Nano-porous hydrogen production catalyst and preparation method thereof

A nanoporous and catalyst technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of anode catalyst activity and cost constraints on large-scale application of direct fuel cells, reduce catalytic efficiency, etc., to achieve improved catalytic effect, uniform distribution, The effect of increasing the stability of the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

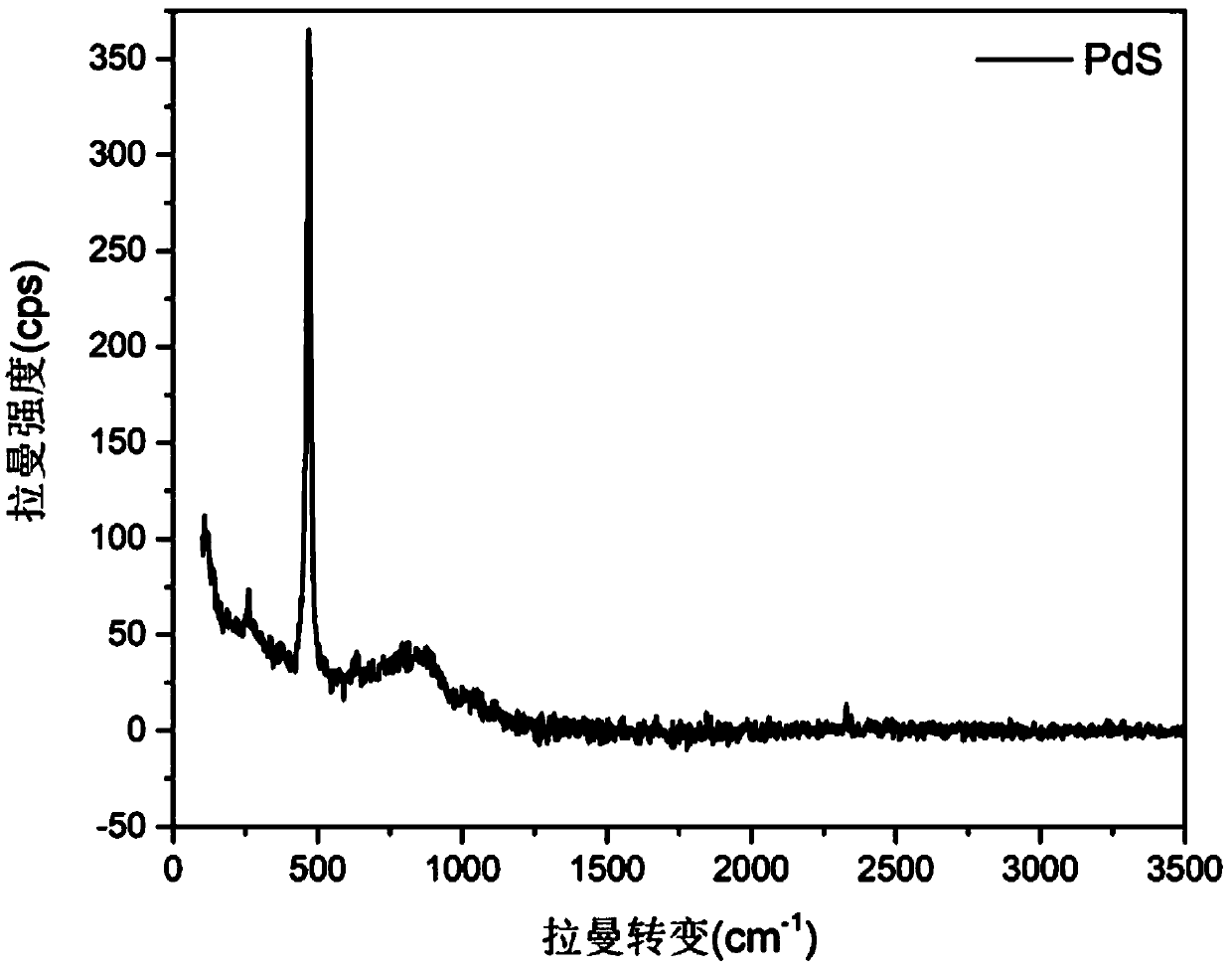

Embodiment 1

[0030] 1. Weigh 4.507g of pure aluminum (Al), 1.600g of pure titanium (Ti), 0.708g of pure copper (Cu), and 1.185g of pure palladium (Pd). The total sample is 8g.

[0031] 2. Put the 8g sample into the argon melting furnace. After the molecular pump evacuated the high-purity argon protective atmosphere, it melted 4 times to make the internal composition of the alloy uniform. get Al 75 Cu 5 Ti 15 PD 5 alloy ingot.

[0032] 3. Afterwards, take out the alloy ingot and crush it, take the fragments and clean them with anhydrous ethanol ultrasonically, put them in a clean quartz tube, place them in a belt throwing machine, and spray the melted liquid alloy on a high-speed rotating copper roller after extracting a high vacuum On, the liquid is rapidly cooled to form amorphous strips instantly. The belt swing machine needs to draw 7×10 -3 Pa. The speed of the copper roll needs to be controlled at 3500 rpm. The pressure difference between the quartz tube and the furnace needs ...

Embodiment 2

[0038] Weigh pure aluminum, pure titanium, pure copper and pure palladium, put them into an argon smelting furnace, put high-purity argon protective atmosphere into the high-purity argon gas protective atmosphere after the molecular pump pumps high vacuum, and smelt 4 times to make the internal composition of the alloy uniform and obtain Al 60 Cu 10 Ti 15 PD 15 Alloy ingots, then take out the alloy ingots and crush them, take the fragments and ultrasonically clean them with anhydrous ethanol, place them in a clean quartz tube, place them in a belt throwing machine, and spray the melted liquid alloy on the high-speed rotating copper tube after extracting a high vacuum. Roll on, allowing the liquid to cool rapidly to form amorphous strips instantly. The belt swing machine needs to draw 7×10 -3 Pa. The speed of the copper roll needs to be controlled at 3500 rpm. The pressure difference between the quartz tube and the furnace body needs to be controlled at 0.3Pa to obtain Al ...

Embodiment 3

[0042] Weigh pure aluminum, pure titanium, pure copper and pure palladium, put them into an argon smelting furnace, put high-purity argon protective atmosphere into the high-purity argon gas protective atmosphere after the molecular pump pumps high vacuum, and smelt 4 times to make the internal composition of the alloy uniform and obtain Al 80 Cu 5 Ti 10 PD 5 Alloy ingots, then take out the alloy ingots and crush them, take the fragments and ultrasonically clean them with anhydrous ethanol, place them in a clean quartz tube, place them in a belt throwing machine, and spray the melted liquid alloy on the high-speed rotating copper tube after extracting a high vacuum. Roll on, allowing the liquid to cool rapidly to form amorphous strips instantly. The belt swing machine needs to draw 7×10 -3 Pa. The speed of the copper roll needs to be controlled at 4000 rpm. The pressure difference between the quartz tube and the furnace body needs to be controlled at 0.3Pa to obtain Al 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com