Folding fan type catalyst module

A catalyst module and folding fan technology, which is applied in chemical instruments and methods, gas treatment, and dispersed particle separation, etc., can solve the problems of insufficient catalyst denitrification performance, small contact area between flue gas and catalyst, and large pressure loss. It is convenient for transportation and on-site installation, improves the catalytic effect and reduces the effect of pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

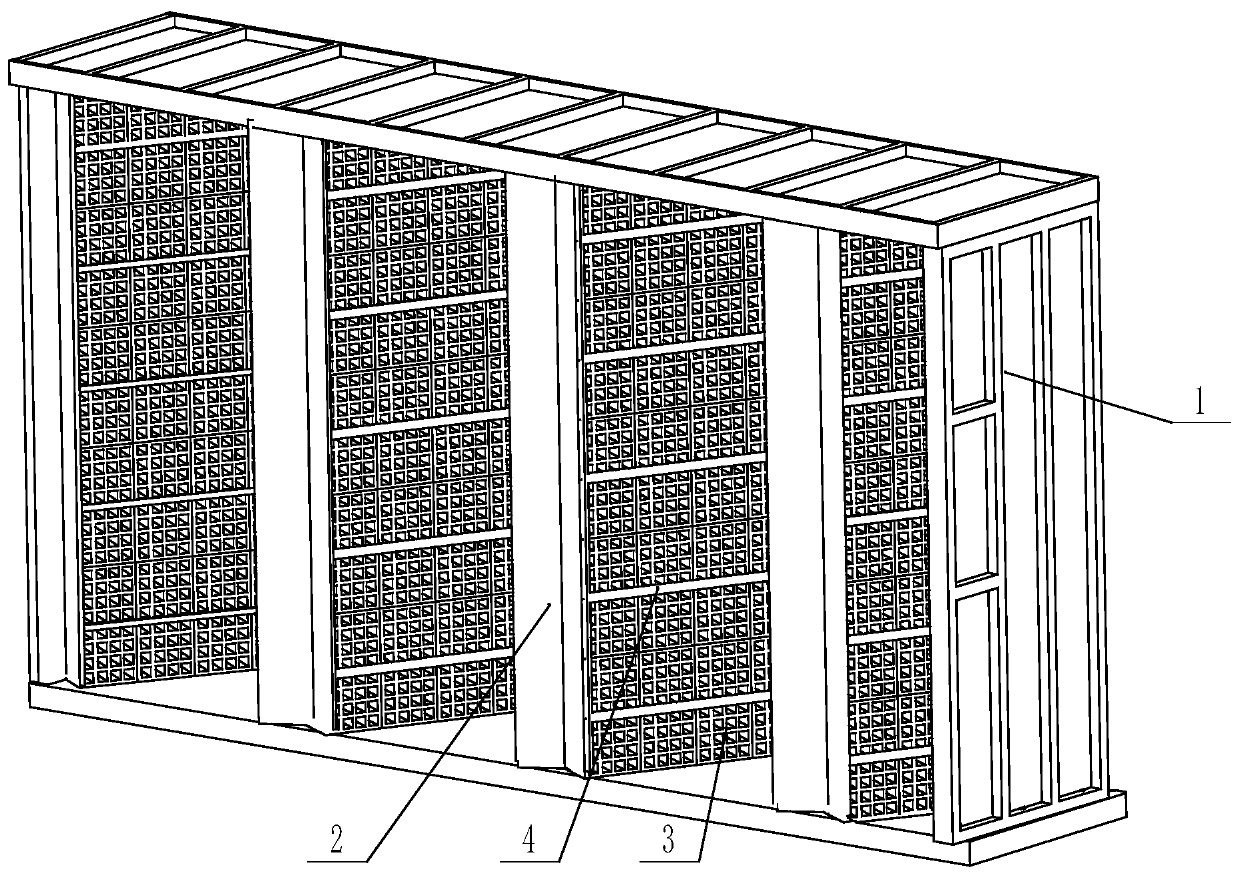

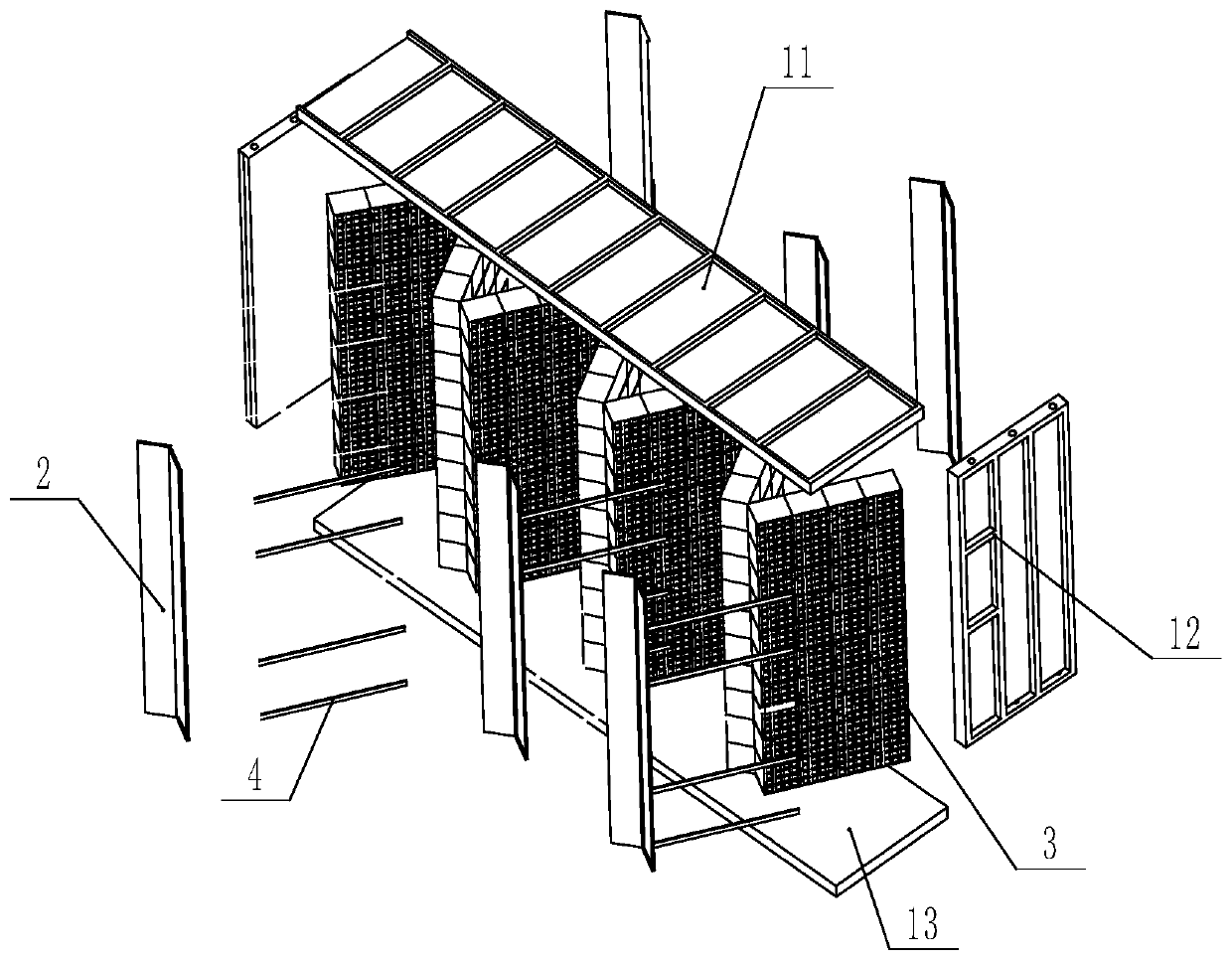

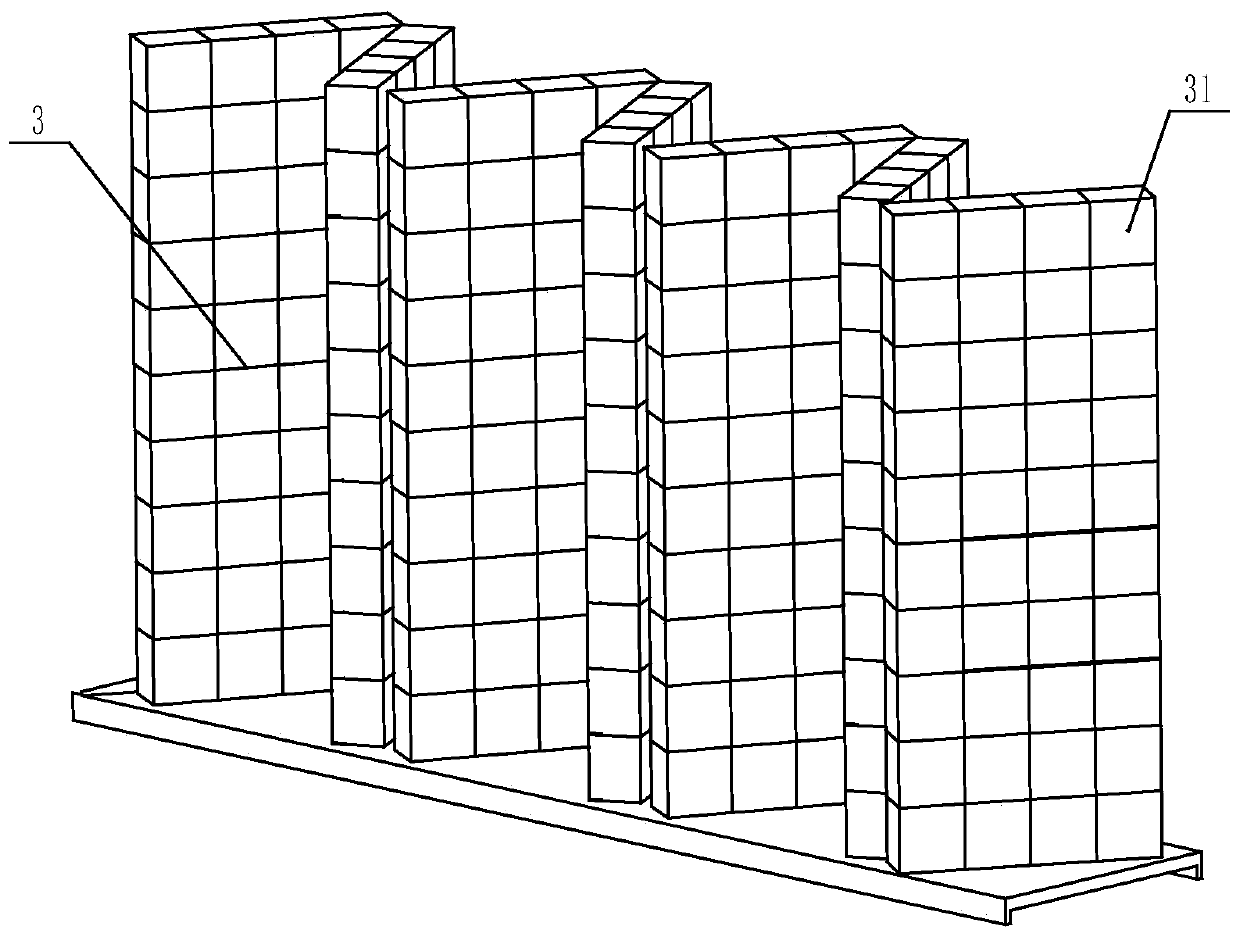

[0022] like Figure 1-3 As shown, the fan-folding catalyst module of the present invention includes a box body 1 and catalyst assemblies 3 arranged in a fan-shaped arrangement inside the box body, the angle between the catalyst assemblies is 0-180 degrees, and the catalyst assembly includes several catalyst units 31; Several catalyst units are arranged to form a catalyst assembly.

[0023] The box body runs through front and back, including a top plate 11, a side plate 12 and a bottom plate 13. A vertical plate 2 is installed between the top plate and the bottom plate of the box body for connecting and fixing the catalyst assembly.

[0024] The vertical plate is a thin plate with knuckles, and the angle between the knuckles and the angle between the catalyst units is a supplementary angle. The vertical plate is installed on the outside of the connection between two adjacen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com