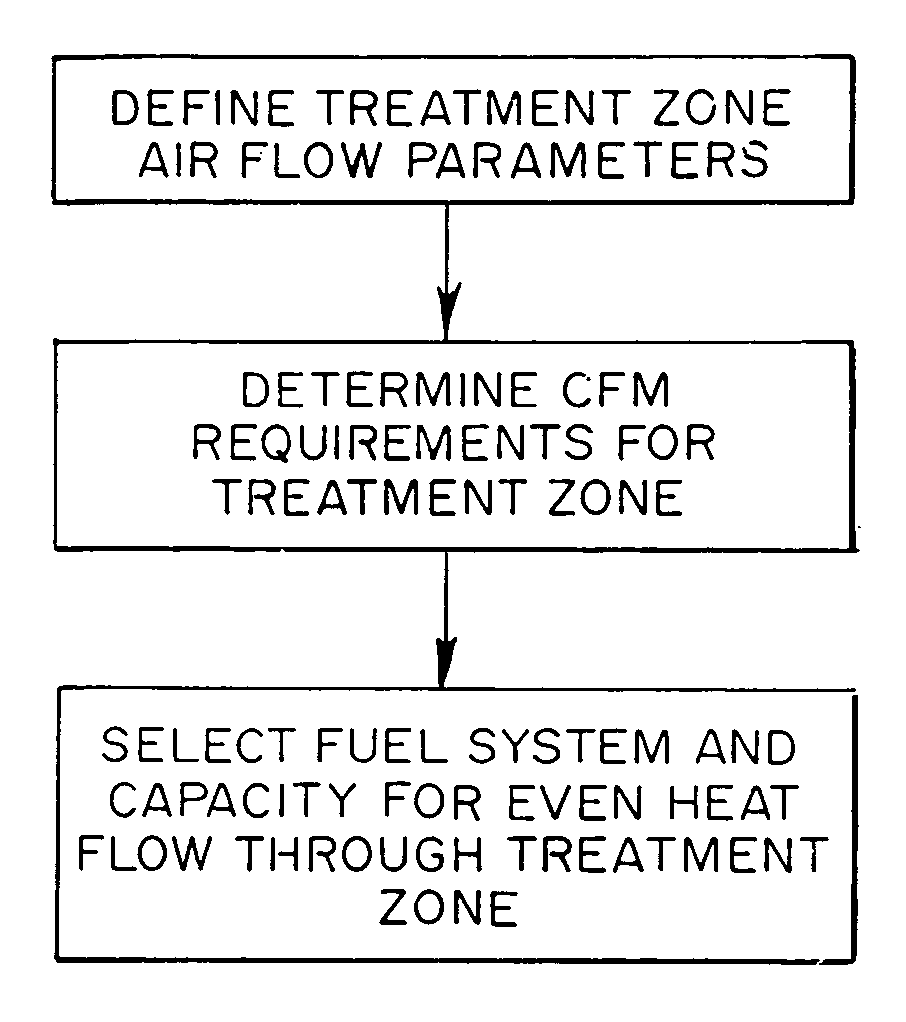

A method of pest control which includes heating the affected area to a temperature which is lethal for the pests being exterminated, and maintaining this elevated temperature in the zone for a predetermined period of time. The treatment is undertaken after determining the air flow parameters for the treatment zone, so as to be able to determine the CFM requirements for achieving a requisite air flow rate of between 0.5 and 70 air changes per hour in the treatment zone. Heated air is introduced to the treatment zone at the requisite air flow rate and at an initial temperature of at least about 240° F., with the temperature in the treatment zone being elevated at a predetermined rate until the air temperature reaches a predetermined set point. Once the predetermined set point temperature is reached within the treatment zone, the introduced heated air is adjusted to an eradication temperature and maintained in such a condition for a predetermined period of time sufficient to eradicate respective pests within the treatment zone.

Owner:ABARAW MIMOUN

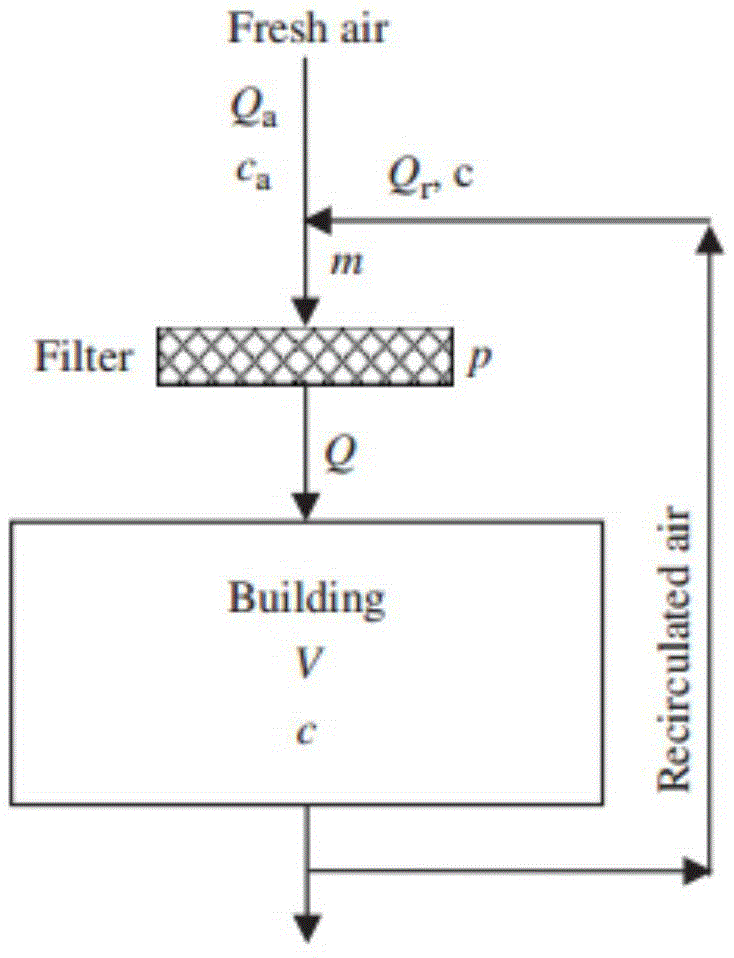

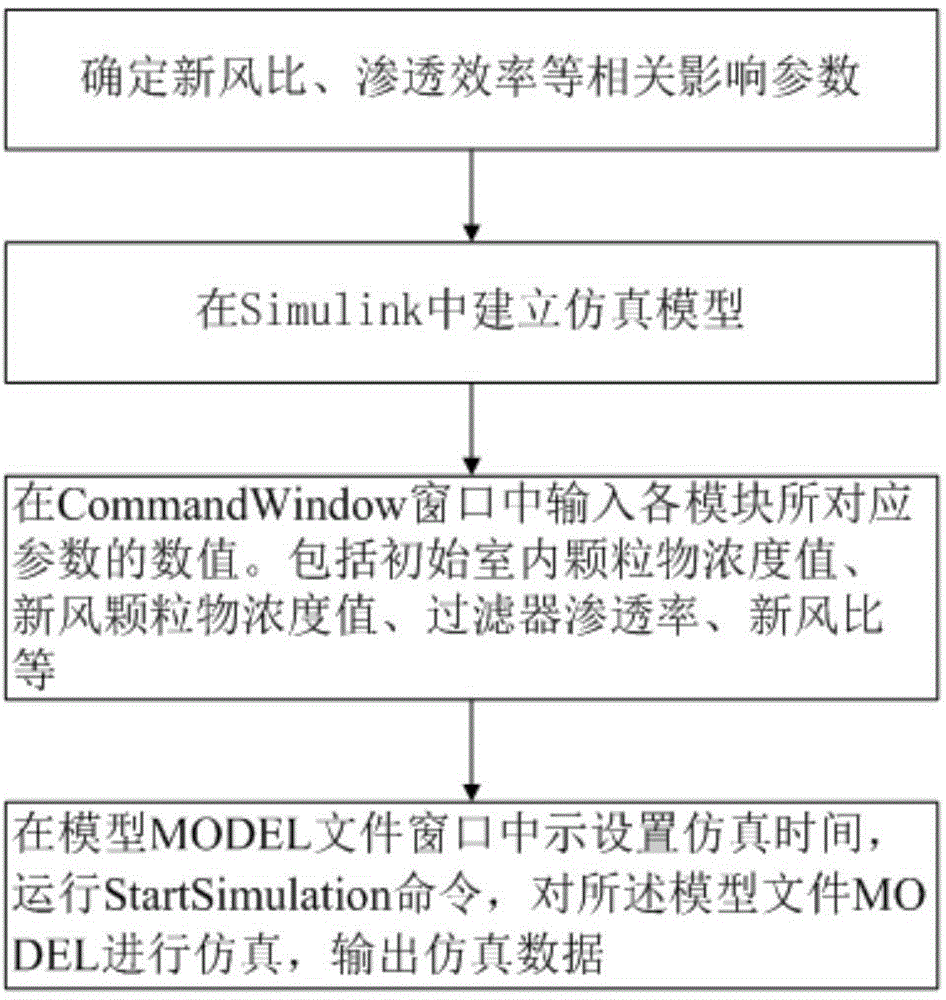

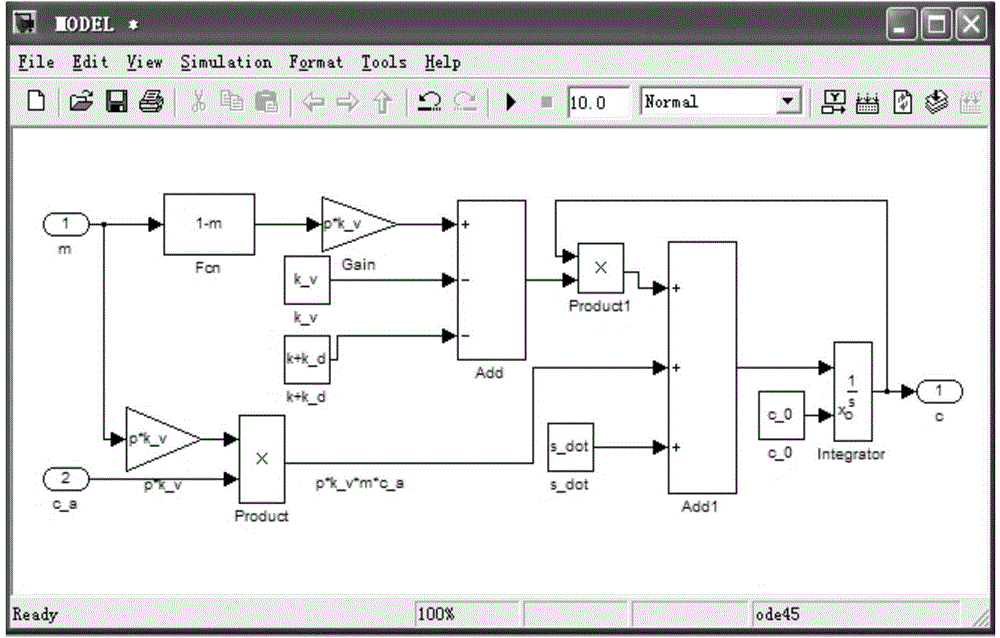

Method for predicating dynamic changes of indoor PM2.5 concentration

InactiveCN104573379AAccurate graspMaster quicklySpecial data processing applicationsAir volumeFresh air

The invention discloses a method for predicating dynamic changes of indoor PM2.5 concentration and belongs to the technical field of monitoring of particle concentration. The method comprises the following steps: 1 establishing a Simulink dynamic simulation model; 2 detecting indoor particle PM2.5 concentration, outdoor particle PM2.5 concentration, and fresh air volume and air returning volume of an air conditioning system, and calculating a fresh air ratio and an air exchange frequency; 3 inputting obtained parameters into the dynamic simulation model, and obtaining indoor particle PM2.5 concentration changing data according to actual detection data; 4 controlling the change of a certain input parameter in the dynamic simulation model and keeping other parameters unchanged; obtaining indoor particle PM2.5 concentration changing data according to a theoretical set value; and 5 analyzing and comparing the data obtained in the step 3 and the step 4 and formulating an optimal indoor ventilation scheme. The detection scheme has a reasonable design, the detection cost is low and the precision is high; the aim of predicating the change of the indoor particle concentration can be realized and the instantaneity is good.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

