Patents

Literature

31results about How to "Improve catalytic effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Selective hydrogenation catalyst of cracked gasoline and preparation method of selective hydrogenation catalyst

ActiveCN102188969AImprove catalytic effectIncrease dispersionCatalyst activation/preparationRefining by selective hydrogenationTungstenOxide

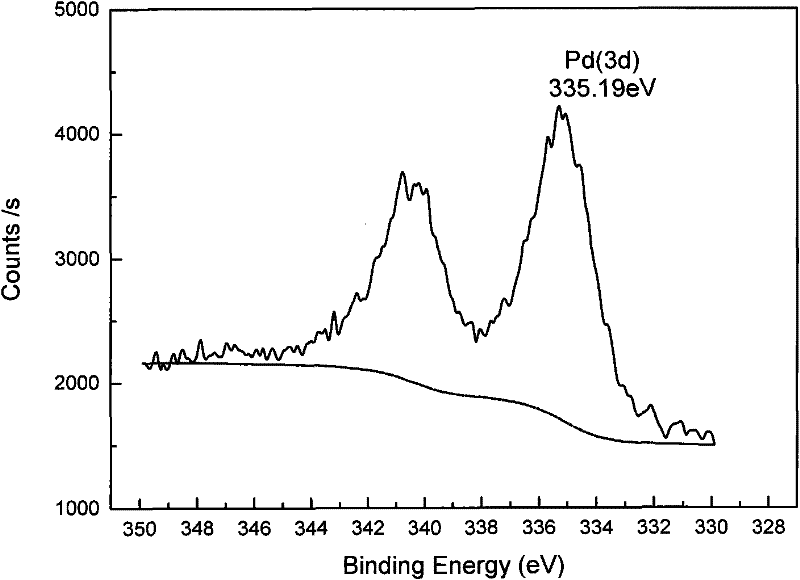

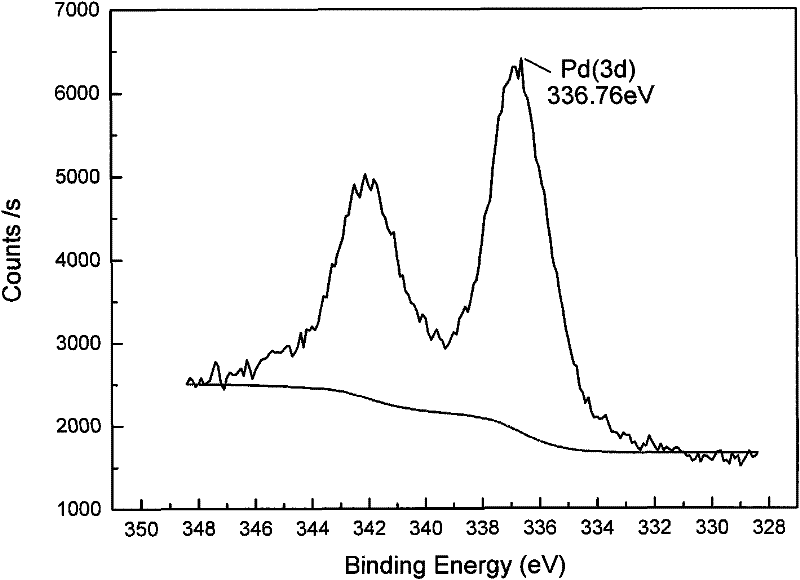

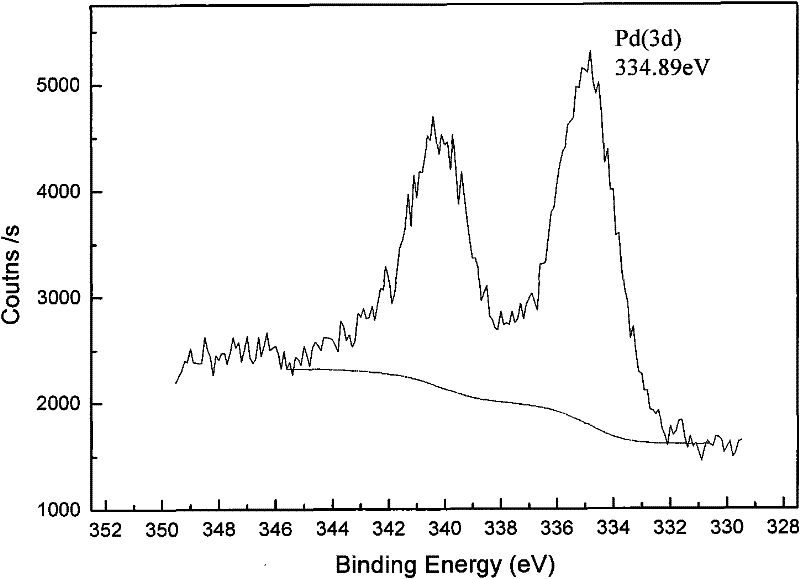

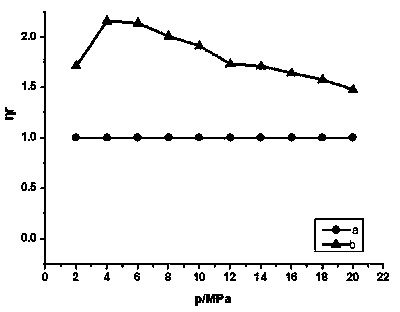

The invention discloses a selective hydrogenation catalyst of cracked gasoline and a preparation method of the selective hydrogenation catalyst. The catalyst comprises a carrier and an active component which is loaded on the carrier; the active component is obtained by ionizing radiation reduction; the active component comprises a main active component (palladium) and an auxiliary active component; the content of the palladium is 0.01 to 1.0 weight percent of the total weight of the carrier; the auxiliary active component is one or more of stannum (Sn), lead (Pb), copper (Cu), gallium (Ga), zinc (Zn), silver (Ag), antimony (Sb), manganese (Mn), cobalt (Co), molybdenum (Mo) and tungsten (W); and the content of the auxiliary active component is 0 to 3.0 weight percent of the total weight of the carrier. A metal active component precursor or oxide which is obtained by roasting the metal active component precursor is subjected to the ionizing radiation reduction to obtain the selective hydrogenation catalyst of the cracked gasoline, wherein the metal active component is loaded on the carrier of the catalyst. The catalyst prepared by the method improves the utilization rate of the main active component (palladium), so that the hydrogenation activity and selectivity of the catalyst are obviously improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

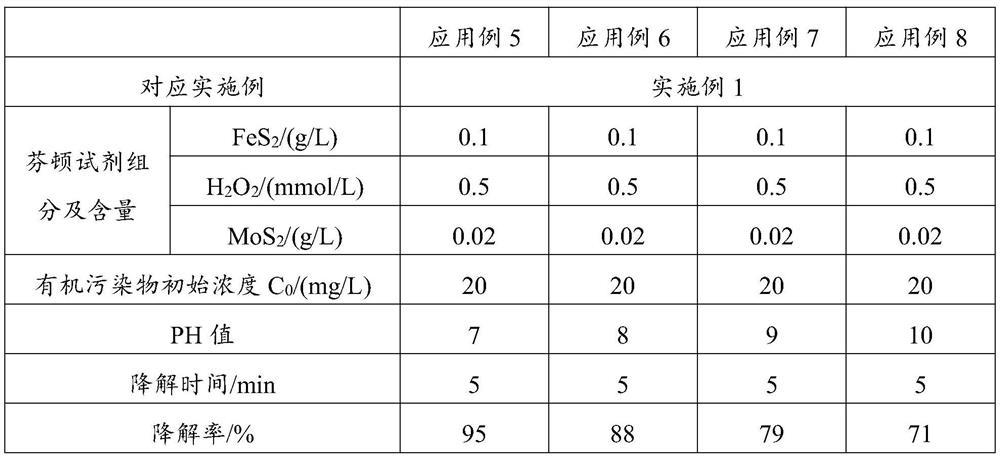

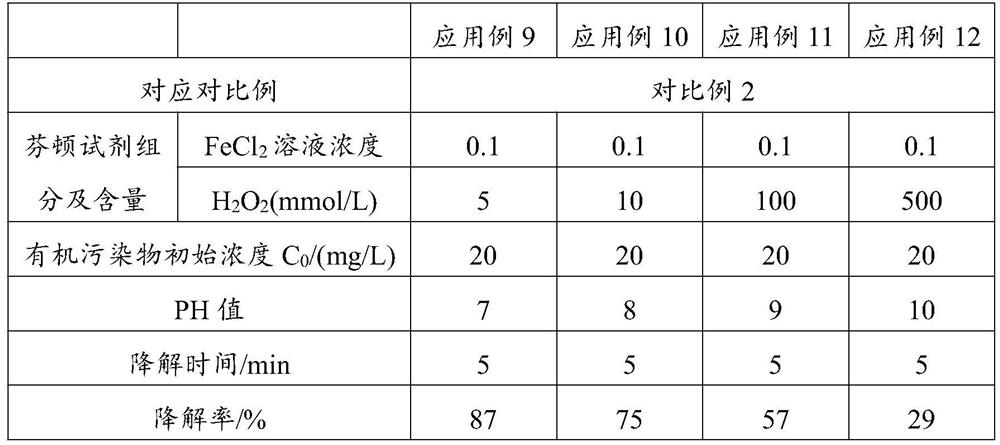

Heterogeneous Fenton reagent and application thereof

PendingCN111732181AImprove generation efficiency and stabilityImprove catalytic effectWater treatment compoundsWater contaminantsIron(II) sulfideHydrogen peroxide

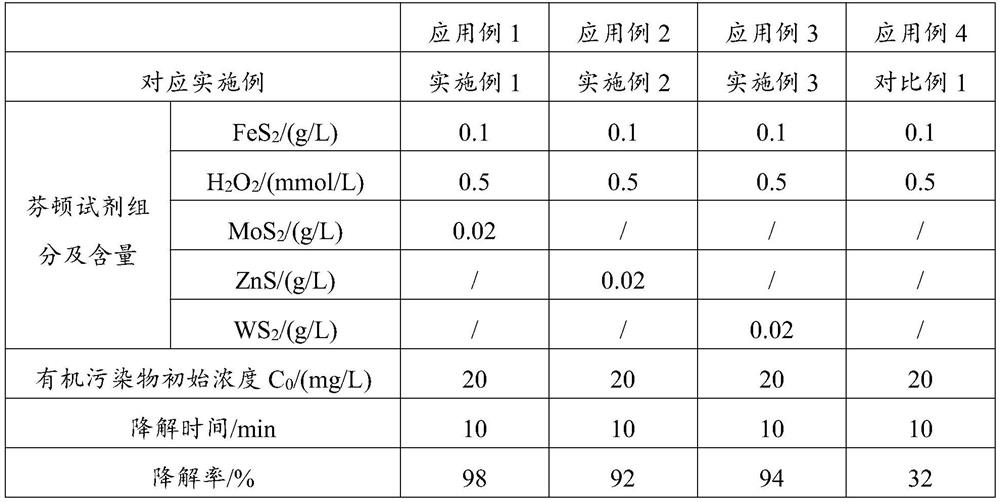

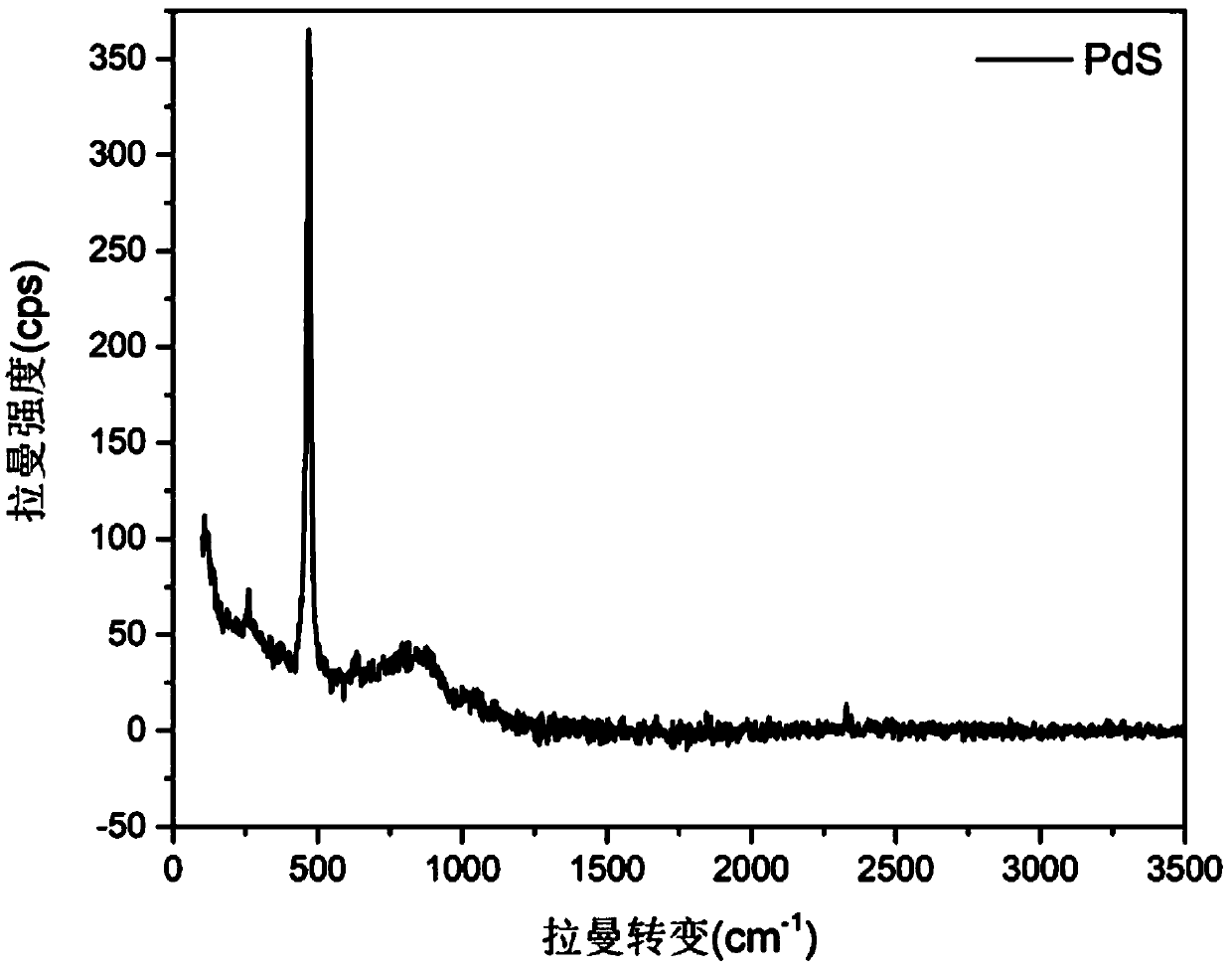

The invention belongs to the technical field of reagents for wastewater treatment, and particularly relates to a heterogeneous Fenton reagent and application thereof. The heterogeneous Fenton reagentprovided by the invention comprises ferrous disulfide, hydrogen peroxide and transition metal sulfide, wherein the transition metal sulfide comprises one or more of molybdenum disulfide, zinc sulfideand tungsten disulfide; and the hydrogen peroxide is independently subpackaged. In the heterogeneous Fenton reagent, the transition metal sulfide is used as a cocatalyst, ferric ions can be reduced into ferrous ions in time to continuously decompose hydrogen peroxide to generate hydroxyl radicals so as to degrade pollutants, the transition metal sulfide is used as a cocatalyst, the self-performance of the transition metal sulfide is not damaged, and the catalysis assisting effect can be continuously and stably exerted, so that the generation efficiency and stability of divalent ferrous ions onthe surface of ferrous disulfide can be improved by the transition metal sulfide, and the problem of secondary pollution caused by ferric ions contained in a homogeneous Fenton system solution is solved.

Owner:GUANGXI UNIV FOR NATITIES

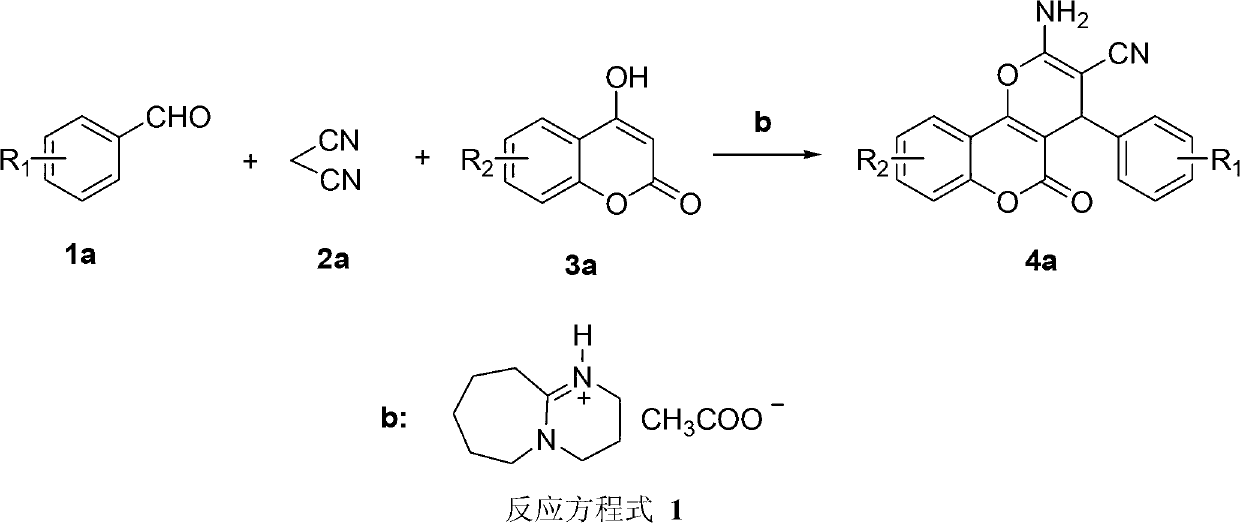

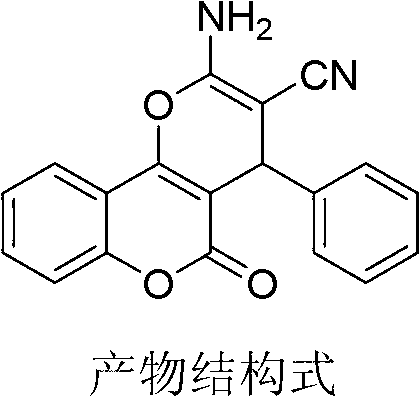

Synthesis method of pyranocoumarin derivatives

InactiveCN102757446AImprove catalytic effectProduct yield is not affectedOrganic chemistryChemical recyclingIonChemistry

The invention discloses a green synthesis method of pyranocoumarin derivatives disclosed as Formula (4a) in the following reaction equation. According to the synthesis method, by using DBU-type ionic liquid disclosed as Formula (b) in the following reaction equation as a catalyst, aromatic aldehyde disclosed as Formula (1a), malononitrile disclosed as Formula (2a) and 4-hydroxycoumarin disclosed as Formula (3a) which are used as raw materials react in water under the promoting action of microwaves to obtain the target products. The operational method disclosed by the invention is simple and environment-friendly, and has the advantages of mild reaction conditions and the like; and the products can be easily separated, and the catalyst can be recycled. The reaction equation is as follows.

