Sectional material used for low voltage switch shell

A technology of low-voltage switches and profiles, applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems of reduced reliability, increased switch failure rate, low heat dissipation effect, etc., and achieve the effect of improving reliability and good working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

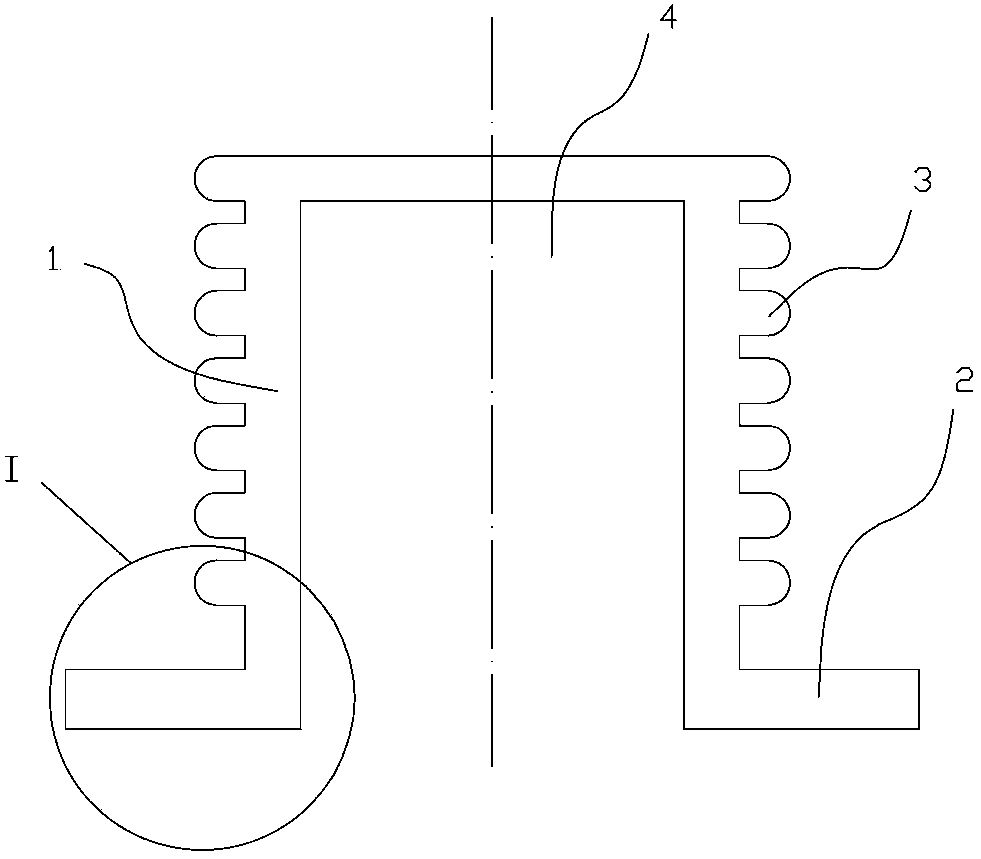

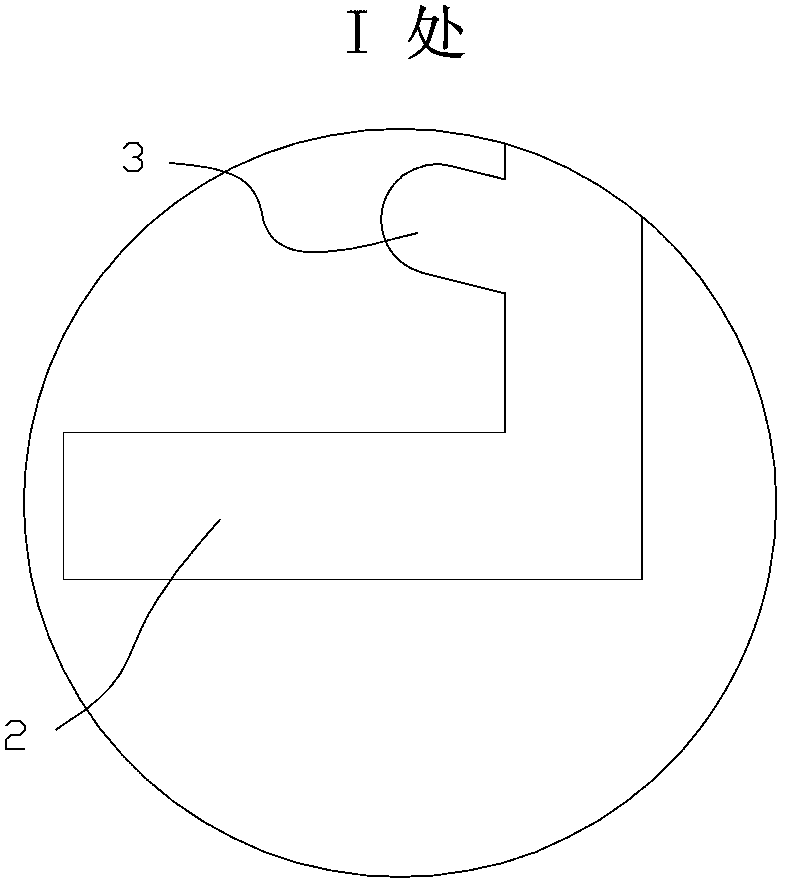

[0011] The present invention as Figure 1-3 As shown, the cross-section of the profile 1 is U-shaped 4, and the opening edges of the U-shaped 4 are respectively provided with side edges 2 facing outward, and the outer surfaces of the two sides of the U-shaped 4 are provided with axial cooling fins 3 .

[0012] The cooling fin 3 forms an angle of 0-15° with the side 2 . The grooves between the heat dissipation fins 3 are made to face outward, further improving the heat dissipation effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com