Low-oxygen isolator

A technology of oxygen isolation and high-efficiency filter, which is applied in the direction of inert gas generation and control of multiple fluid ratios, and can solve the problem of inability to adjust the oxygen concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

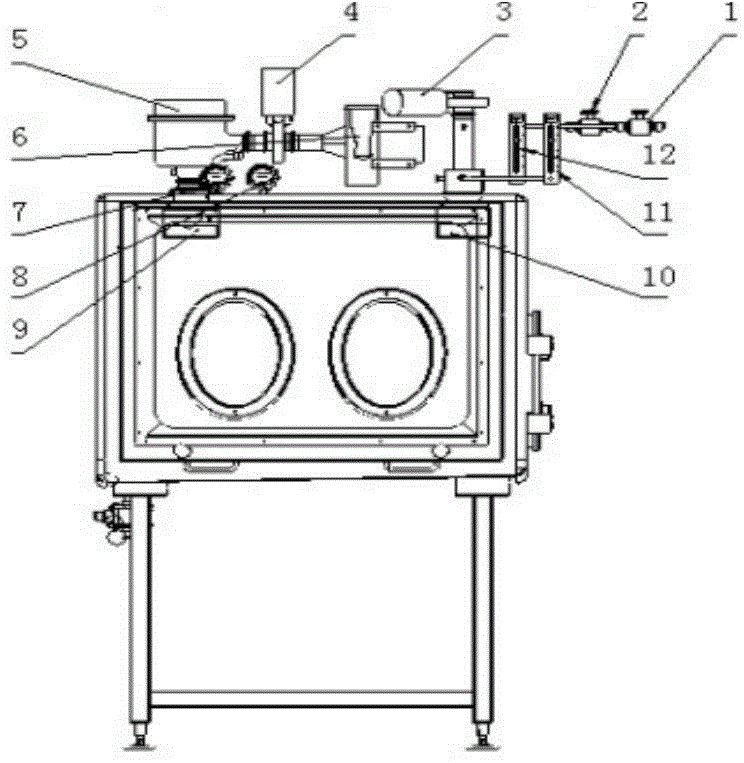

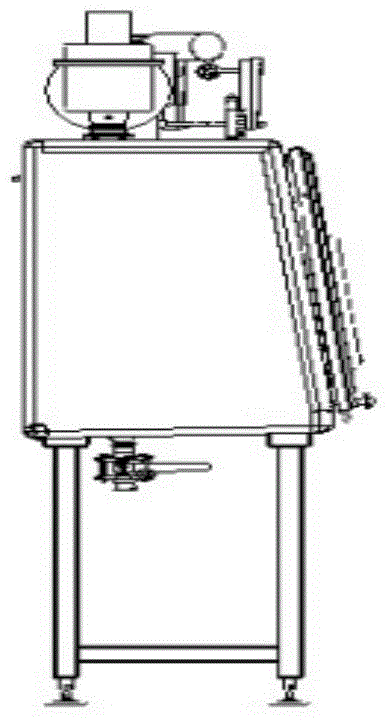

Embodiment 1

[0036]Prepare the isolator of the present invention, which is composed of a box body, an exhaust system, an air intake system and a control system; the exhaust system adopts a high-efficiency filter, and a pneumatic switch valve is arranged on the pipeline, which is automatically closed when the equipment leaks. When the equipment is shut down, the exhaust valve is closed to avoid contact between the box and the outside world; the airflow mode of the air intake system is a turbulent flow mode, which is divided into air intake and nitrogen intake, which can be switched freely; the intake of the air intake system The air port is equipped with a manual butterfly valve to adjust the number of air changes of the equipment; the nitrogen intake system is divided into two intakes, and the intake flow is adjusted and monitored by the flow meter. The nitrogen intake is weighed when the intake is single. Mode, at this time, the nitrogen gas flow enters the box smoothly, without affecting ...

Embodiment 2

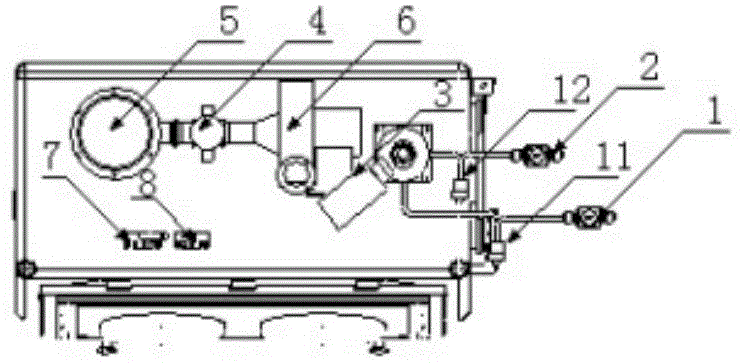

[0039] The isolator is used to adjust the oxygen concentration of the isolator cabin. The equipment includes two intake modes: nitrogen intake mode, which is suitable for materials sensitive to oxygen concentration; air intake mode, which is suitable for ordinary materials. Nitrogen gas intake mode: After starting the work, after the oxygen content meter detects that the oxygen content is higher than the set value, the nitrogen control valves 1, 2, exhaust valve 4, and fan 6 are opened, and the air intake valve 3 is closed, and the air in the box is started. After the detection value of the oxygen content meter 7 is lower than the set value, the nitrogen control valve 1 is closed, the air intake valve 3 is closed, and the nitrogen control valve 2, exhaust valve 4, and fan 6 are kept running, and the equipment enters In the slow air flow replacement mode, weighing and sub-packaging can be carried out at this time. During the whole process, the differential pressure transmitter 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com