Owner:李佰林 +1

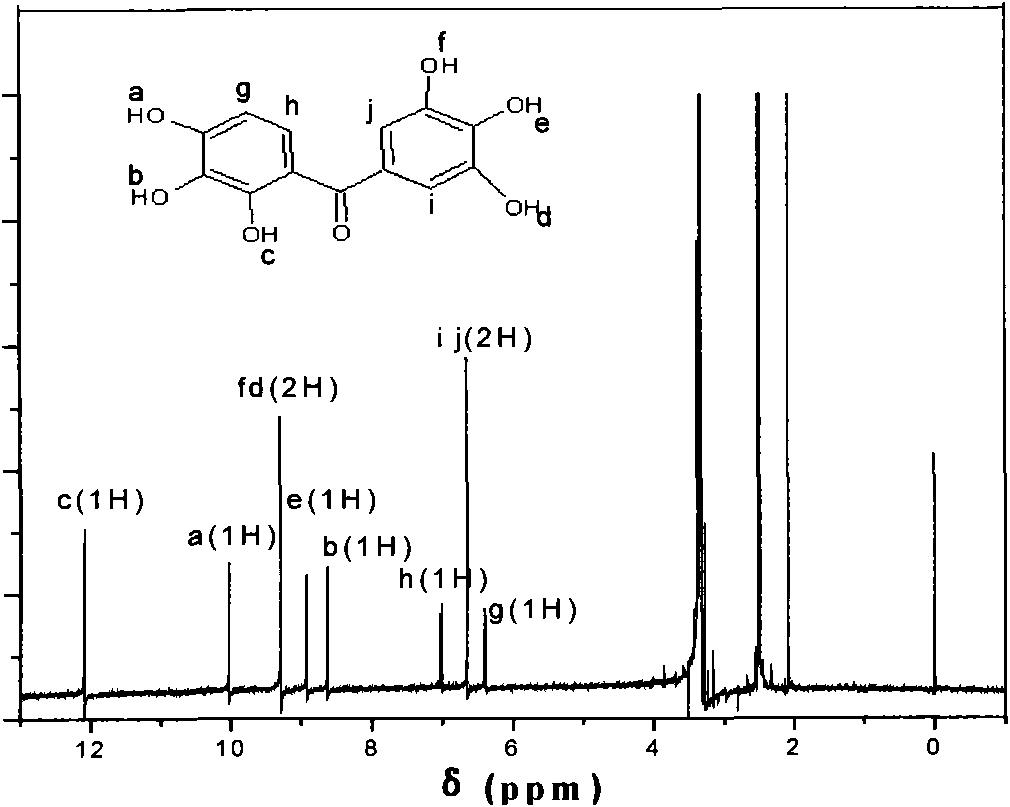

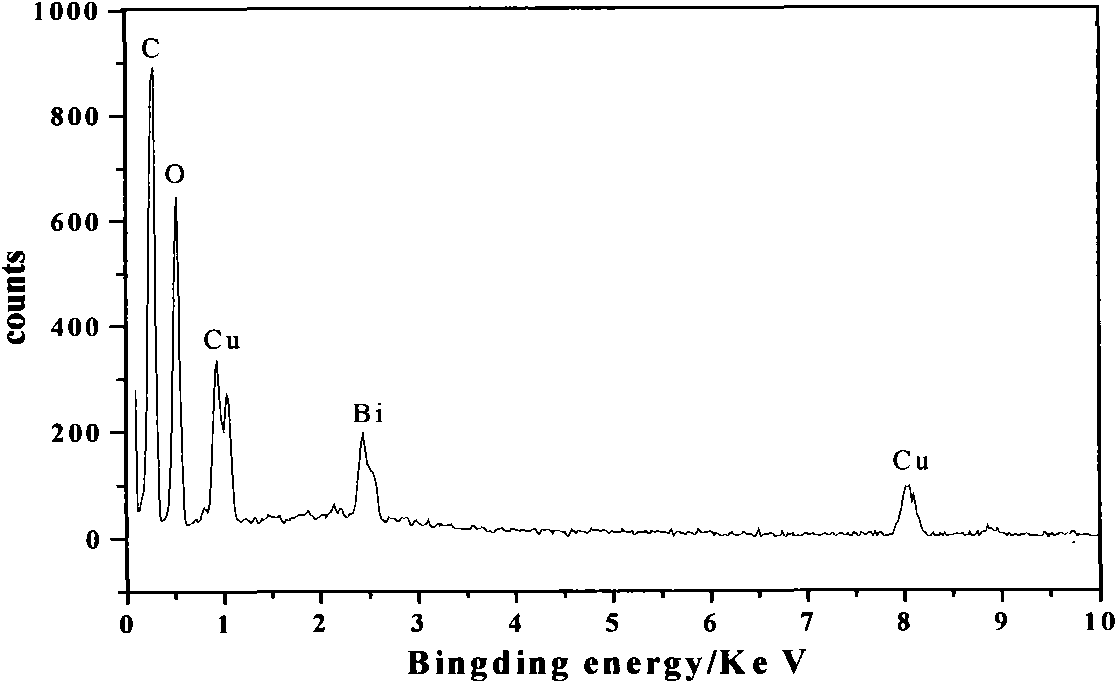

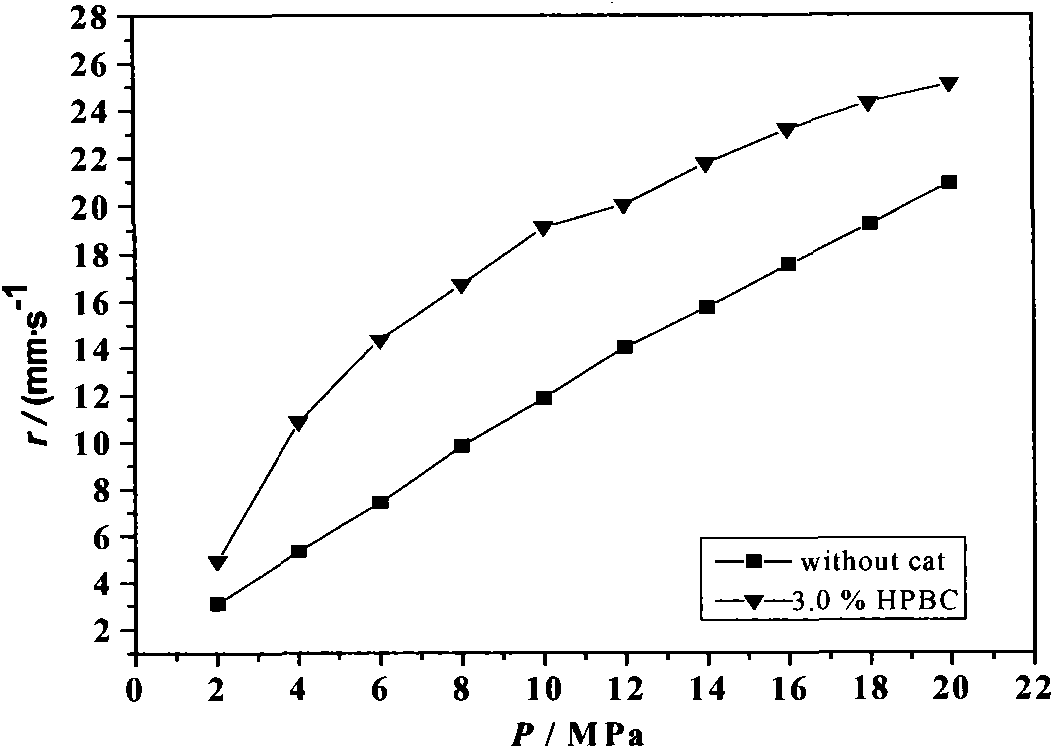

2, 3, 3', 4, 4', 5'-hexahydroxy benzophenone bismuth (III) and copper (II) binuclear complex and preparation method thereof

InactiveCN101817848AImprove catalytic effectImprove catalytic performanceOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsCopper saltBismuth preparation

The invention discloses a 2, 3, 3', 4, 4', 5'-hexahydroxy benzophenone bismuth (III) and copper (II) binuclear complex and a preparation method thereof. The components of the 2, 3, 3', 4, 4', 5'-hexahydroxy benzophenone bismuth (III) and copper (II) binuclear complex are Cu2+, Bi3+ and 2, 3, 3', 4, 4', 5'-hexahydroxy benzophenone, and the weight proportions are as follows: 33-40 percent of Cu2+ and Bi3+ (wherein 6-23 percent of Cu2+ and 77-94 percent of Bi3+) and 60-67 percent of the 2, 3, 3', 4, 4', 5'-hexahydroxy benzophenone. The preparation method is as follows: taking gallic acid, pyrogallic acid and POC13 as raw materials, taking anhydrous ZnCl2 as catalyst and reacting under heating and stirring to obtain the 2, 3, 3', 4, 4', 5'-pentahydroxy benzophenone. The 2, 3, 3', 4, 4', 5'-hexahydroxy benzophenone is mixed with soluble copper salt and bismuth salt solution, and then the product is prepared after the working procedures of stirring, heating reflux, standing, washing, filtering and the like. As combustion catalyst, the prepared 2, 3, 3', 4, 4', 5'-hexahydroxy benzophenone bismuth (III) and copper (II) binuclear complex has very high catalytic effect for combustion of double-base or modified double-base propellant and is environmental-friendly high-efficient combustion catalyst.

Owner:SHENZHEN UNIV

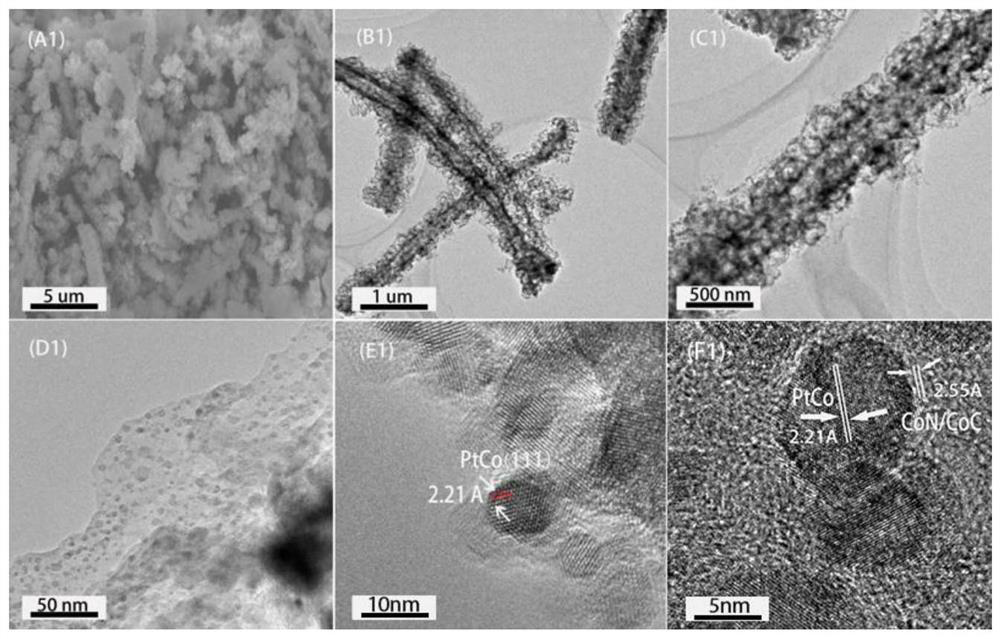

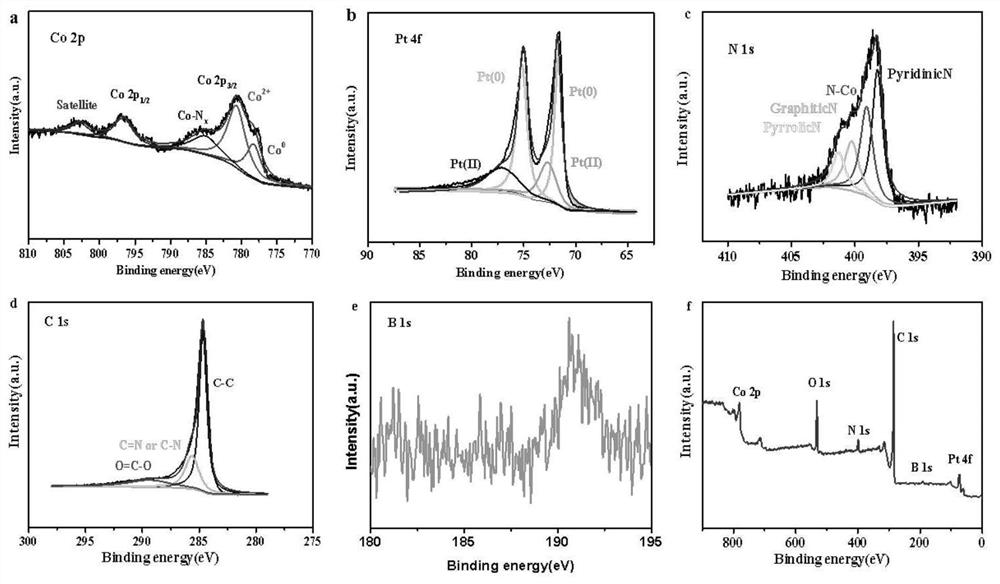

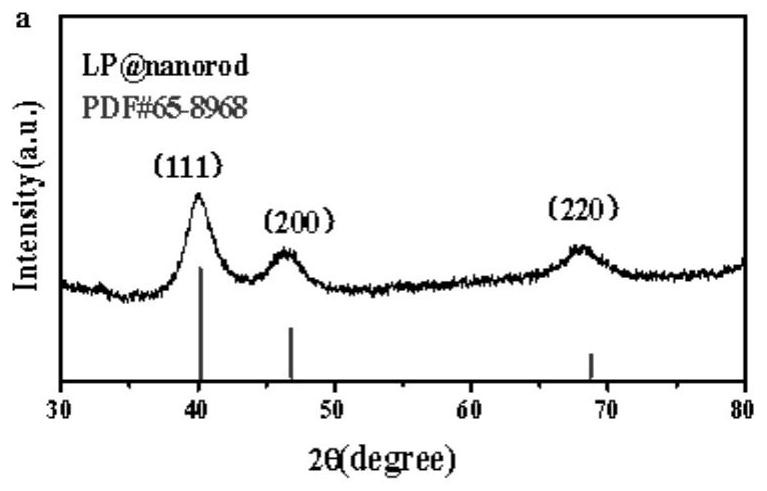

Method for synchronously preparing hierarchical pore cobalt and nitrogen co-doped nanorod loaded platinum-cobalt alloy nano oxygen reduction electrocatalyst

PendingCN111653792APromote contact, penetrationImprove catalytic effectMaterial nanotechnologyCell electrodesPtru catalystReducing agent

The invention discloses a method for synchronously preparing a PtCo / Co-N-C catalyst. The preparation method comprises the following steps: homogenizing cobalt salt, zinc salt and ultrapure water, adding a 2-methylimidazole aqueous solution, uniformly stirring, adding a strong reducing agent aqueous solution, carrying out a mixing reaction, adding a platinum salt aqueous solution, carrying out a mixing reaction, centrifuging the product, cleaning, drying, and carrying out high temperature annealing in an inert gas environment to obtain the PtCo / Co-N-C catalyst. The method is simple and easy tooperate. The material with the PtCo nano-particle structure loaded on the Co-N-C nano-rod with the hollow structure is rapidly prepared. The preparation method is simple in process, easy to operate, suitable for large-scale production, short in reaction time, low in cost and clean, and the prepared PtCo / Co-N-C catalyst is used as a cathode oxygen reduction reaction catalyst of a hydrogen-oxygen fuel cell and shows excellent electrochemical performance.

Owner:GUANGXI UNIV

Citrazinic acid lead-zirconium double metal salts and preparation method and application thereof

InactiveCN103641777AThe synthesis process is simpleImprove catalytic effectOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsDecompositionOxide

The invention discloses a citrazinic acid lead-zirconium double metal compound shown in a structural formula (I). Uniform and new ecological lead and oxide thereof generated by decomposition can be used as main catalytic active components when the citrazinic acid lead-zirconium double metal compound is applied as a combustion catalyst and a combustion stabilizer, and zirconium dioxide with a high melting point generated by decomposition is taken as a cocatalyst. Thus, the catalytic effect can be further improved.

Owner:XIAN MODERN CHEM RES INST

Nano-porous hydrogen production catalyst and preparation method thereof

InactiveCN110923737AImprove material stabilityImprove catalytic effectElectrodesHydrogen productionSulfuric acid

The invention discloses a nano-porous hydrogen production catalyst and a preparation method thereof. The preparation method comprises the following steps: preparing an amorphous alloy strip from the following components in percentage by mass: 50-80% of pure Al, 5-20% of pure Cu, 10-20% of pure Ti and 10-20% of pure Pd; and carrying out alloy removing on the prepared amorphous alloy strip twice sequentially in sodium hydroxide and sulfuric acid to obtain the nano-porous Al-Pd-Cu-Ti material, wherein the pore size and the strip size are both in the nanoscale, the nano-porous Al-Pd-Cu-Ti materialhas large specific surface area and more catalytic active sites, the water electrolysis catalytic hydrogen production capacity of the nano-porous Al-Pd-Cu-Ti material is similar to the commercial platinum-carbon electrode, and the operation is easy.

Owner:TIANJIN UNIV

Solid catalyst and catalytic preparation method of propylene carbonate by using solid catalyst

InactiveCN106378140AStable in natureImprove catalytic effectOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsCopper nitrateTetramine

The present invention discloses a solid catalyst and a catalytic preparation method of propylene carbonate by using the solid catalyst. According to the technical scheme of the invention, the modified attapulgite is adopted as a carrier, and the copper nitrate is adopted as a precursor. The copper oxide is loaded onto the modified attapulgite through the dipping, drying and roasting process. The preparation method of the modified nano-attapulgite comprises the following steps of dispersing 30-40 parts of nano attapulgite into 45-55 parts of 5-15 wt% of triethylene tetramine, stirring at 40-50 DEG C for 25-35 minutes, adding 5-15 parts of Zn(NO3)2*6H2O, stirring for 20-30 minutes, cooling, filtering and drying. The solid catalyst is stable in property and high in catalytic effect, which can be repeatedly used. The catalytic preparation method of propylene carbonate by using the solid catalyst is simple, feasible, and low in production cost.

Owner:安徽金邦医药化工有限公司

TiO2/tourmaline composite photocatalyst and TiO2/ tourmaline gauze

ActiveCN107774241AImprove catalytic effectGood for light absorptionGas treatmentPhysical/chemical process catalystsIonChemistry

The invention provides a TiO2 / tourmaline composite photocatalyst and a TiO2 / tourmaline gauze. A preparation method for the photocatalyst comprises the following steps: adding glacial acetic acid in anhydrous ethanol, and stirring; slowly adding tetrabutyl titanate and stirring to obtain a tetrabutyl titanate solution; adding tourmaline powder in another anhydrous ethanol, and carrying out ultrasound treatment to obtain a tourmaline powder solution; dropwise adding the tetrabutyl titanate solution in the tourmaline solution, and stirring to obtain a mixed solution; uniformly mixing the anhydrous ethanol, deionized water and concentrated hydrochloric acid, then dropwise adding the mixture into the mixed solution, stirring to firm grey sol, and stirring the grey sol at a certain temperatureto form gel; and drying, grinding and calcining the gel to form TiO2 / tourmaline catalyst powder. The bottleneck problem in application of an active photocatalyst and a fixed photocatalyst is solved.The TiO2 / tourmaline composite photocatalyst has an environment additional function of releasing air negative ions, is long in service life, simple and convenient to operate and low in application cost; the quality of air can be improved effectively; and the practical application prospect is remarkable.