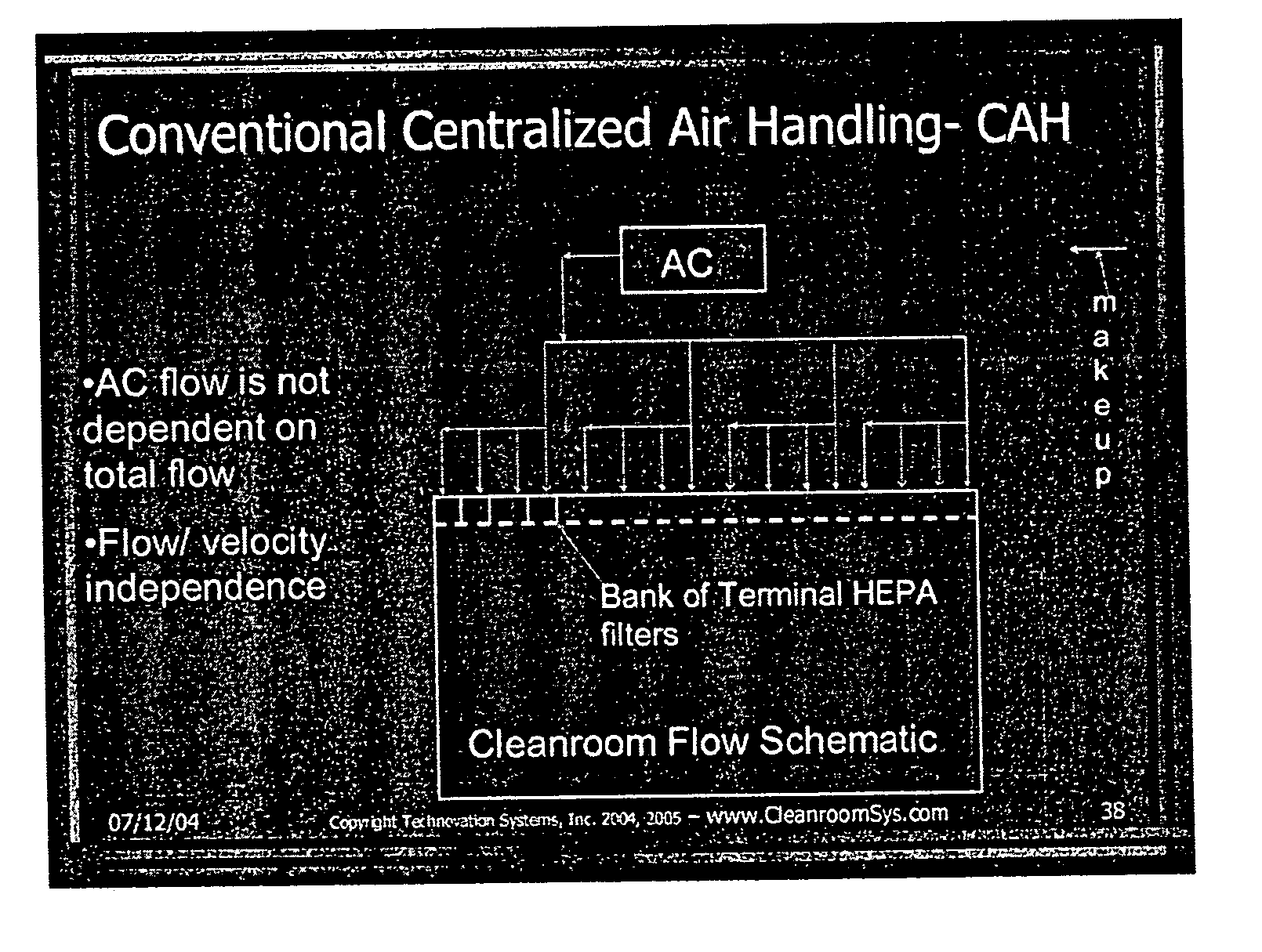

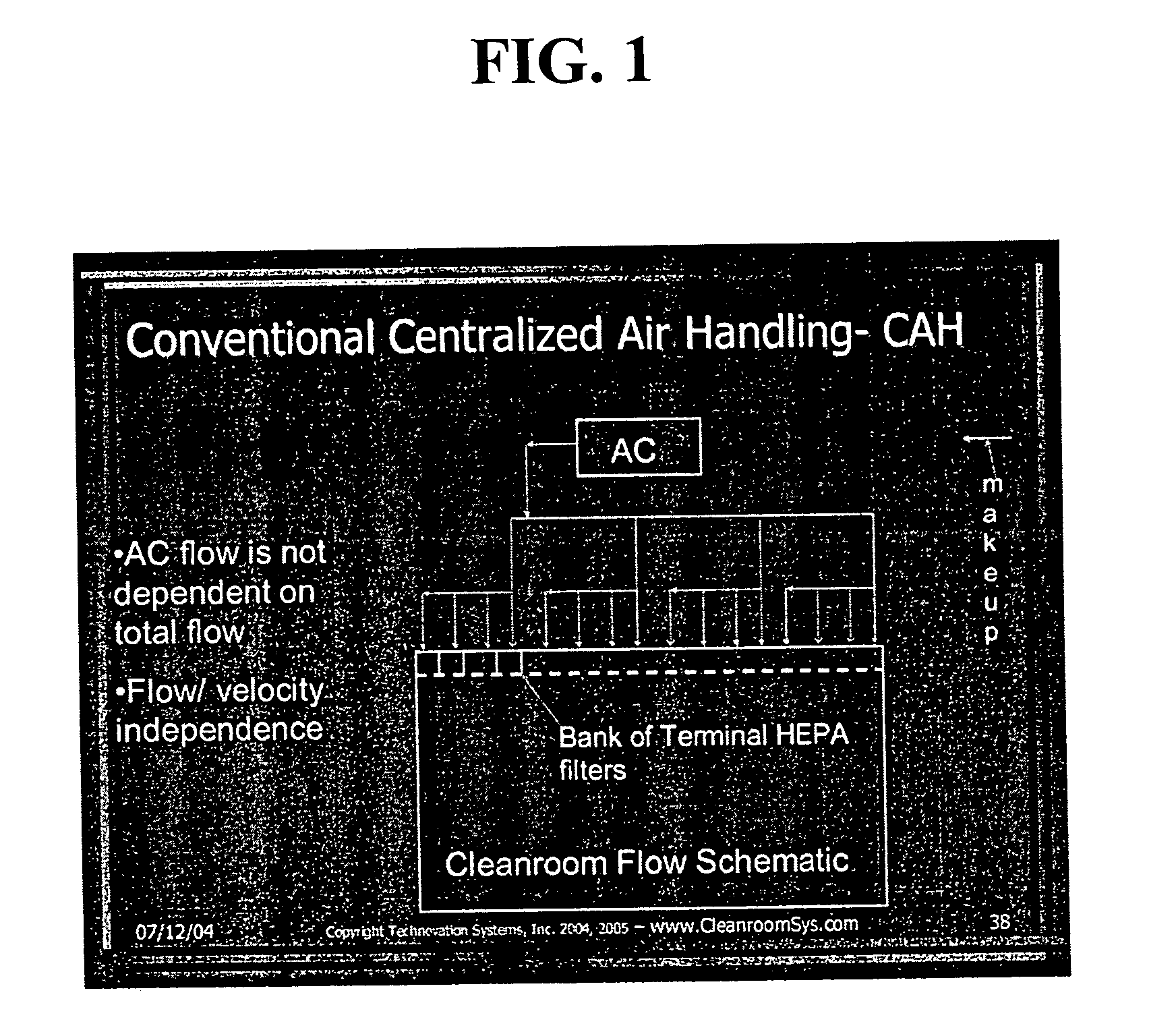

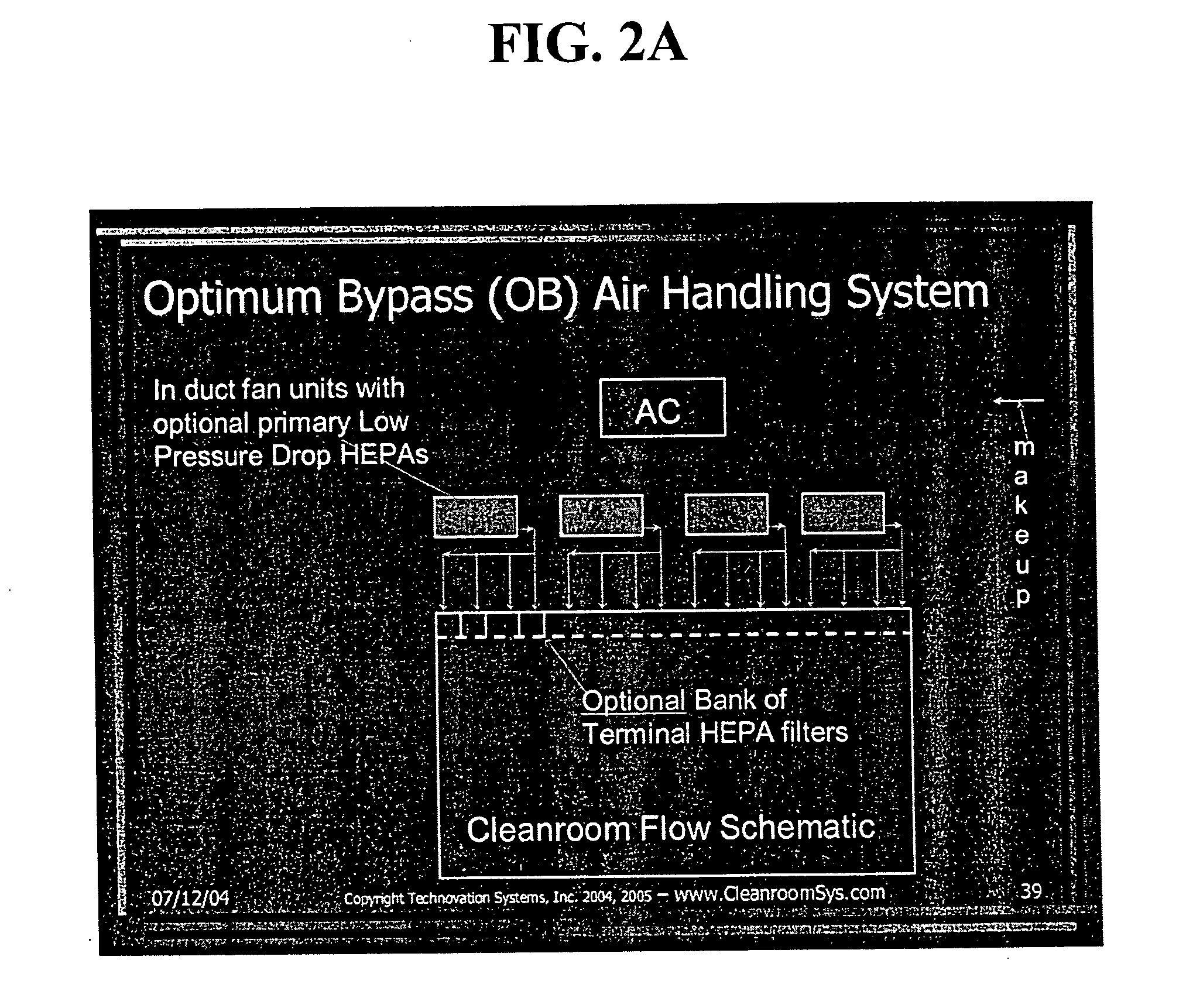

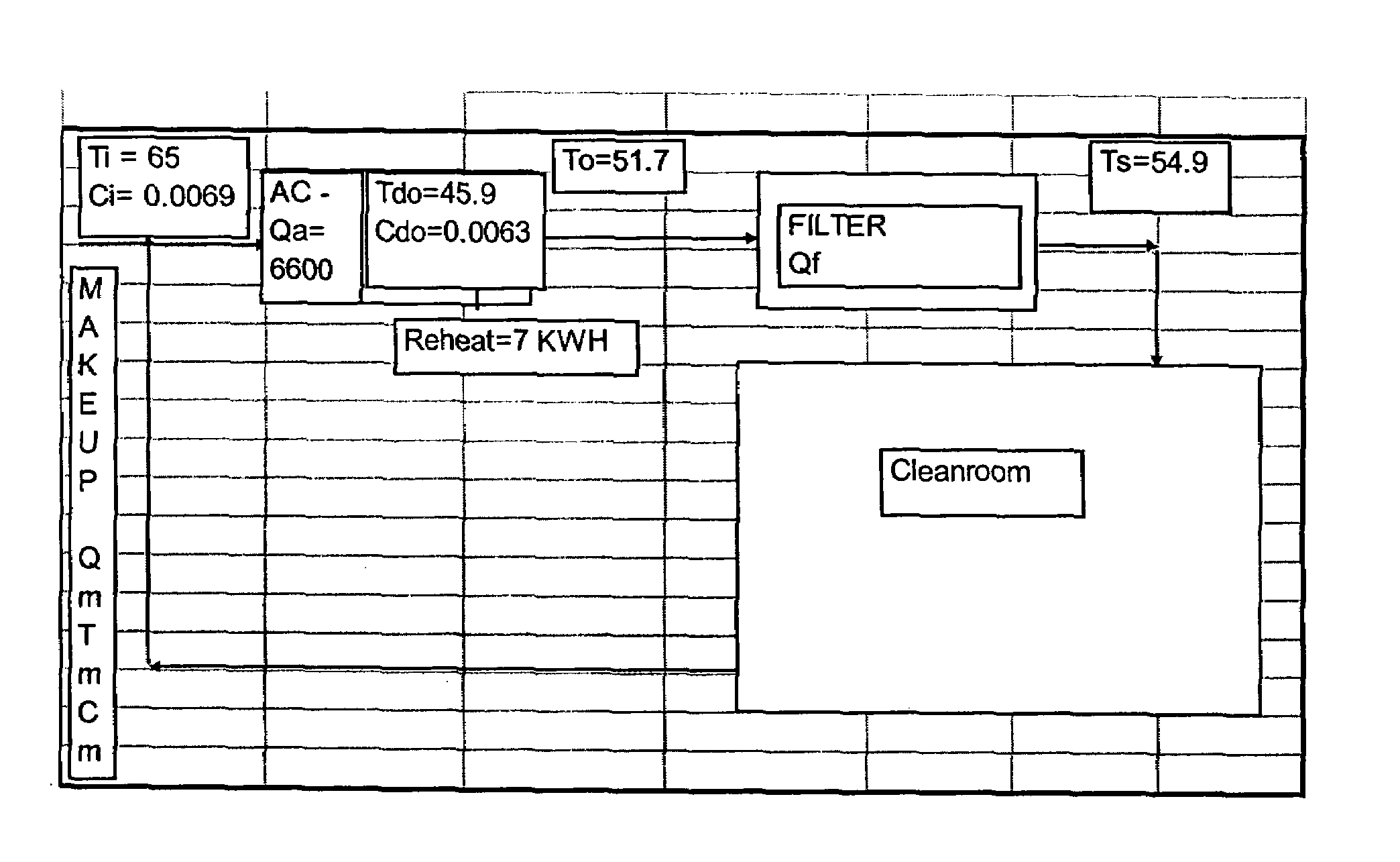

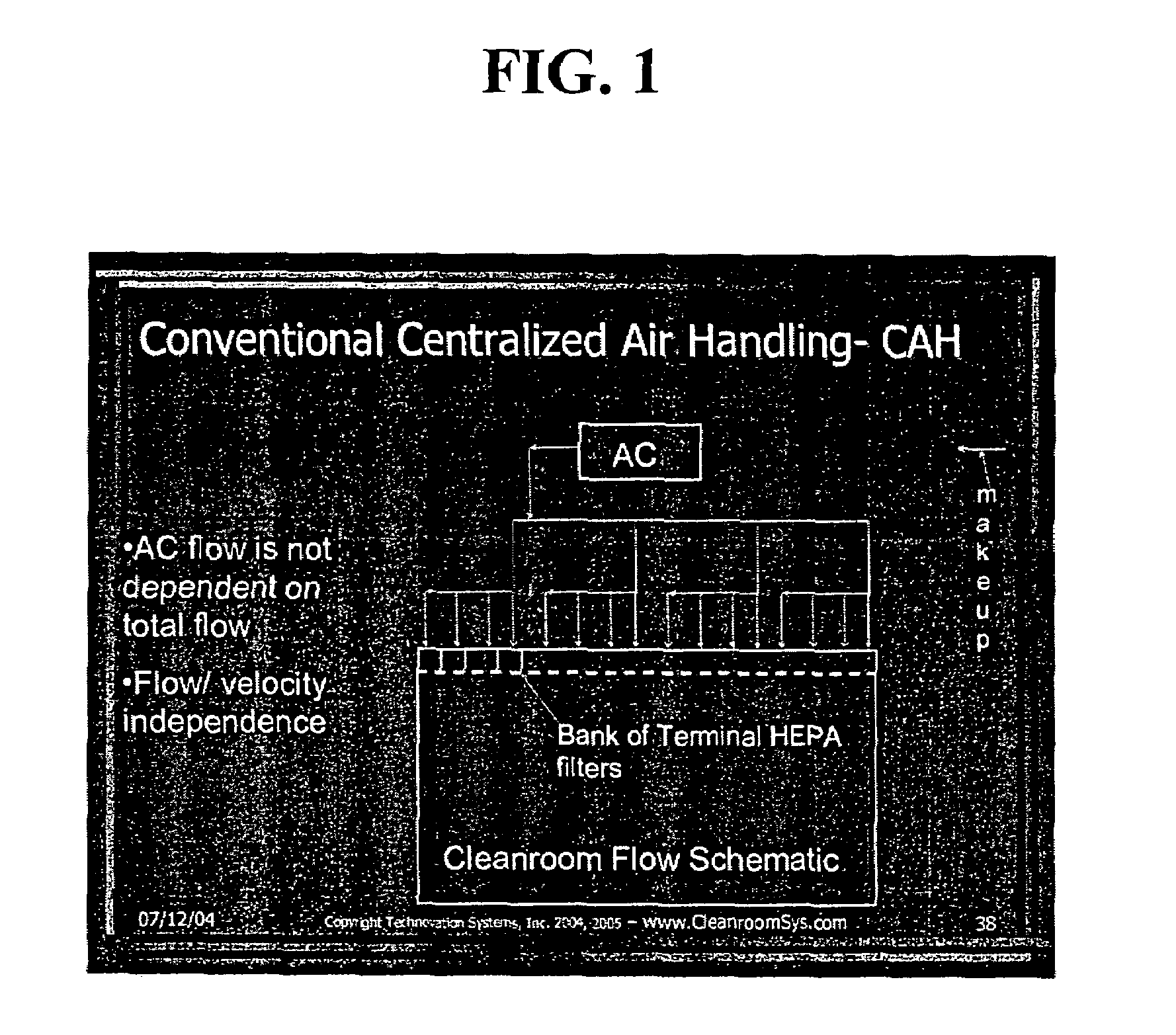

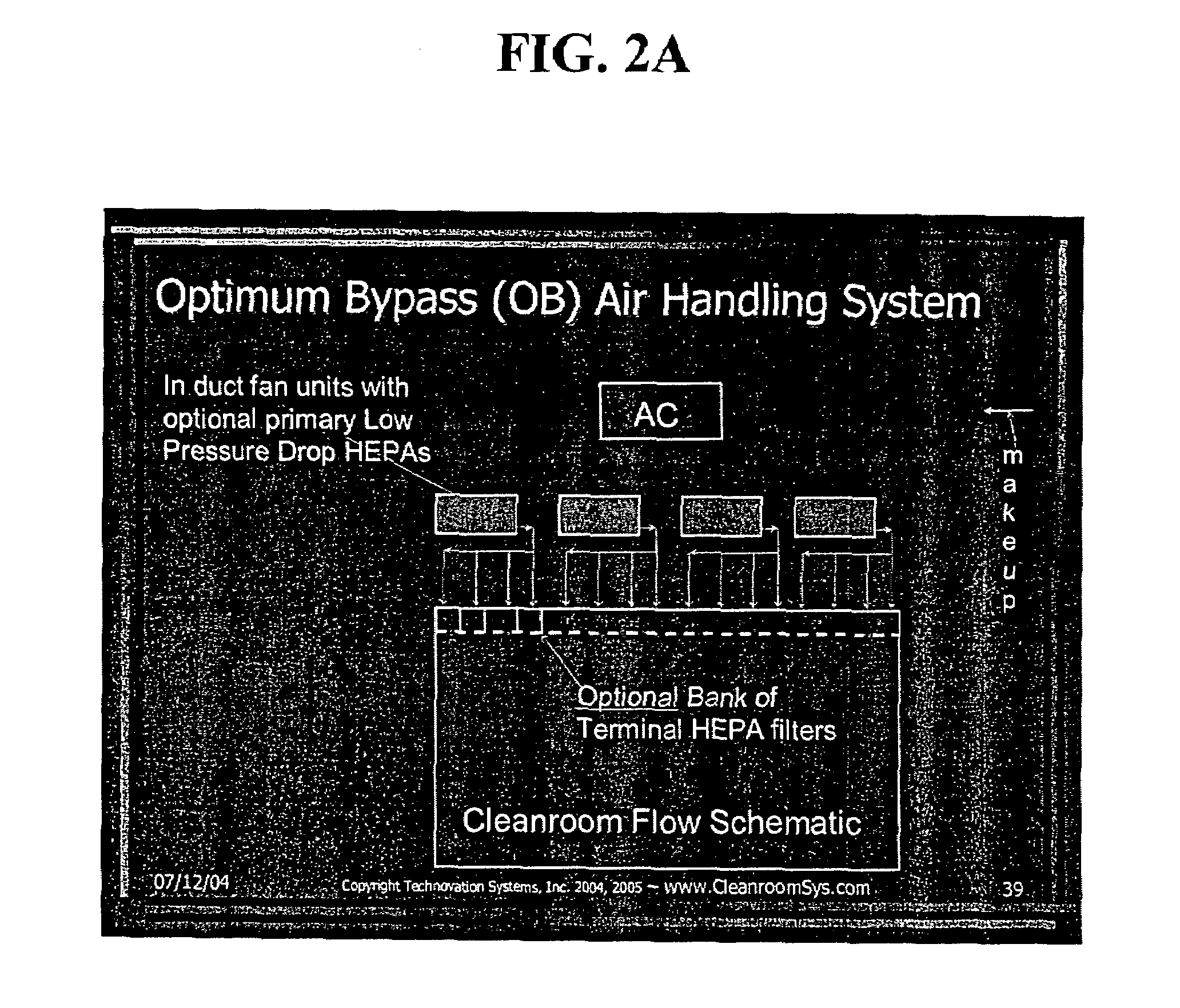

Energy efficient air handling system for cleanrooms

InactiveUS20070089854A1Low costEliminate useMechanical apparatusMilk preservationEngineeringAir change

A refrigeration based air handling system design process for significant energy and cost savings in cleanroom and other applications requiring large air change rates is presented. The process utilizes a by pass around the air conditioning system, the ratio of bypass to air conditioning flow being such that minimal or no reheat of the air is required for applications having relative humidity (RH) control requirements and with RH control being achieved via cooling. If dehumidification is achieved by adsorptive processes, then the by pass ratio is varied so as to minimize cooling of the heated dry air. In other non relative humidity control applications the bypass is varied to minimize the air conditioning flow, thereby decreasing cost, but by using optimum cooling coil velocities in a manner such that system energy for airflow is minimized. The energy and cost savings achieved by this process vary between 65% to 15% depending on the Class of the cleanroom and / or on the number of air changes per hour required.

Owner:JAISINGHANI RAJAN A

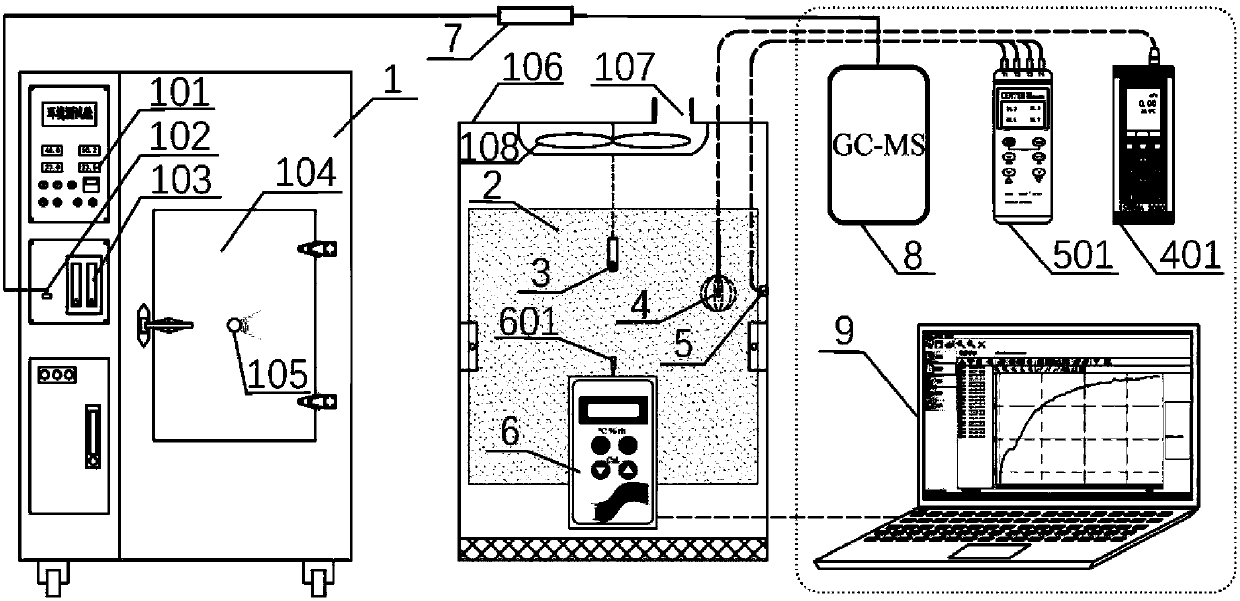

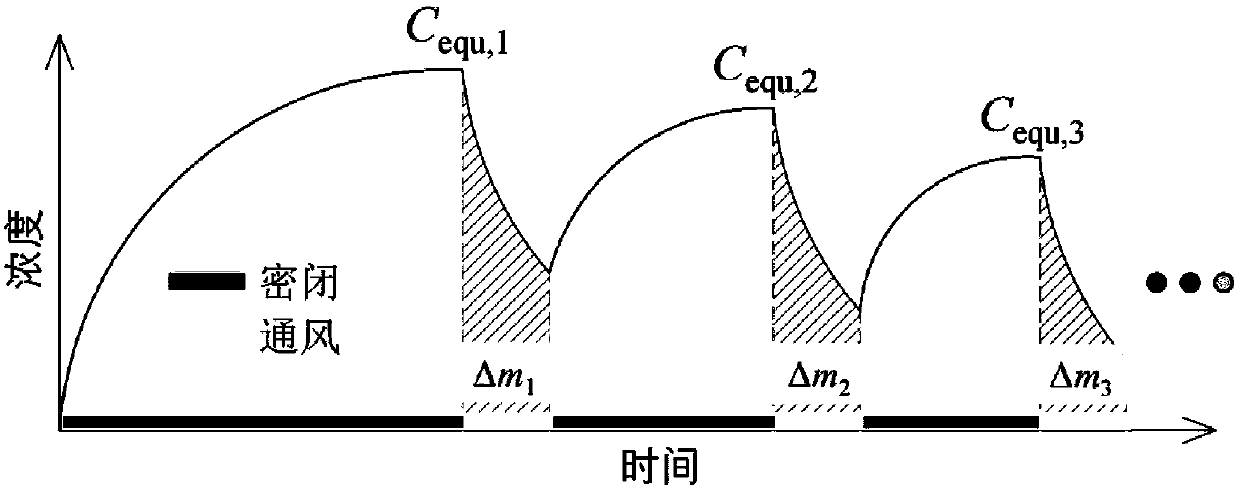

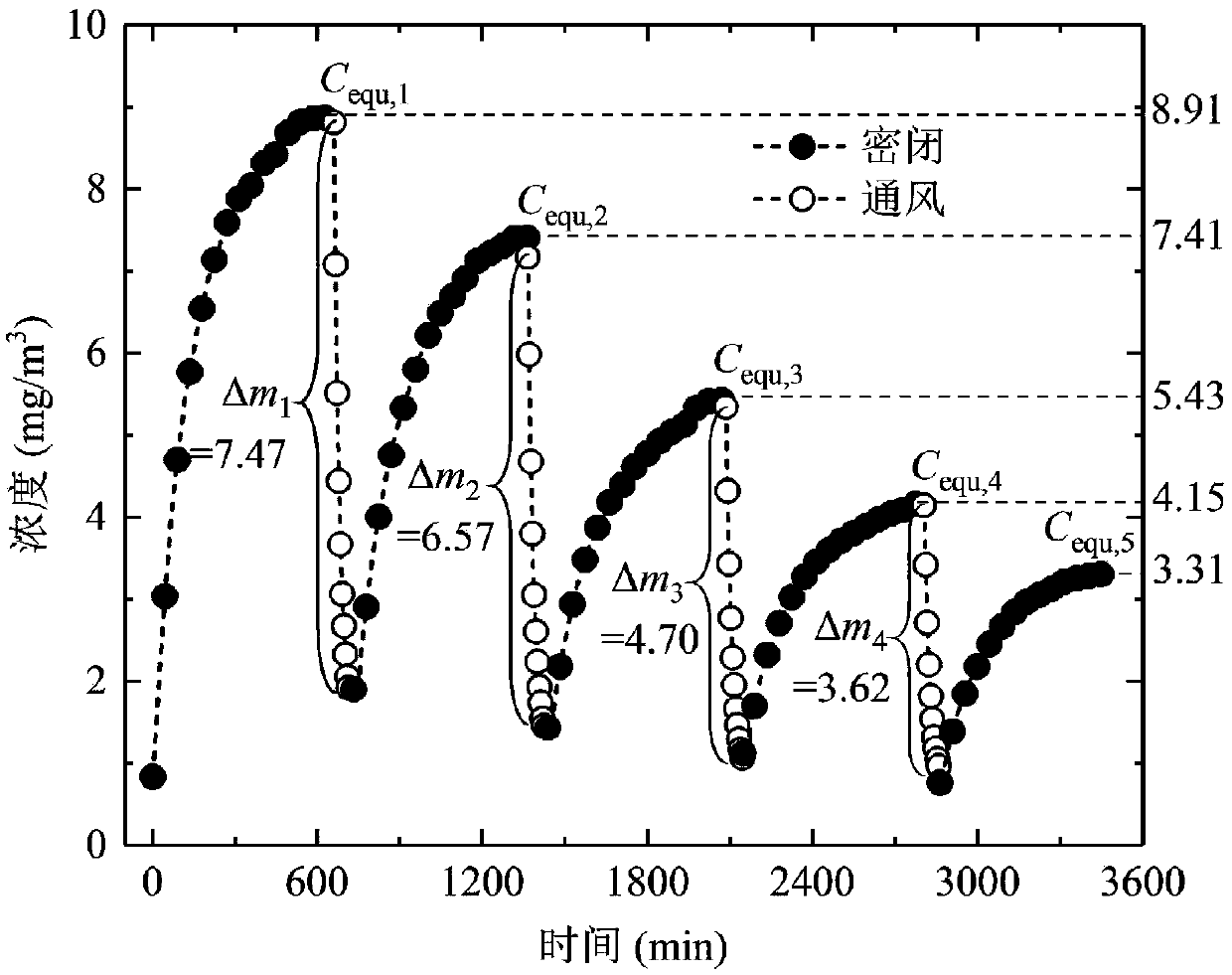

Intermittent ventilation method of determining VOC (volatile organic compound) emission characteristic parameter of building material

ActiveCN108107149AReduce consumptionSimple calculationComponent separationSeparation factorEngineering

The invention discloses an intermittent ventilation method of determining a VOC (volatile organic compound) emission characteristic parameter of a building material. The method comprises the steps ofkeeping a space that is relatively constant in temperature, relative humidity, ventilation rate and wind speed by using an environmental chamber, putting the building material to be determined in theenvironmental chamber, determining a dynamic VOC concentration change situation in a closed state and a ventilation state for a building material sample in a closed emission mode and a ventilation emission mode, recording a VOC equilibrium concentration in each closed state, and exhausted VOC mass in the ventilation state, establishing a VOC mass conservation equation, substituting experimental data of 4-6 closed-ventilation emission cycles into the VOC mass conservation equation for linear fitting, and obtaining a separation factor and an initial emission concentration describing a VOC emission characteristic of the building material according to a slope and an intercept of a fitting straight line, wherein the ventilation state and the closed state of the environmental chamber can be switched over by opening and closing an air inlet and an exhaust outlet.

Owner:XI AN JIAOTONG UNIV

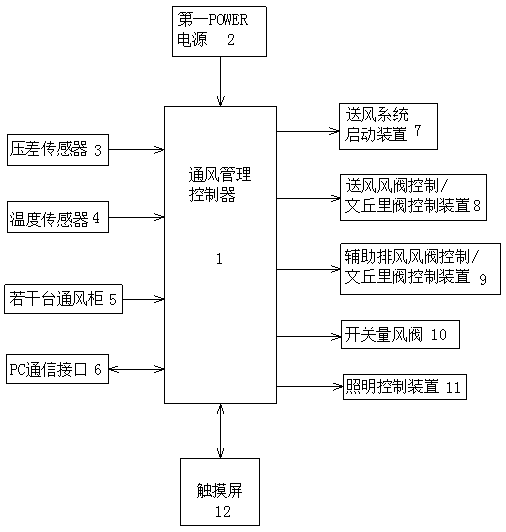

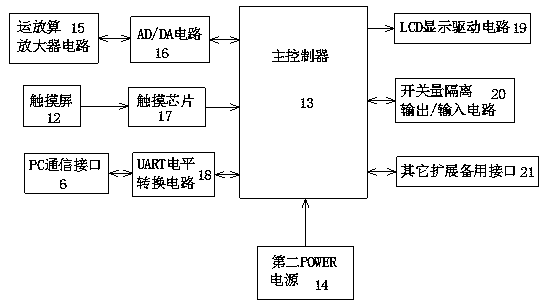

Laboratory ventilating management control system

PendingCN107830608AIncrease the air supplyIncrease the starting device of the air supply systemMechanical apparatusSpace heating and ventilation safety systemsCommunication interfaceAir volume

The invention relates to the technical field of laboratory ventilating control equipment, in particular to a laboratory ventilating management control system. The laboratory ventilating management control system comprises a ventilating management controller, a first POWER, a differential pressure sensor, a temperature sensor, a plurality of ventilation hoods, a PC communication interface, a ventilating system starting device, an air supply air valve control / Venturi valve control device, an auxiliary exhausting air valve control / Venturi valve control device, a switching value air valve, an illuminating control device and a touch screen. The constant differential pressure is utilized, the differential pressure in a room is detected and compared with a preset value, and the size of a valve isadjusted (the air volume of a Venturi valve is adjusted), for example, when the preset value is larger than an actual value, under the condition of meeting the air exchange frequency, auxiliary exhausted air is increased, or supplied air is reduced; when the preset value is smaller than the actual value, under the condition of meeting the air exchange frequency, the auxiliary exhausted air is reduced, and the supplied air is increased; and intelligent control management is achieved, operation is easy, and use is convenient.

