Preparation method and application of gold-copper bimetallic nano-enzyme composite material

A bimetallic nano-composite material technology is applied to the gold-copper bimetallic nano-enzyme composite material and its catalysis/photothermal antibacterial application field, which can solve the problems of low catalytic efficiency and weak interaction of gold-based nano-enzymes, and achieves The effect of promoting Fenton-like reaction, improving distribution density, and improving generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Preparation of lysozyme fiber:

[0029] Prepare 10 mL of hydrochloric acid solution with a concentration of 1 M, and add 0.015 g of glycine to prepare A solution. Prepare 1 mL of glacial acetic acid solution with a concentration of 1 mM, and add 0.1396 g of choline chloride to prepare B solution. Take 0.01g of lysozyme, add 4750μL of LA solution and 250μL of B solution to dissolve. Stir the reaction in an oil bath at 70°C for 5h. After the reaction was completed, centrifuge at 12000rpm and wash with ultrapure water twice, each time for 20min. Obtain final lysozyme fiber aqueous solution 8ml.

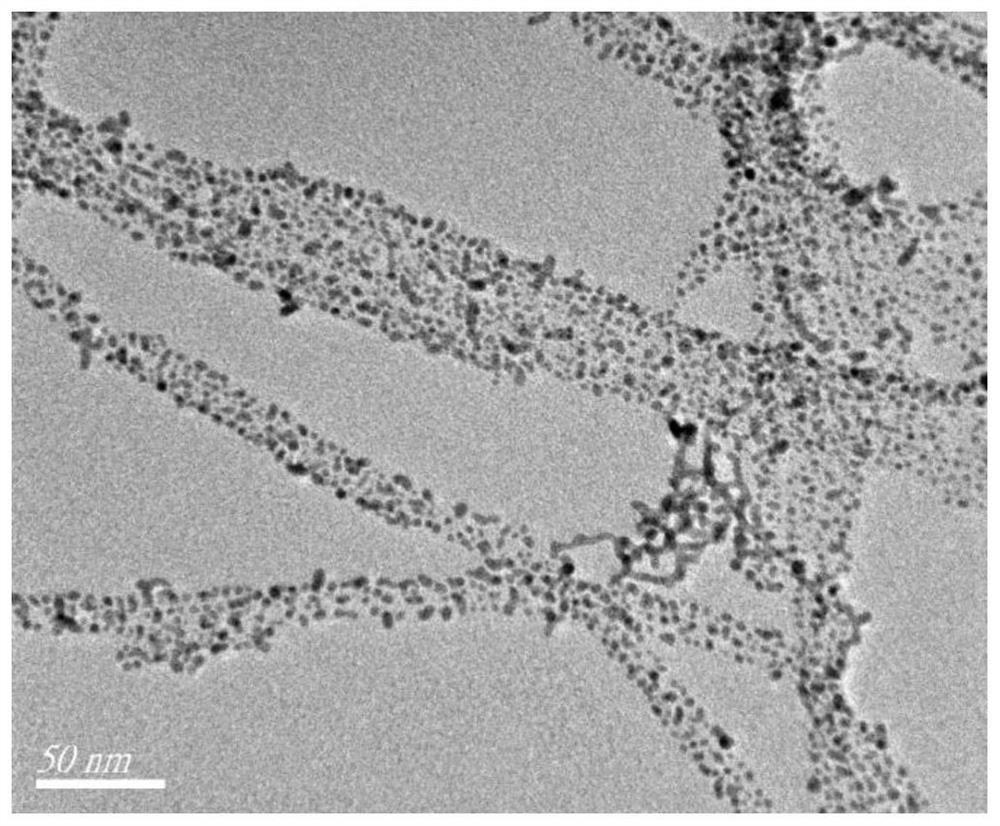

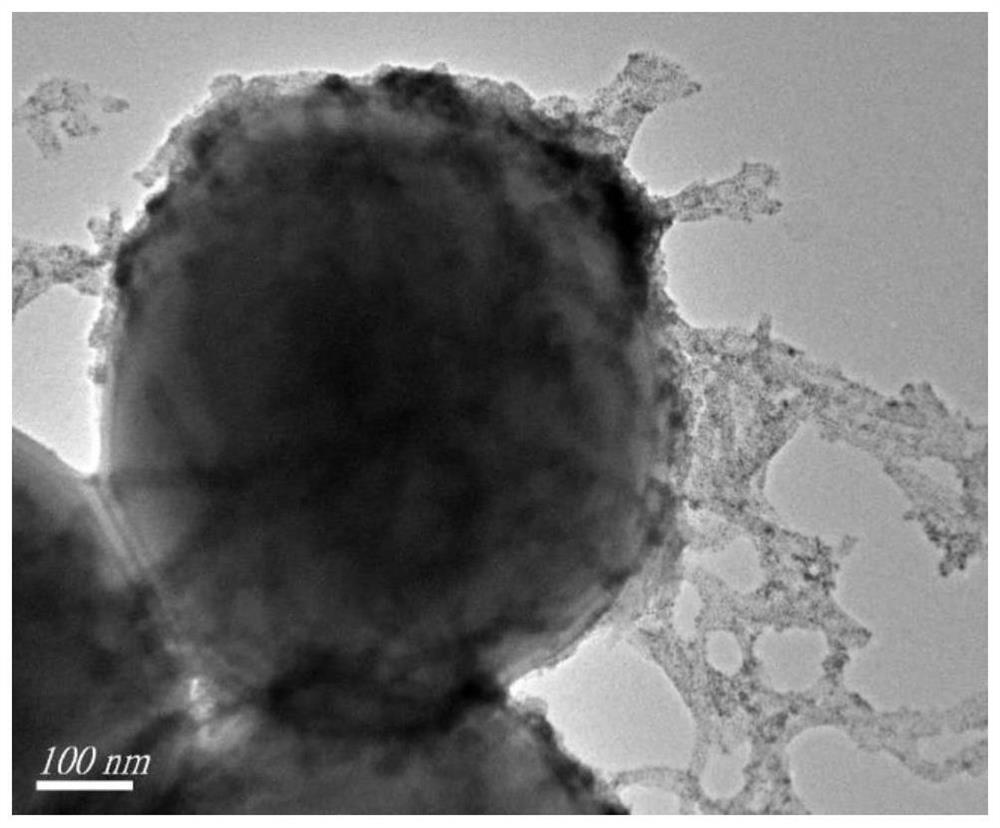

[0030] Preparation of LNFs@Au / Cu nanozyme composites:

[0031] Take 800 μL of lysozyme fiber solution, add 800 μL of chloroauric acid and copper chloride solution in total, react for 30 minutes, add 800 μL of freshly prepared sodium borohydride solution, and quickly reduce to obtain metal nanoparticle composites.

[0032] Wherein, the concentration of the lysozyme fiber is 5 ...

Embodiment 2

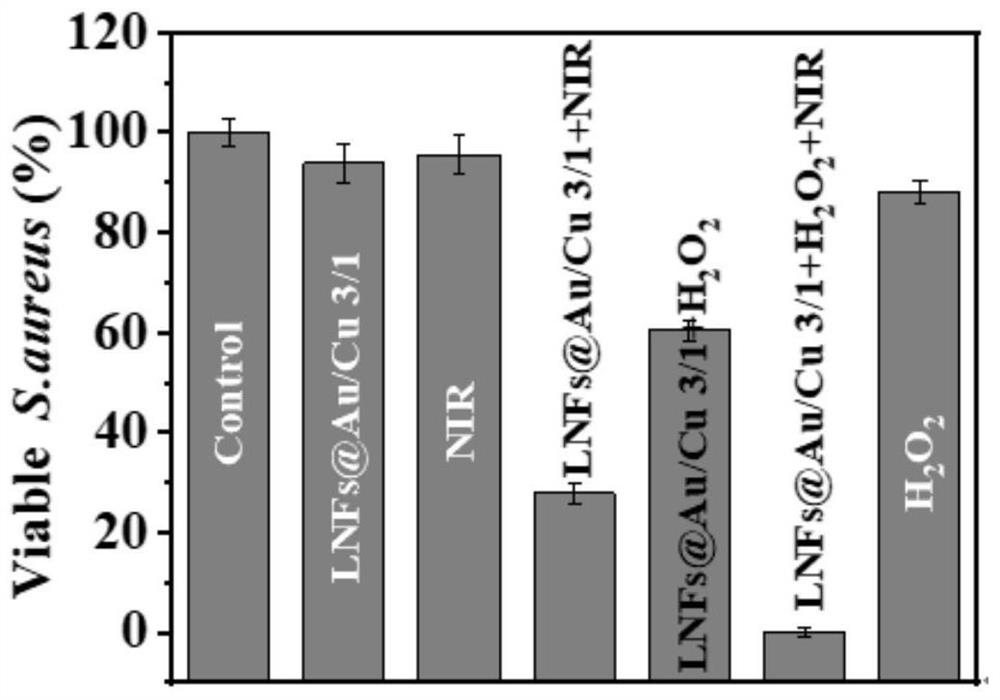