Owner:NANKAI UNIV

Composite sodium supplement additive and application thereof in sodium ion battery

ActiveCN113113681AIncrease contact areaImprove catalytic effectSecondary cells servicing/maintenanceBattery energyCarbocatalysis

The invention provides preparation and application of a composite sodium supplement additive. The sodium supplement additive contains a metal oxide carbon catalyst and a sodium salt, and the metal oxide carbon catalyst is a compound of a metal oxide and a carbon substrate. The sodium salt in the sodium supplement additive is completely decomposed and releases sodium ions and carbon dioxide gas when the sodium ion battery is charged for the first circle, and the carbon dioxide generated by decomposition can be removed in the formation stage; and sodium ions generated by decomposition can effectively solve the problems of low battery energy density and poor cycling stability caused by irreversible consumption of the sodium ions.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Graphene-schiff base iron complex and synthesis method thereof

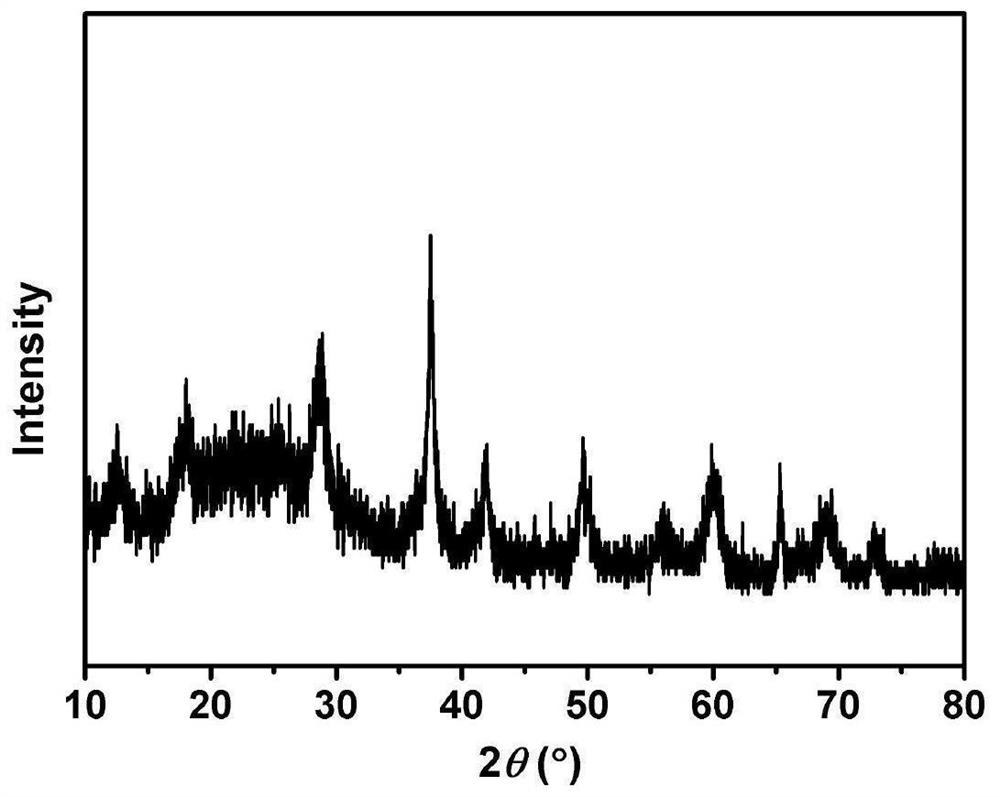

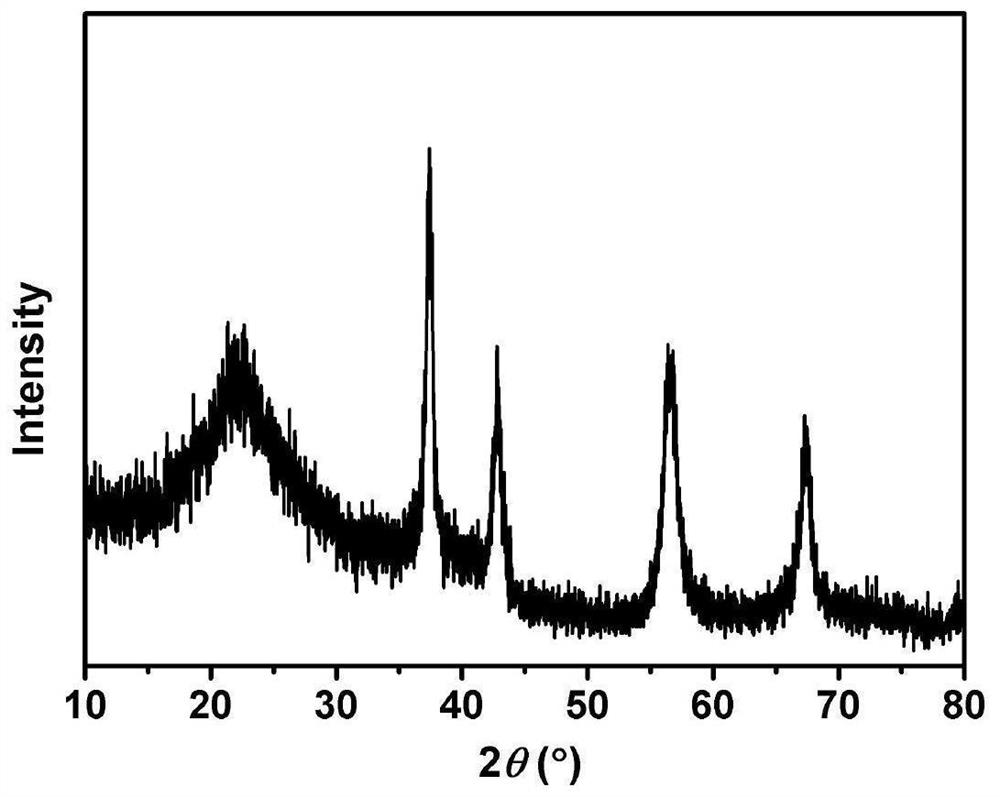

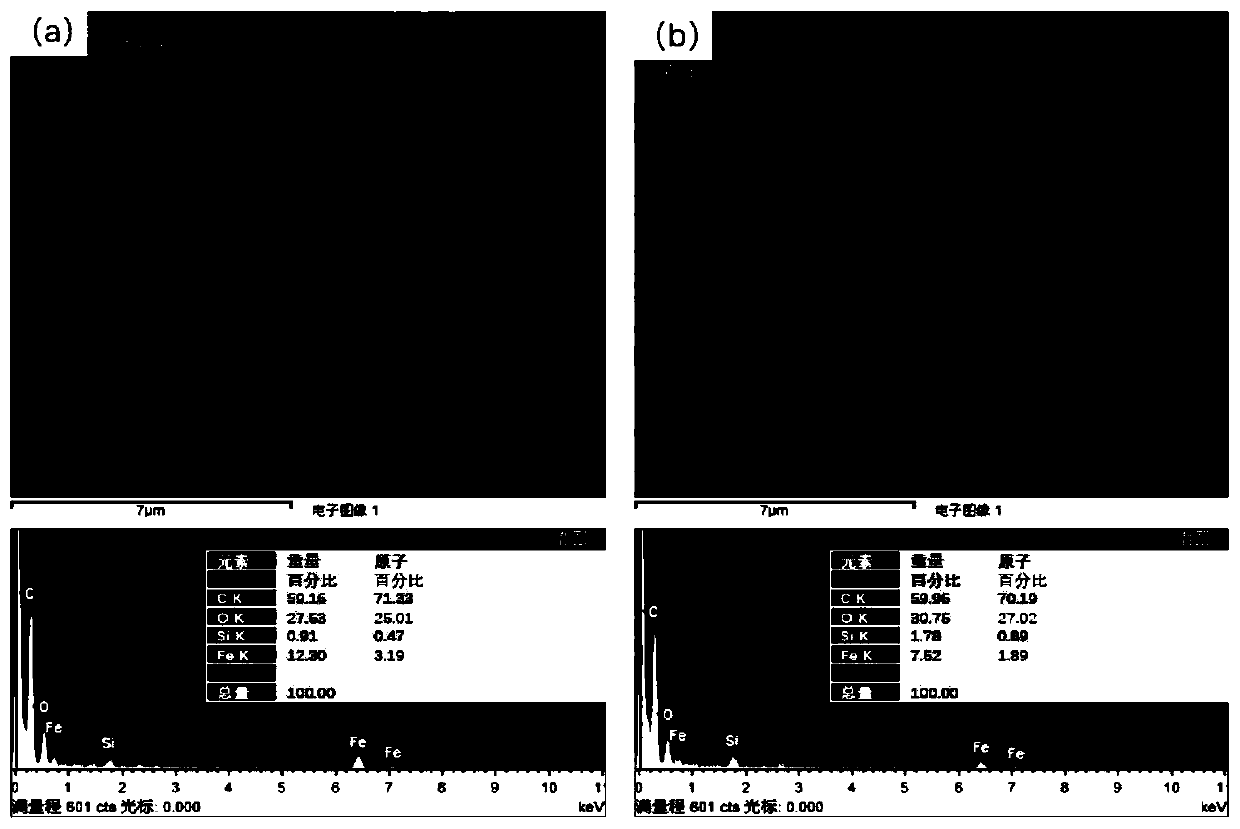

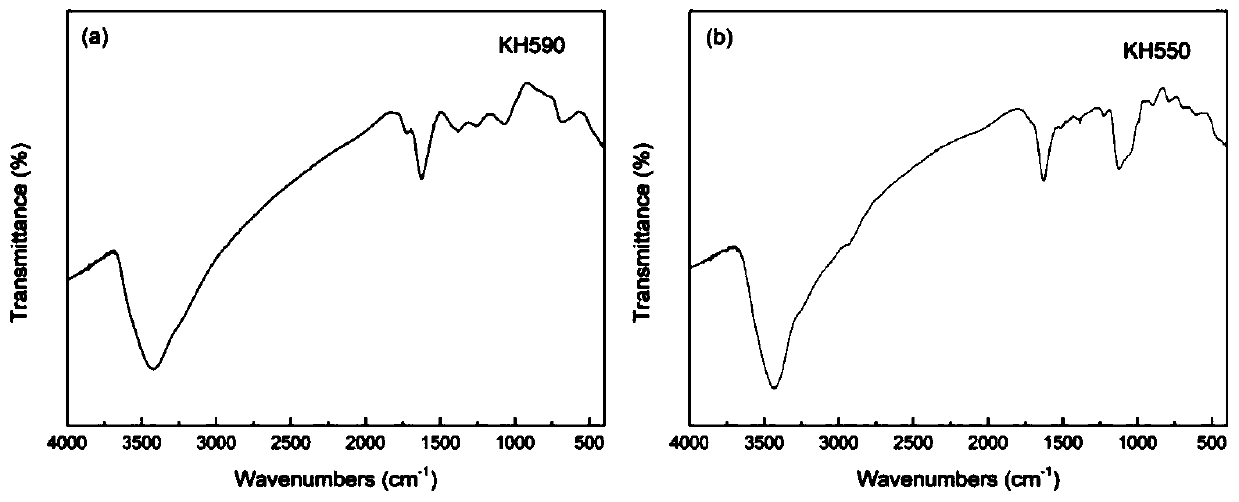

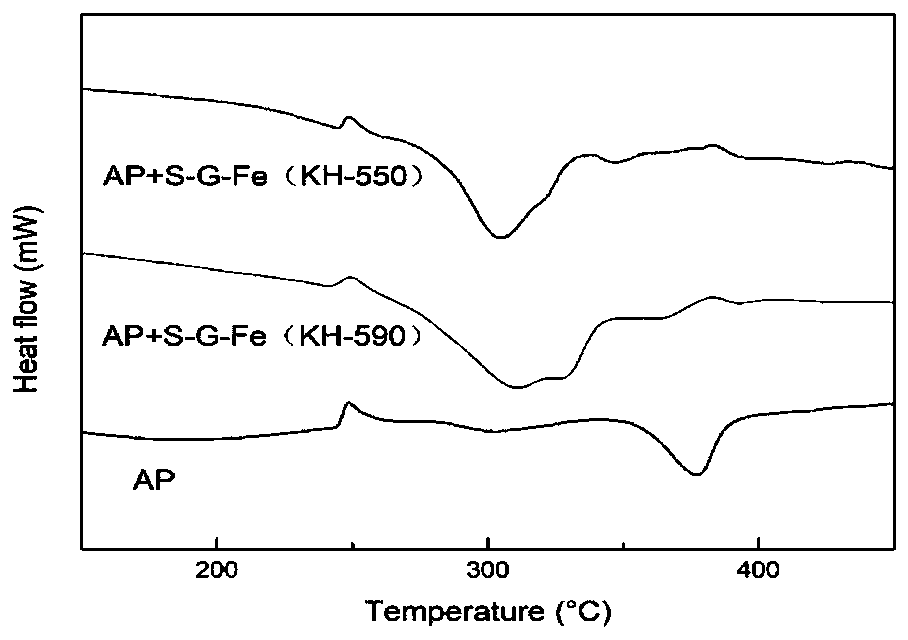

PendingCN110698510AImprove catalytic effectImprove catalytic performanceGroup 4/14 element organic compoundsNon-explosive/non-thermic compositionsChemistrySilane coupling

The invention discloses a graphene-schiff base iron complex and a preparation method thereof, wherein the structural formula is shown as I. The synthesis process comprises the following steps: (1) twosilane coupling agents respectively modify graphene oxide to obtain two kinds of surface modified graphene; (2) the two kinds of surface modified graphene react with salicylaldehyde to synthesize a graphene-Schiff base ligand; (3) the graphene-schiff base ligand is coordinated with divalent iron ions to synthesize the graphene-schiff base iron complex. The graphene-schiff base iron complex synthesized by the method has a remarkable catalytic effect on that thermal decomposition of ammonium perchlorate (AP), and can be used as a combustion catalyst in an AP-based composite propellant.

Owner:XIAN MODERN CHEM RES INST

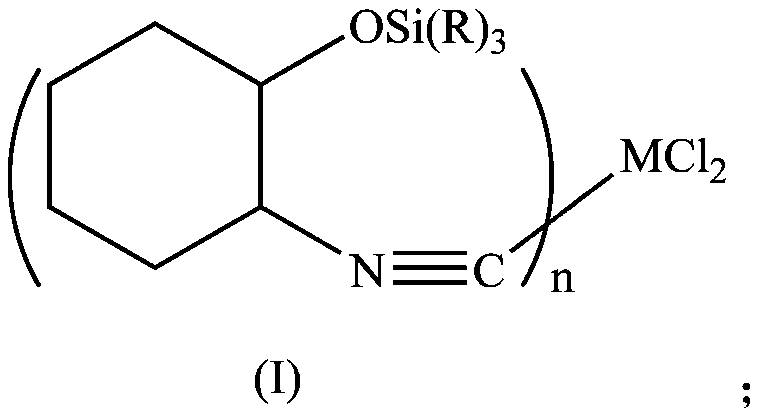

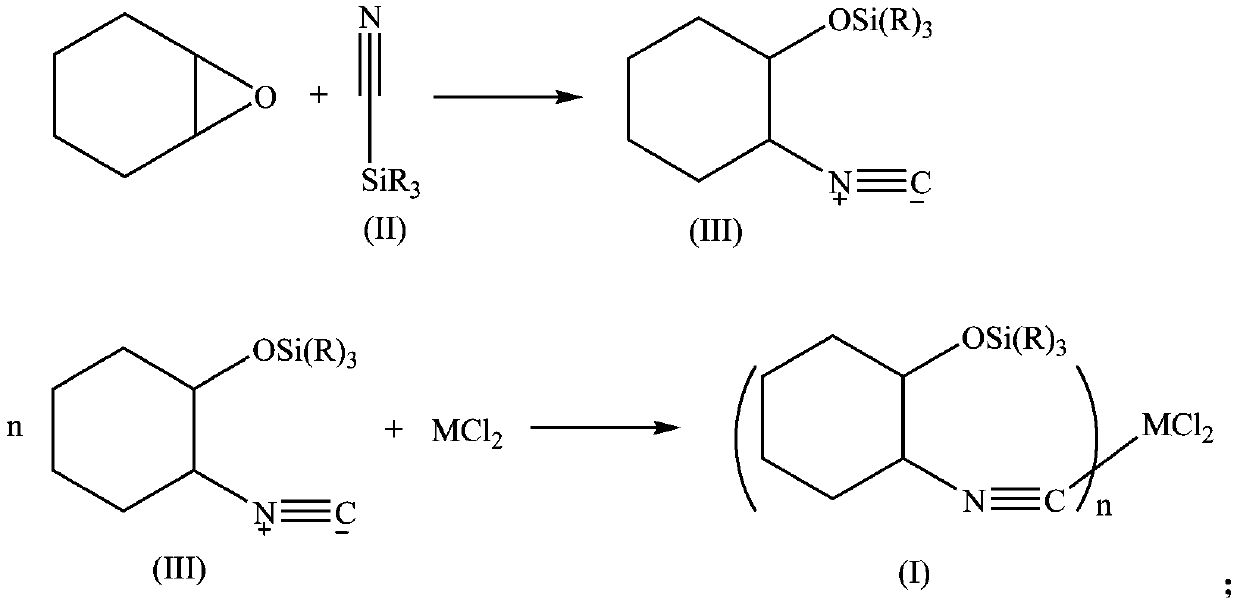

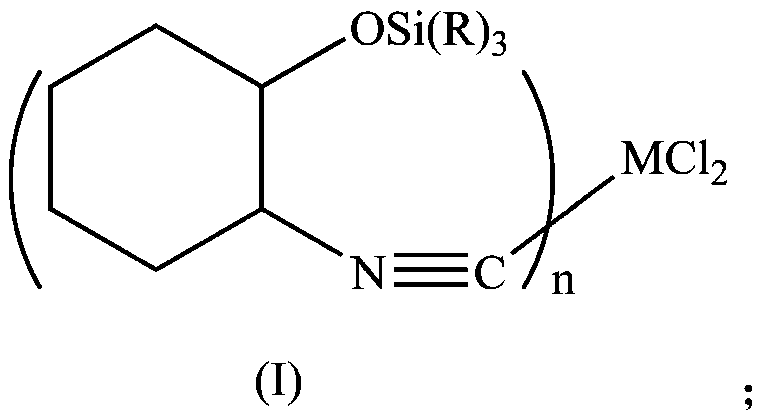

Silicon-based modified isonitrile metal salt catalyst and preparation method and application thereof

ActiveCN110117296AImprove compatibilityImprove catalytic effectGroup 4/14 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsDivalent metalAddition reaction

The invention relates to the field of catalysts, and discloses a silicon-based modified isonitrile metal salt catalyst. The silicon-based modified isonitrile metal salt catalyst has a structure shownin formula (I), wherein R is C1-C6 alkyl groups or C1-C6 alkoxy groups, n is an integer ranging from 1 to 6, and M is divalent metal. The invention further discloses a preparation method of the silicon-based modified isonitrile metal salt catalyst. The preparation method is simple, the reaction conditions are mild, the cost is low, and the substrate universality is wide. The invention further discloses a hydrosilylation reaction catalyzed by applying the catalyst. The catalyst is used for hydrosilylation of olefin, which not only improves the compatibility of the catalyst and a hydrosilylationreaction substrate and improves the catalytic effect, but also can inhibit the generation of by-products in the reaction process and effectively increase the yield of a target product.