Owner:湖南普信工程技术有限公司

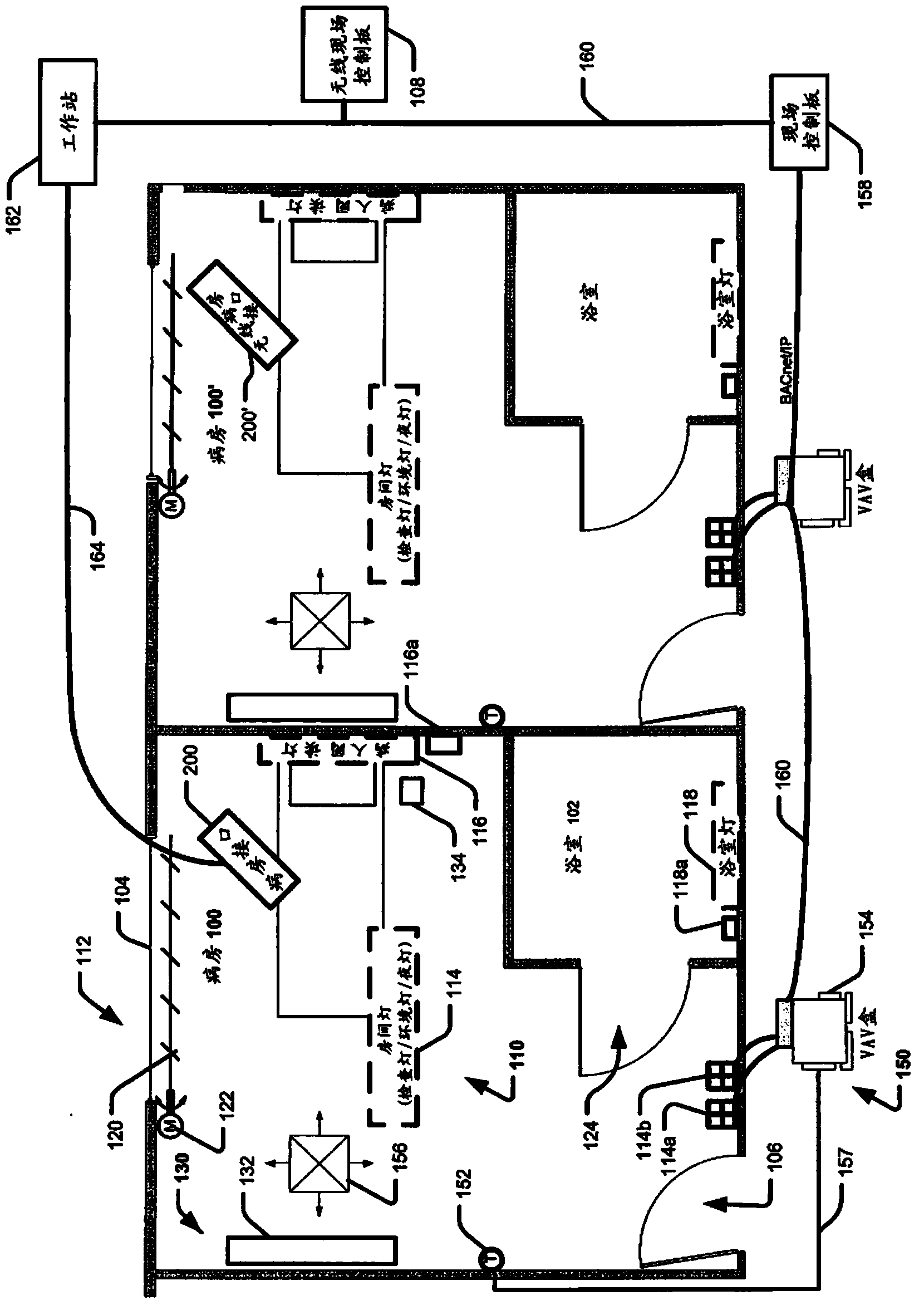

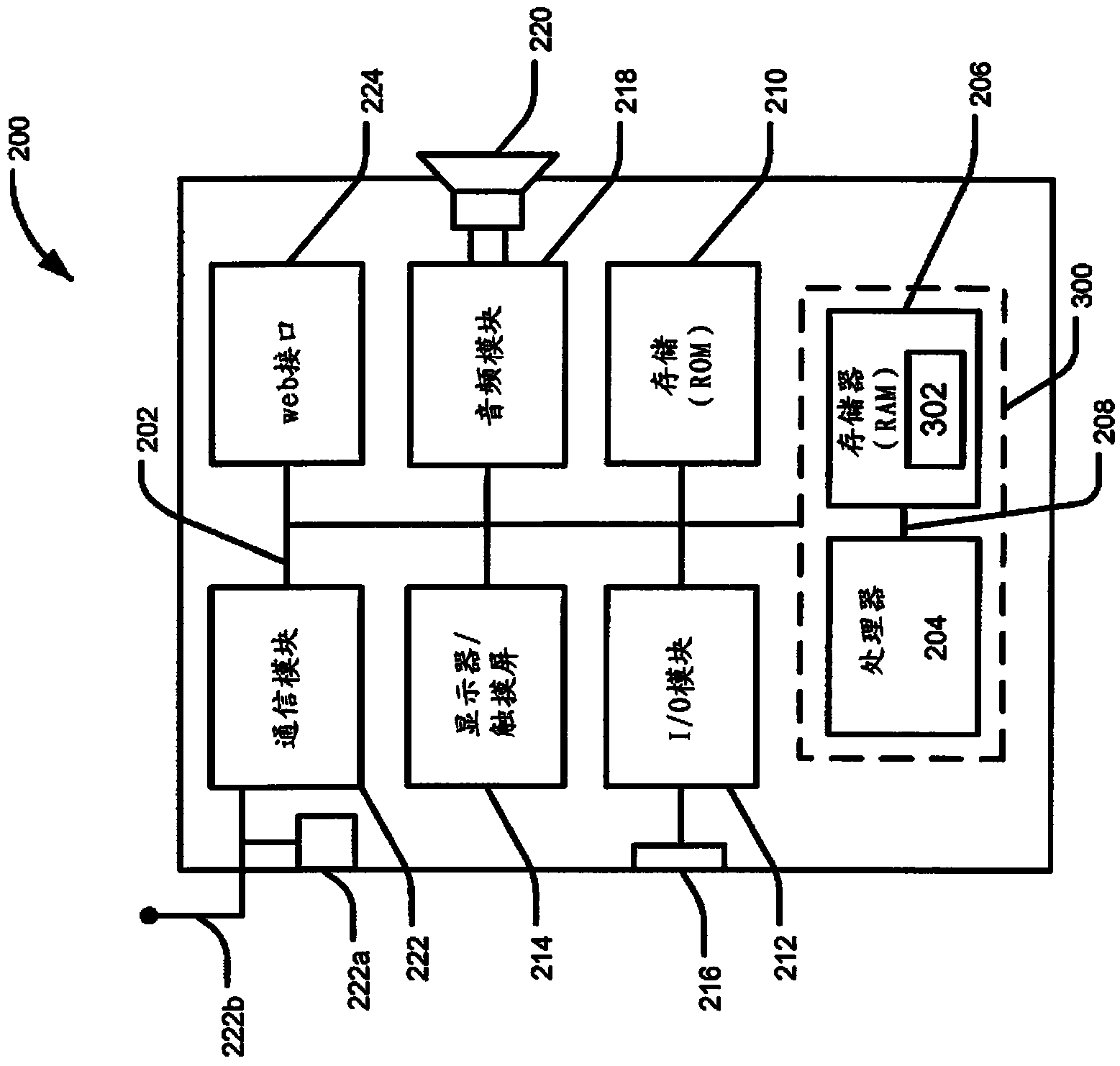

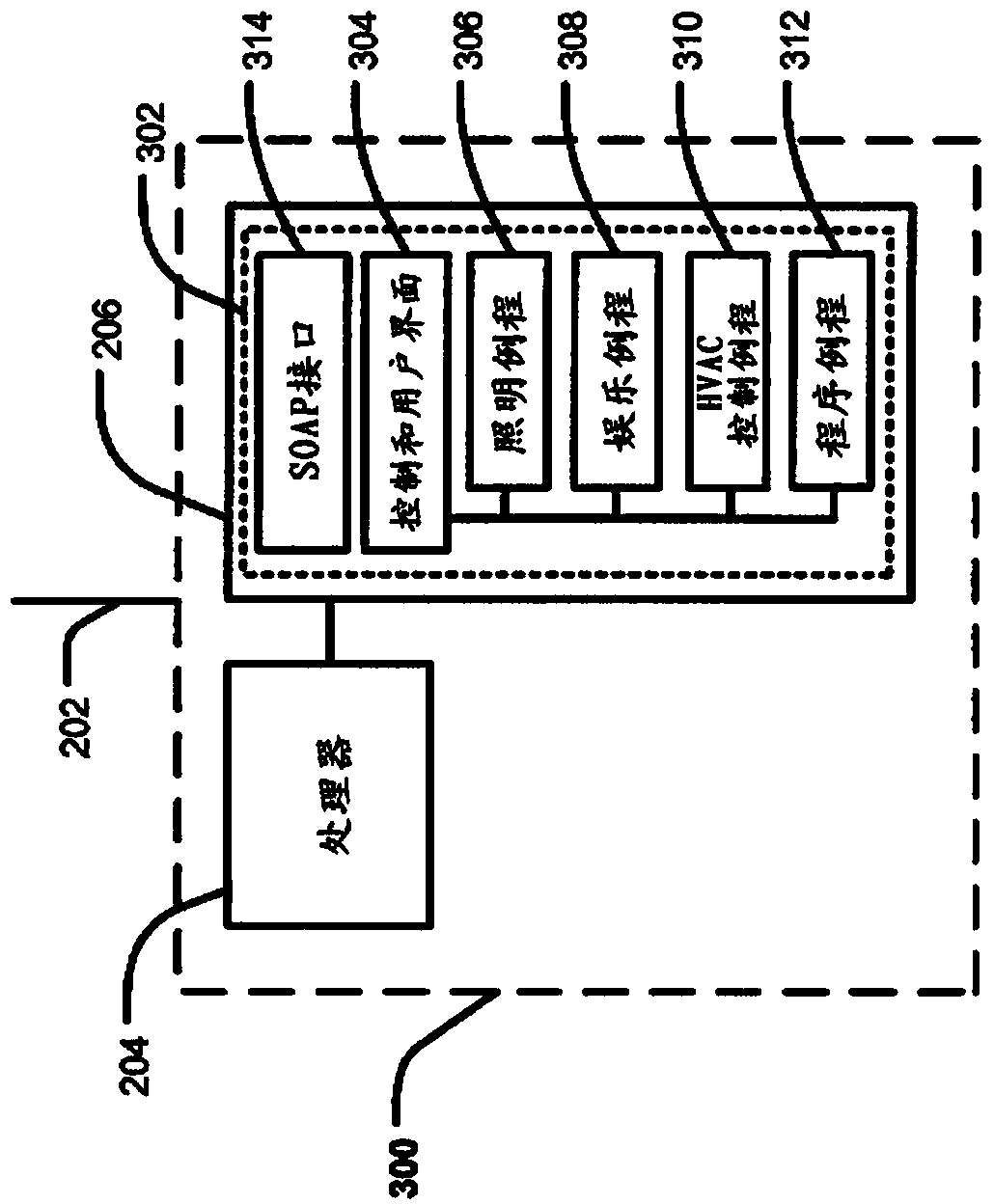

Occupancy driven patient room environmental control

InactiveCN103918243AImprove energy efficiencyBreathing protectionMechanical apparatusPatient roomMedicine

Using a real-time location system, the hospital environment is controlled locally. By categorizing individuals detected at different locations, the proper control may be provided to enhance energy savings and maintain a comfortable patient environment without sacrificing safety. By altering the environment within a room for patients and not staff and / or based on the type of patient, more optimized and localized control may be provided, such as implementing a number of air changes per hour appropriate for detected patients within rooms.

Owner:SIEMENS IND INC

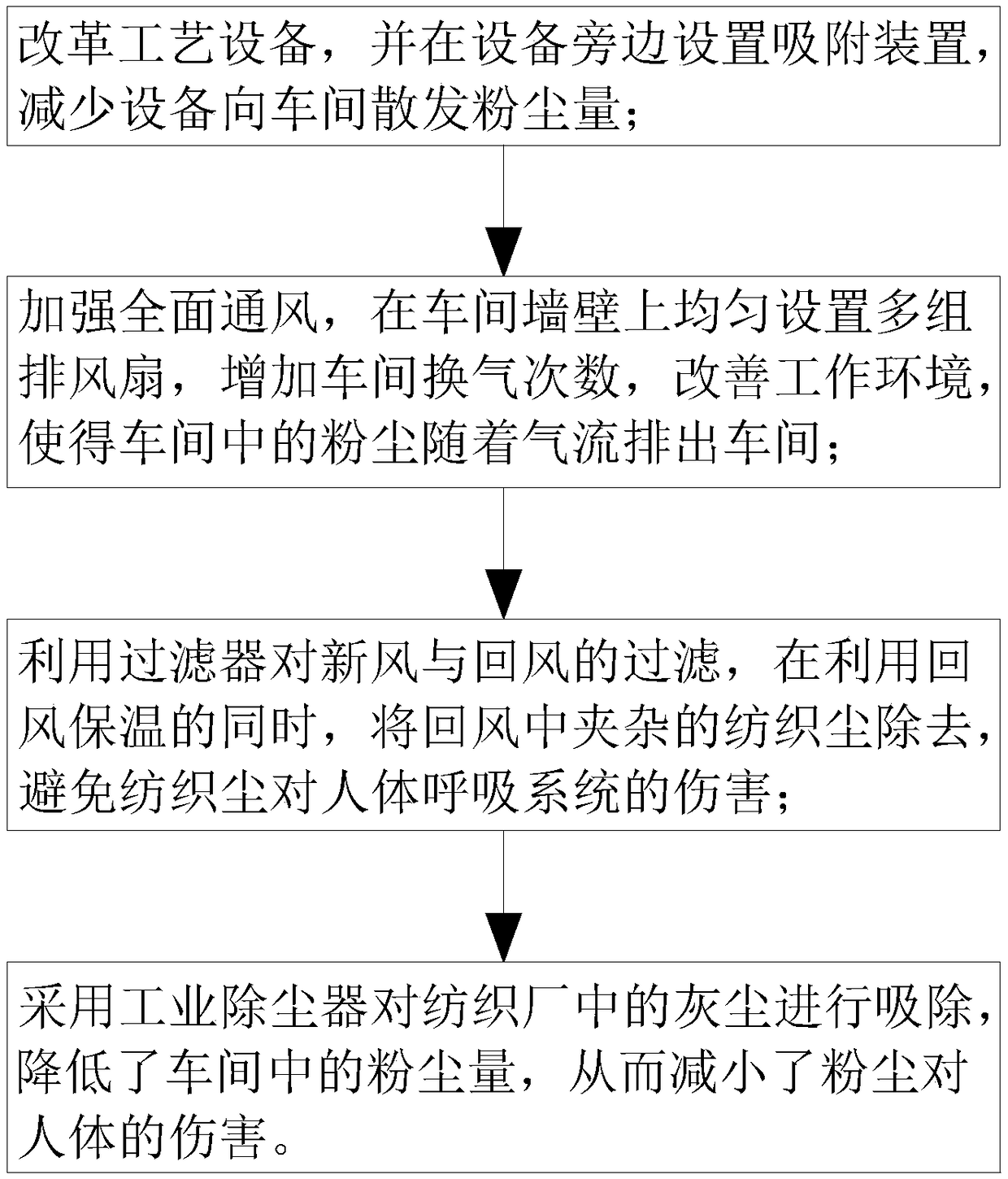

Treatment method for dust hazard in textile factory

ActiveCN109316878AFalling smoothlyImprove practicalityCombination devicesProcess equipmentTreatment effect

The invention belongs to the technical field of dust hazard treatment, in particular to a treatment method for dust hazard in a textile factory. The treatment method comprises the following steps of innovating technology equipment, arranging an adsorption device besides the equipment, and reducing the emission amount of dust to the workshop by the equipment; reinforcing comprehensive air ventilating, and uniformly arranging a plurality of groups of fans at the wall of the workshop, so as to increase the air exchange times of the workshop, improve the working environment, and exhaust the dust out of the workshop along with air flow; filtering the fresh air and returned air by filters, and removing the entrapped textile dust in the returned air when the returned air is used for warming, so as to avoid the injury to a respiratory system of a human body by the textile dust; adsorbing the dust in the textile factory by an industrial deduster, so as to reduce the amount of dust in the workshop, and decrease the injury to the human body by the dust. The treatment method is suitable for the treatment of dust hazard in the large textile factory, the treatment effect is good, and the injuryto the human body by the dust can be effectively decreased.

Owner:南通柯林纺织品有限公司

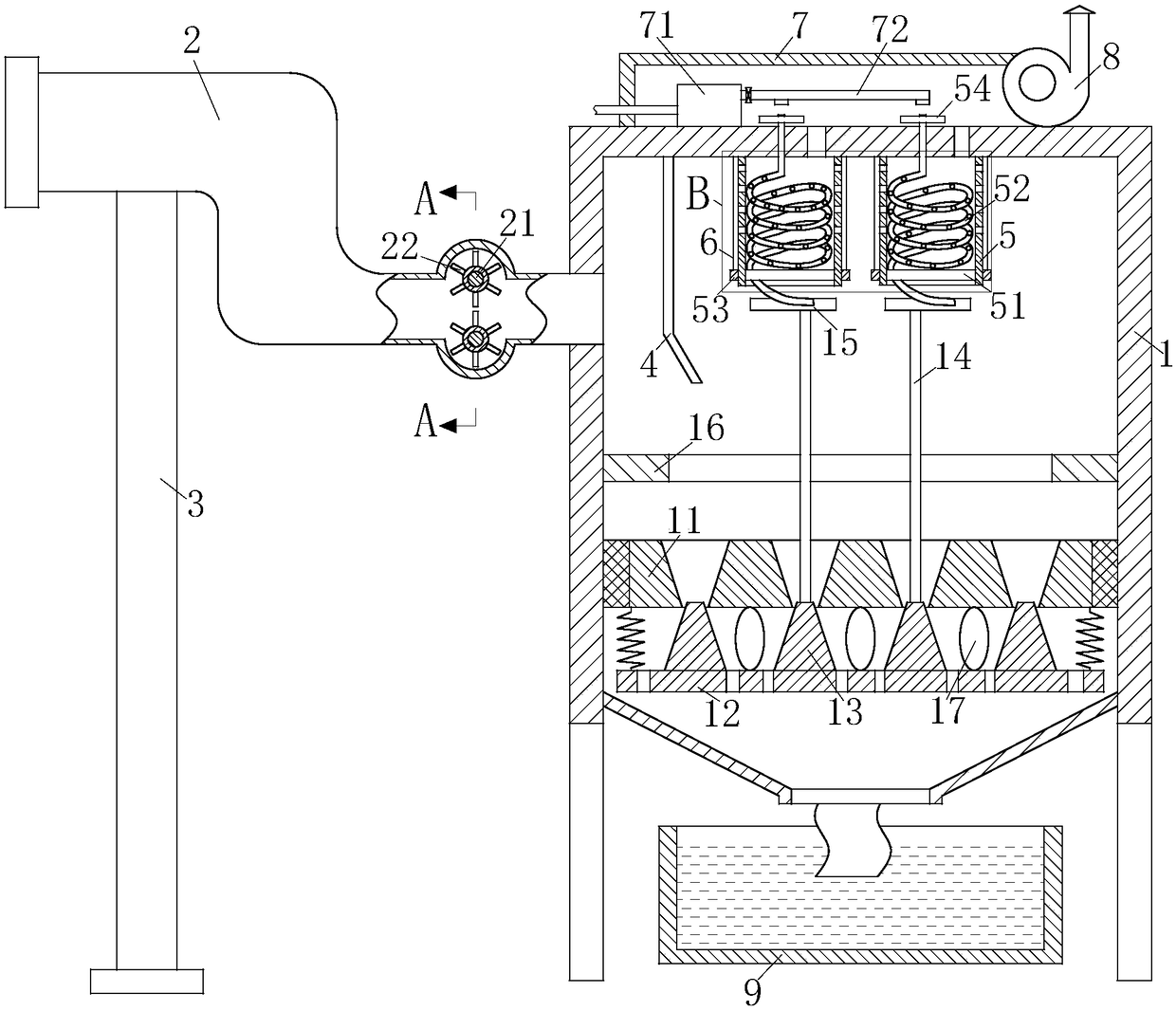

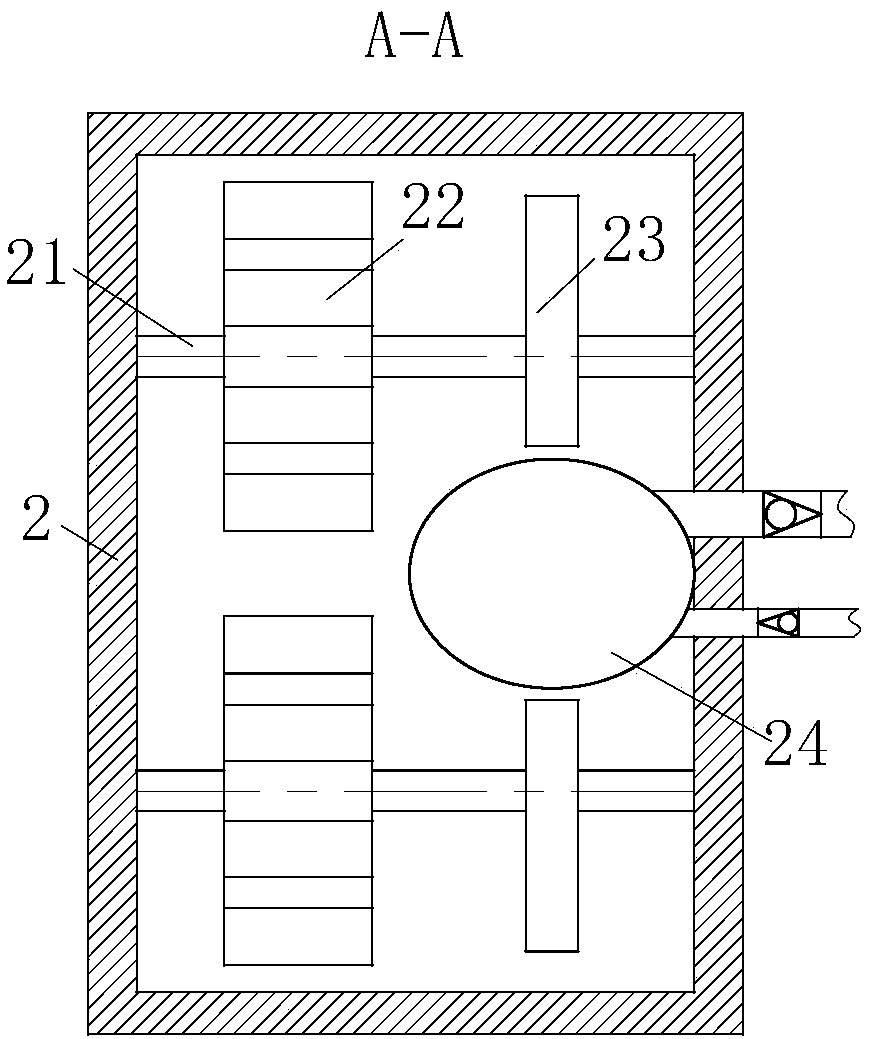

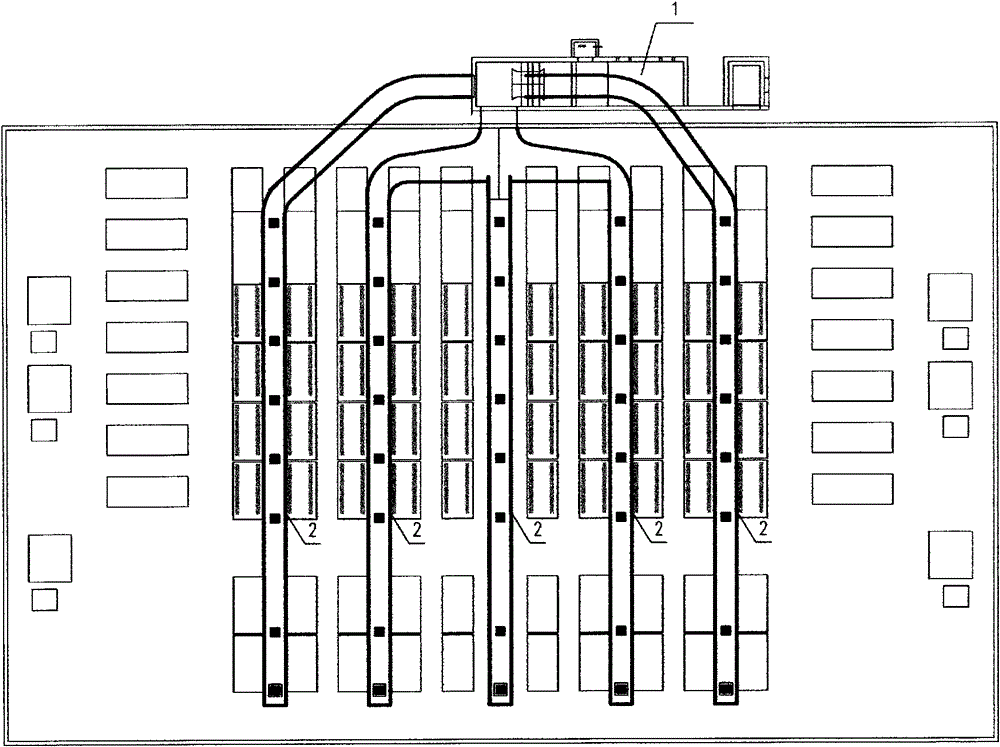

Device and method for controlling air supply volume of purification system of a clean area

PendingCN112815412AStabilized ventilation rateStable relative pressure differenceMechanical apparatusSpace heating and ventilation safety systemsProcess engineeringAir change

The invention discloses a device for controlling the air supply volume of a purification system of a clean area. The device comprises an air conditioning cabinet, a static pressure sensor, a high-efficiency filter and a PLC or DDC system, wherein the air conditioning cabinet comprises a variable-frequency fan and is used for regulating and controlling the air supply volume, the static pressure sensor is used for detecting static pressure of each clean room, the high-efficiency filter is used for filtering air entering each clean room; and the PLC or DDC system is in signal connection with the air conditioning cabinet and the static pressure sensor and is used for adjusting the frequency of the variable-frequency fan according to the static pressure, detected by the static pressure sensor, of each clean room so as to regulate and control the air supply volume. The invention further relates to a method for controlling the air supply volume of the purification system of the clean area. The method is characterized in that the method adopts the device; and return air of the clean room is constant, and the air supply volume of the purification system of the clean area is controlled by associating the static pressure of the clean room with the frequency of the variable-frequency fan of the air conditioning cabinet. The device and the method have the advantages that the air supply volume of the system can be simply and effectively constant; and the ventilation rate of each clean room and the relative pressure difference between the clean rooms can be stabilized.

