Fault discrimination method and device for rolling bearings of doubly-fed generators for wind power

A technology of doubly-fed generators and rolling bearings, which is applied in the direction of mechanical bearing testing, etc., and can solve problems such as unfavorable maintenance, failure of doubly-fed generator bearings and other component failures, and inability to determine the degree of bearing failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

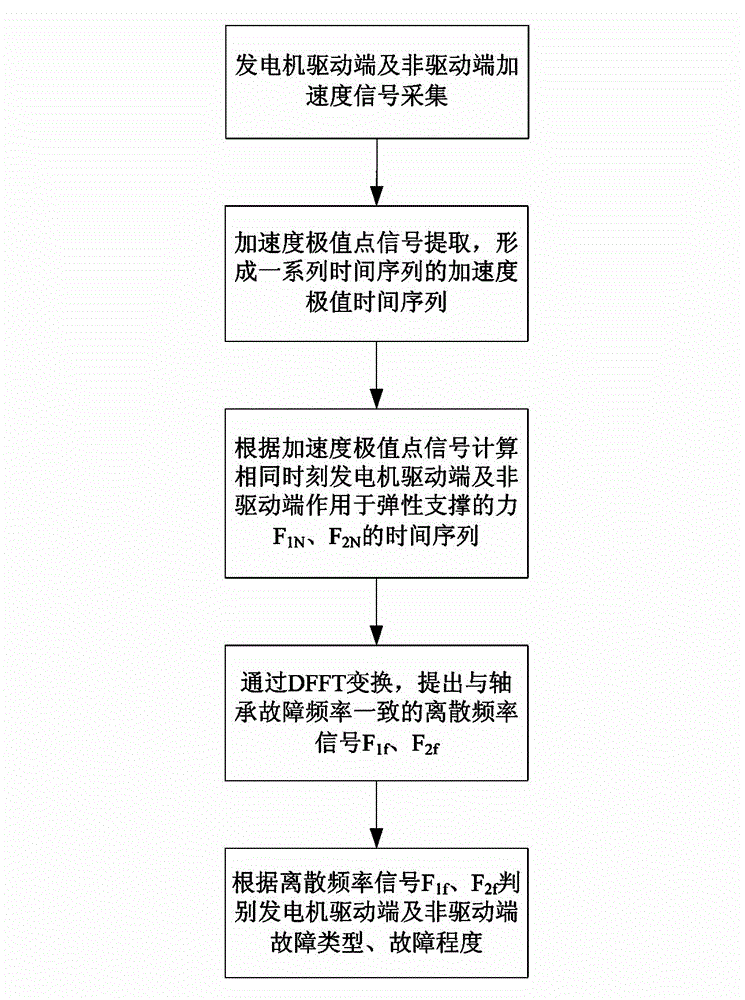

[0062] Such as figure 1 As shown, the implementation steps of the method for identifying rolling bearing faults of double-fed generators for wind power in this embodiment are as follows:

[0063] 1) Detect the acceleration signal of the driving end of the doubly-fed generator and the acceleration signal of the non-driving end when the doubly-fed generator is running.