Owner:HANGZHOU NORMAL UNIVERSITY

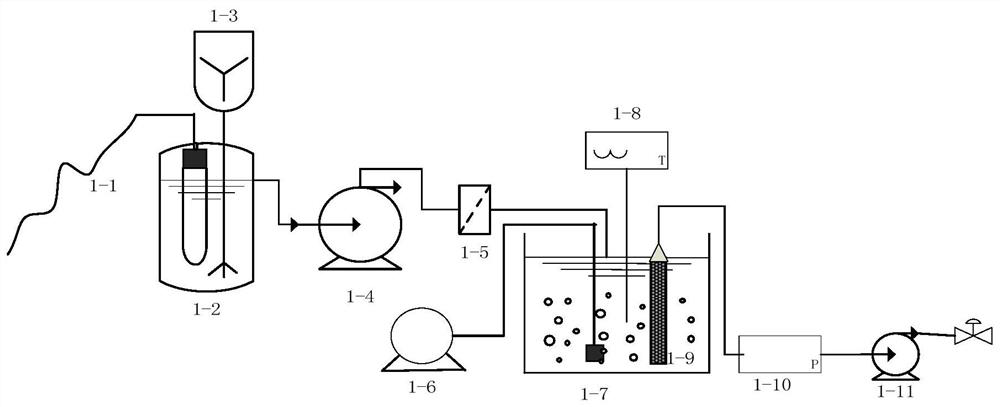

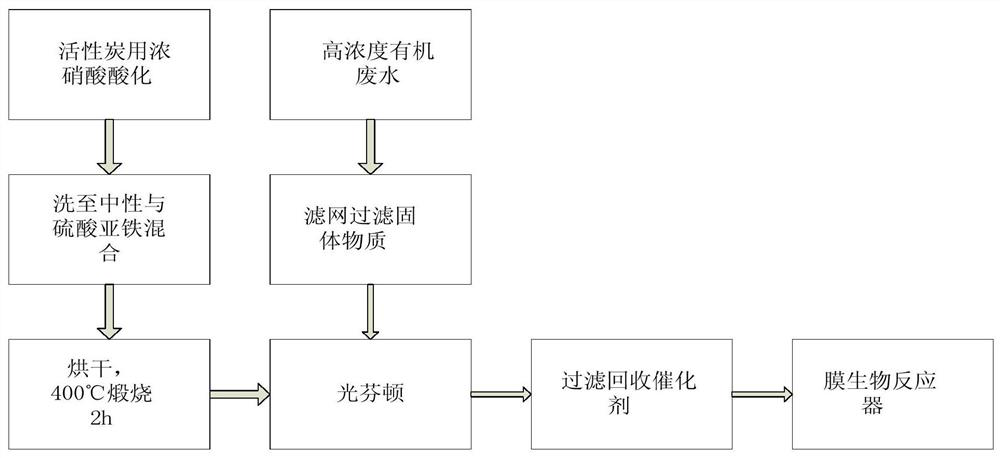

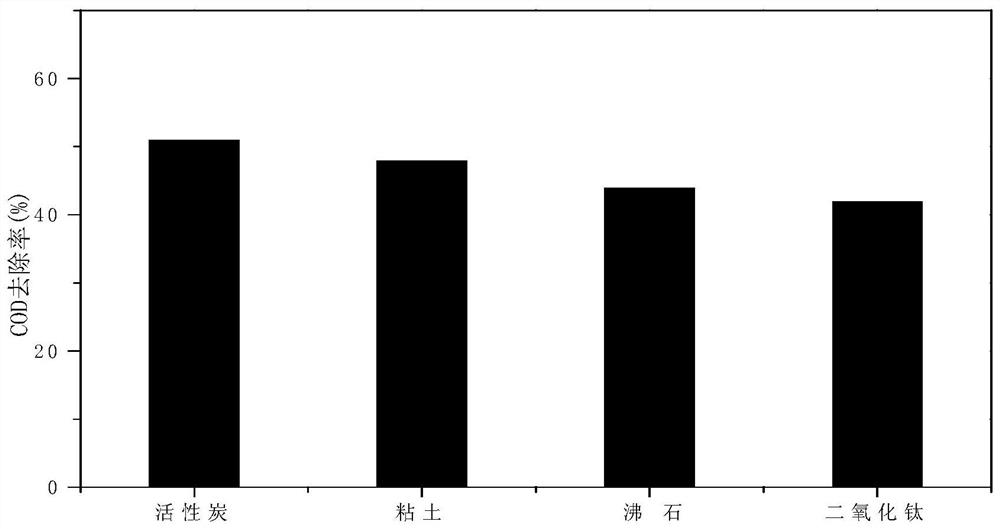

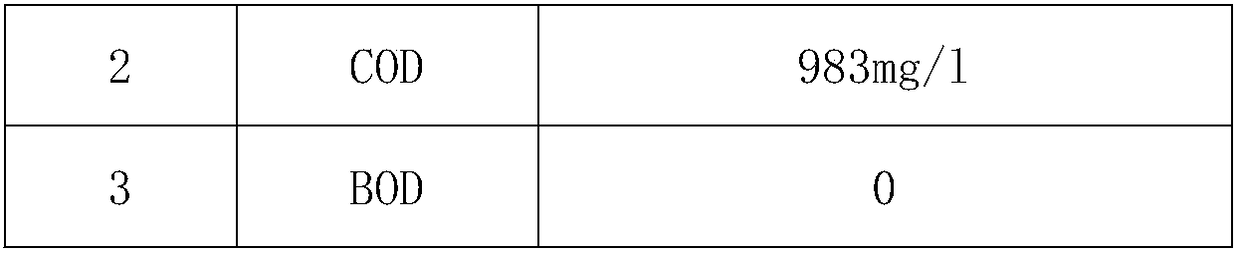

Efficient heterogeneous photo-Fenton and membrane bioreactor coupling process

PendingCN111718062ALarge specific surface areaImprove catalytic effectWater/sewage treatment by irradiationWater treatment compoundsPre treatmentEnvironmental chemistry

The invention discloses an efficient heterogeneous photo-Fenton and membrane bioreactor coupling process. The process comprises the following steps: (1) pretreating an inorganic porous material; (2) preparing a photo-Fenton catalyst; (3) carrying out photo-Fenton treatment on the high-concentration organic wastewater; (4) recycling the photo-Fenton catalyst; and (5) operation of the membrane bioreactor. The process is based on the difference between heterogeneous photo-Fenton and the treatment effect of the membrane bioreactor on substances in the high-concentration organic wastewater and hascharacteristics with complementary effects so as to have the advantage of having the following advantages: refractory substances are removed before the membrane bioreacto, the toxicity of wastewater to activated sludge is reduced, and recycling of a catalyst is guaranteed, the wastewater treatment efficiency is improved, membrane pollution is reduced, and the service life of a membrane is prolonged so that the problems that a traditional membrane bioreactor is low in high-concentration organic wastewater treatment efficiency, serious in membrane pollution and short in membrane service life aresolved.

Owner:YIWU SCI & TECH INST CO LTD OF ZHEJIANG UNIV OF TECH +1

Method for catalytically oxidizing wastewater by carbonyl iron complex

InactiveCN102701396AImprove catalytic effectReduce dosageOrganic-compounds/hydrides/coordination-complexes catalystsWater/sewage treatment by oxidationCarbonyl groupChemistry

The invention relates to a method for catalytically oxidizing wastewater by carbonyl iron complex, and belongs to the technical field of metal complex catalytic oxidation. The method comprises the following steps of: 1) adding a carbonyl compound-containing ligand in water solution; 2) adjusting the pH value to be 1.5-5.5; 3) adding a ferric ion-containing compound, wherein the addition of the ferric ion is 5-65mg / L and the mole ratio of the ferric ion to the carbonyl compound-containing ligand is 1: 1-4; 4) reacting at 5-65 DEG C for 5-30min; and 5) adding oxidant to carrying out oxidation at 5-65 DEG C, wherein the carbonyl compound is primary amine or aliphatic or aromatic compound of primary amine and the ferric ion-containing compound is inorganic compound of divalent or trivalent iron. According to the invention, the catalytic effect is effectively improved, the dosage of iron is reduced and the oxidation efficiency is improved, so that the oxidant consumed by unit mass COD (chemical oxygen demand) is reduced and the wastewater treatment cost is effectively reduced.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Efficient preparation method of methyl salicylate

InactiveCN105601512AImprove catalytic effectIncrease responsivenessOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSodium carbonateChemistry

The invention relates to an efficient preparation method of methyl salicylate, comprising the following steps: (1) pretreatment: I, preparing modified kieselguhr; II, preparing kieselguhr load particles; III, taking the kieselguhr load particles, adding dicyclohexylcarbodiimide, 4-dimethylamino pyridine and ethyl alcohol, and preparing a solid composite catalyst; (2) synthesis reaction: adding salicylic acid and methyl alcohol into a reaction kettle, and putting in the solid composite catalyst to prepare reaction liquid; (3) product extraction and purification: recovering the solid composite catalyst, skimming to take an oil layer, washing by using a sodium carbonate solution, adding the oil layer into water for washing, collecting a fraction, and adding activated carbon for heating and decoloring, thus obtaining a fine product of the methyl salicylate. By adopting the efficient preparation method, the production efficiency and product quality of the methyl salicylate can be improved, meanwhile the recovery rate is increased, pollution is reduced, and production risk degree and production cost are lowered.

Owner:ZHENJIANG GAOPENG PHARMA

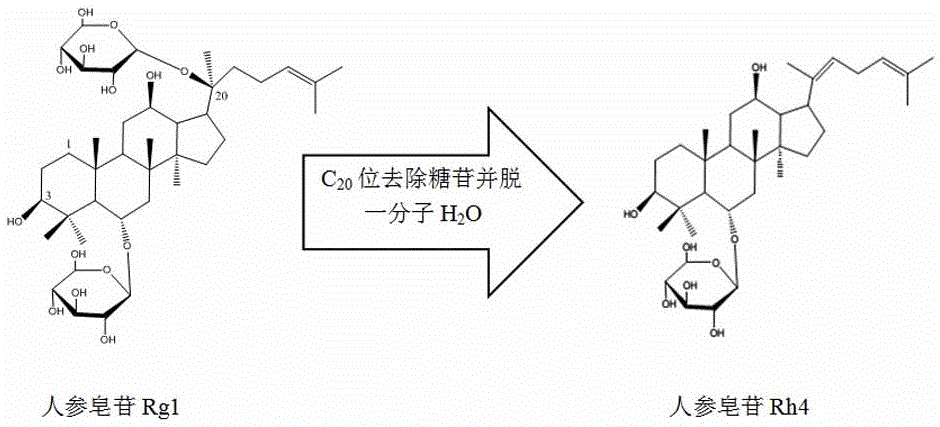

Method for producing ginsenoside Rh4 by utilizing panaxatriol ginsenoside through large-scale conversion

InactiveCN106046096AImprove catalytic effectImprove conversion rateOrganic active ingredientsDispersion deliveryOrganic acidChemistry

The invention discloses a method for producing ginsenoside Rh4 by utilizing panaxatriol ginsenoside through large-scale conversion, belonging to the field of biochemical industry. The method comprises the following steps: dissolving the panaxatriol ginsenoside in deionized water in a fermentation tank, introducing N2 for protection, then carrying out online sterilization, adding an organic acid solution and a heteropoly acid HxYW12O40-nH2O catalyst with a Keggin structure and a certain catalytic amount, wherein Y is selected from the group consisting of P, Si, Fe or Zn, and x is 3 or 4 and n is a positive integer of 0 to 30, then carrying out a directional conversion reaction under the protection of N2 at a constant temperature and in a constant pressure, and finally collecting a reaction product and carrying out purifying so as to obtain high-purity ginsenoside Rh4, wherein the condition of online sterilization is at 121 DEG C for 20 min; N2 is introduced for protection before online sterilization; and added organic acid is a combination of one or more selected from the group consisting of lactic acid, malic acid, citric acid, alpha-ketoglutaric acid, succinic acid, trans-butenoic acid and pyruvic acid. The method provided by the invention has the advantages of simple and practicable process, fewer side reactions, high product purity and facilitation to industrial production.

Owner:NORTHWEST UNIV

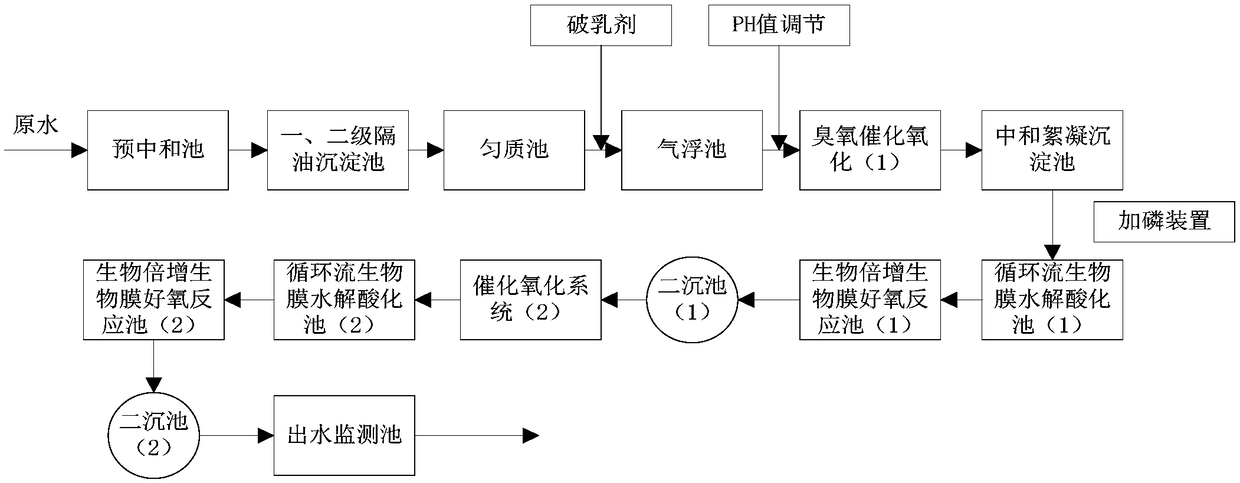

Method for improving biodegradability of organic silicon wastewater through two stages of ozone catalytic oxidation

ActiveCN109319920AImprove catalytic effectLow running costWater contaminantsMultistage water/sewage treatmentChemistryTreatment costs

The invention discloses a method for improving biodegradability of organic silicon wastewater through two stages of ozone catalytic oxidation. The two stages of ozone catalytic oxidation are adopted for wastewater at different treatment stages, a two-stage biochemical treatment process is adopted, the two stages of ozone catalytic oxidation are set before two stages of biochemical treatment, thusby adopting an ozone catalytic oxidation process before the two stages of biochemical treatment, the biodegradability of the wastewater is improved, the purpose of decreasing effluent COD to 100 mg / lis achieved, the treatment cost is low, and operation is easy.

Owner:JIANGXI BLUESTAR XINGHUO SILICONE CO LTD

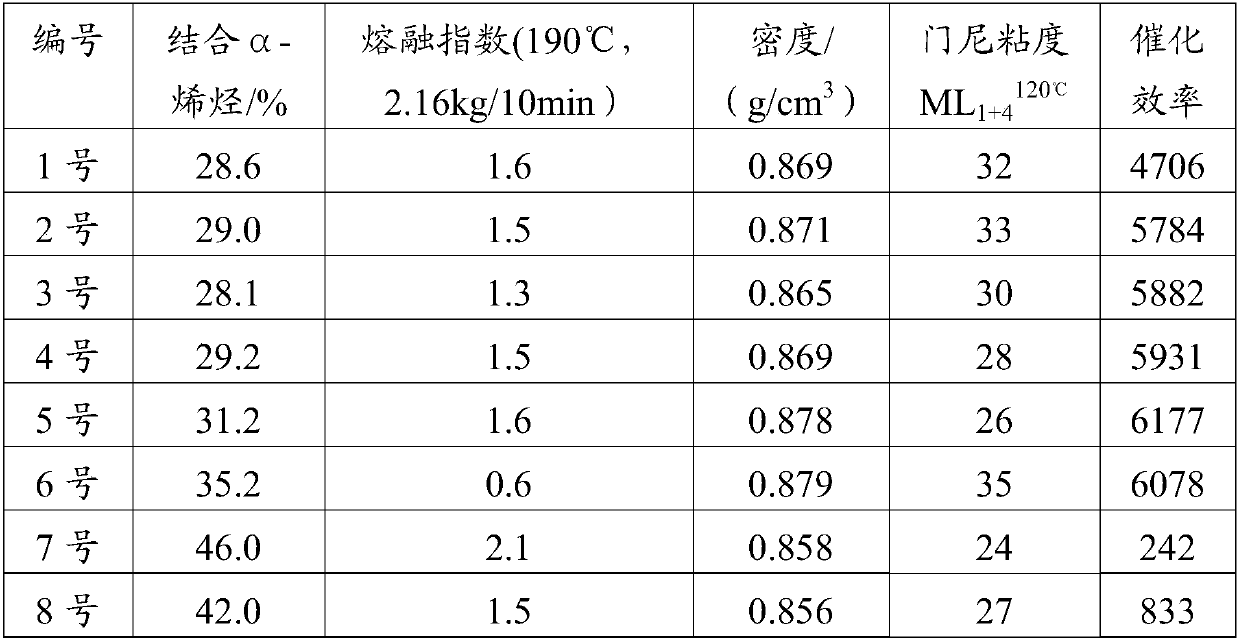

Catalyst composition, and ethylene-alpha-olefin polymer and preparation method thereof

The invention discloses a catalyst composition, and an ethylene-alpha-olefin polymer and a preparation method thereof, and belongs to the field of polyolefin elastomers. The catalyst composition comprises: a vanadium-based catalyst, alkylaluminum halide and an activator, wherein the vanadium-based catalyst has a general formula of VO(OR)nClm, V is the positive pentavalent central atom of vanadium,OR and Cl are ligands, OR is phenoxy, n is 1, 2 or 3, m is 0, 1 or 2, m+n is equal to 3, and a molar ratio of Al in the alkylaluminum halide to V in the vanadium-based catalyst to the activator is 1-100:1:1-20. According to the present invention, by adding the activator, the vanadium-based catalyst permanently maintains catalytic activity; through the synergetic effect of the vanadium-based catalyst and the alkylaluminum halide, the catalyst composition has excellent catalytic effect; with the method, the consumption of the catalyst composition is reduced, and the cost is reduced; and the efficiency of the ethylene-alpha-olefin polymer obtaining through the polymerization of the catalyst composition is high, and the obtained ethylene-alpha-olefin polymer has advantages of excellent resilience, excellent flexibility and excellent Mooney viscosity.