Owner:无锡药明合联生物技术有限公司

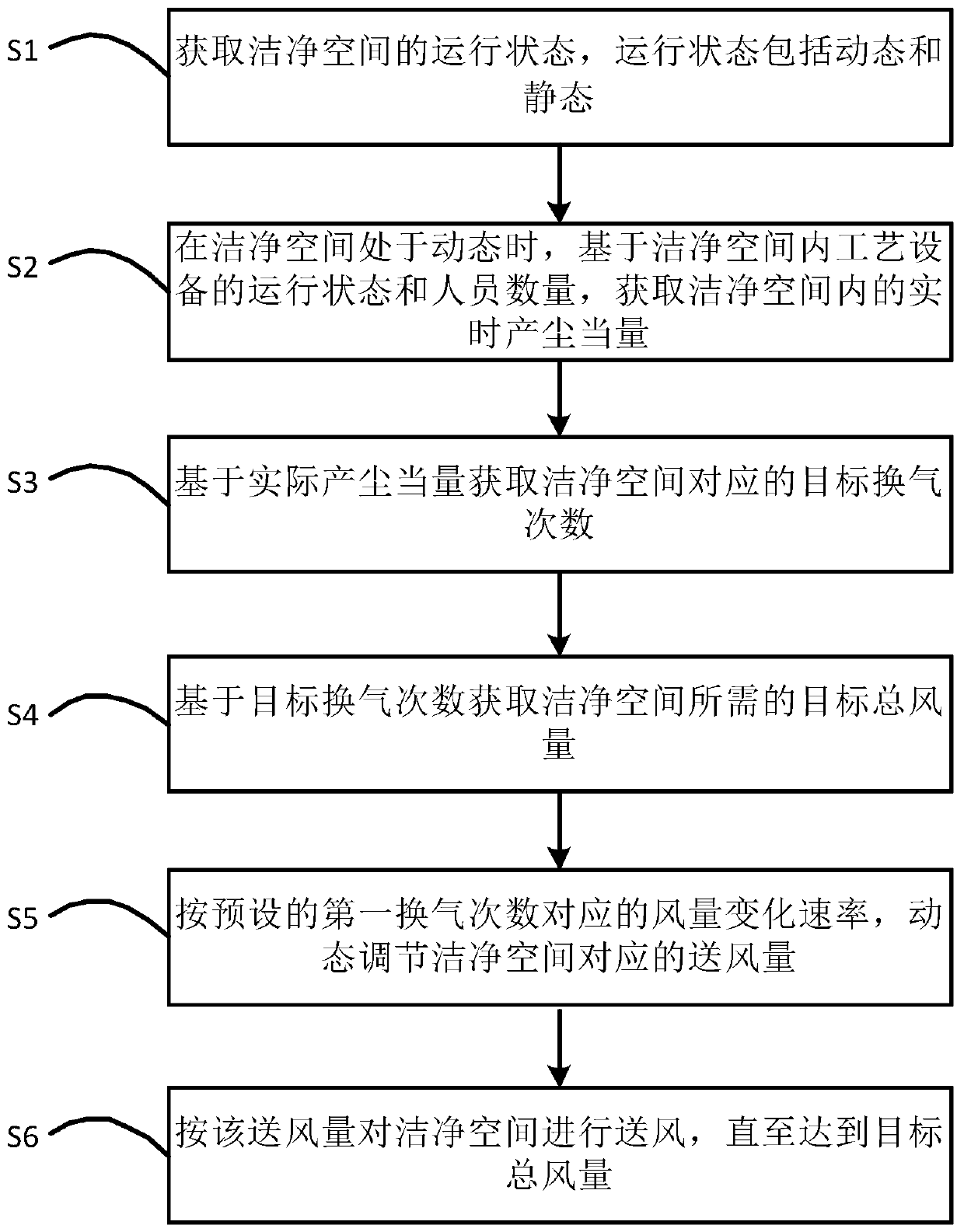

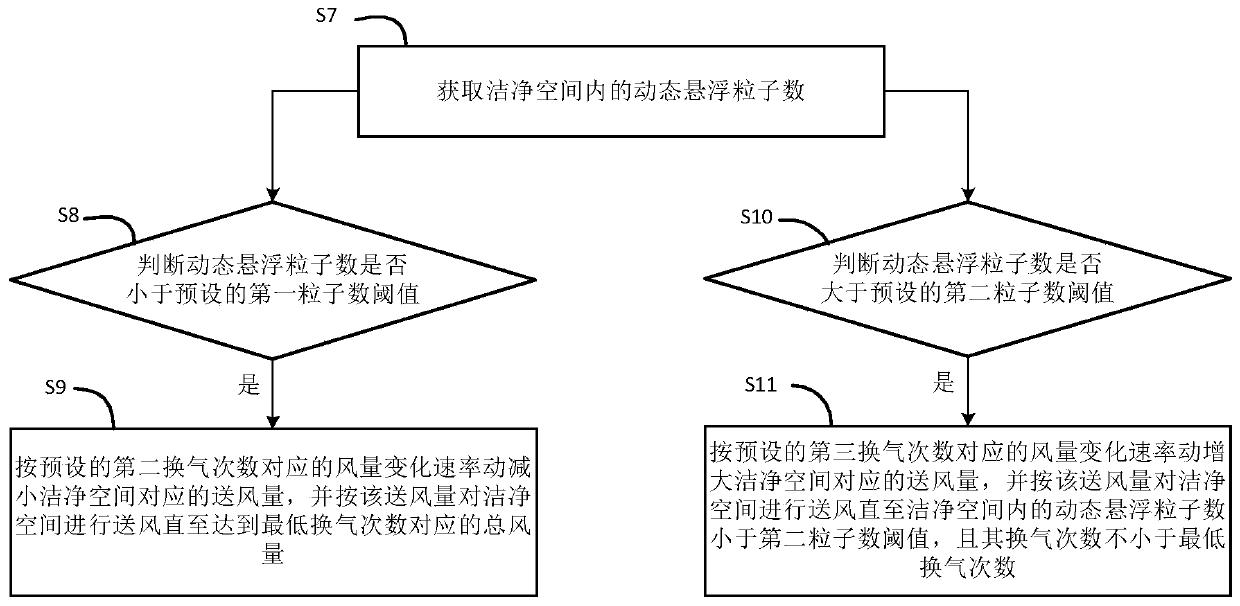

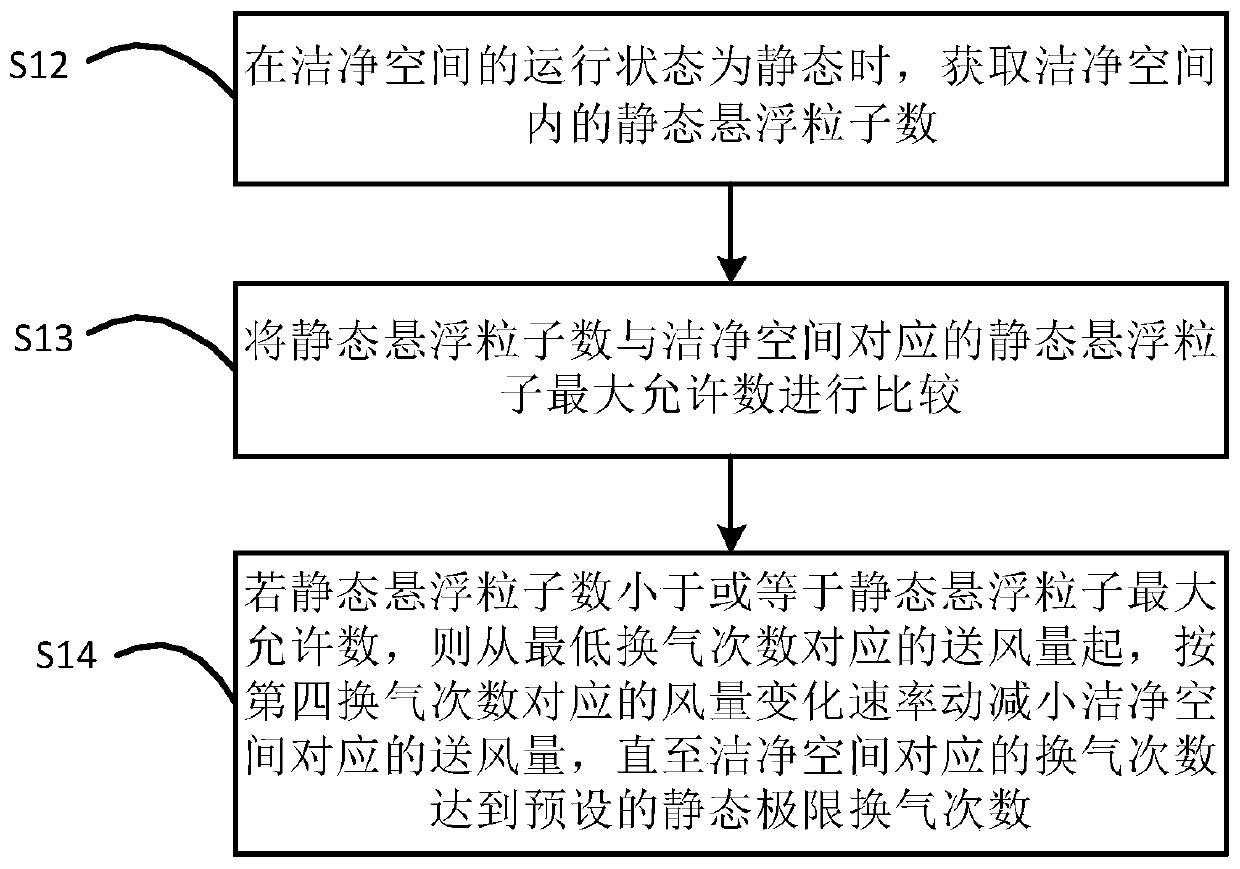

Air quantity control method and device for clean workshop

InactiveCN110057058AGuaranteed differential pressureRealize dynamic adjustmentMechanical apparatusSpace heating and ventilation safety systemsProcess equipmentEquivalent weight

The invention discloses an air quantity control method and device for a clean workshop. The clean workshop comprises a clean space. The method comprises the following steps: the running state of the clean space is obtained, and the running state comprises a dynamic state and a static state; when the clean space is in the dynamic state, a real-time dust generation equivalent weight in the clean space is obtained on the basis of the running state of process equipment in the clean space and the number of personnel; a target ventilation rate corresponding to the clean space is obtained on the basis of the real-time dust generation equivalent weight; a target total air quantity needed by the clean space is obtained on the basis of the target ventilation rate; an air supply quantity corresponding to the clean space is dynamically adjusted according to an air quantity change speed corresponding to a preset first ventilation rate; and air supply is carried out on the clean space according to the air supply quantity, until a target total air quantity is reached. The air quantity control method and device for the clean workshop are capable of dynamically adjusting the air supply quantity inthe clean space as needed, effectively guaranteeing pressure difference in the clean space, and reducing the redundant air quantity to reduce the energy consumption.

Owner:BEIJING UNION UNIVERSITY

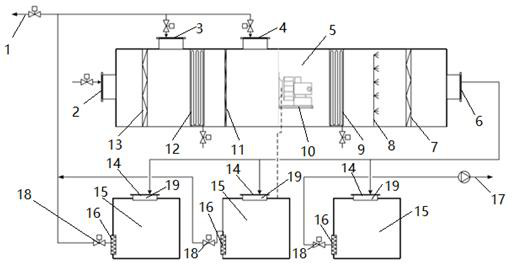

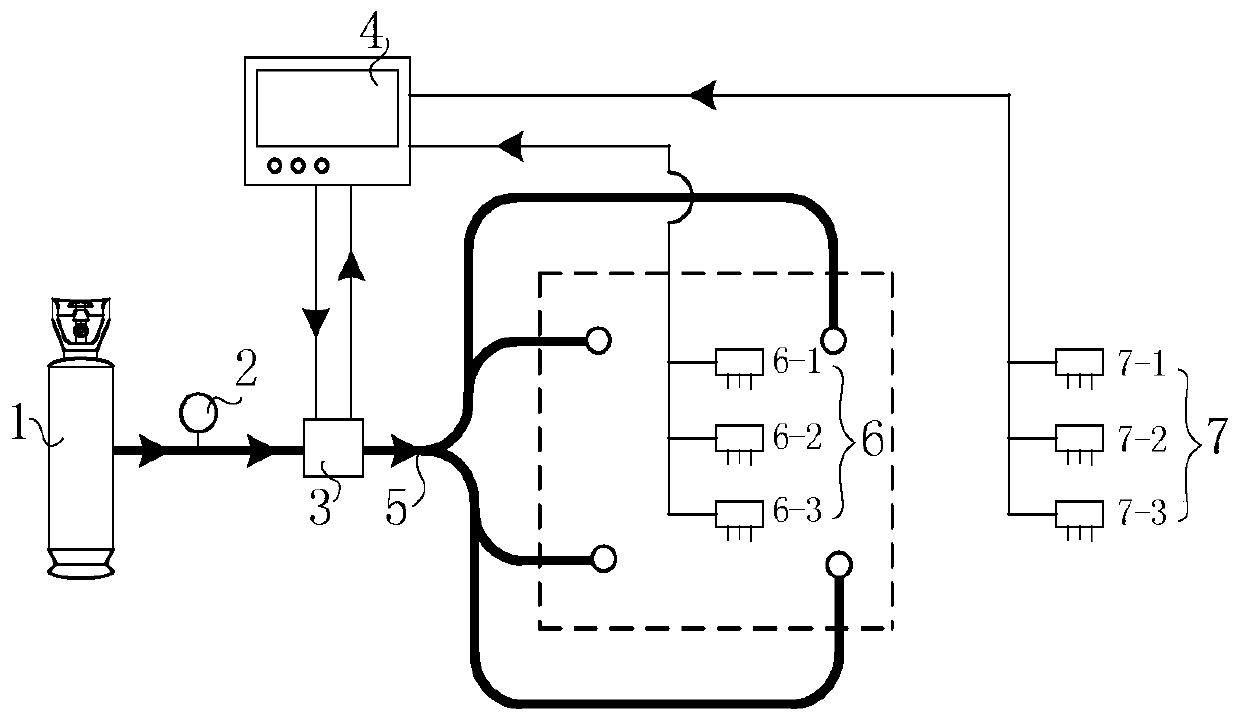

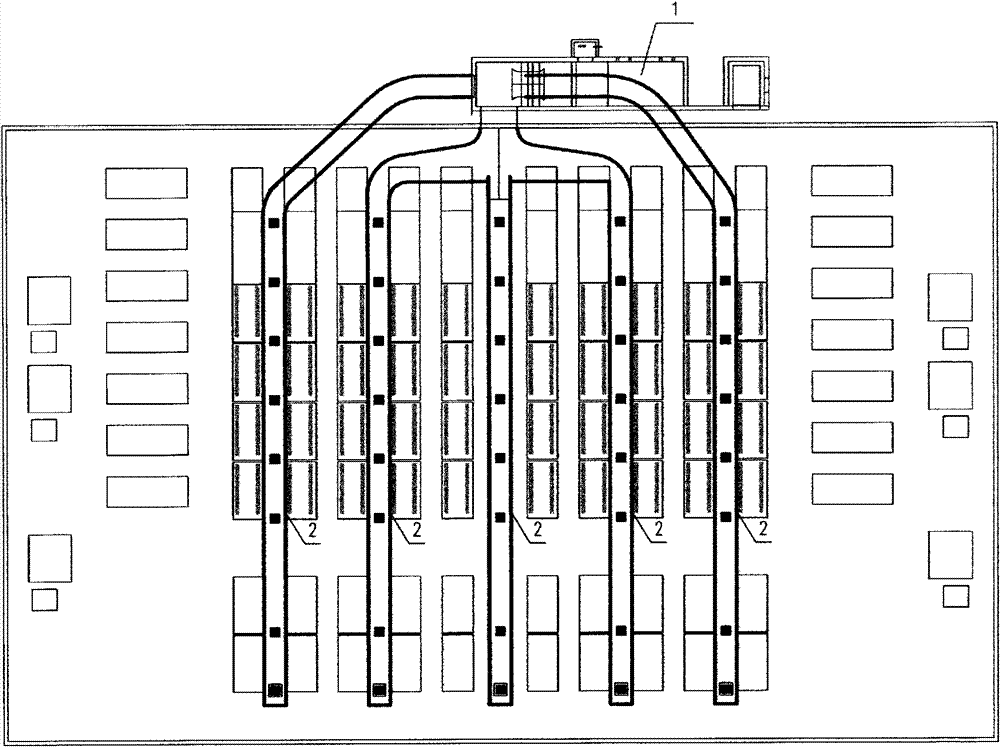

Carbon dioxide tracing gas method-based room ventilation frequency testing system and method

PendingCN110260909ALow costImprove measurement efficiencyMechanical apparatusMeasurement devicesCarbon dioxide cylinderProcess engineering

The invention discloses a carbon dioxide tracing gas method-based room ventilation frequency testing system and method. The system comprises a carbon dioxide steel cylinder, a pressure gauge, a mass flow rate controller, a control center, a gas pipeline system, an indoor sensor and an outdoor sensor; the indoor sensor and the outdoor sensor are arranged inside and outside a room to be tested respectively; the carbon dioxide steel cylinder is communicated with the mass flow rate controller; the mass flow rate controller is communicated with the room to be tested through the gas pipeline system; the mass flow rate controller, the indoor sensor and the outdoor sensor are in signal connection with the control center; the control center controls the carbon dioxide steel cylinder to release carbon dioxide gas at a constant speed and conveys the carbon dioxide gas to the room to be tested through the gas pipeline system, meanwhile, the indoor sensor and the outdoor sensor collect data according to a step length; after set time comes, calculation is performed according to the data acquired by the sensors, so that ventilation frequency values under indoor and outdoor working conditions are obtained. The system and the method have the advantages of low equipment cost, high testing speed and high accuracy.

Owner:ZHEJIANG UNIV

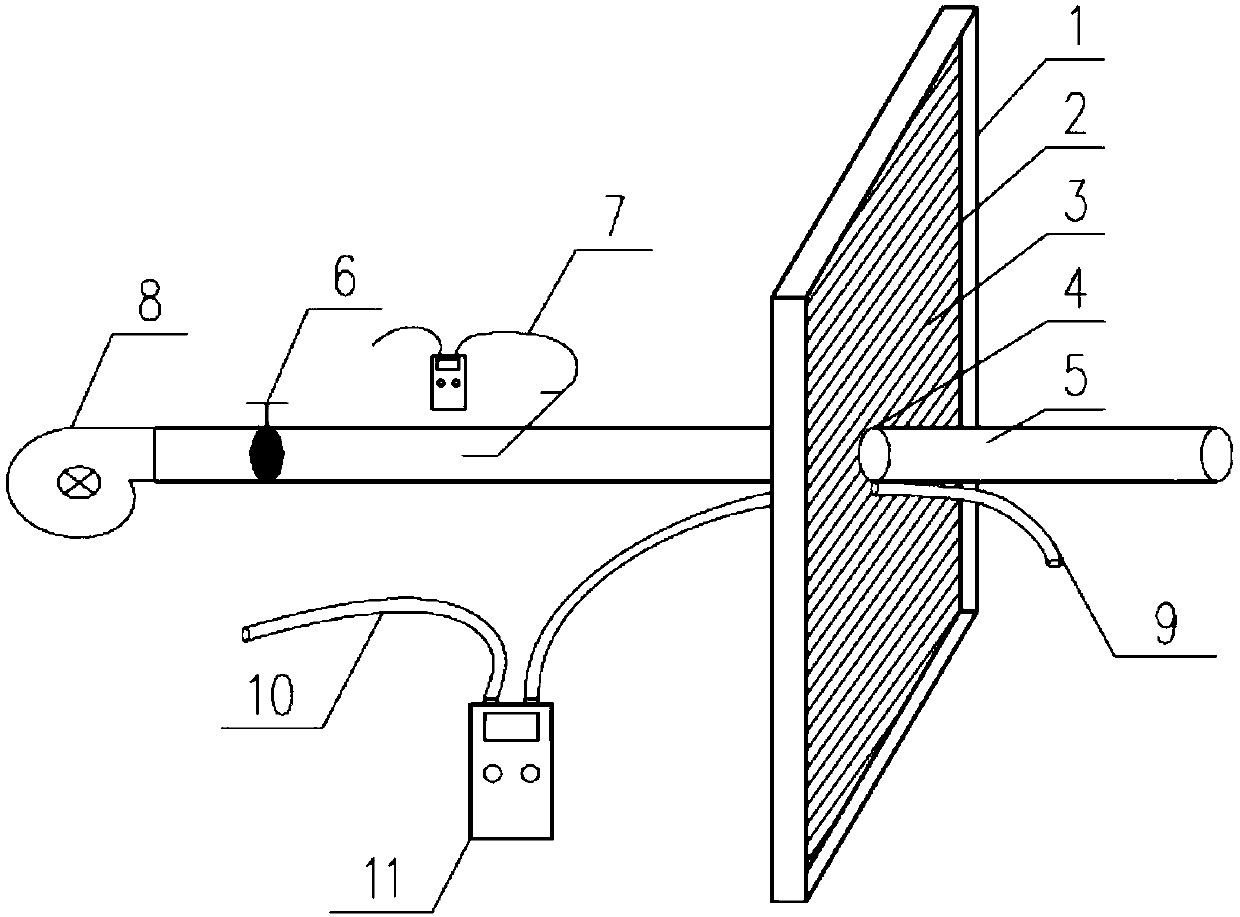

Building ventilation frequency testing method

InactiveCN109540410AEasy to controlSealing is simple and feasibleMeasurement of fluid loss/gain rateAir volumeDifferential pressure

The invention relates to the field of buildings, and aims to solve the problems that special building ventilation tightness detection equipment is expensive and high in price. The invention provides afeasible method for simply and conveniently testing the ventilation frequency of a building. The method for testing the ventilation frequency of the building comprises the following steps: step 1, opening an entry door, and opening an air pipe hole in the closed material; step 2, enabling an air pipe to enter a room through the air pipe hole, installing an air volume adjusting valve and an air volume testing device on the outdoor air pipe, and connecting the air pipe with a fan; step 3, feeding a rubber pipe into the room along the air pipe hole, and connecting the outdoor part of the rubbertube with one end of a differential pressure meter, and connecting the other end of the differential pressure meter with another rubber pipe; step 4, measuring the indoor and outdoor pressure difference value by adopting the differential pressure meter, controlling the air volume adjusting valve according to the tested pressure difference value, and testing the air volume of the fan under the given pressure difference by adopting the air volume testing device. According to the invention, the method is mainly applied to the building ventilation frequency testing occasion.