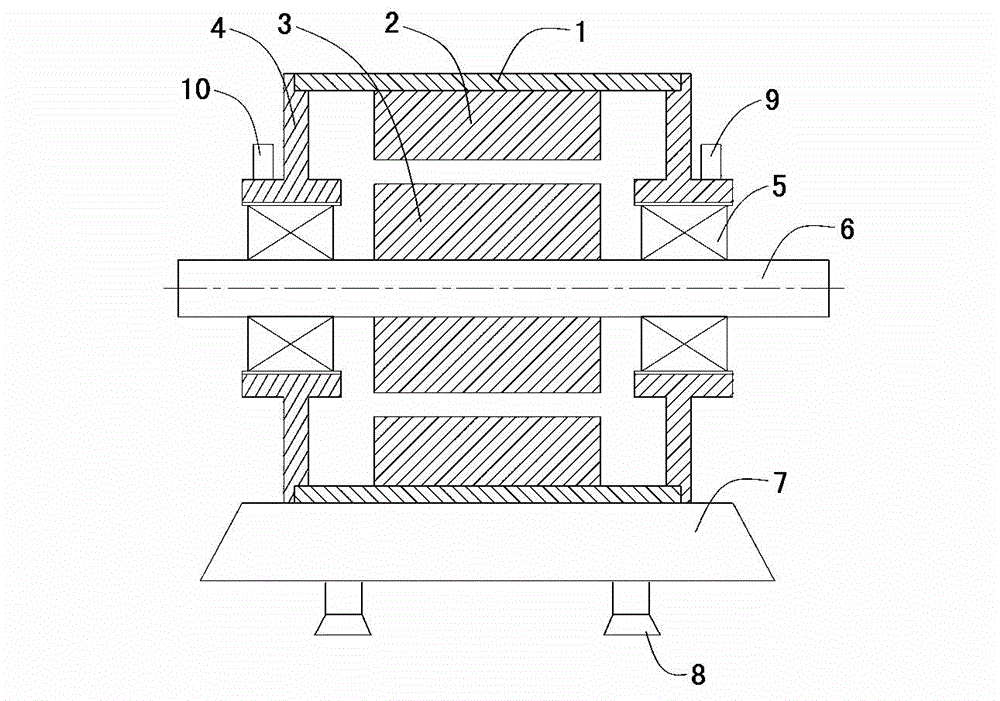

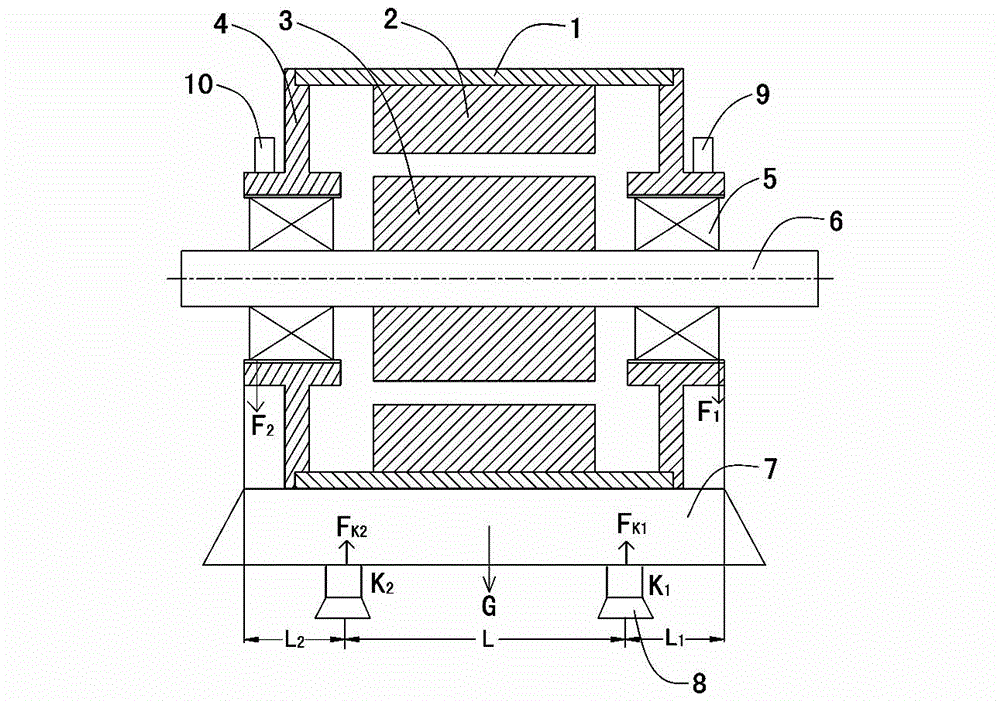

[0064] In this embodiment, the acceleration signals of the driving end and the non-driving end of the doubly-fed generator are respectively detected when the doubly-fed generator is running through the acceleration sensors respectively installed at the driving end and the non-driving end of the doubly-fed generator. Such as figure 2As shown, the base 1 of the current common doubly-fed generator is supported and fixed on the base 7, and the rotating shaft 6 is inserted in the base 1, and the left side (non-driving end) and right side (driving end) of the rotating shaft 6 respectively pass through The bearing o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com