Owner:PETROCHINA CO LTD

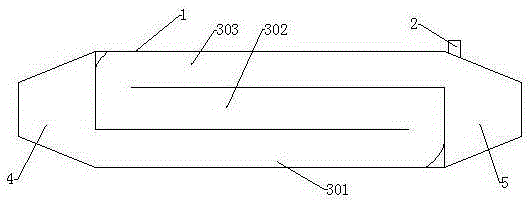

Automobile three-way catalyst convenient to clean

InactiveCN105298598AExtension of timeImprove catalytic effectInternal combustion piston enginesExhaust apparatusEngineeringFlange

The invention discloses an automobile three-way catalyst convenient to clean. The automobile three-way catalyst convenient to clean is characterized by comprising a front connecting flange, an air inlet pipe, a barrel body and an air exhausting pipe, wherein a catalyzer module and a liner are arranged in the barrel body; the catalyzer module is provided with three layers including a first layer of catalyzer module, a second layer of catalyzer module and a third layer of catalyzer module which are sequentially communicated; the end of the air inlet pipe is connected with the first layer of catalyzer module; the third layer of catalyzer module is connected with the end of the air exhausting pipe. The automobile three-way catalyst convenient to clean has the beneficial effects that due to the design of the three layers of the catalyzer module, impurities with larger particles are basically stayed in the first layer of catalyzer module, and the first layer of catalyzer module needs to be cleaned seriously during detachment and cleaning; if the first layer of catalyzer module is blocked or oxidized seriously, the first layer of catalyzer module can be replaced independently. Meanwhile, the time of waste gas staying in the catalyzers is prolonged, the catalyzing effect is improved, and the catalyzing efficiency can be greatly improved.

Owner:SUZHOU LIANCHI ENVIRONMENTAL SCI & TECH DEV CO LTD

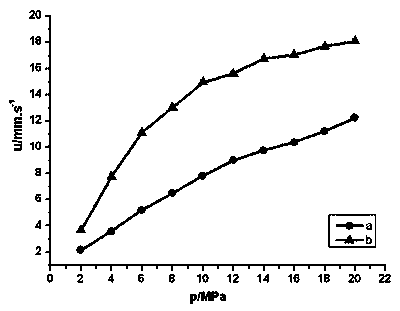

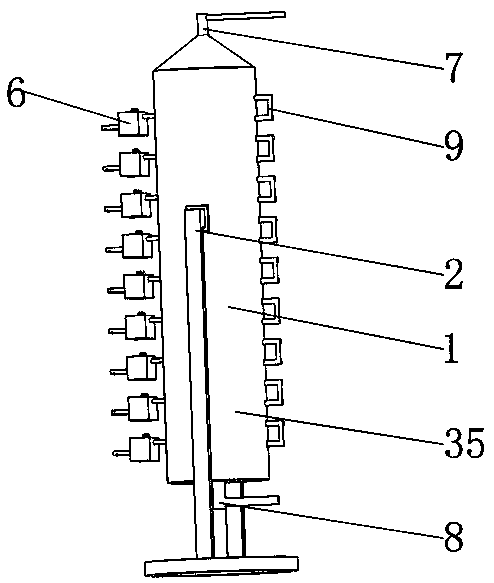

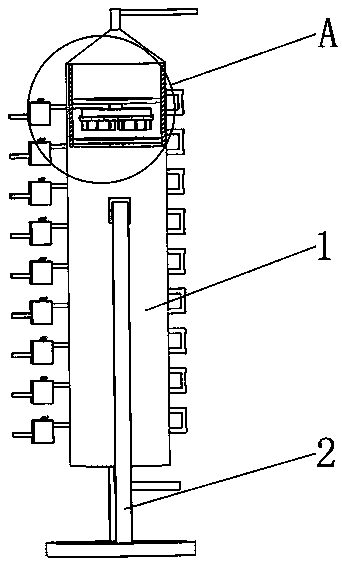

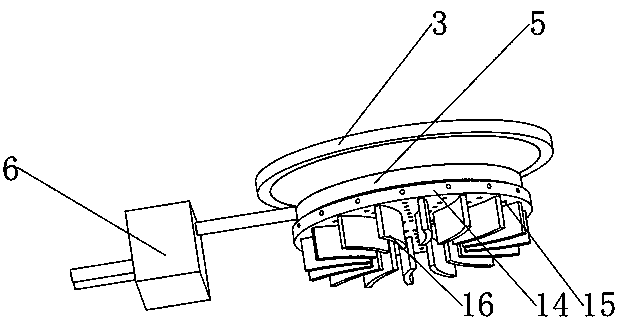

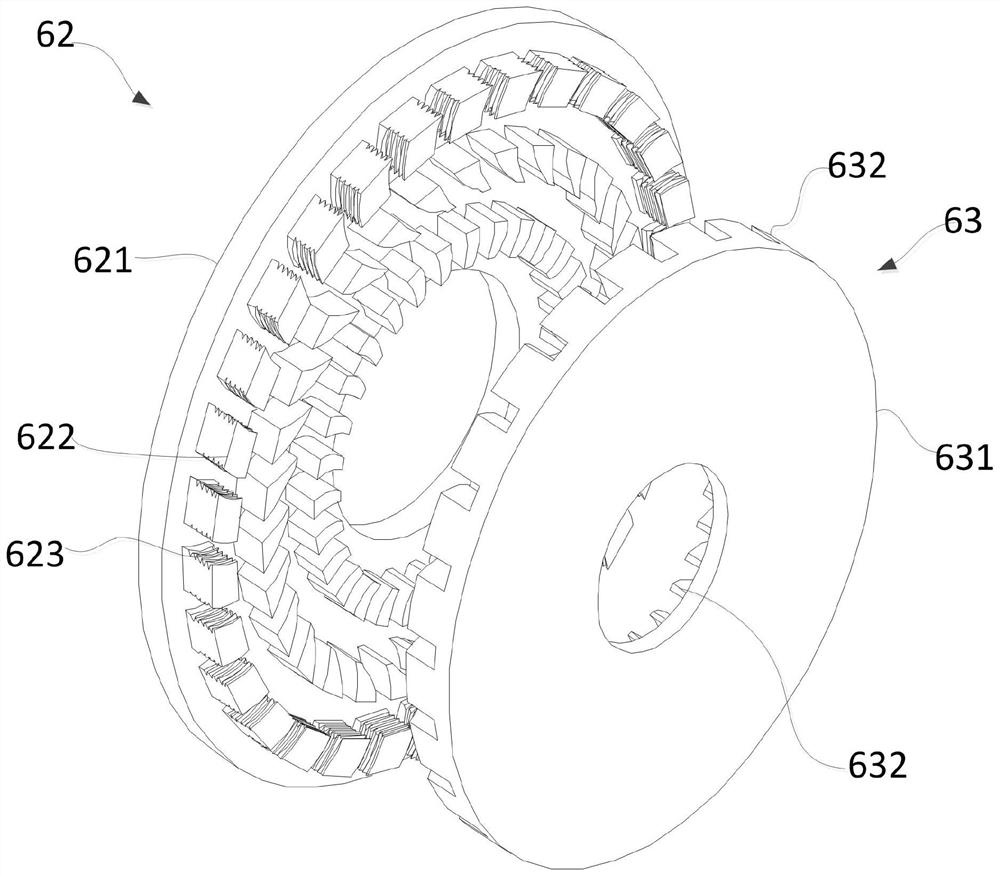

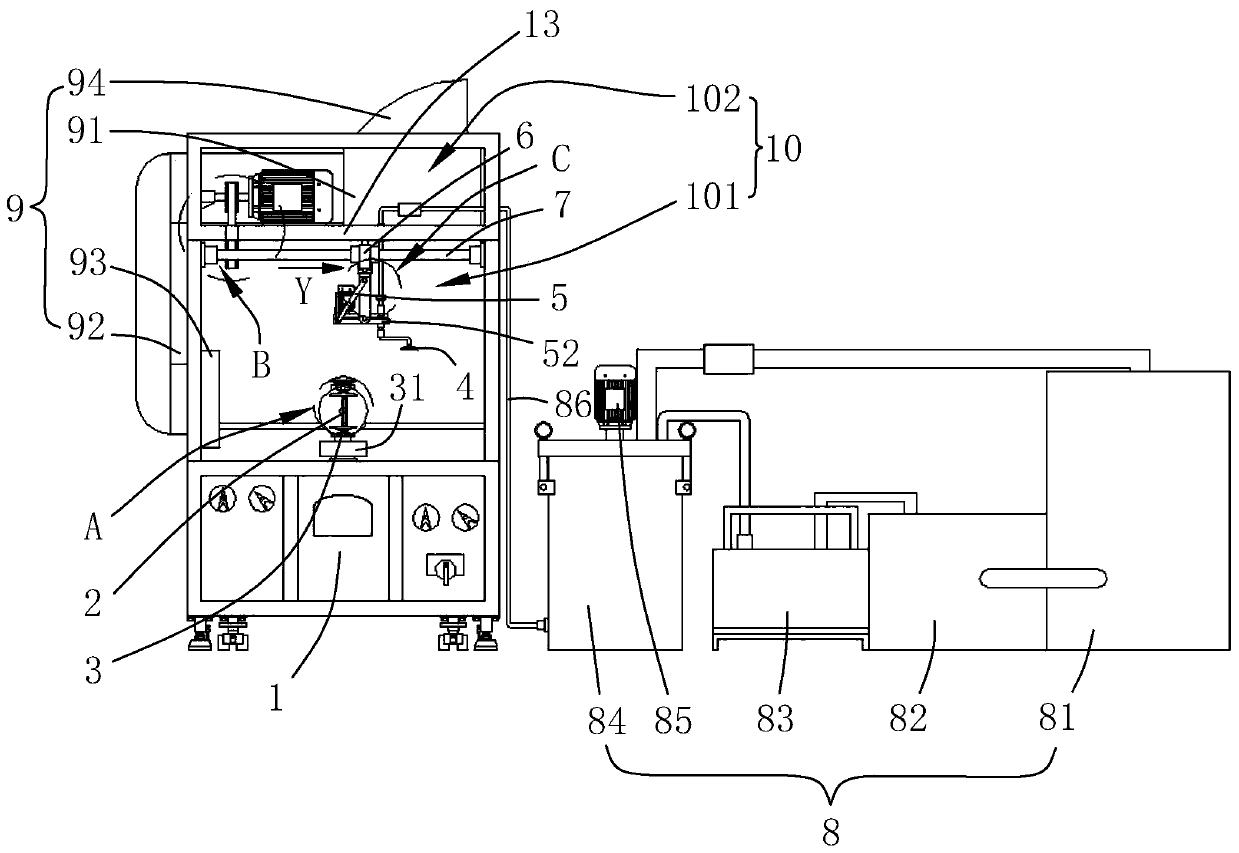

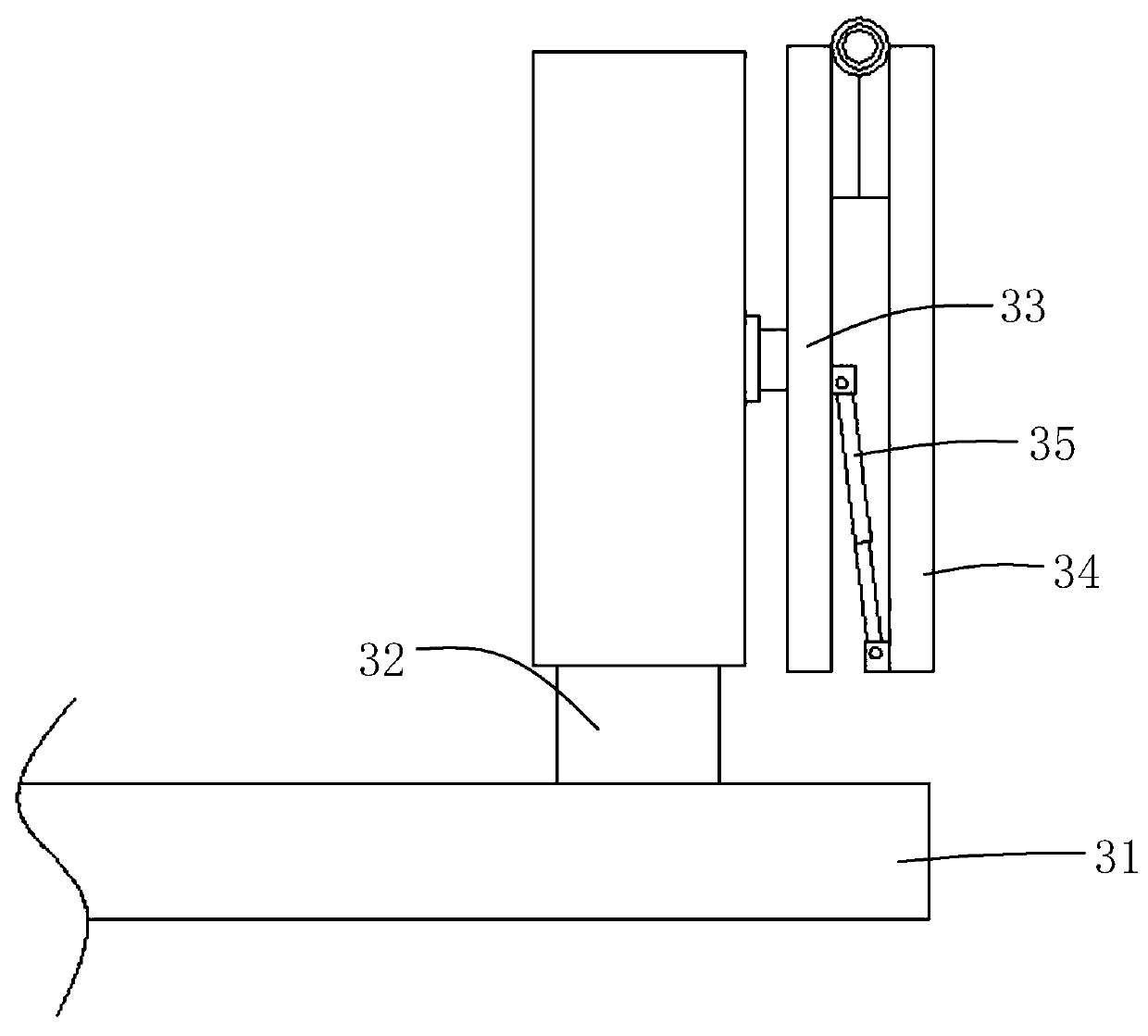

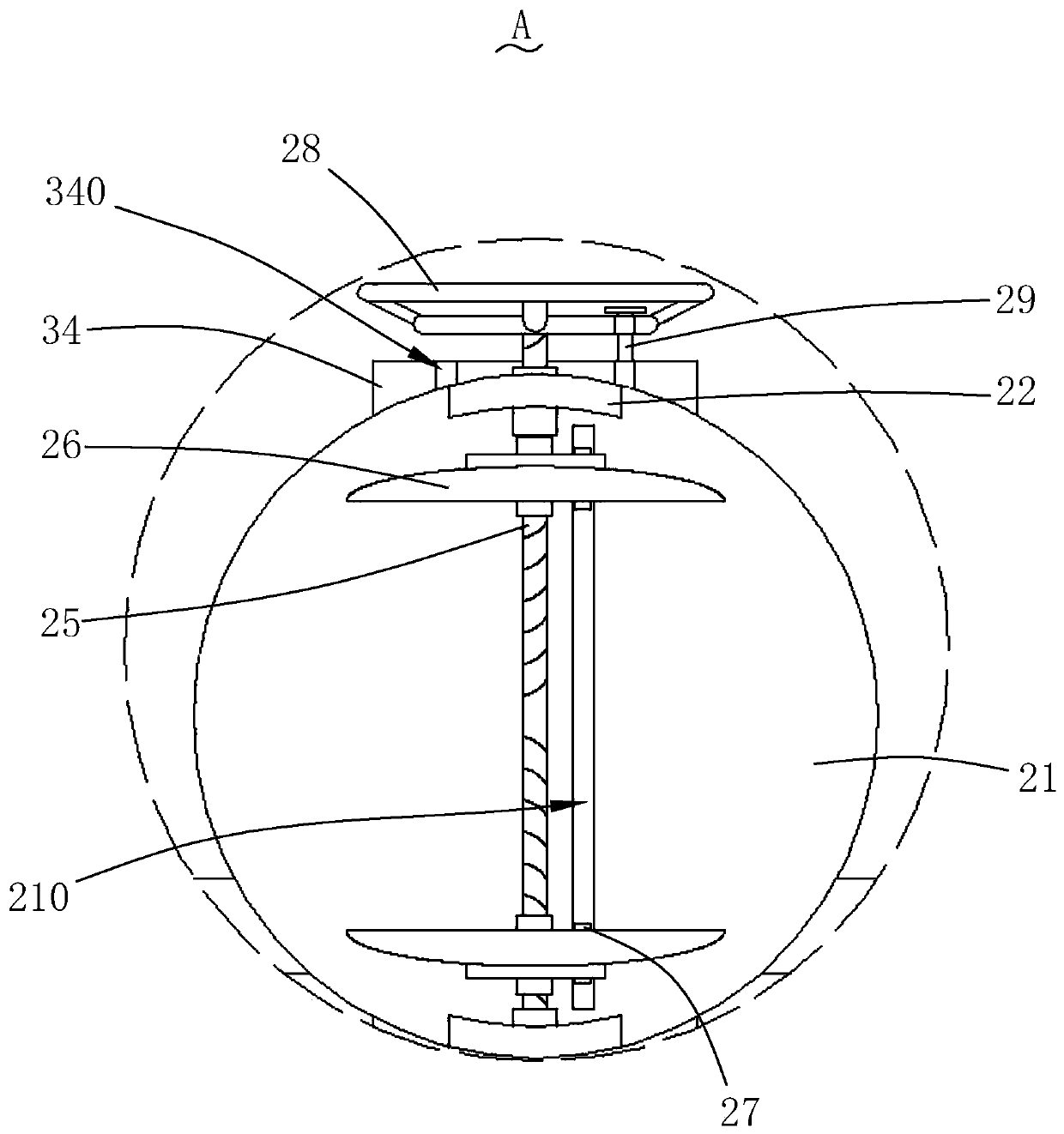

Propionaldehyde hydrogenation reactor

ActiveCN109908843AIncrease the degree of mixingImprove catalytic effectOrganic compound preparationHydroxy compound preparationCatalytic effectPropionaldehyde

The invention discloses a propionaldehyde hydrogenation reactor which comprises a reaction tank body, a fixed support, a plurality of regulators, an inlet pipe and an output pipe; the inlet pipe is fixed at the top of the reaction tank body, and the top of the reaction tank body is communicated with the inside of the inlet pipe; the fixed support is fixed on one side on the outer surface of the reaction tank body; the plurality of regulators are arranged on one side of the fixed support equidistantly, and the insides of the regulators are communicated with one another; the output pipe is fixedat the bottom of the reaction tank body, and the bottom of the reaction tank body is communicated with the inside of the output pipe. The propionaldehyde hydrogenation reactor disclosed by the invention has the benefits that an automatic hydrogenation device is designed, so that the addition of hot hydrogen and cold hydrogen can be automatically switched; the switching between hot and cold hydrogen gas inlets is automatically controlled by a motor; hydrogen gas is directly introduced into a catalyst layer and is mixed with mixed gas by the internal stirring regulators, so that not only is thetemperature of the catalyst layer is more quickly regulated, but also the mixing degree of the hydrogen gas with the mixed gas can be increased, therefore, the catalytic effect is further improved.