Owner:TIANJIN UNIV

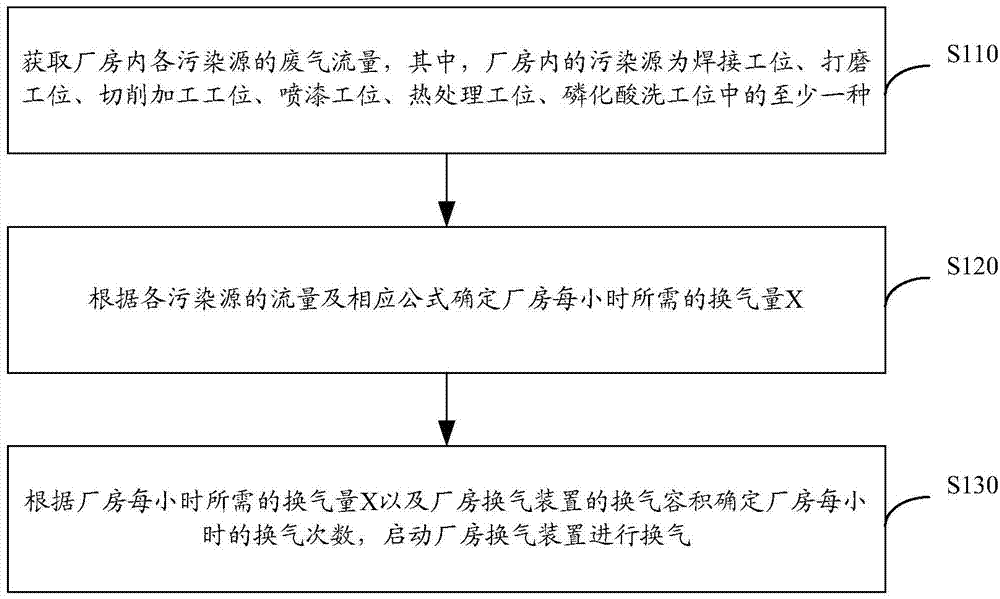

Practical ventilation method for plant building

ActiveCN104764135AAccurate ventilationImprove working environmentMechanical apparatusSpace heating and ventilation safety systemsVentilation volumePhosphoric acid

The invention discloses a practical ventilation method for a plant building. The method comprises the steps of acquiring waste gas flow rate of each pollution source in the plant building, wherein the pollution source in the plant buildings includes at least one of a welding station, a grinding station, a cutting processing station, a painting station, a thermal treating station and a phosphoric acid pickling station; determining the ventilation quantity X per hour of the plant building by the formula of X=k(Q+nP) if each pollution source has the same flow rate, wherein Q is the volume of the plant building, n is the quantity of the pollution sources, P is the waste gas flow rate of each pollution source, and k is the air leakage coefficient of the plant building and ranges from 1 to 1.5; determining the ventilation times per hour of the plant building according to the required ventilation quantity X per hour of the plant building and the ventilation volume of a ventilation device of the plant building; starting the ventilation device of the plant building to ventilate according to the determined ventilation times.

Owner:哈尔滨新海德智能环境工程有限公司

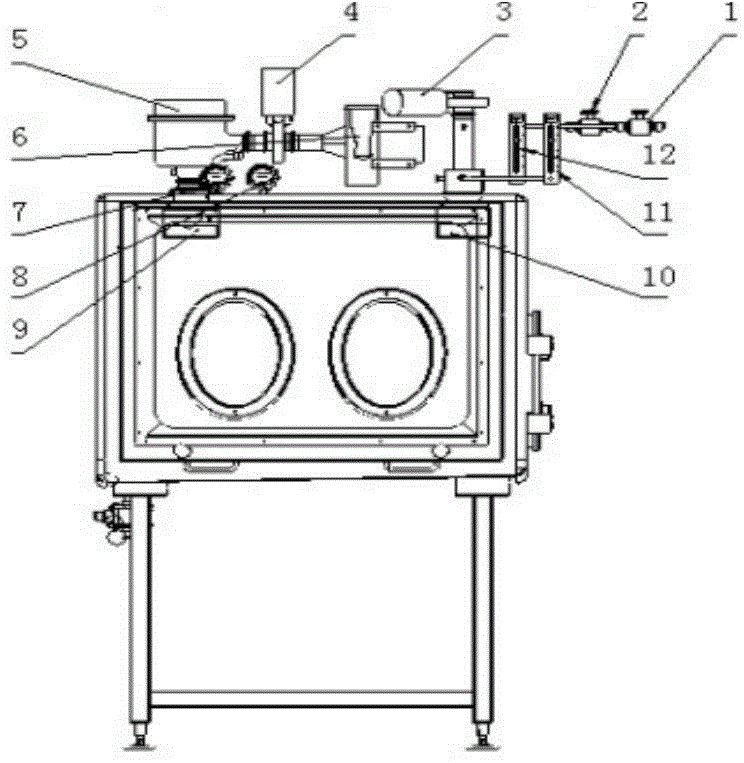

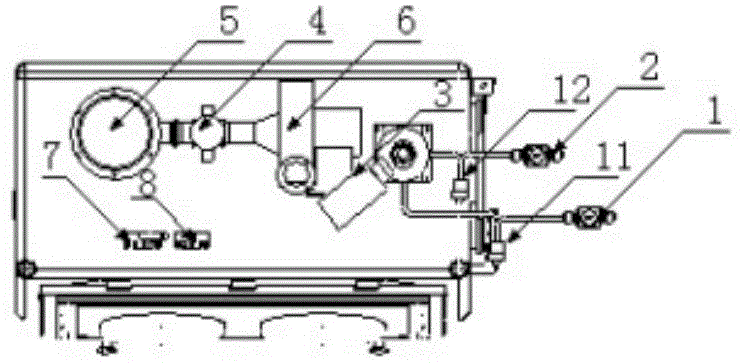

Low-oxygen isolator

InactiveCN104977948AWith explosion-proof abilitySuitable for productionControlling ratio of multiple fluid flowsInert gas productionExhaust valveControl system

The invention relates to a novel isolator capable of adjusting concentration of oxygen in a cabin. The isolator comprises a box body, an air exhaust system, an air intake system and a control system. The air exhaust system adopts an efficient filter; a pipeline is provided with a pneumatic on-off valve, and when leakage detection is performed on equipment, the pneumatic on-off valve is automatically closed; when the equipment is in a shutdown state, an air exhaust valve is closed, so that the box body can be prevented from contacting the outside world; the air flow mode of the air intake system is a turbulent flow mode and is divided into an air intake mode and a nitrogen intake mode which can be switched freely; an air intake port of the air intake system is provided with an manual butterfly valve used for adjusting the air exchange times of the equipment; a nitrogen intake system is divided into two air-intake paths; air-intake flow can be adjusted and monitored through a flowmeter; when nitrogen intake is in a single-path air-intake state, a weighing mode is realized, nitrogen flow enters the box body slowly and smoothly, and weighing is not influenced; and when nitrogen intake is in a double-path air-intake state, a replacement mode is realized, and oxygen content quickly drops to 5% and below. The isolator has an oxygen concentration adjustment function in the turbulent flow mode, and is suitable for being applied to the production of highly-toxic or highly-active products requiring lower oxygen concentration.

Owner:TRUKING TECH LTD

Adaptive optimization for dynamic room pressurization control

ActiveUS10352578B2Maximize energy savingSlow changeMechanical apparatusSamplingControl systemControl signal

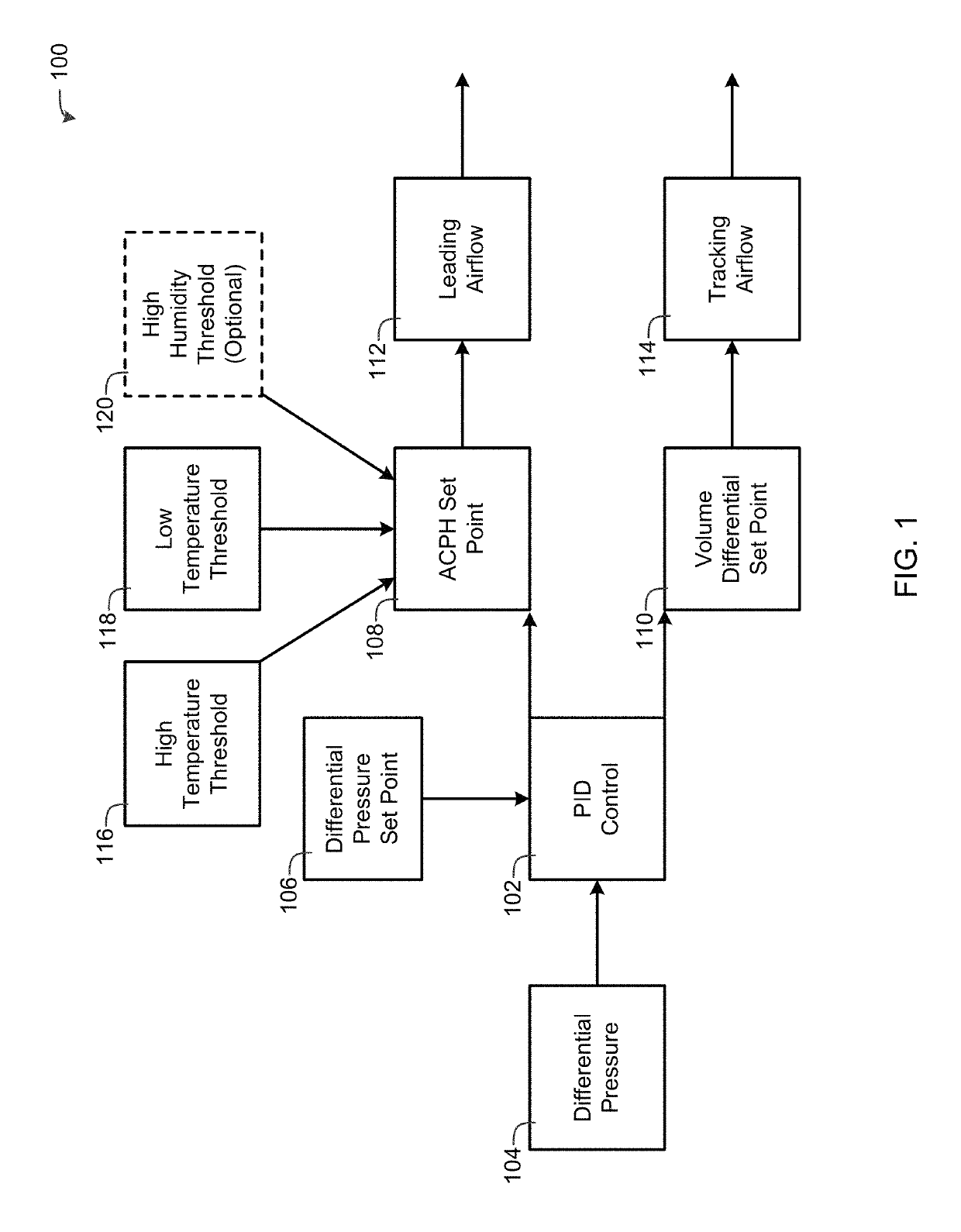

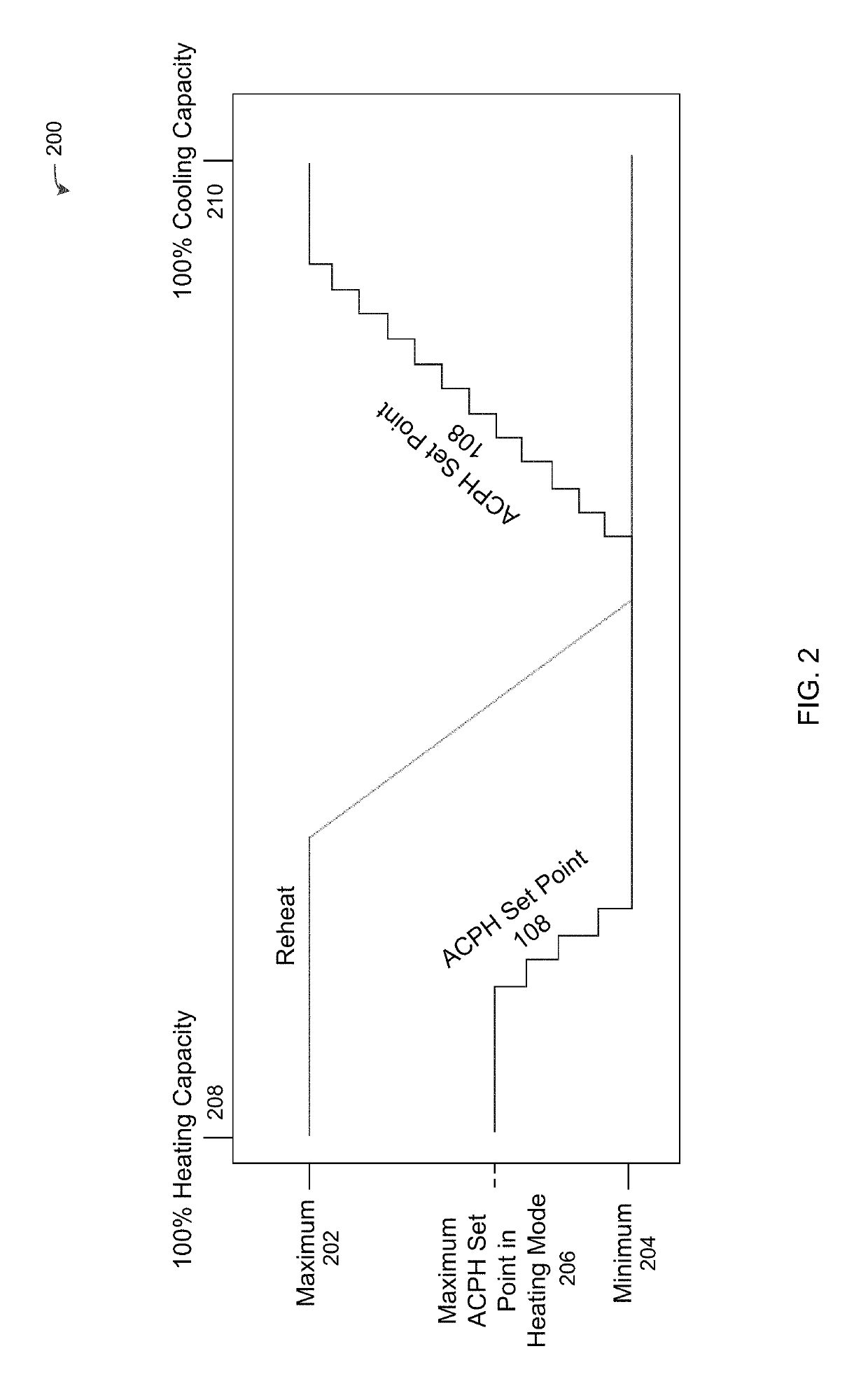

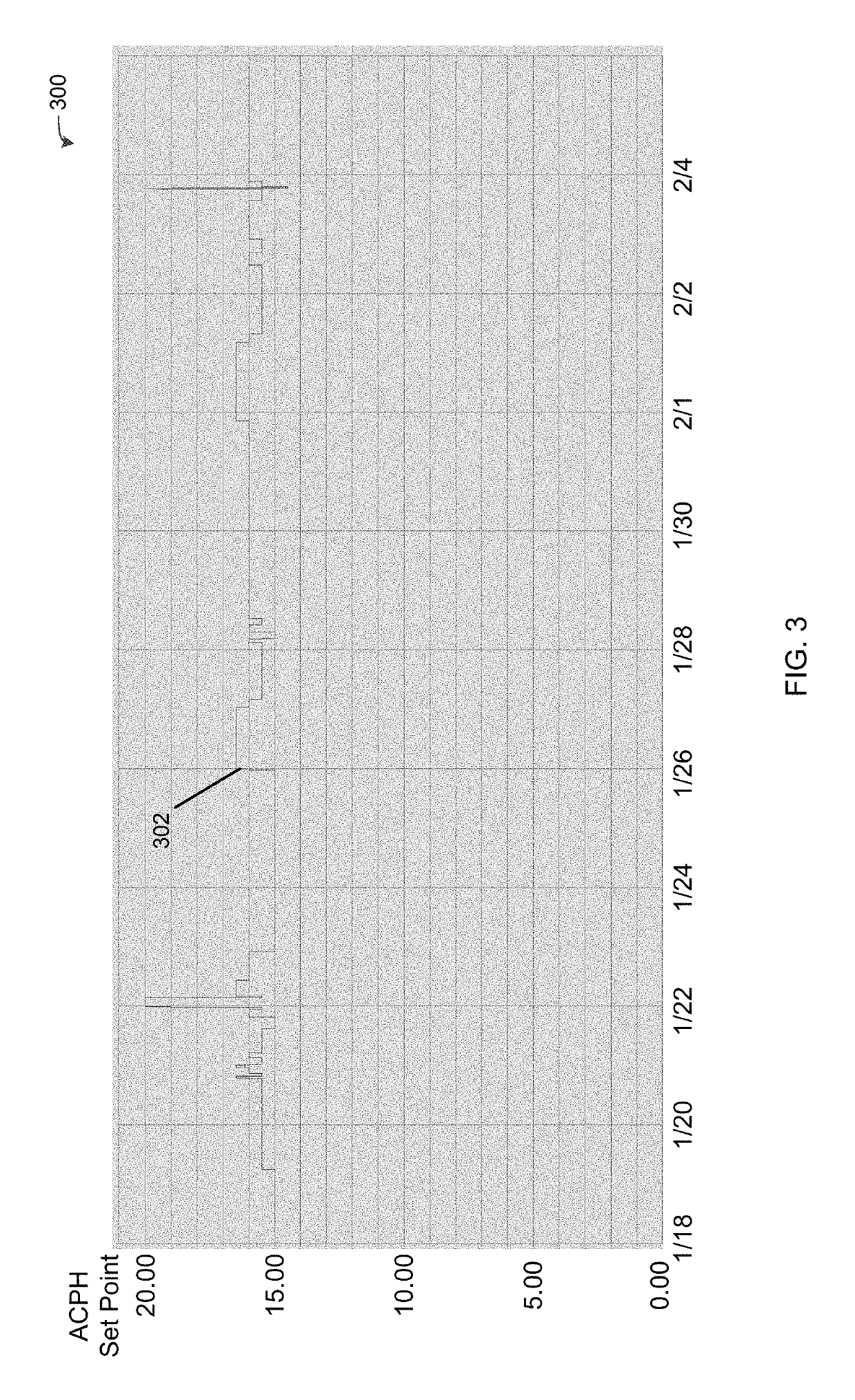

An apparatus and method controls an environmental control system to maintain a differential pressure between a room and one or more adjacent areas by (1) determining a differential pressure error based on the differential pressure and a differential pressure set point using a proportional-integral-derivative (PID) controller; (2) increasing an air change per hour set point whenever one or more first parameters are satisfied; (3) decreasing the air change per hour set point whenever one or more second parameters are satisfied; and (4) sending one or more control signals to the environmental control system that maintain the differential pressure between the room and the one or more adjacent areas by adjusting: (a) the leading airflow to be approximately equal to the air flow change set point multiplied by a volume of the room divided by 60, and (b) the tracking airflow to maintain a volume differential set point.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

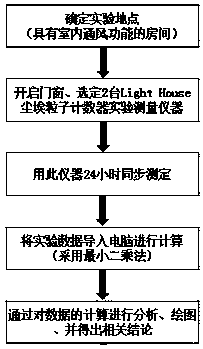

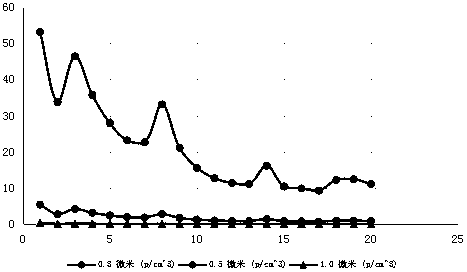

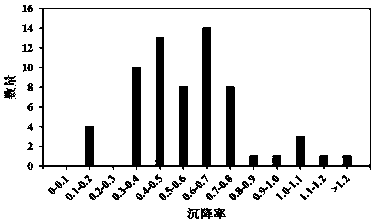

Determination method of indoor particle sedimentation parameters based on dynamic mass balance

The invention discloses a determination method of indoor particle sedimentation parameters based on dynamic mass balance, and belongs to the field of environmental science. The method includes the following steps: firstly, selecting a to-be-measured room, and arranging dust particle counters inside and outside the to-be-measured room as measuring instruments for indoor and outdoor particles; secondly, starting the measuring instruments for synchronous determination; thirdly, obtaining the parameters of indoor and outdoor particle concentration ratios, ventilation times, sedimentation rates andpermeability factors through the dust particle counters and data analysis; and finally, establishing a mass balance equation based on the dynamic balance of particles and calculating to obtain a sedimentation rate Kcomp and permeability P of the to-be-measured room by using a least square method. The determination method of the indoor particle sedimentation parameters based on the dynamic mass balance determines the permeability and the sedimentation rate by using the mass balance equation, which can better understand indoor particle dynamics and behavior under natural ventilation conditionsand helps to analyze the particle size distribution of the indoor particles.

