Temperature control module for glass electric kettle

A technology of temperature control module and electric kettle, which is applied in the direction of using electric mode for temperature control, auxiliary controller with auxiliary heating device, etc. Safety hazards, the effect of improving reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

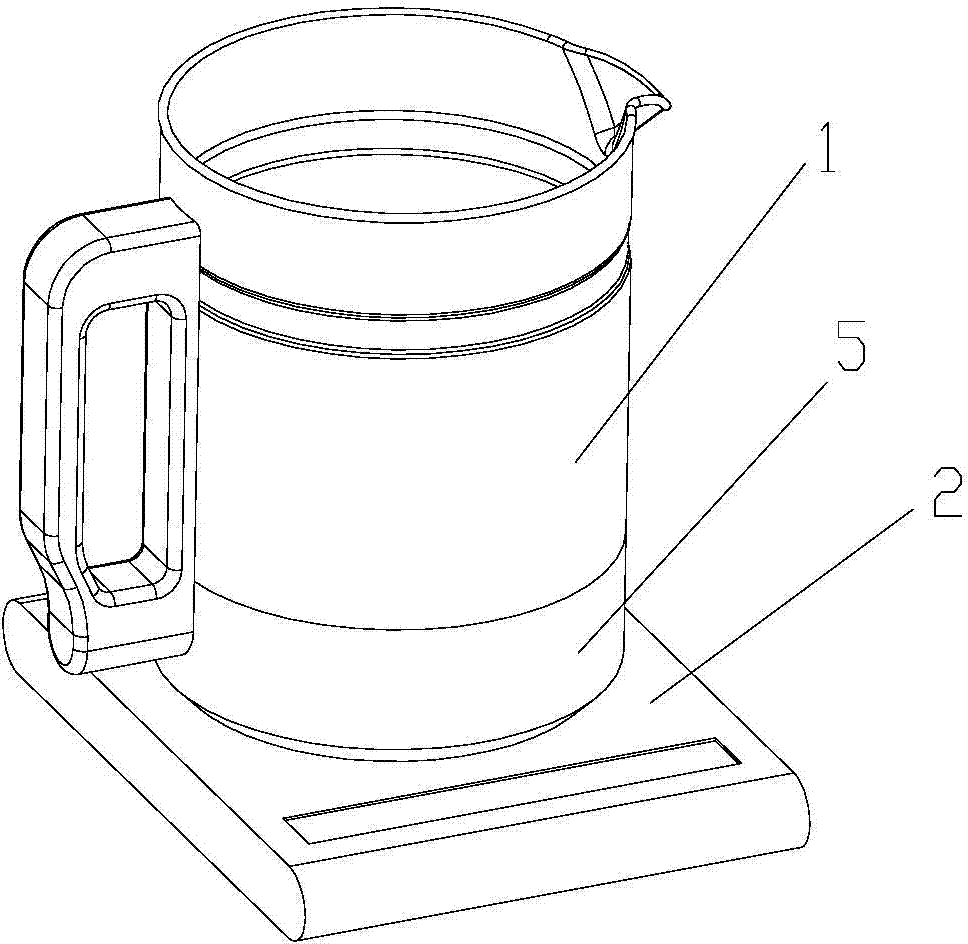

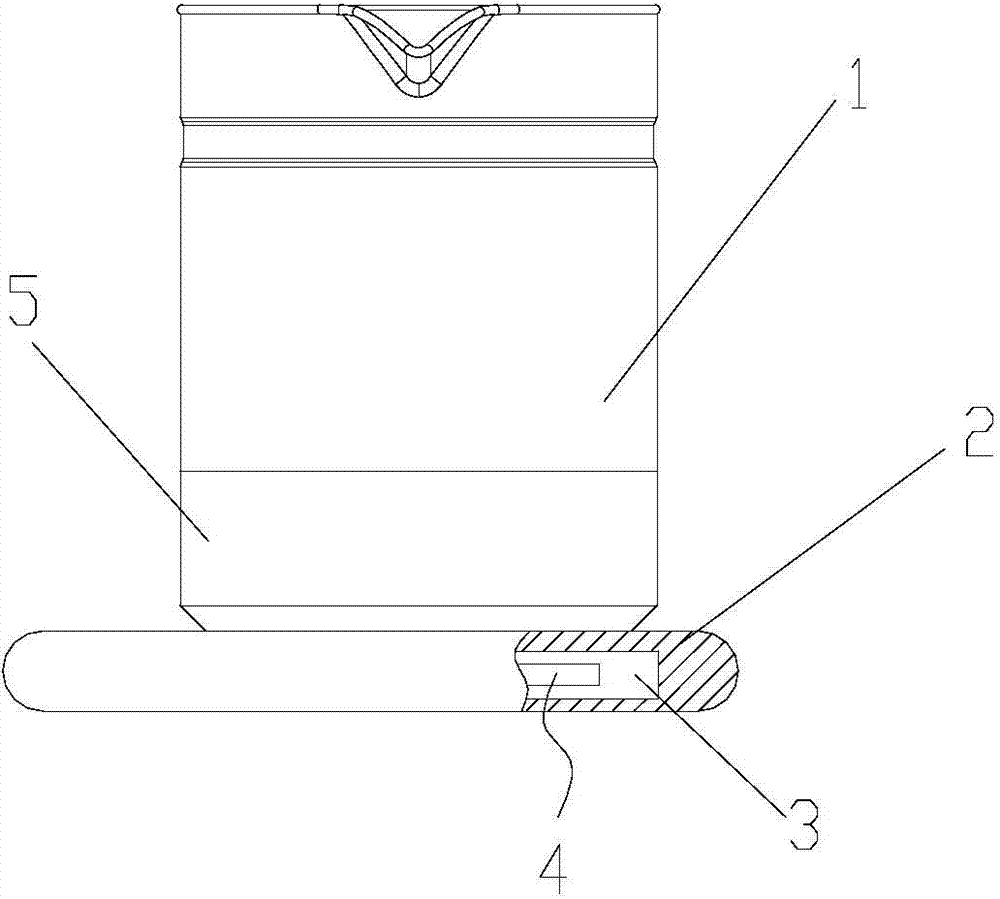

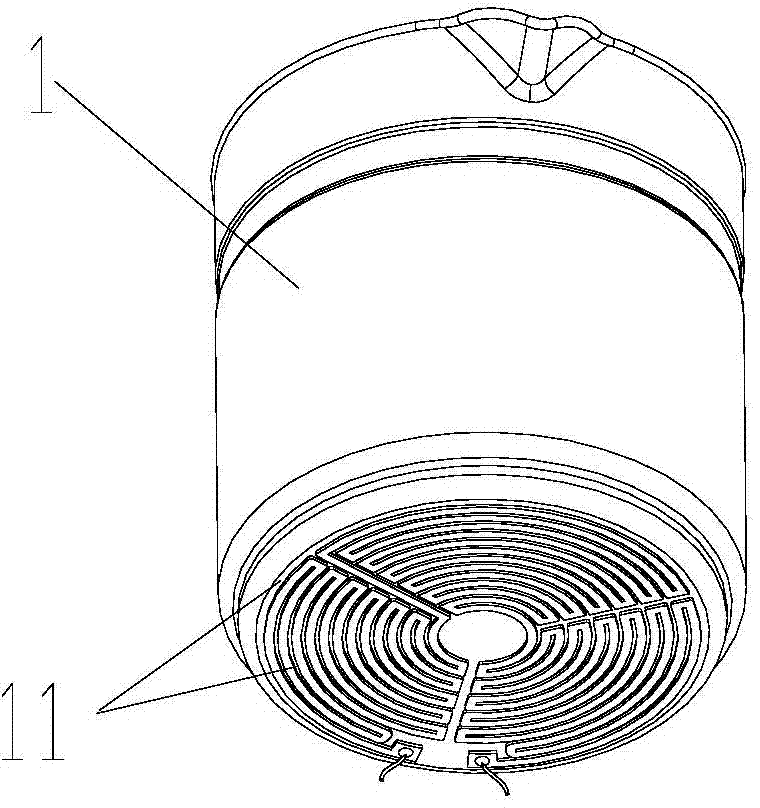

[0035] Such as figure 1 , figure 2 , image 3 As shown, a glass electric kettle includes a glass kettle body 1 and a base 2 coated with a far-infrared electric heating film 11 at the bottom, and a sheath 5 is arranged outside the bottom of the glass kettle body 1, and a temperature sensor and an electric plug are installed inside the sheath 5 connector. A cavity 3 is arranged inside the base 2, a control circuit board 4 is installed in the cavity 3, and a heating control circuit is arranged on the control circuit board 4.

[0036] Such as Figure 4 , Figure 5 and Figure 6As shown, a glass electric kettle temperature control module, the electric kettle function includes a glass kettle body, a far-infrared electric heating film, a far-infrared electric heating film RL is installed on the outer surface of the bottom surface of the glass kettle body, and the far-infrared electric heating film RL is connected in series A temperature control switch JK is connected to an ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com