Owner:NINGBO JUHUA CHEM TECH CO LTD

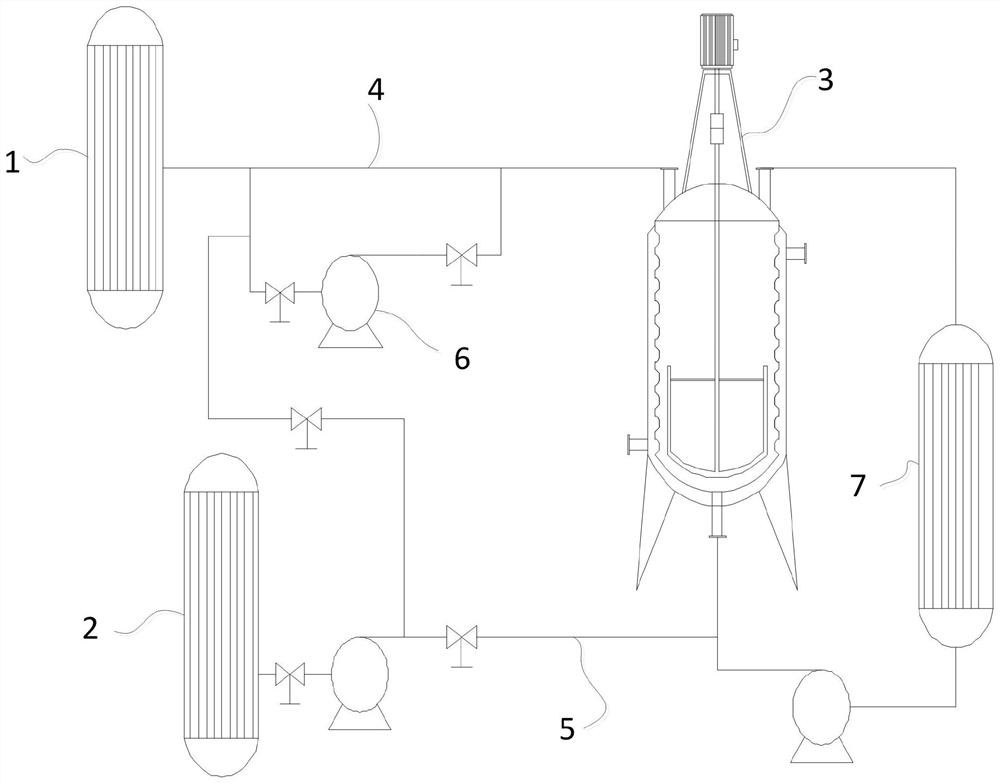

System for improving molecular weight distribution of middle-molecular polyisobutene

PendingCN113600113AImprove catalytic effectLow reaction temperatureChemical/physical/physico-chemical stationary reactorsFeed devicesPolymer chemistryDegree of polymerization

The invention relates to the technical field of production and application of polyisobutene, and in particular, relates to a system for improving molecular weight distribution of middle-molecular polyisobutene. The system comprises a raw material deep freezer, a catalyst tank and a polymerization reaction kettle; the raw material deep freezer is communicated with the polymerization reaction kettle through a raw material pipe, the catalyst tank is communicated with the polymerization reaction kettle through a catalyst pipe, and a homogenizing pump is further communicated between the raw material deep freezer and the catalyst tank. By addition with a homogeneous pump, the combination of raw materials and catalysts is effectively improved; the catalytic effect is effectively improved by arranging a traditional one-way catalyst into a two-way catalyst; the reaction temperature of the polymerization reaction kettle is effectively reduced by arranging an external circulation heat exchanger, the problems of short polymer molecular chains, more small-molecular-weight products and failing to meet the requirement of the required polymerization degree caused by the fact that heat cannot be removed are solved, and the molecular weight distribution of a polyisobutene product is effectively controlled to be 3.5 or below.

Owner:SHANDONG HONGRUI NEW MATERIAL TECH

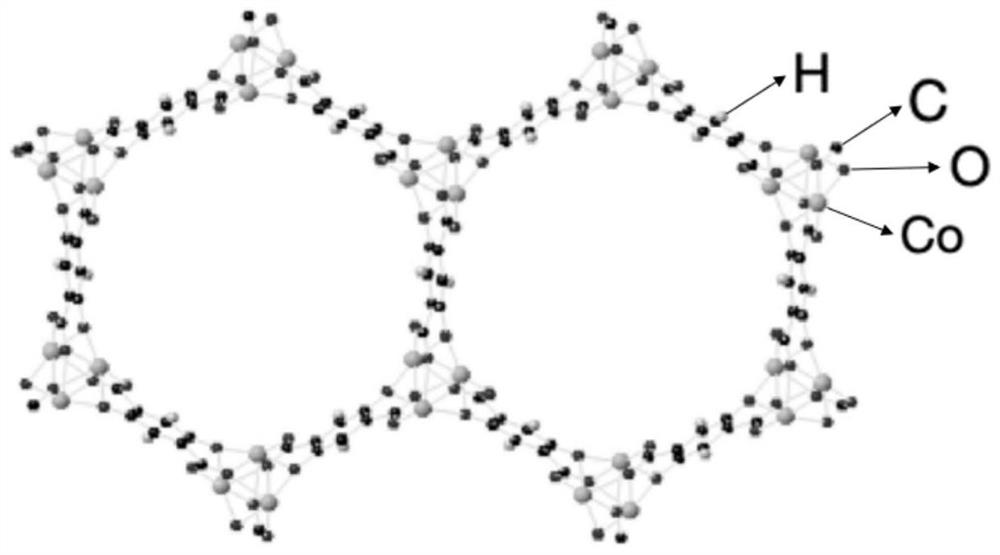

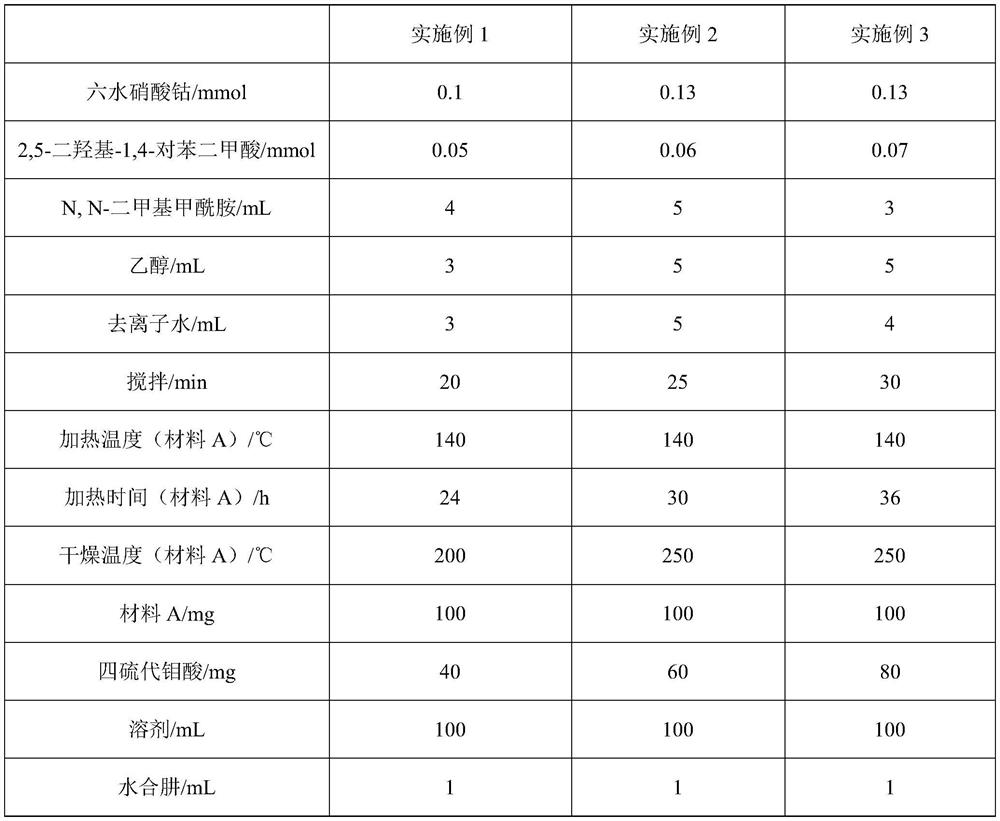

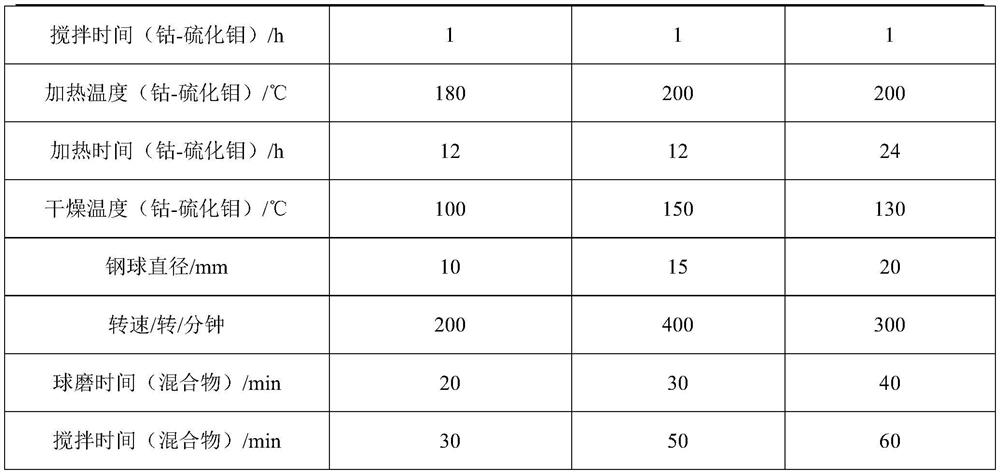

Cobalt-molybdenum sulfide composite flame retardant, fireproof coating and preparation methods of cobalt-molybdenum sulfide composite flame retardant and fireproof coating

ActiveCN113637347ALarge specific surface areaImprove catalytic effectFireproof paintsEpoxy resin coatingsSulfidationFire retardant

The invention discloses a cobalt-molybdenum sulfide composite flame retardant, a fireproof coating and preparation methods of the cobalt-molybdenum sulfide composite flame retardant and the fireproof coating, and belongs to the technical field of fireproof coatings. The cobalt-molybdenum sulfide composite flame retardant comprises Co-MOF and MoS2, the MoS2 is embedded in holes and combined with open positions of Co2+ ions to form a CoMoS phase, and a molybdenum sulfide modified organic framework material synthesized on the basis of the Co-MOF by the flame retardant has a larger specific surface area and a larger catalytic effect, has more active sites, can be used for preparing a high-performance flame retardant, and facilitates the combination with oxygen to form a complete combustion product.

Owner:JIANGSU CHAMPION TECHNOLOGY GROUP CO LTD

Preparation method of Fenton-like catalytic material and sewage treatment method

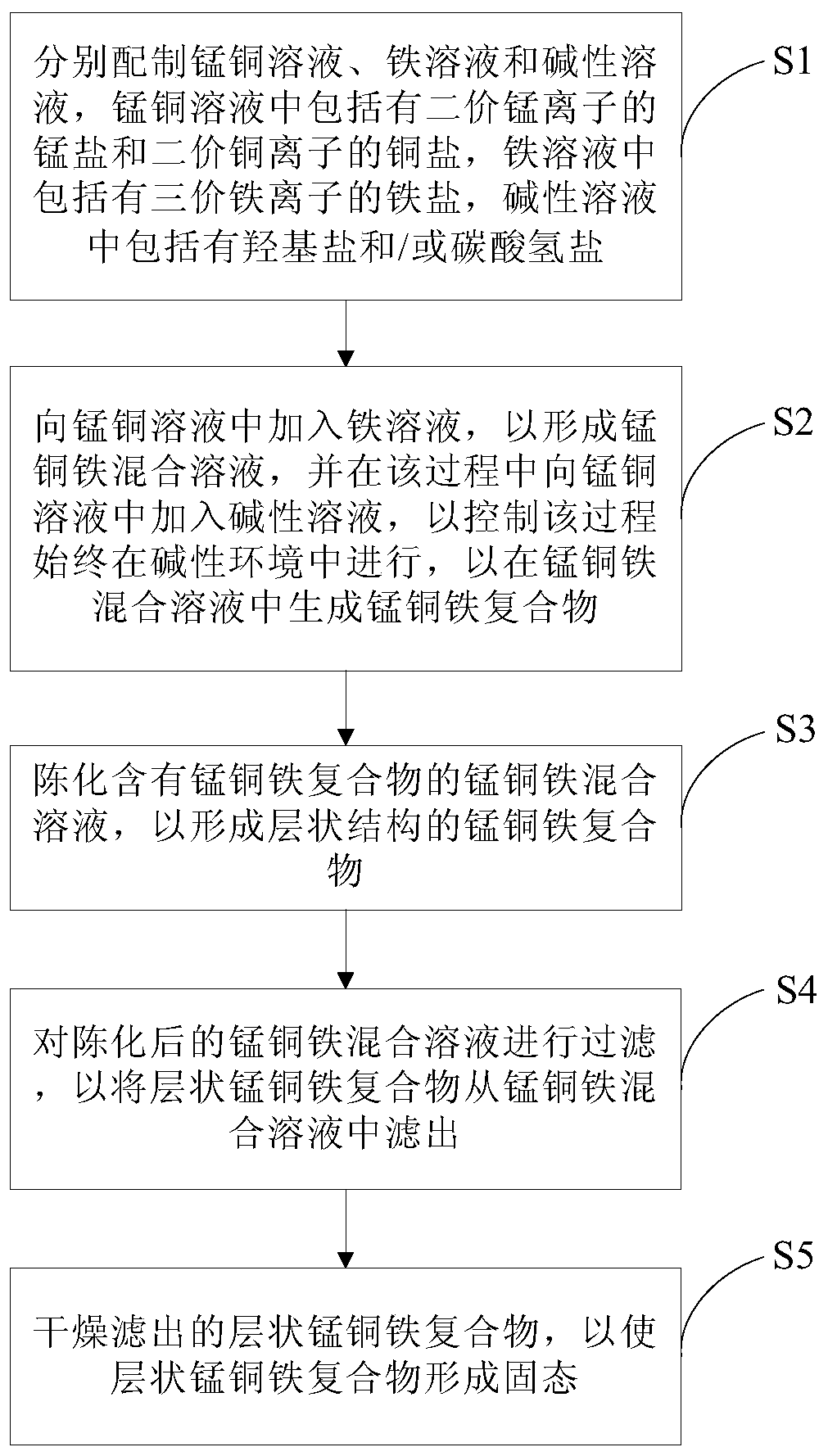

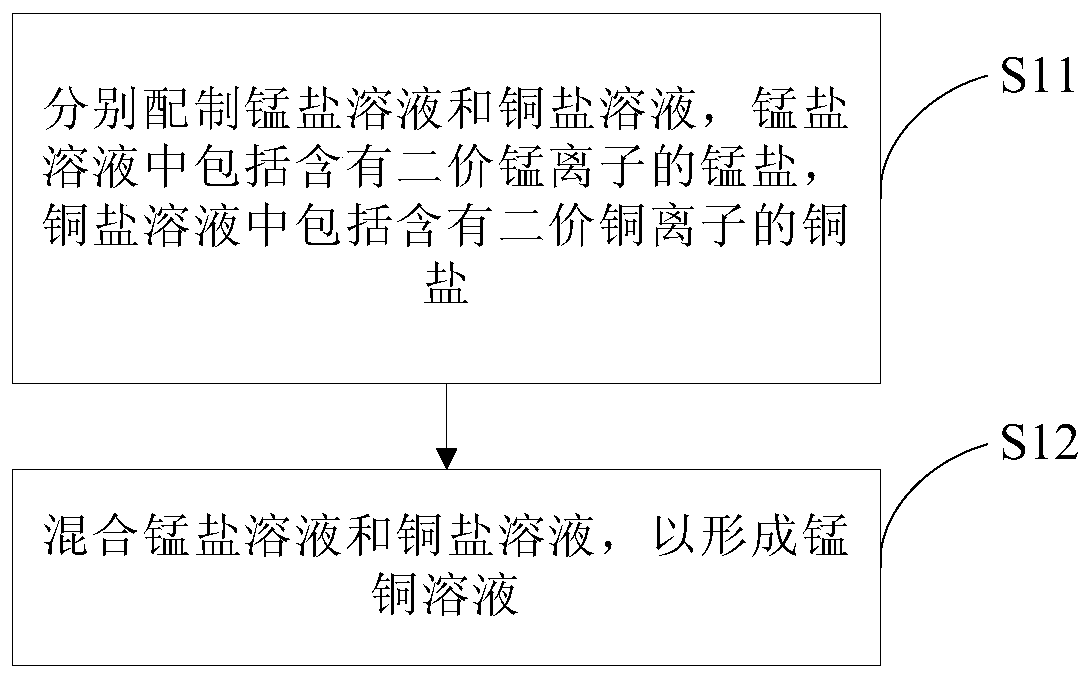

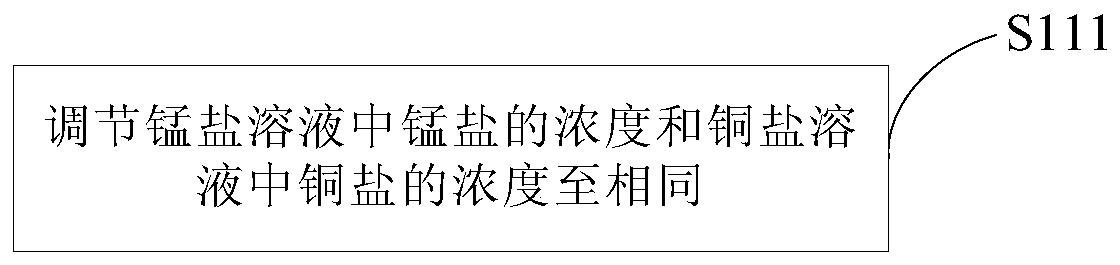

PendingCN110947395AImprove catalytic effectImprove the effect of sewage treatmentWater treatment parameter controlWater treatment compoundsBicarbonateCopper salt

The invention provides a preparation method of a Fenton-like catalytic material and a sewage treatment method. The preparation method of the Fenton-like catalytic material comprises the following steps: respectively preparing a manganese-copper solution containing manganous salt of divalent manganese ions and copper salt of divalent copper ions, an iron solution containing ferric salt of ferric ions and an alkaline solution containing hydroxyl salt and / or bicarbonate; adding the iron solution into the manganese-copper solution to form a manganese-copper-iron mixed solution, adding the alkalinesolution into the manganese-copper solution in the process, and controlling the process to be always carried out in an alkaline environment to generate a manganese-copper-iron complex; aging the manganese-copper-iron mixed solution to form a manganese-copper-iron complex with a layered structure; and filtering the aged manganese-copper-iron mixed solution, and drying the filtered layered manganese-copper-iron complex to enable the layered manganese-copper-iron complex to form a solid state. According to the preparation method of the Fenton-like catalytic material and the sewage treatment method provided by the invention, the catalytic effect can be improved, the operation difficulty is reduced, and the cost is reduced.