Owner:SHANDONG UNIV OF SCI & TECH

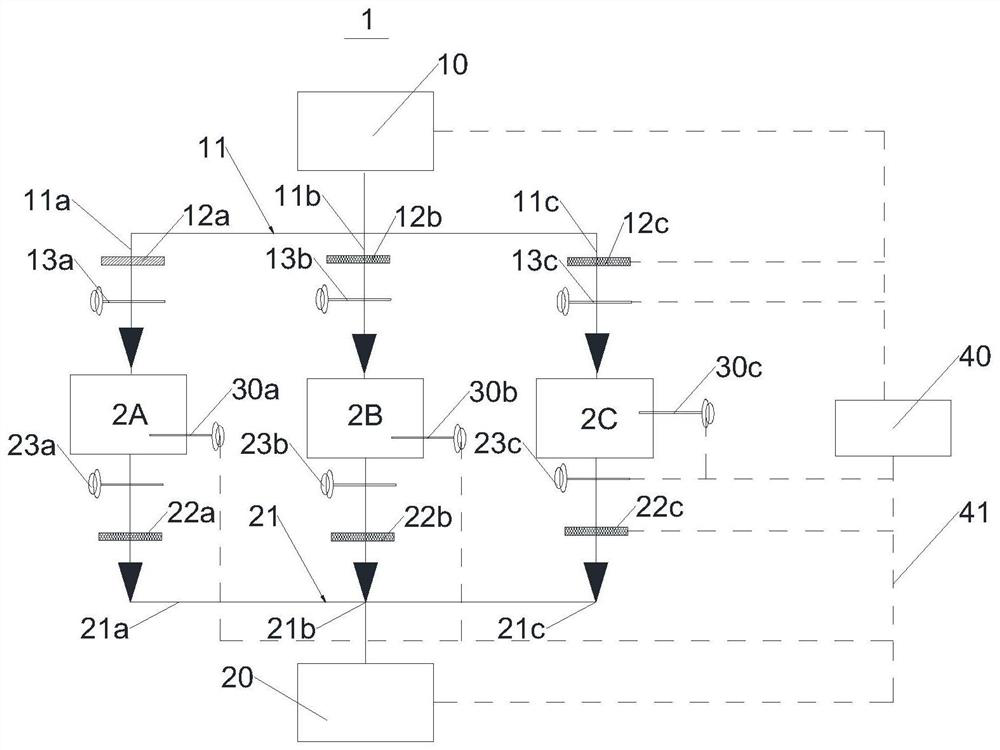

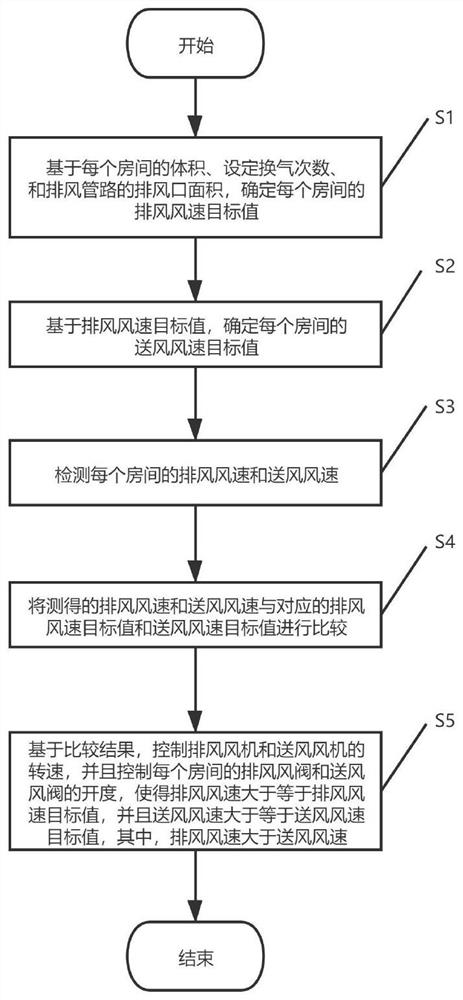

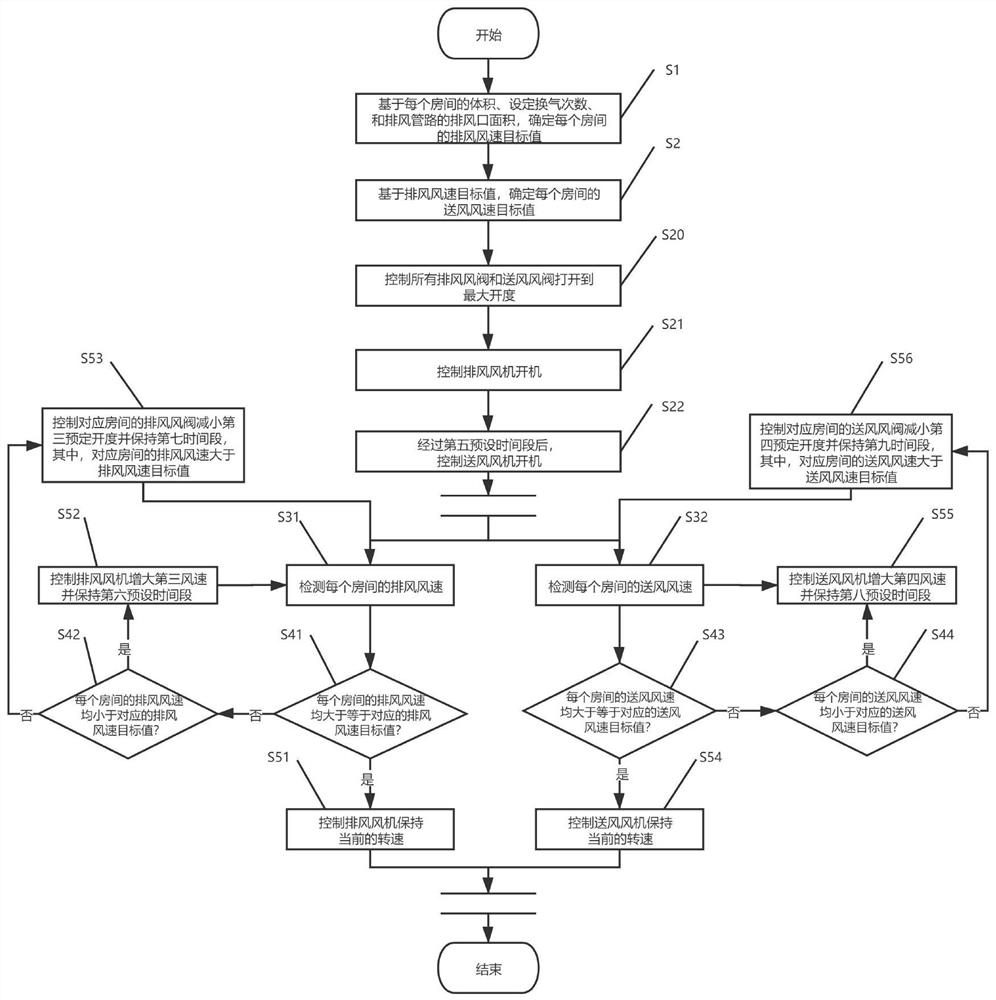

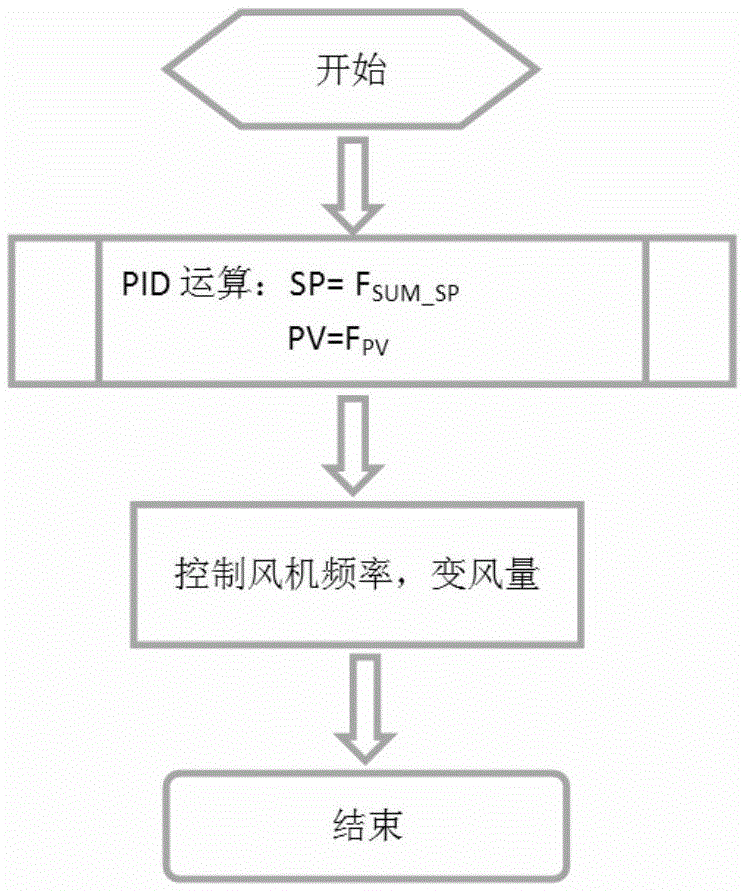

Control method of ventilation system and ventilation system

ActiveCN113465073AHigh precisionMechanical apparatusSpace heating and ventilation safety systemsAir velocityAir change

The invention relates to a control method of a ventilation system and the ventilation system using the control method. The control method comprises the steps that an exhaust air speed target value of each room is determined based on the size of each room, the set ventilation frequency and the exhaust outlet area of an exhaust pipeline; based on the exhaust air speed target value, an air supply air speed target value of each room is determined; the exhaust air speed and the air supply speed of each room are detected; the measured exhaust air speed and the measured air supply speed are compared with the corresponding exhaust air speed target value and the corresponding air supply speed target value respectively; and based on the comparison result, the rotating speed of an exhaust fan and the rotating speed of an air supply fan are controlled, the opening degree of an exhaust air valve and the opening degree of an air supply valve corresponding to each room are controlled, the exhaust air speed is larger than or equal to the exhaust air speed target value, the air supply speed is larger than or equal to the air supply speed target value, and the exhaust air speed is larger than the air supply speed. The control method of the ventilation system can be controlled based on the set ventilation frequency and the set pressure difference, and the control precision is high.

Owner:QINGDAO HAIER AIR CONDITIONING ELECTRONICS CO LTD +2

Energy efficient air handling system for cleanrooms

InactiveUS7539601B2Low costEliminate useMechanical apparatusMilk preservationAir changeAir conditioning

A refrigeration based air handling system design process for significant energy and cost savings in cleanroom and other applications requiring large air change rates is presented. The process utilizes a by pass around the air conditioning system, the ratio of bypass to air conditioning flow being such that minimal or no reheat of the air is required for applications having relative humidity (RH) control requirements and with RH control being achieved via cooling. If dehumidification is achieved by adsorptive processes, then the by pass ratio is varied so as to minimize cooling of the heated dry air. In other non relative humidity control applications the bypass is varied to minimize the air conditioning flow, thereby decreasing cost, but by using optimum cooling coil velocities in a manner such that system energy for airflow is minimized. The energy and cost savings achieved by this process vary between 65% to 15% depending on the Class of the cleanroom and / or on the number of air changes per hour required.

Owner:JAISINGHANI RAJAN A

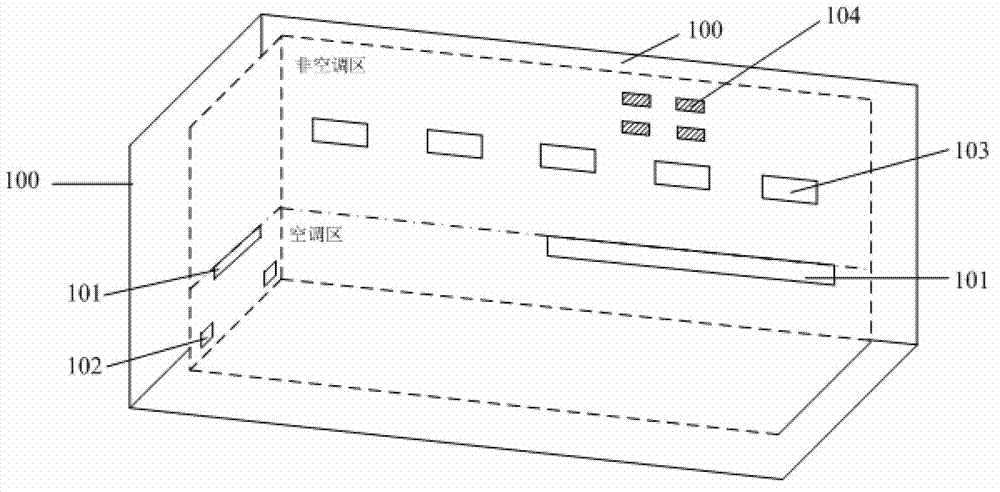

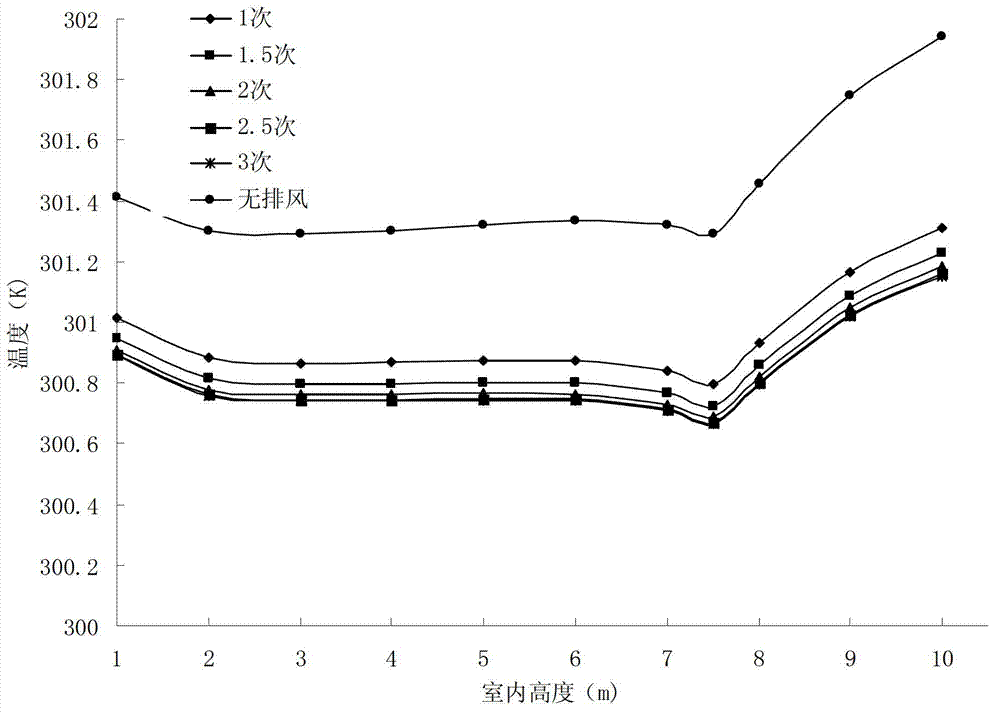

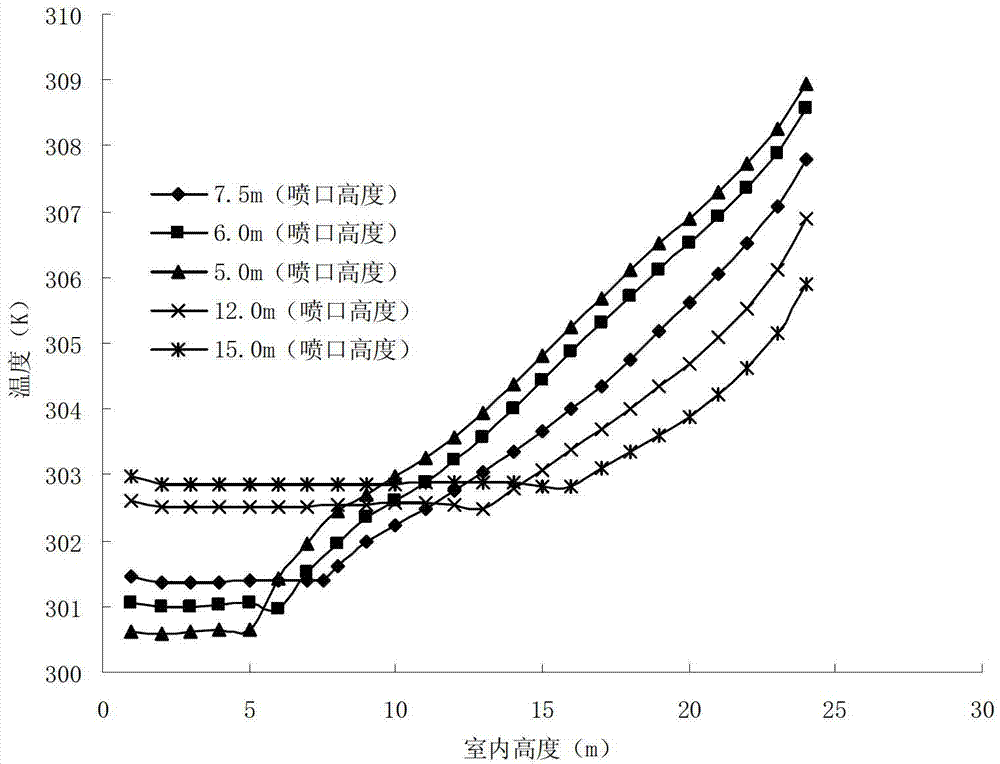

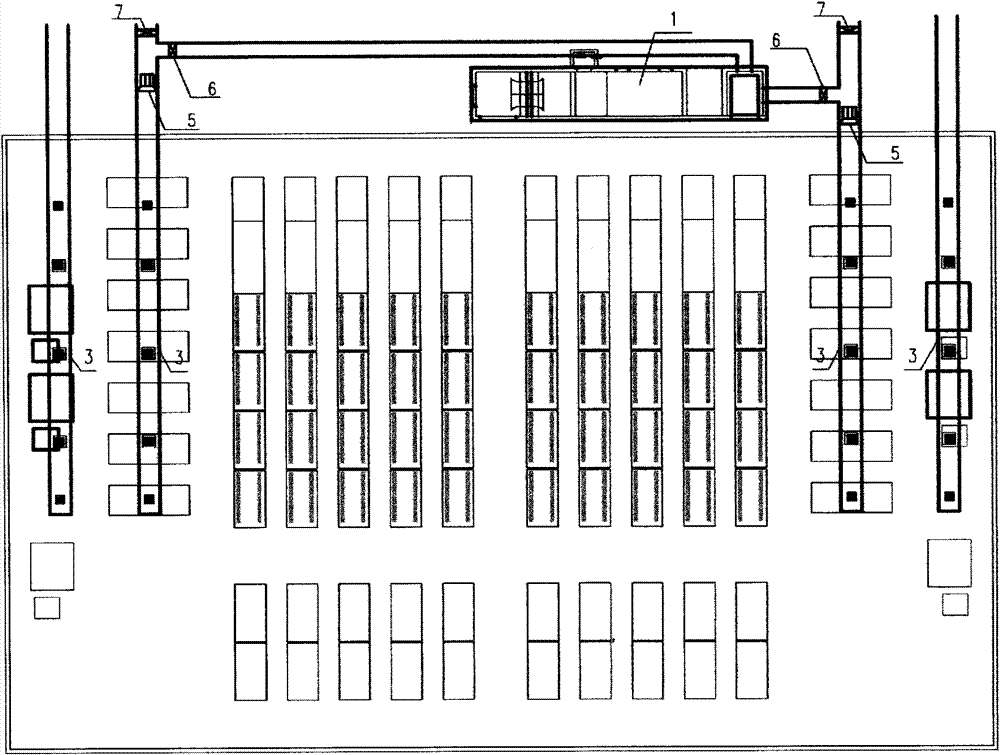

Layered air-conditioning system and its energy-saving method serving the high space of railway passenger station

ActiveCN103277857BReduce energy consumptionTake heat transfer into accountSpace heating and ventilation safety systemsLighting and heating apparatusCombined useEngineering

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

Temperature control method and device

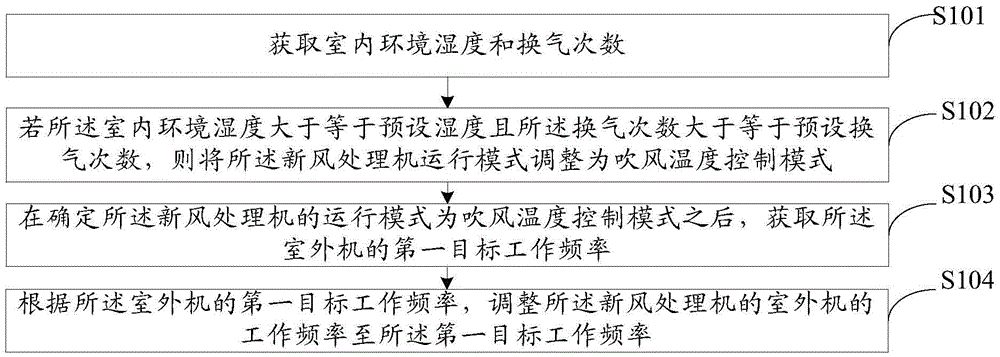

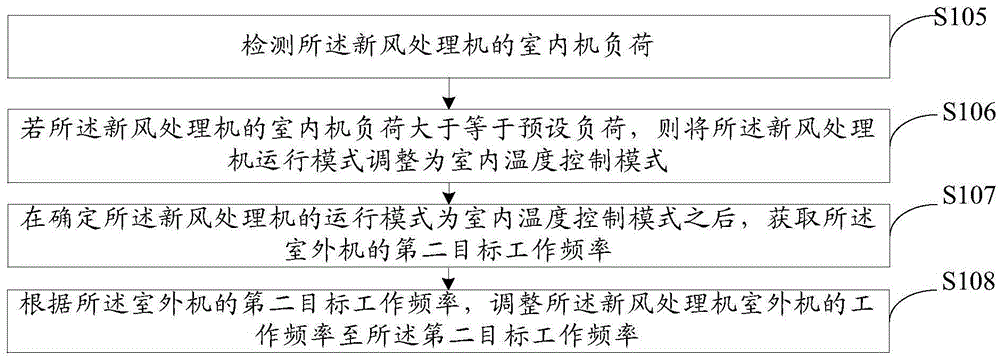

ActiveCN105588283AImprove qualityHigh quality workMechanical apparatusSpace heating and ventilation safety systemsTemperature control modeAir exchange

The embodiment of the invention provides a temperature control method and device, and relates to the field of fresh air processors. The temperature control method and device are used for meeting the requirement for high quality of indoor temperature. The method comprises the steps that the indoor environment humidity and the air exchange frequency are acquired; if the indoor environment humidity is larger than or equal to preset humidity and the air exchange frequency is larger than or equal to preset air exchange frequency, the running mode of a fresh air processor is adjusted into a blowing temperature control mode; when the running mode of the fresh air processor is determined as the blowing temperature control mode, the first target work frequency of an outdoor unit is acquired; and the work frequency of the outdoor unit of the fresh air processor is adjusted into the first target work frequency according to the first target work frequency of the outdoor unit. The temperature control method and device are applied to the fresh air processor.

Owner:QINGDAO HISENSE HITACHI AIR CONDITIONING SYST

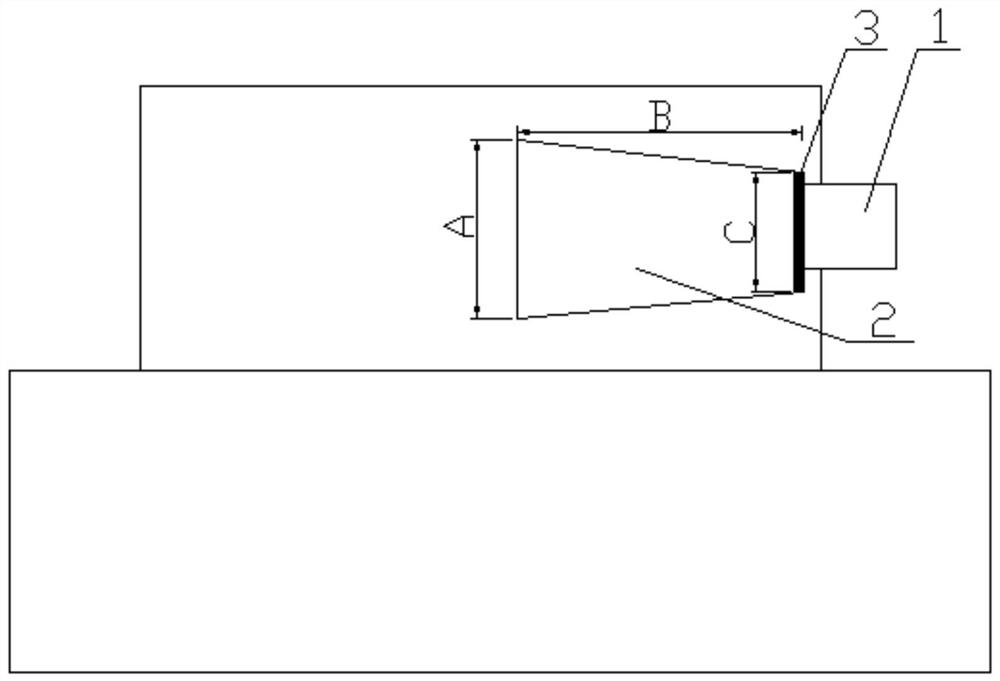

Method for detecting ventilation frequency of independent ventilation cage box

ActiveCN112504324ALarge diameterAvoid the problem of inaccurate wind speed measurementFluid speed measurement using thermal variablesAir velocityEngineering

The invention discloses a method for detecting the ventilation frequency of an independent ventilation cage box, and the method comprises the steps: firstly, measuring the volume V0 of the independentventilation cage box, enabling the small-diameter end of an enclosure structure of a hollow circular-truncated-cone-shaped structure to be communicated with an air inlet in the inner side of the independent ventilation cage box, and enabling the diameter of the small-diameter end to be the same as that of the air inlet; adhering a rubber pad to the inner side of the small-diameter end, wherein the diameter of the large-diameter end is twice larger than that of the small-diameter end, and the height of the enclosure structure is 3.33 times larger than that of the small-diameter end; and then measuring the average wind speed v at the large-diameter end of the enclosure structure, the area S of the large-diameter end of the enclosure structure and the air inlet temperature t, and finally obtaining the ventilation frequency of the independent ventilation cage box according to a calculation formula. The problems that the wind speed is not concentrated and measurement is inaccurate due to the fact that the diameter of the air opening of each independent ventilation cage box is too small or the air opening is provided with an air diffuser can be solved, and the ventilation frequency of each independent ventilation cage box can be reflected more accurately and truly.

