Engine box digital grating sensing micro-distance detector

A digital grating and engine technology, applied in the electromechanical field, can solve problems such as impossibility, and achieve the effect of rapid product inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

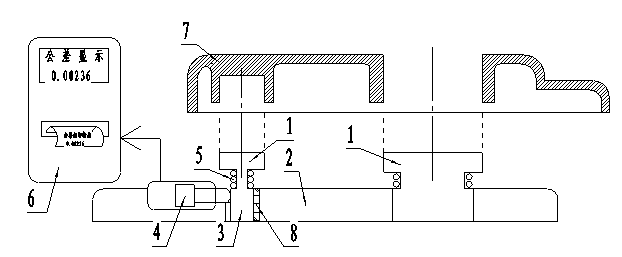

[0009] The specific working conditions proposed by the present invention will be described in detail below with reference to Figure 1. figure 1 In the middle, the silicone elastic sleeve 8 is sleeved on the guide post 3 and fixed on the workbench 2, the grating sensor 4 is installed close to the guide post 3, and is electrically connected to the digital display printer 6, at the guide post 3 and the reference hole positioning post A reference hole positioning spring 5 is installed between 1, and the engine box 7 is pressed and fixed on the reference hole positioning column 1.

[0010] The silicone elastic sleeve 8 covered by the guide post 3 has certain elastic deformation. Because the reference hole positioning post 1 and the guide post 3 are fixedly connected, the tested positioning hole on the engine box 7 is pressed against the reference hole positioning post After 1 is up, under the action of the reference hole positioning spring 5, the reference hole positioning column 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com