Owner:SINOCHEM ENERGY SAVING ENVIRONMENTAL PROTECTION HLDG BEIJING +1

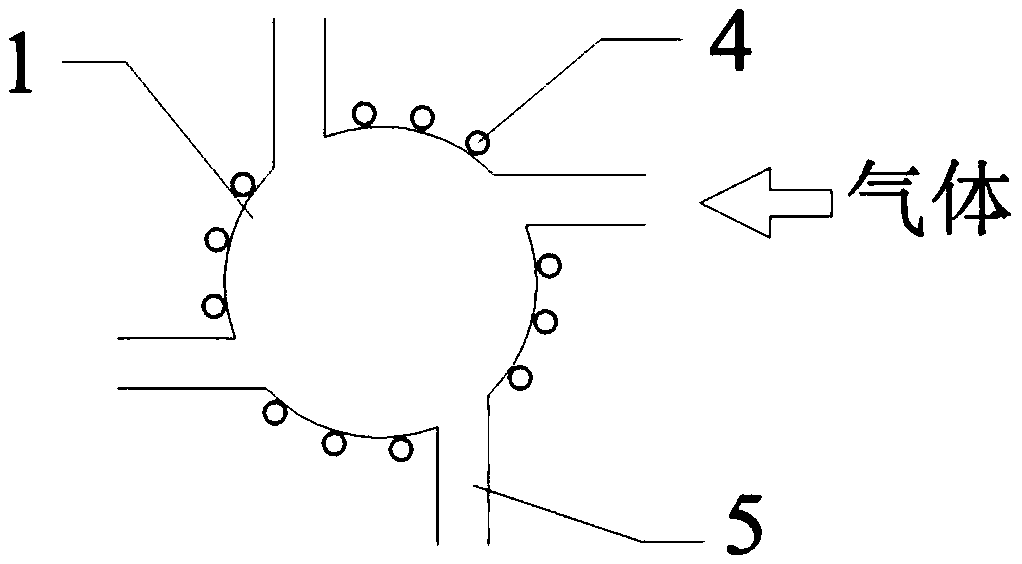

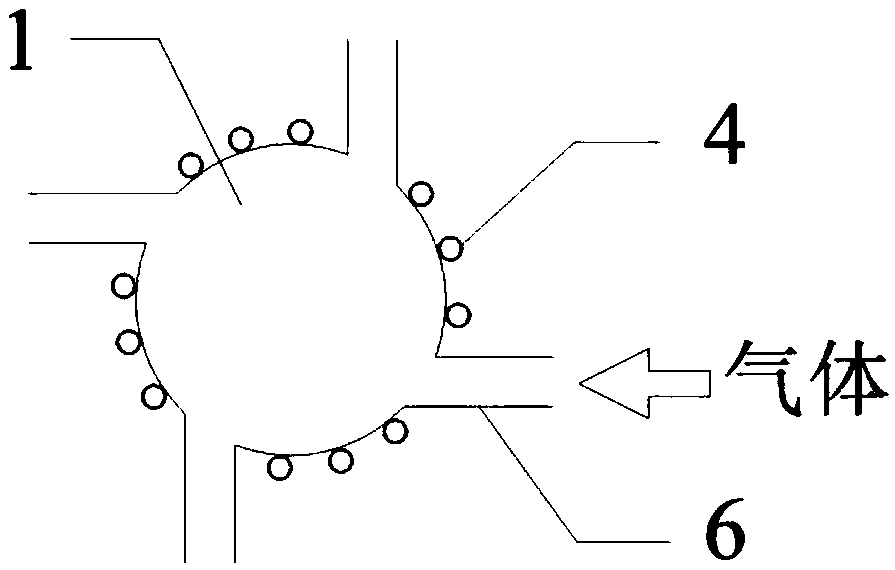

Bitangent circle reactor applied to urea pyrolysis to produce ammonia

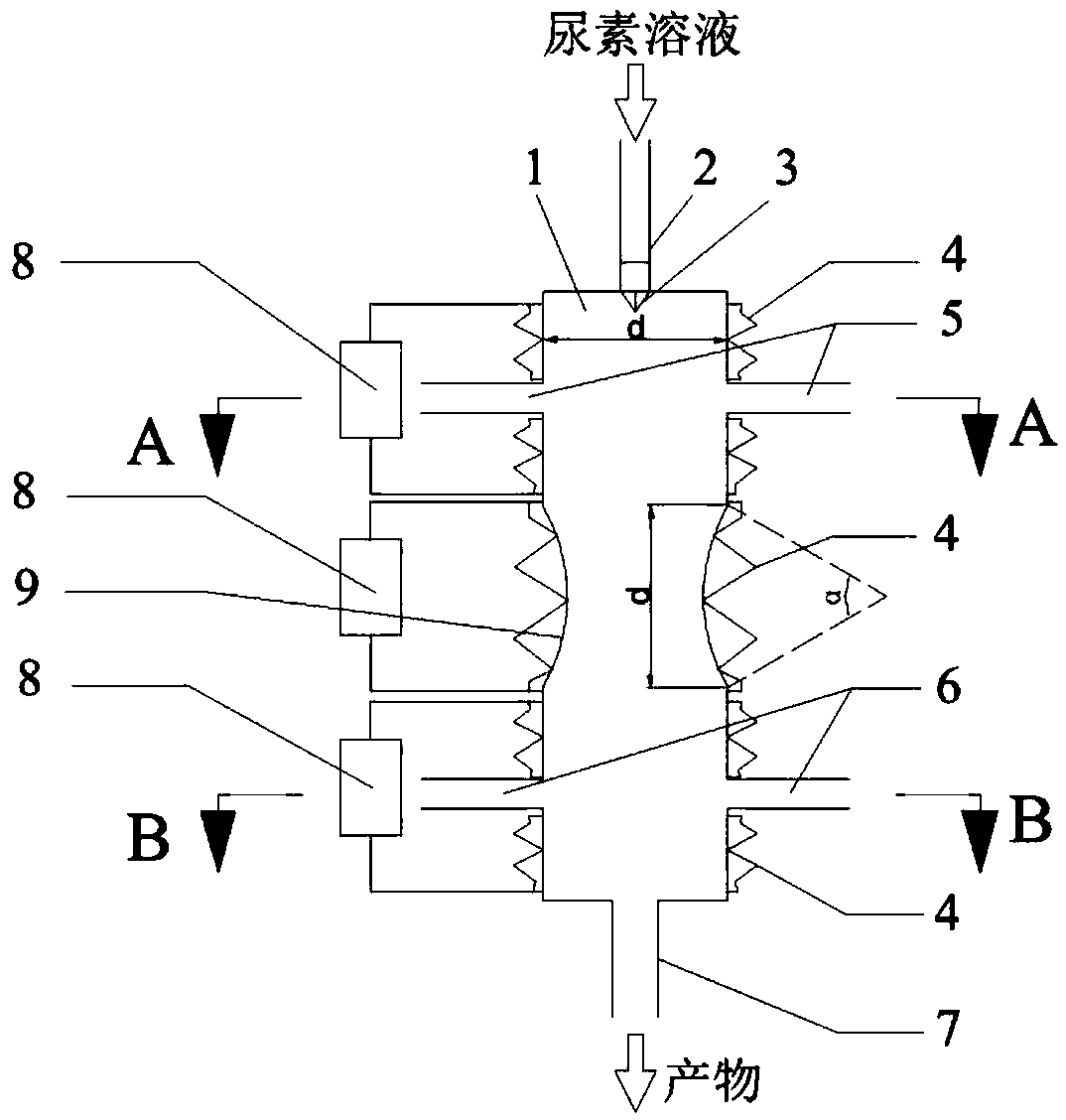

PendingCN108675318AImprove catalytic effectAvoid spin wash actionAmmonia preparation/separationChemistryDecomposition

The invention discloses a bitangent circle reactor applied to urea pyrolysis to produce ammonia. The bitangent circle reactor comprises a urea solution inlet and a decomposition product outlet, wherein the urea solution inlet and the decomposition product outlet are respectively formed in the upper part and the lower part of the reactor body, two groups of gas inlets for introducing air or smoke are formed in a lateral side of the reactor body, the two groups of the gas inlets of the reactor body are respectively distributed along an upper lateral wall and a lower lateral wall of the reactor body according to a rotational flow tangent circle, the tangent circle directions of the upper gas inlets and the lower gas inlets are opposite to each other, a zooming section is arranged in the middle section of the reactor body, an inner wall of the zooming section is of an annular corrugated structure, the outer side of the reactor body is wrapped by a plurality of groups of heating electric resistance wires from top to bottom, each group of heating electric resistance wires are respectively connected with a corresponding temperature control device, the reactor body is an aluminum cylinder,the zooming section is arranged between the solution inlet and the product outlet, and the inner wall of the zooming section of the reactor is of the annular corrugated structure. The bitangent circle reactor disclosed by the invention can effectively improve the ammonia producing efficiency through urea pyrolysis, reduce pyrolysis energy consumption and achieve both low cost and high efficiency.

Owner:XI AN JIAOTONG UNIV

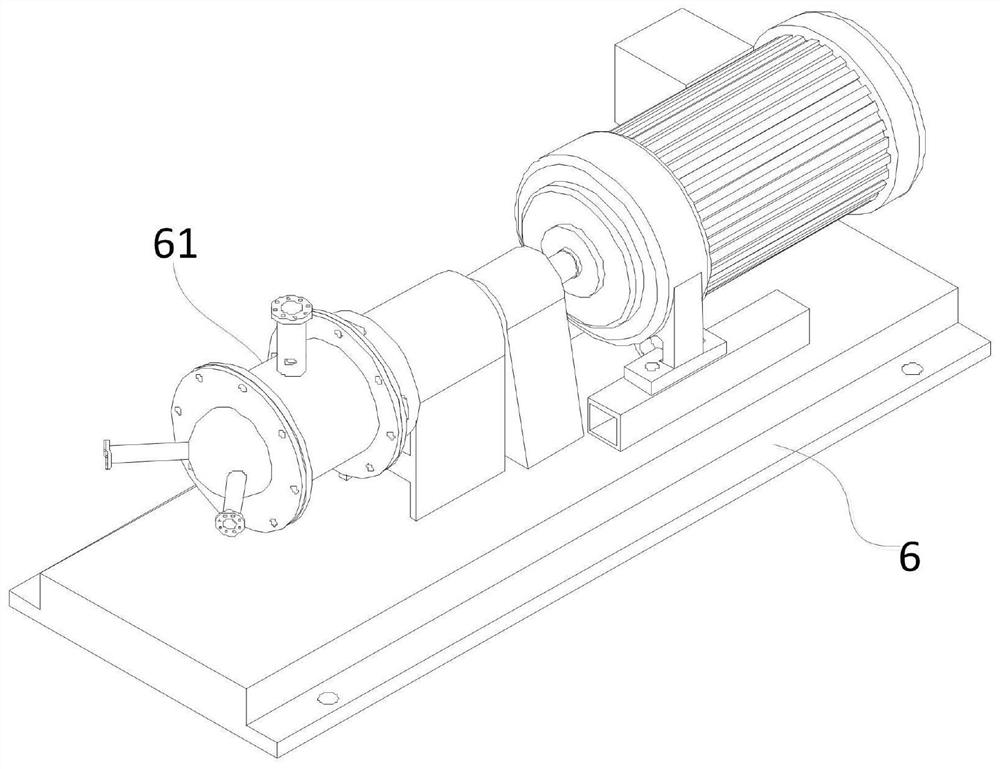

Spraying method of titanium dioxide photocatalyst and spraying equipment of spraying method

ActiveCN111495639AImprove catalytic effectImprove degradation rateLiquid surface applicatorsSpraying apparatusAluminium saltsCopper salt

The invention discloses a spraying method of a titanium dioxide photocatalyst and spraying equipment of the spraying method. The spraying method comprises the following steps that S1, raw materials are provided, the raw materials are prepared from the following components in weight by percentage: 1%-5% of copper salt,1%-5% of sodium salt, 1%-5% of aluminum salt, 1%-4% of nitric acid, 0.1%-0.8% ofnano silver, 0.1%-0.5% of nano palladium, 0.1%-0.5% of nano gold, 50% of deionized water and 29.2%-45.7% of nano titanium dioxide; S2, the titanium dioxide photocatalyst is prepared; S3, profiles arefixed; S4, spraying is carried out; S5, the angle of a spraying pipe or the positions of the profiles are adjusted; S6, spraying again is carried out; and S7, the step S5 and the step S6 are repeated.Compared with the prior art, precious metal is added in the titanium dioxide photocatalyst used in the spraying method of the titanium dioxide photocatalyst, the catalytic effect of the titanium dioxide photocatalyst is significantly improved. After pollutants are degraded repeatedly, the catalyst is not prone to inactivating, the service life is longer, and the durability is higher.

Owner:SHENZHEN XIBAO SHIP ELECTRONICS

Preparation method of ferrimanganic composite oxides with three-phase catalytic function

InactiveCN108786841AImprove catalytic effectRealize three-phase catalysisWater/sewage treatment by irradiationWater treatment compoundsMuffle furnaceChemistry

The invention discloses a preparation method of ferrimanganic composite oxides with a three-phase catalytic function. The method sequentially comprises the following steps that under the water bath stirring condition, a sodium carbonate solution is dropwise added into a mixed solution of ferric chloride and manganese chloride; after the dropwise addition is completed, the product is continuously aged for 24 to 36h in a water bath; a polyhydroxy ferrimanganic solution is obtained through preparation; sodium dodecyl benzene sulfonate solids are added into the prepared polyhydroxy ferrimanganic solution; stirring is performed for 2 to 3h; precipitation and separation are performed; the solids are washed by distilled water for 2 to 3 times; drying is performed at 105 DEG C; a dodecyl sulfonatecombined ferrimanganic solid is obtained and is then put into a muffle furnace; under the nitrogen gas protection, calcination is performed for 2 to 5h at 350 to 550 DEG C; nitrogen gas is switched into air; the introduced air quantity is controlled to be 30 to 50mL / g of dodecyl sulfonate combined ferrimanganic solid; then, nitrogen gas is continuously introduced; the nitrogen gas introduction stops until the cooling is performed to room temperature; the ferrimanganic composite oxides with the three-phase catalytic function is obtained; the catalytic effect is obviously enhanced.

Owner:CHANGZHOU UNIV

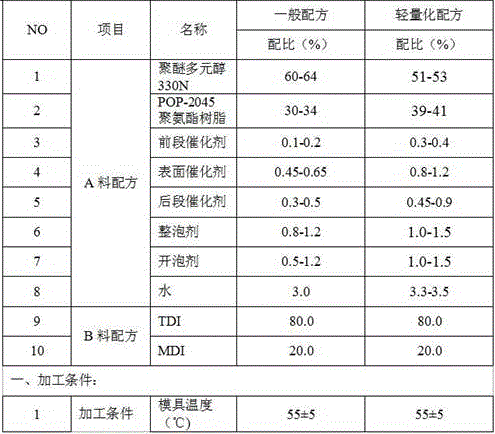

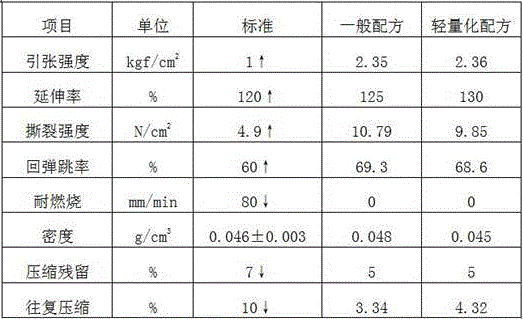

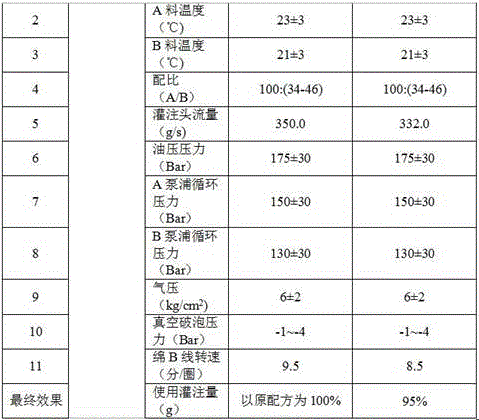

Lightweight foam for automotive interiors and preparation method of lightweight foam

The invention belongs to the field of preparation of synthetic foam and particularly relates to lightweight foam for automotive interiors and a preparation method of the lightweight foam. The lightweight foam consists of a material A and a material B, wherein the material A is prepared from raw materials in percentage by weight as follows: 51%-53% of polyether glycol 330N, 39%-41% of POP-2045 polyurethane resin, 0.1%-0.2% of a pre-catalyst, 0.5%-0.7% of a surface catalyst, 0.35%-0.6% of a post-catalyst, 1.4%-1.5% of a foam shaping agent, 1.3%-1.5% of a foam opening agent and 3.3%-3.5% of water; the material B is toluene disocynate and diphenyl-methane-diisocyanate. The moisture content, the quantity of the foam shaping agents and the quantity of the foam opening agents in the material A are increased, the pre-catalyst and the post-catalyst are substantially increased, the foaming speed is higher, and the lightweight effect of synthetic foam is realized in combination with improvement of increase of the rotating speed of a foam line B.

Owner:FUZHOU LIANHONG MOTOR PARTS

Composite solid catalyst for preparing methyl salicylate and preparation method thereof

InactiveCN105498837AImprove catalytic effectIncrease responsivenessOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsMethyl salicylateCellulose

The invention relates to a composite solid catalyst for preparing methyl salicylate and a preparation method thereof. In the composite solid catalyst, the mass ratio of modified composite soil particles to dicyclohexylcarbodiimide to 4-dimethylaminopyridine is 20:9:8, wherein the modified composite soil particles are prepared from the following components in parts by mass: 20-35 parts of modified diatomite, 10-20 parts of modified attapulgite clay, 3-12 parts of hydroxy propyl cellulose, 1-4 parts of carboxymethylcellulose and 8-16 parts of water. The preparation method has the advantages of high catalyzing rate, convenience in recycling and utilization, contribution to reduction of the process difficulty, and increase of the production efficiency.

Owner:ZHENJIANG GAOPENG PHARMA

Preparation method of optically pure cis-2-(diphenylphosphine)-1-cyclohexanecarboxylic acid

ActiveCN111484522AImprove catalytic effectHigh yield and purityGroup 5/15 element organic compoundsCarboxylateAddition reaction

The invention discloses a preparation method of optically pure cis 2-(diphenylphosphine)-1-cyclohexanecarboxylic acid. The preparation method comprises the following steps: carrying out an addition reaction on methyl 1-cyclohexylene-1-carboxylate and diphenyl phosphine oxide to obtain a first intermediate, reducing the first intermediate to obtain a second intermediate, and hydrolyzing the secondintermediate to obtain the cis-2-(diphenylphosphine)-1-cyclohexanecarboxylic acid. The preparation method of the optically pure cis-2-(diphenylphosphine)-1-cyclohexanecarboxylic acid is creatively researched, the vacancy of optically active pure cis-2-(diphenylphosphine)-1-cyclohexanecarboxylic acid in phosphine ligands is filled, and the catalytic effects of asymmetric lewis acid and transition metal are effectively promoted.