Owner:武汉世纪久海检测技术有限公司

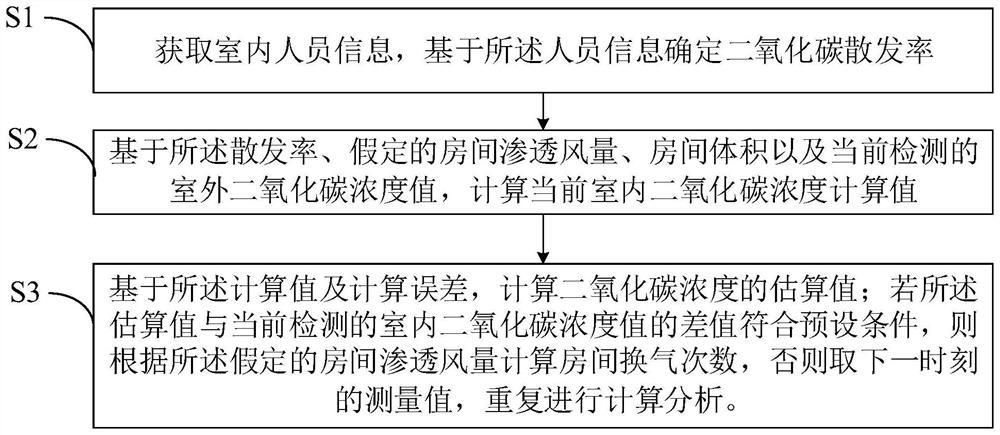

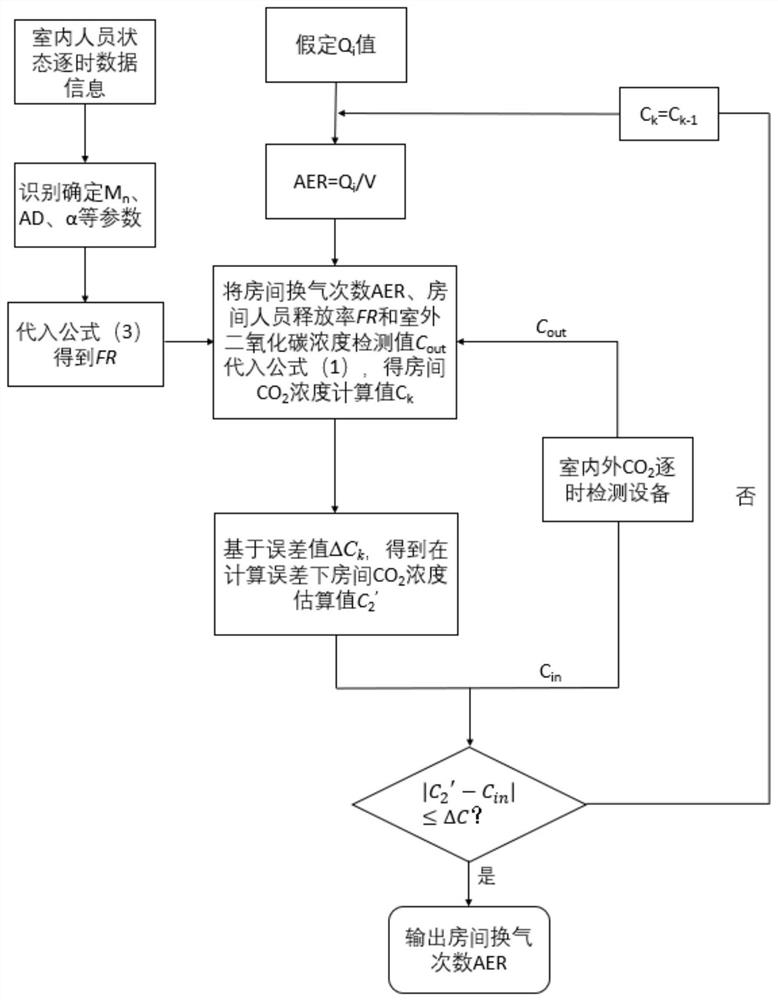

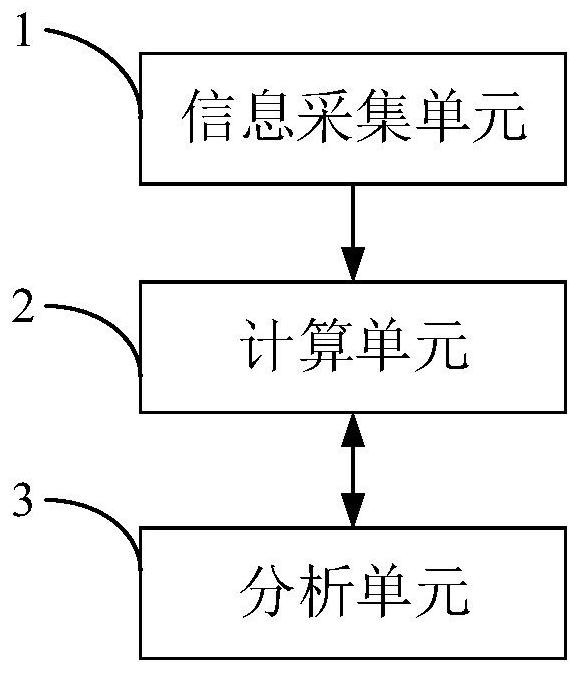

Method and system for testing room ventilation frequency based on carbon dioxide release source

PendingCN114493270AFacilitate the number of air changes per hourSimplify workloadAerodynamic testingResourcesRoombaProcess engineering

The invention provides a method and system for testing room ventilation times based on a carbon dioxide release source, and the method comprises the steps: obtaining indoor personnel information, and determining a CO2 emission rate based on the personnel information; calculating a current indoor CO2 concentration calculation value based on the emission rate, the assumed room permeation air volume, the room volume and the currently detected outdoor CO2 concentration value; calculating an estimated value of the CO2 concentration based on the calculation value and the calculation error; and when the difference value between the estimated value and the currently detected indoor CO2 concentration value meets the preset condition, the number of times of room ventilation is calculated according to the assumed room permeation air volume. According to the method, the indoor ventilation quantity is iteratively solved under the condition that the maximum measurement error of the estimated value and the measured value is guaranteed, and then the ventilation frequency of the room is obtained. The workload of measuring the ventilation times in the room is simplified, the measurement cost is reduced, and the hourly ventilation times of the room can be conveniently detected.

Owner:中认国证(北京)评价技术服务有限公司 +1

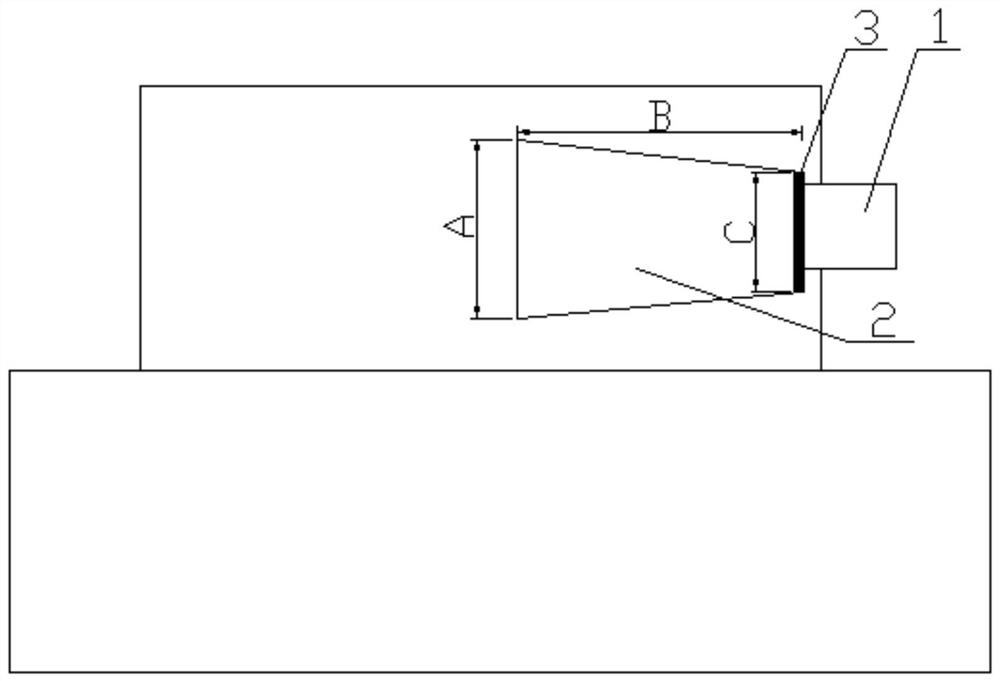

A method for detecting the number of air changes of an independent ventilated cage box

ActiveCN112504324BLarge diameterAvoid the problem of inaccurate wind speed measurementFluid speed measurement using thermal variablesAir velocityEngineering

The invention discloses a method for detecting the ventilation frequency of an independent ventilated cage box. The steps are as follows: firstly, the volume of the independent ventilated cage box is measured as 0 , connect the small-diameter end of the enclosure structure of the hollow conical structure with the air inlet inside the independent ventilation cage box, wherein the diameter of the small-diameter end is the same as the diameter of the air inlet, and the inside of the small-diameter end is glued with a rubber pad, and the diameter of the large-diameter end is larger than the small diameter 2 times of the end diameter, the height of the enclosure structure is 3.33 times of the diameter of the small diameter end; then measure the average wind speed v at the large diameter end of the enclosure structure, the area S and the inlet air temperature t of the large diameter end, and finally According to the calculation formula, the number of air changes of the independent ventilation cage box is obtained. The beneficial effect of the present invention is: the enclosure structure is added, which can avoid the wind speed being not concentrated due to the too small diameter of the tuyere of the independent ventilation cage box or the diffuser at the tuyere. , The problem of inaccurate measurement can more accurately and truly reflect the number of air changes of each independent ventilation cage box.

Owner:武汉世纪久海检测技术有限公司

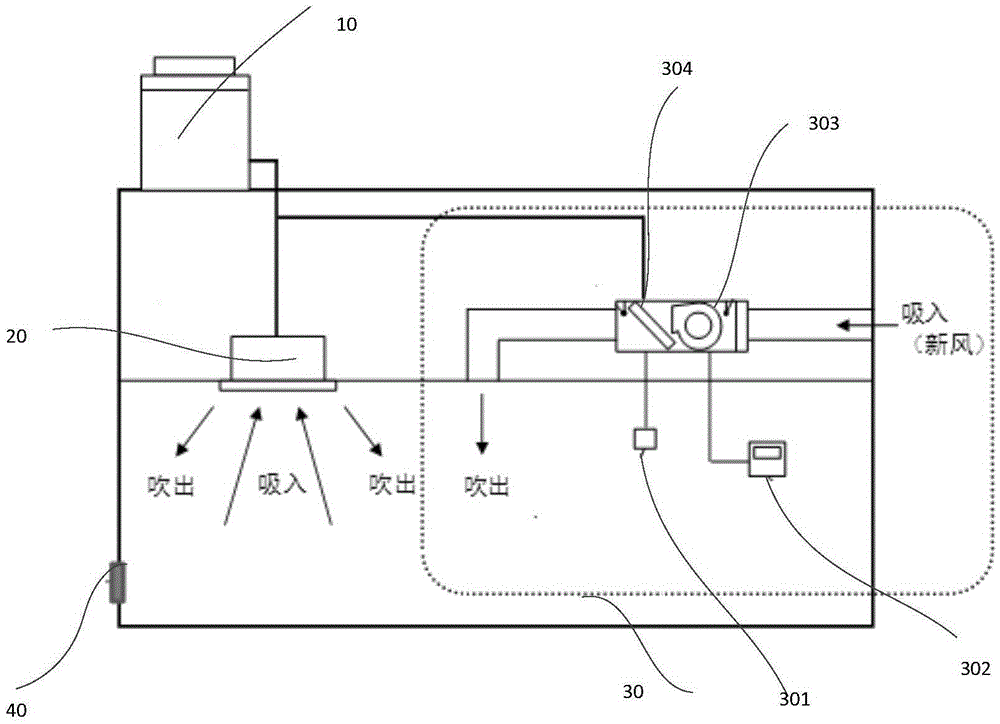

Direct-evaporation temperature and humidity exchange air-conditioning system

InactiveCN102818320AFully functionalQuickly adjust temperature and humidityDucting arrangementsSpace heating and ventilation safety systemsAir conditioningAir blower

A direct-evaporation temperature and humidity exchange air-conditioning system comprises an air-conditioning chamber and an air feed and return system, wherein the air-conditioning chamber consists of an air feed chamber, a spray chamber and an air return chamber, and the air feed and return system comprises air feed pipes, an air feed inlet, air return pipes and an air return inlet. An air blower is mounted between the air feed chamber and the spray chamber, a water baffle, spray pipes and spray nozzles are mounted in the spray chamber, and the air feed chamber feeds cold and humid air into a working area through the air feed pipes and the air feed inlet on the upper portion of the working area. The spray pipes are modified to be arranged in 2-6 rows, ground air return pipes are arranged under the ground of the working area, upper air return pipes are arranged above the working area, an air return fan in the air return chamber and the air return inlet and a disc type filter screen on the wall of a workshop are omitted, so that the integral system runs circularly and naturally by air density difference, and temperature and humidity can be dynamically balanced. The direct-evaporation temperature and humidity exchange air-conditioning system has the advantages of few air exchange times, low water consumption and power consumption and proper temperature and humidity in the workshop, static electricity during technical process of products can be avoided, and off-machine moisture regain of cashmere can reach 18% and the like.

Owner:马利娜

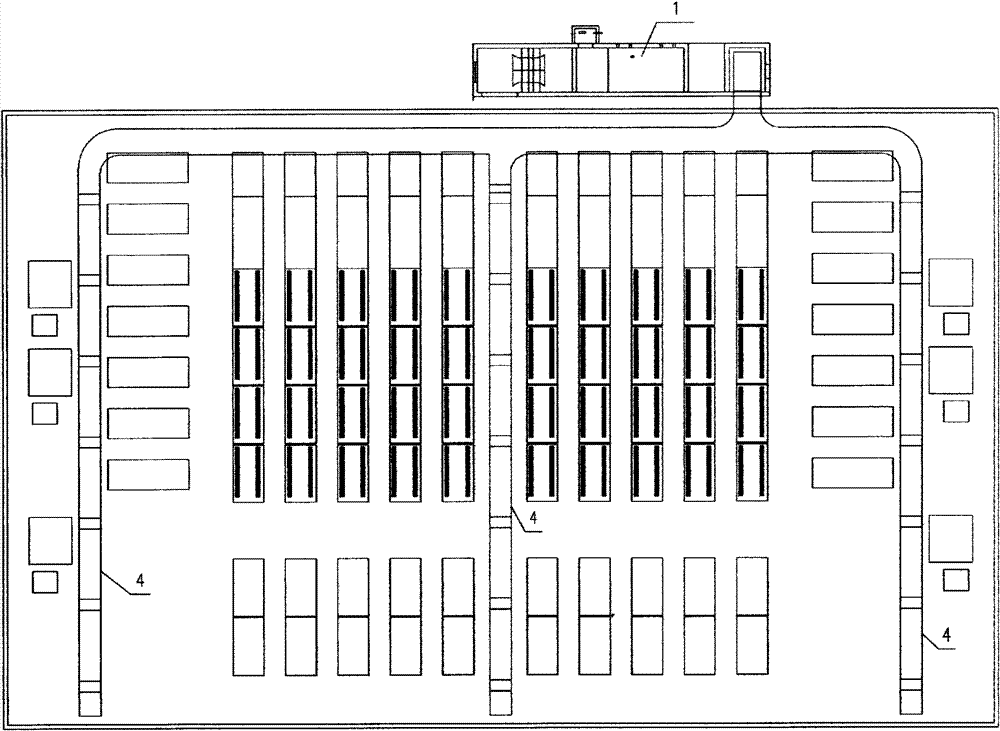

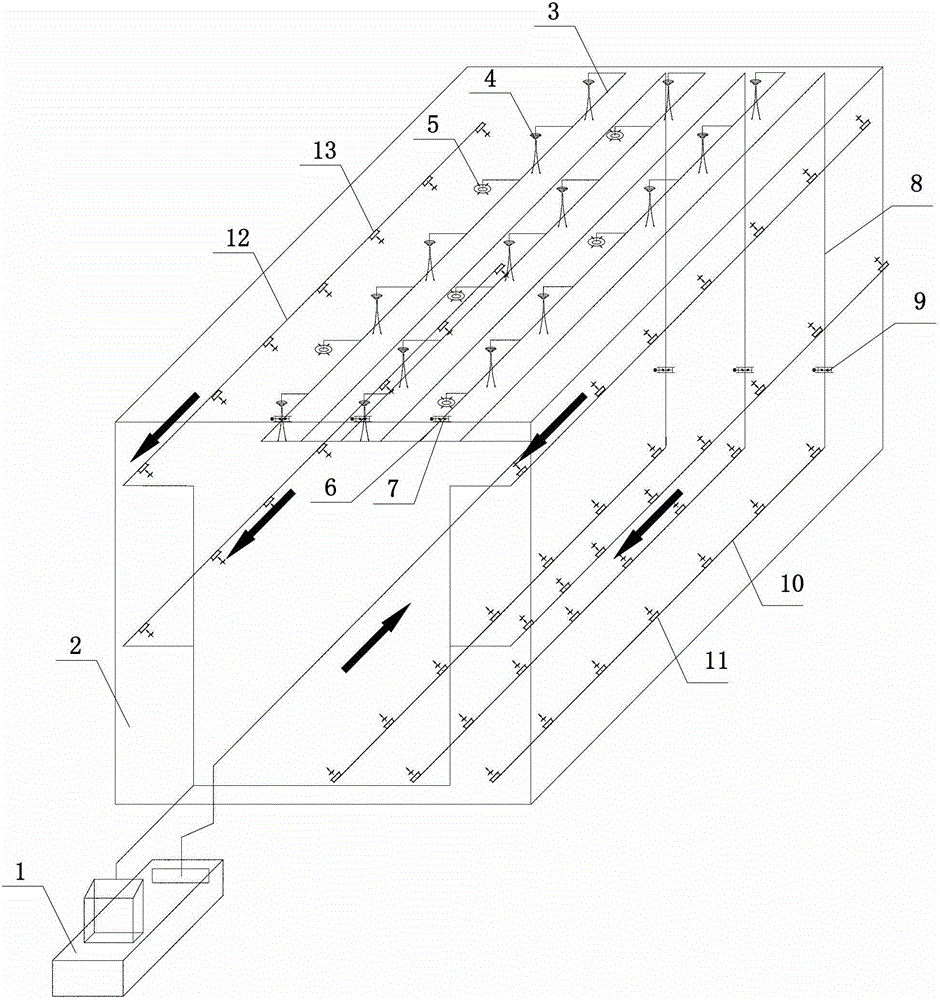

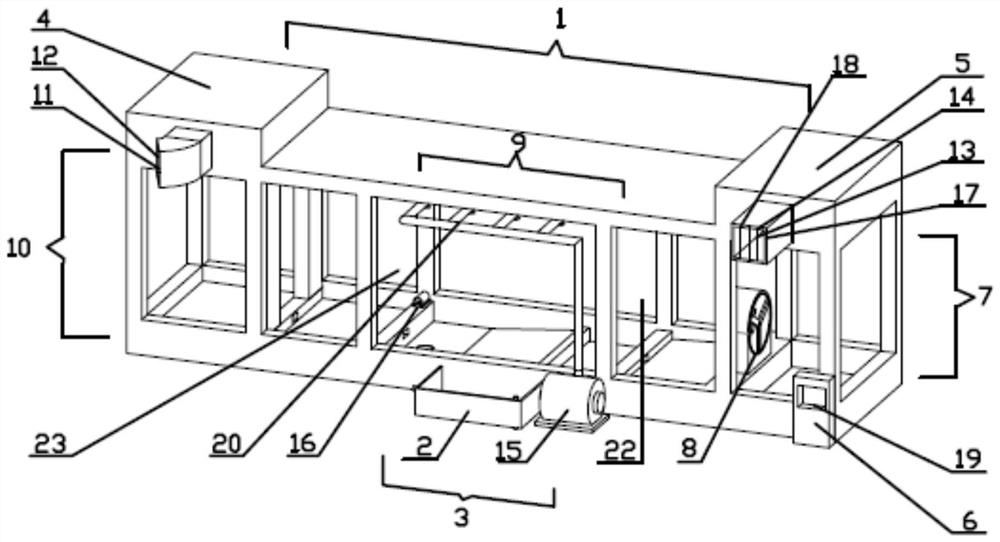

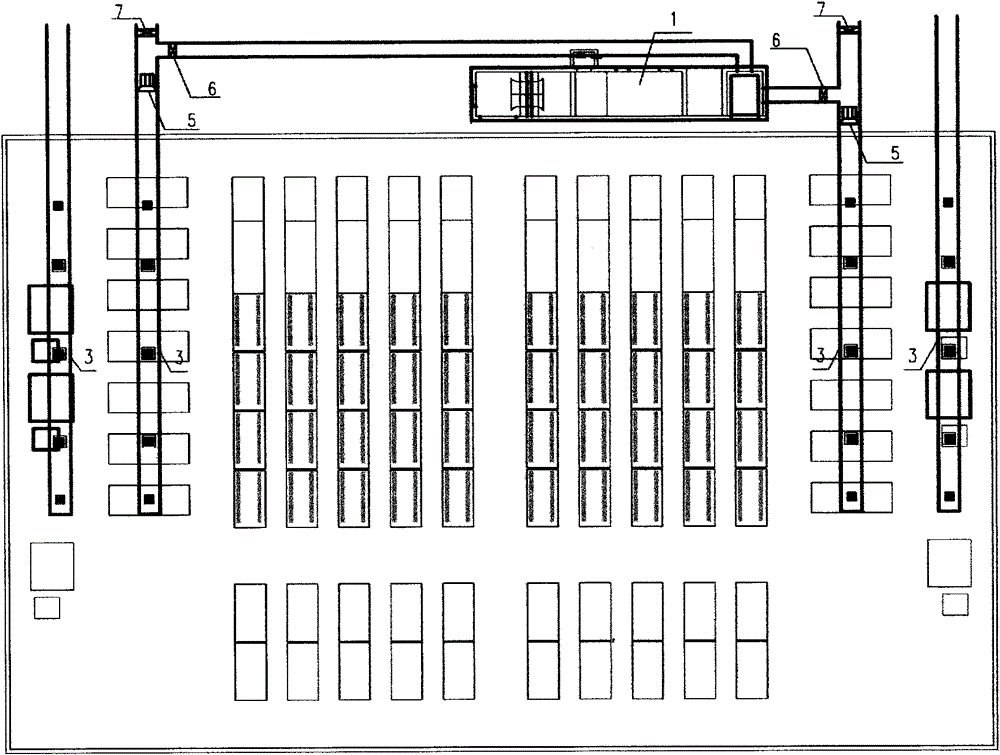

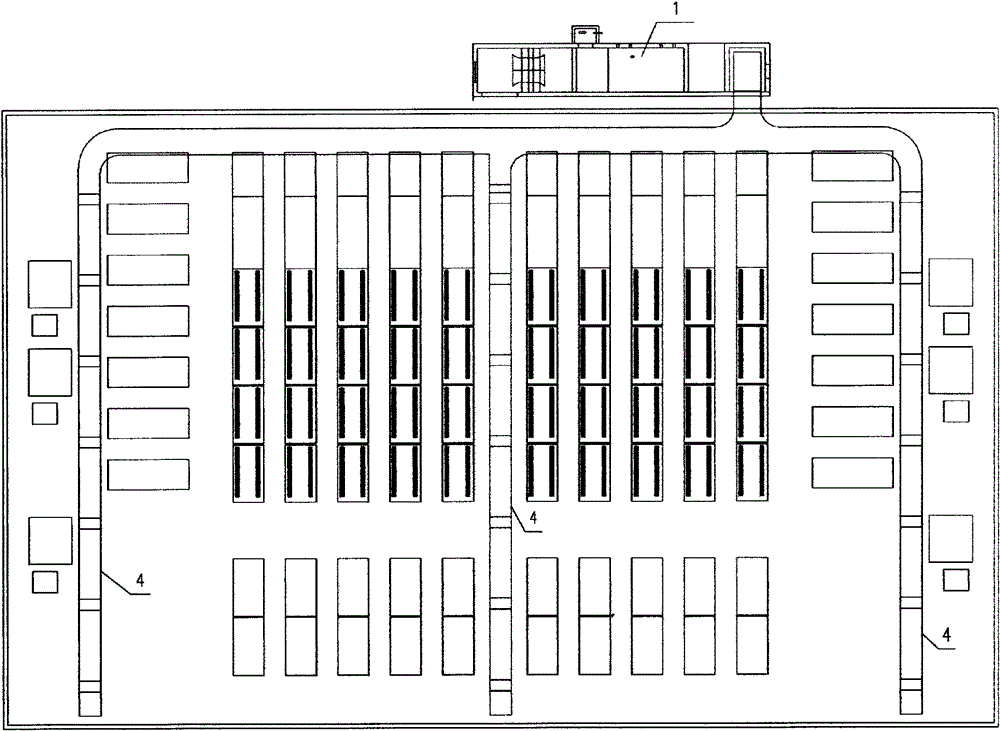

An air-conditioning air supply system for improving the uniformity of temperature and humidity in the elevated warehouse of a cigarette factory