[0036] As in Example 1, only the ratio of the gold-copper salt solution in the preparation step of the gold-copper nanozyme composite material was changed, and LNFs@Au / Cu photothermal sterilization was performed. The survival rate of the bacteria obtained is shown in Table 1. The results showed that the bactericidal efficiency of LNFs@Au / Cu increased with the increase of copper addition compared with the unmodified gold nanoparticle material, but further increasing the copper content, its bactericidal efficiency decreased, which could be attributed to the higher copper content The addition of LNFs@Au / Cu metal nanoparticles makes the size of LNFs@Au / Cu metal nanoparticles larger, and the near-infrared absorption decreases, which reduces the photothermal conversion efficiency.

[0037] Table 1 Effect of different copper additions on LNFs@Au / Cu photothermal sterilization

[0038] Copper addition amount (Au to Cu molar ratio) Bacterial Survival Rate (%) 1:0 65.13 ...

Embodiment 3

[0040] As in Example 1, only the ratio of the gold-copper salt solution in the preparation step of the gold-copper nanozyme composite material was changed, and the LNFs@Au / Cu catalyzed hydrogen peroxide sterilization was carried out. The survival rate of the bacteria obtained is shown in Table 2. It can be seen that with the increase of copper content, the catalytic bactericidal efficiency of LNFs@Au / Cu increases, but further increasing the copper content, its bactericidal efficiency decreases, which can be attributed to the addition of higher copper content to promote the LNFs@Au / Cu metal The size of the nanoparticles becomes larger and the catalytic activity decreases.

[0041] Table 2 Effect of different copper additions on LNFs@Au / Cu catalytic sterilization

[0042] Copper addition amount (Au to Cu molar ratio) Bacterial Survival Rate (%) 1:0 87.26 4:1 68.13 3:1 61.34 2:1 73.46 1:1 91.74 0:1 100

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com