Owner:NANJING UNIV OF TECH +1

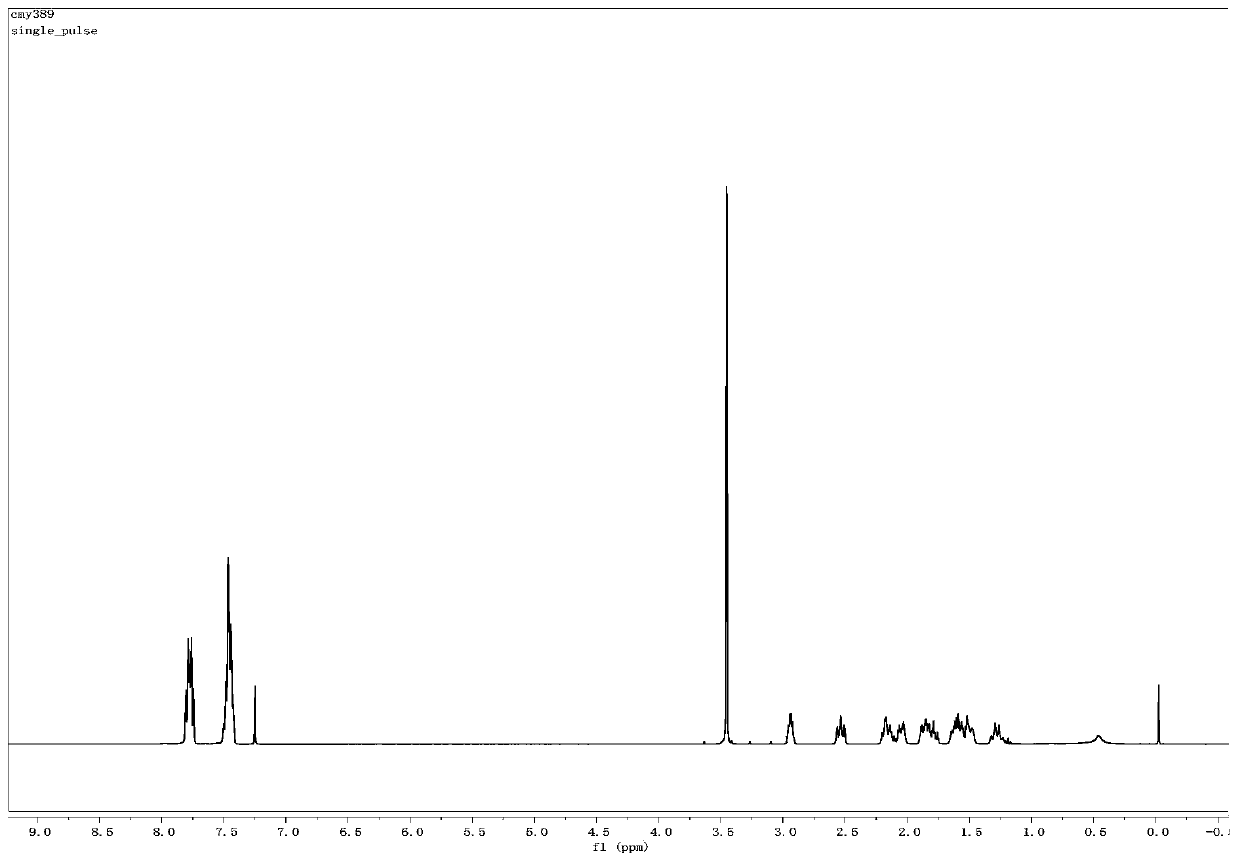

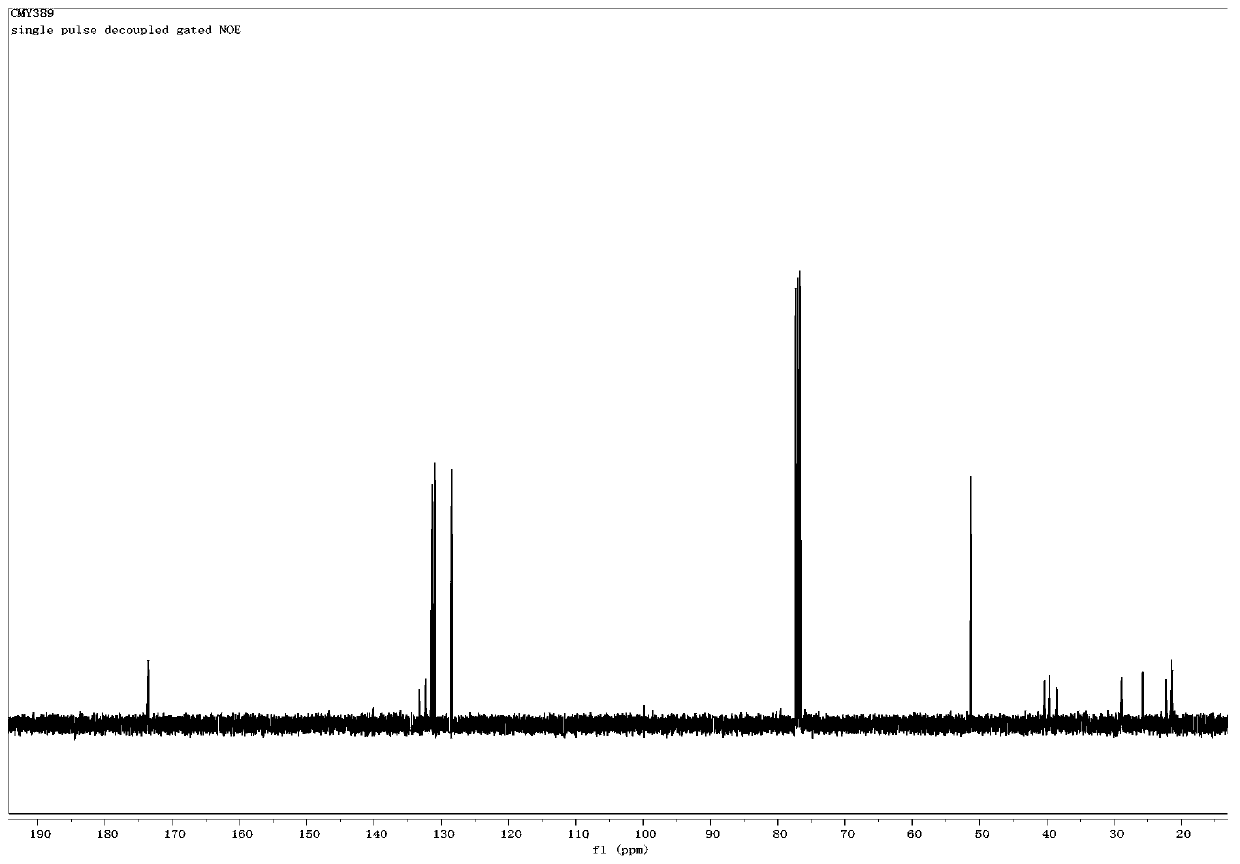

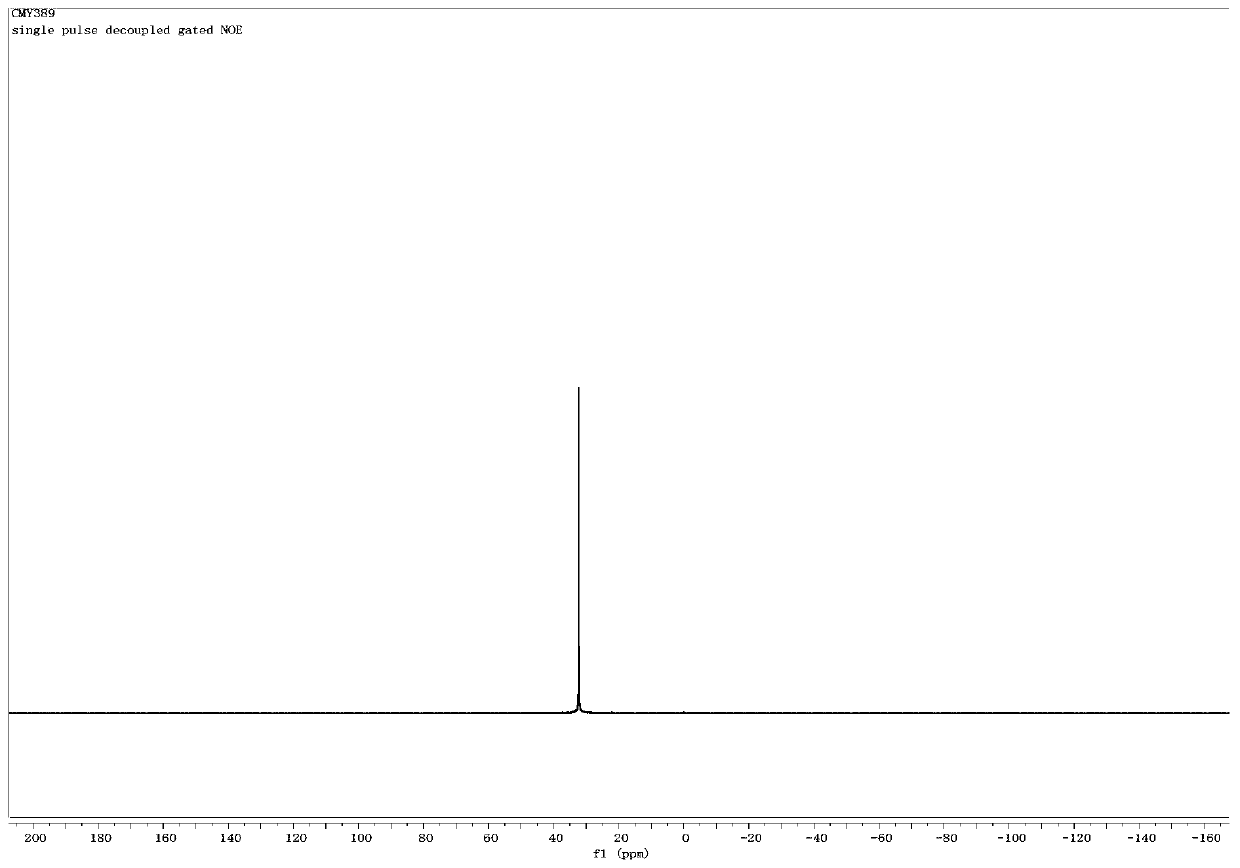

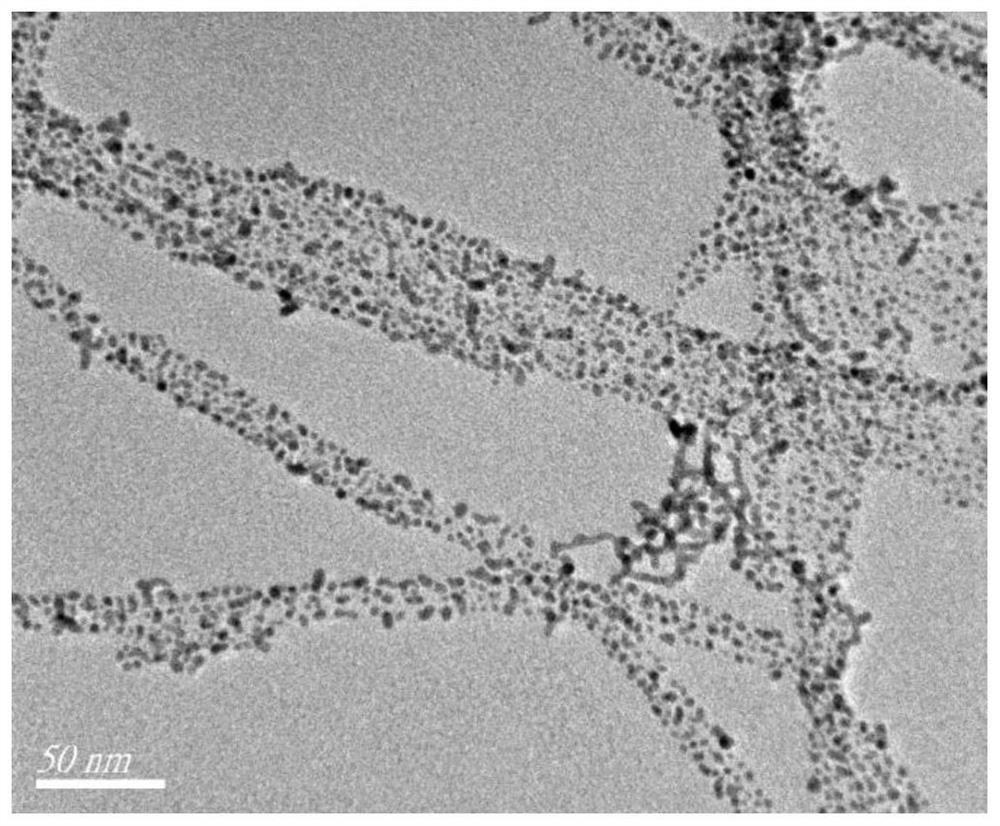

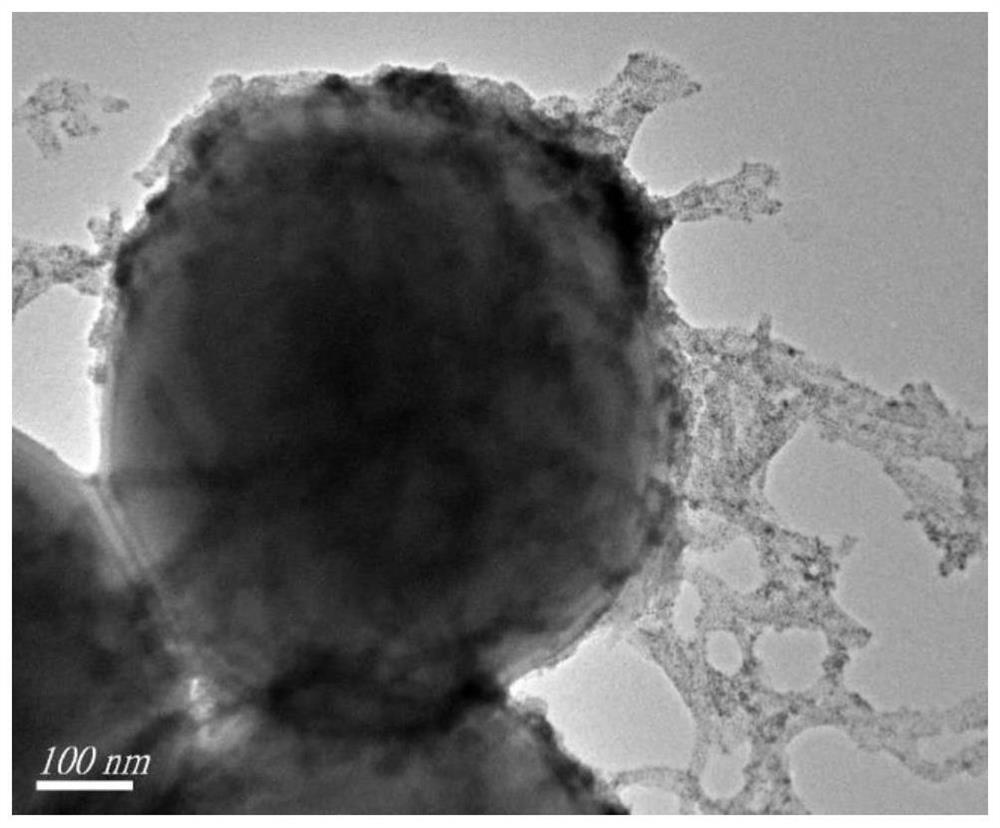

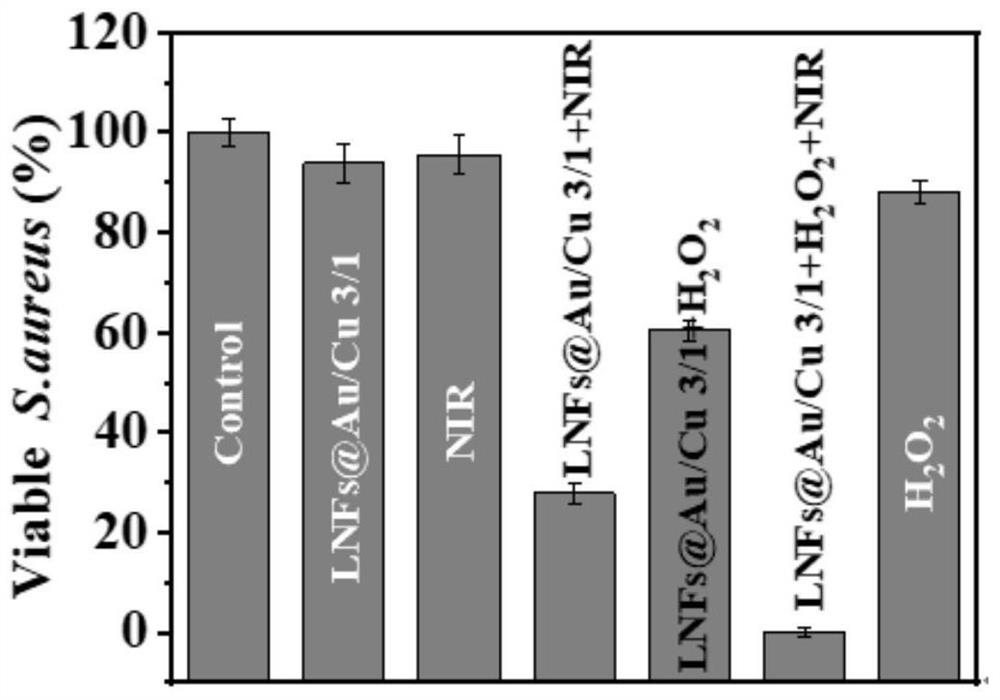

Preparation method and application of gold-copper bimetallic nano-enzyme composite material

PendingCN114452386AIncrease distribution densityImprove catalytic effectAntibacterial agentsOrganic active ingredientsHigh densityMixed solution

The invention belongs to the technical field of nano-materials, and discloses a preparation method and application of a gold-copper bimetallic nano-enzyme composite material. The preparation method comprises the following steps: adding a mixed solution of chloroauric acid and copper chloride into a lysozyme fiber solution, standing for fully mixing, and adding a freshly prepared sodium borohydride solution as a reducing agent to obtain the gold-copper bimetallic nano-enzyme composite material. In the gold-copper bimetallic nano-enzyme composite material, the lysozyme fibers are uniform in size, small-size gold-copper nano-particles are uniformly distributed on the surfaces of the lysozyme fibers at high density, under the radiation of near-infrared light, the catalytic activity of peroxidase can be remarkably enhanced, and the purpose of efficient sterilization is achieved.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com