ActiveCN103134161BReduce air consumptionReduce air changesDucting arrangementsAir compressionEngineering

The invention relates to an air conditioner air supply system for improving uniformity of temperature and humidity of an elevated warehouse of a cigarette factory. The air conditioner air supply system for improving the uniformity of the temperature and the humidity of the elevated warehouse of the cigarette factory comprises an air compression device, an air supply system, and an air return system. The air supply system comprises an upper-layer air supply pipeline, twist outlets, spraying outlets, a lower-layer air supply pipeline and double deflection grilles. The upper-layer air supply pipeline is connected with an air outlet of the air compression device. The twist outlets and the spraying outlets are arranged and distributed in the upper-layer air supply pipeline. The lower-layer air supply pipeline is connected with the air compression device. The double deflection grilles are arranged in the lower-layer air supply pipeline. The air return system comprises an air return pipeline and single deflection grilles, wherein the single deflection grilles are distributed and arranged in the air return pipeline. The air return pipeline is connected with an air return mouth of the air compression device. According to the air conditioner air supply system for improving the uniformity of the temperature and the humidity of the elevated warehouse of the cigarette factory, the temperature and the humidity of the warehouse can meet design requirements, the temperature and the humidity of an upper layer of the storehouse and the temperature and the humidity of a lower layer of the warehouse are enabled to be uniform, and therefore air circulation ratio of the warehouse is reduced, and energy consumption for air supply of air conditioners is reduced.

Owner:CHINA TOBACCO ZHEJIANG IND

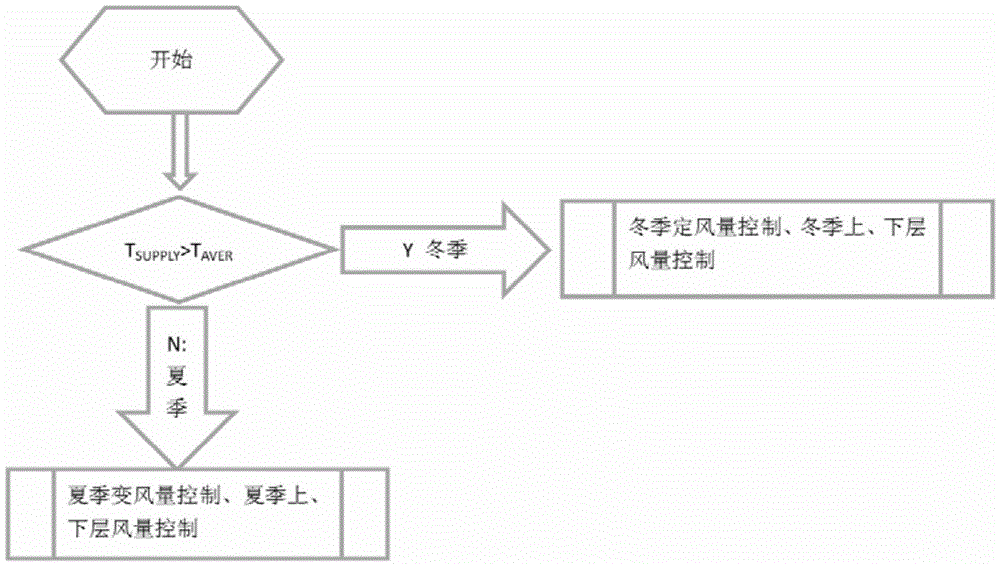

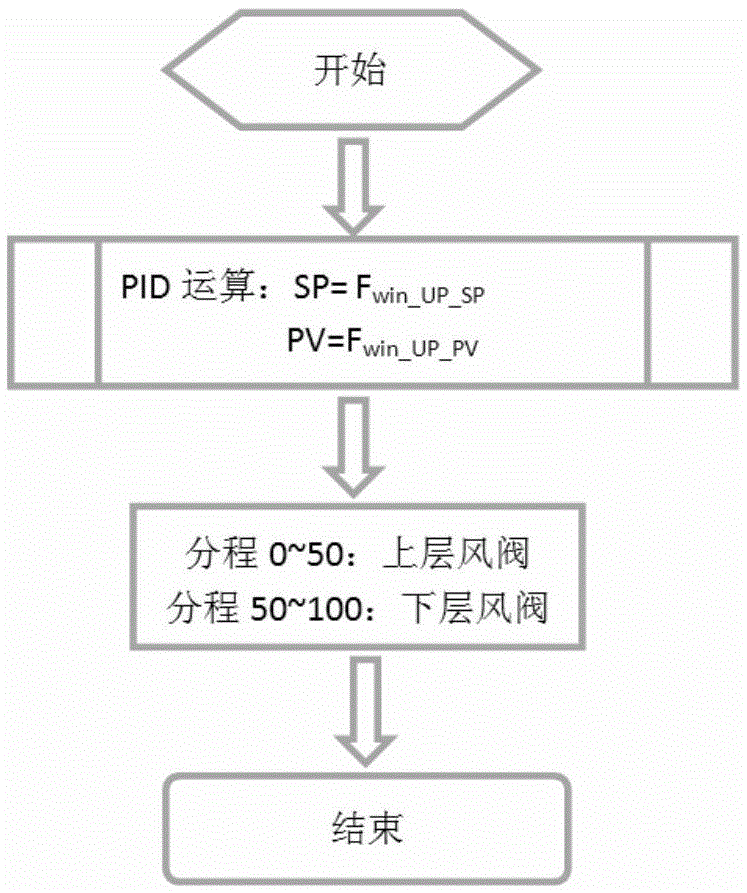

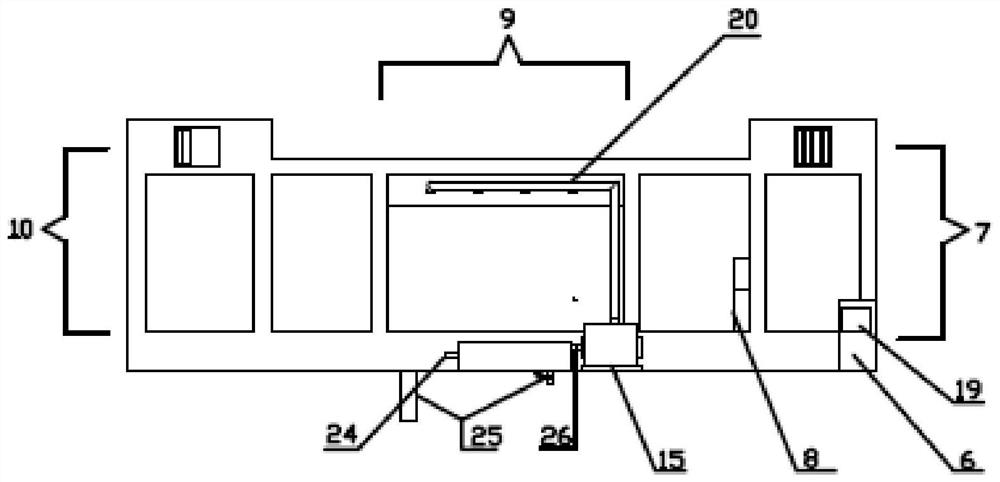

An air-conditioning self-control method for improving the temperature and humidity uniformity of elevated warehouses in cigarette factories

ActiveCN103574846BReduce air consumptionReduce air changesSpace heating and ventilation safety systemsLighting and heating apparatusAir volumeAutomatic control

The invention relates to an air conditioner automatic-control method for improving the cigarette factory high rack storage temperature and humidity uniformity. The air conditioner automatic-control method is formed by a summer mode and a winter mode, and includes the steps of (1) arranging sensors to automatically detect the supply air temperature T<supply> and the high rack storage practical temperature T<aver>, wherein when the supply air temperature T<supply> is higher than the high rack storage practical temperature T<aver>, the air conditioner automatic-control method is in the winter mode, otherwise, the air conditioner automatic-control method is in the summer mode, and the relation between the air conditioning system load rate y<1> and the supply air volume x is y<1> = -0.1*x+1.1; and (2) arranging sensors to respectively detect the supply air volume of an upper-layer air pipe and the supply air volume of a lower-layer air pipe, and controlling the supply air volume of the upper-layer air pipe and the supply air volume of the lower-layer air pipe according to the relations between the upper-and-lower layer supply air proportions and the load rates in different seasons. According to the scheme of the air conditioner automatic-control method for improving the cigarette factory high rack storage temperature and humidity uniformity, the aims that the storage temperature and the storage humidity meet the design requirements, and the temperature and the humidity of the upper layer and the lower layer of a storage area are uniform are achieved; on the basis, the storage ventilation rate is reduced, and air supplying energy consumption of an air conditioner is reduced.

Owner:CHINA TOBACCO ZHEJIANG IND

A household constant temperature and humidity square warehouse system

ActiveCN107894046BConvey evenlySuitable temperature and humidityMechanical apparatusSpace heating and ventilation safety systemsEngineeringWater circulation

Owner:WUHAN TEXTILE UNIV

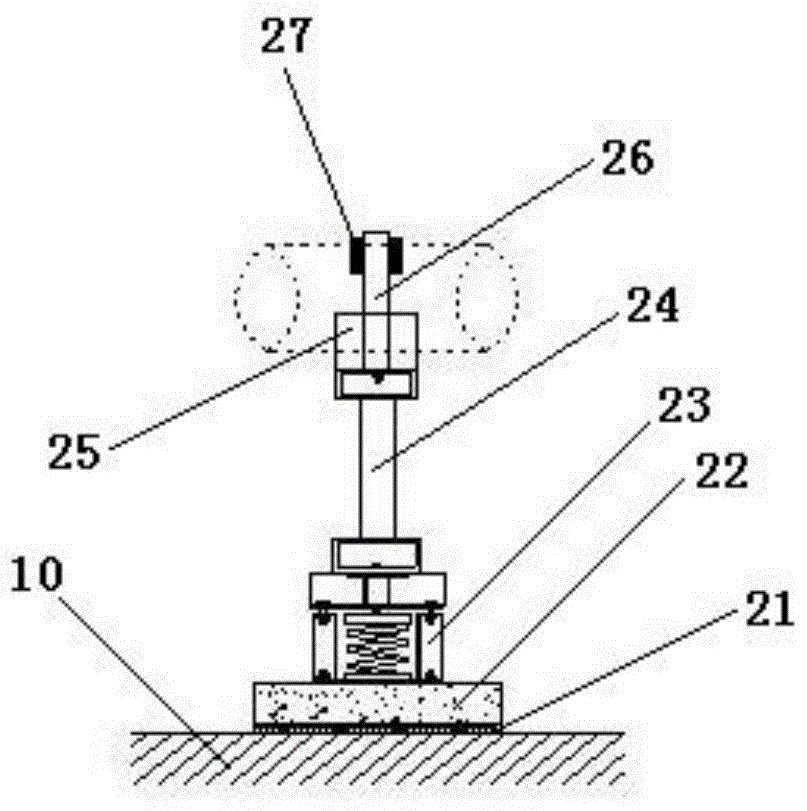

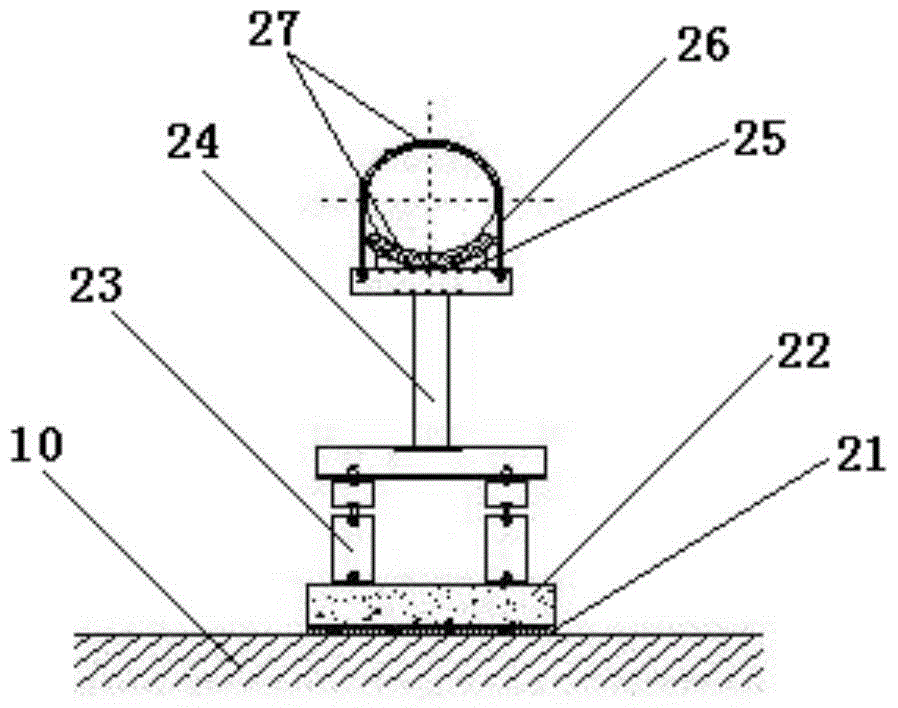

Seismic isolation construction method of ventilation and air-conditioning equipment room

ActiveCN104695740BSolve ventilation problemsEasy to manageLighting and heating apparatusNon-rotating vibration suppressionReinforced concreteFresh air

The invention discloses a vibration-isolated construction method for a ventilation air-conditioning machine room. The method comprises steps as follows: a damper spring shock absorber and a steel reinforced concrete hybrid structured base are added below a refrigerating unit, a water inlet pipeline and a water outlet pipeline obtain horizontal vibration-proof support through a steel frame support structure, a fresh air pipeline is hoisted and mounted in a vibration isolation manner, acoustical board construction is performed on both the wall surface and the top surface, and a soundproof and fireproof door is mounted. The vibration-isolated construction method has the benefits as follows: vibration isolation supports are arranged independently for different pipelines, and collision with other pipelines can be avoided; the noise can be reduced by 24 dB effectively, the noise in the machine room is only about 32 dB, and the vibration and noise reduction effects are obvious; mounting and dismounting are convenient, construction is easy, the cost is lower, indoor air ventilation is solved effectively, ordered and effective ventilation is realized, indoor polluted air is treated rapidly and economically, and the method is particularly suitable for places with higher air quality requirements, more people activities and higher ventilation rate and requiring air change and circulation.

Owner:南通市中南建工设备安装有限公司

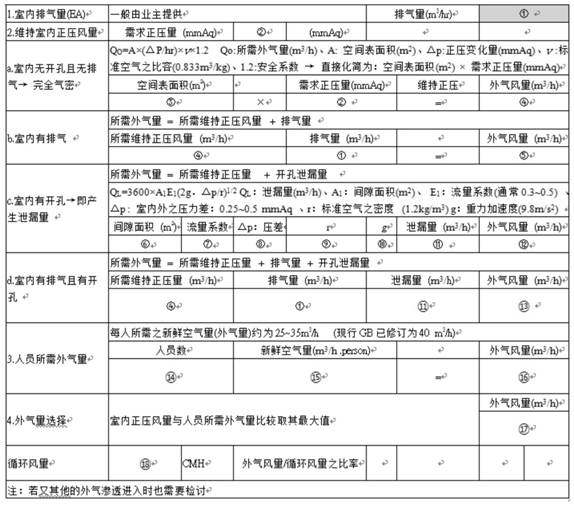

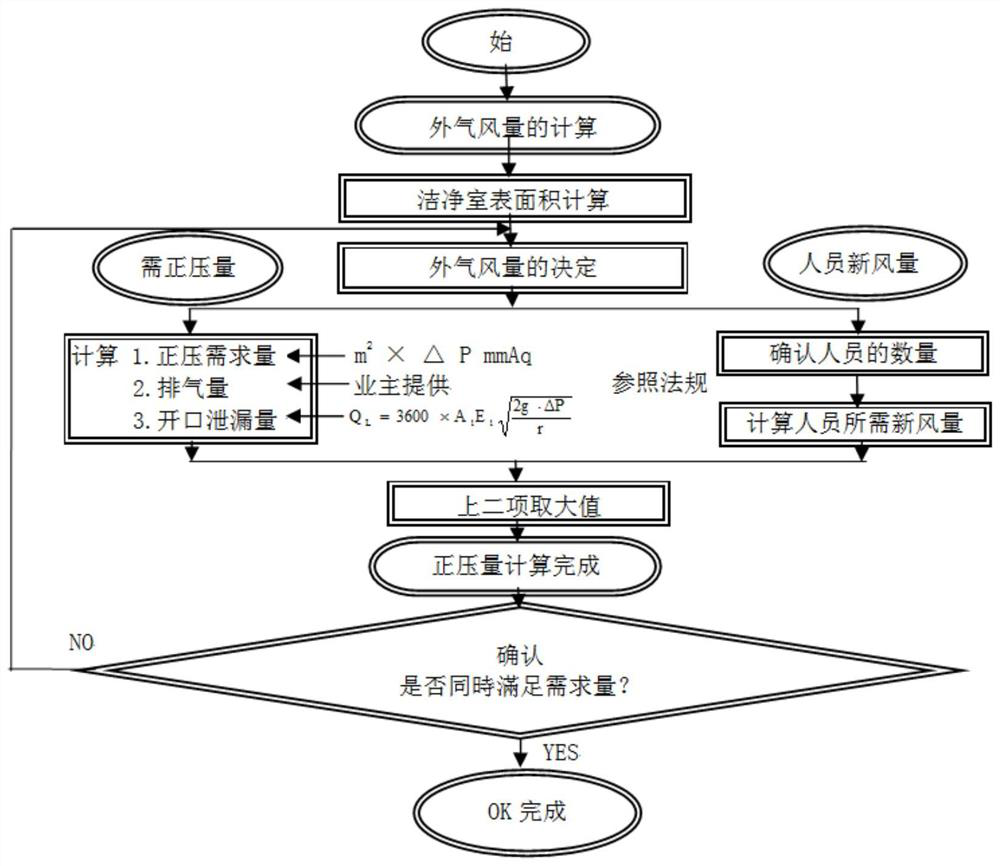

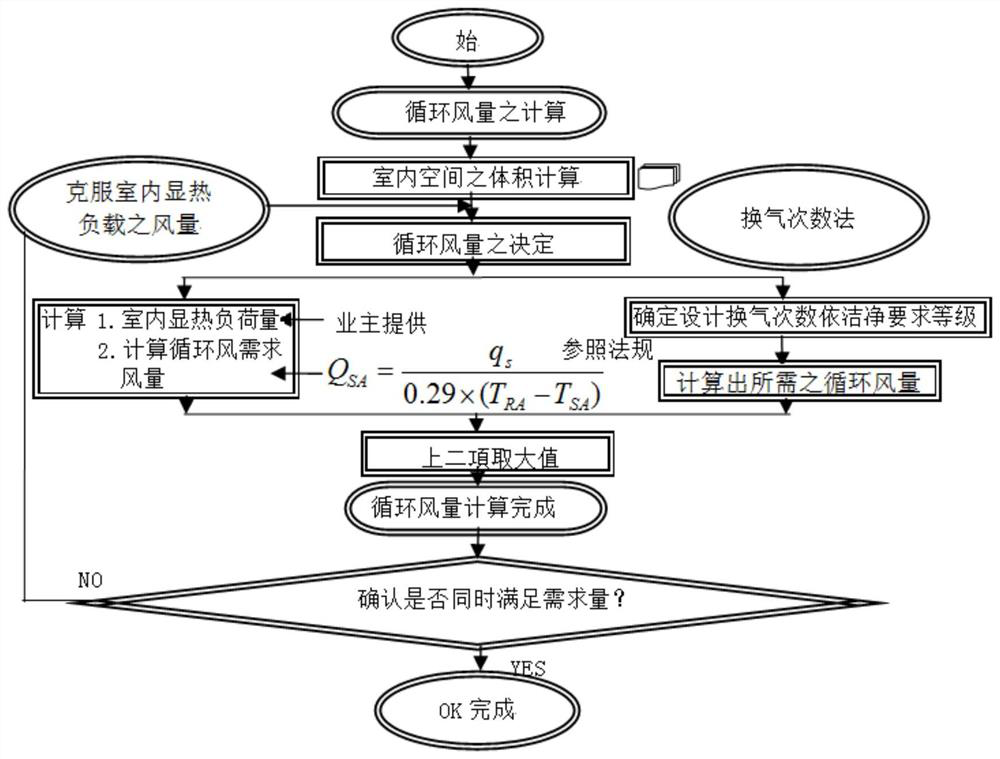

Design method for circulating air volume of clean room

PendingCN113158455ASatisfy the amount of fresh airCorrectly designedDigital data information retrievalDesign optimisation/simulationAir volumeFresh air

The invention discloses a design method for circulating air volume of a clean room, which comprises the following steps of: firstly, acquiring outdoor dry-bulb temperature DB of the clean room in summer and winter, then calculating the area and the volume of the clean room, and determining the air exchange frequency of circulating air in the clean room according to the cleanliness grade of the clean room; superposing personnel sensible heat, compartment sensible heat, introduced external air sensible heat and permeation sensible heat to obtain indoor total sensible heat, calculating theoretical circulating air volume in a clean room and required air volume for overcoming indoor sensible heat, and comparing the theoretical circulating air volume with the required air volume for overcoming the indoor sensible heat; the obtained clean room circulating air volume can meet the requirement that the pressure of the clean room is larger than the outdoor pressure, pollution particles are prevented from entering the clean room to cause pollution, the fresh air volume needed by indoor personnel can also be met, it is guaranteed that the clean room circulating air volume is designed accurately, and the air quality is improved. And the condition of insufficient circulating air volume or energy waste is avoided.

Owner:上海艾正系统集成有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com