Method for improving biodegradability of organic silicon wastewater through two stages of ozone catalytic oxidation

A technology of ozone catalytic oxidation and ozone catalysis, which is applied in chemical instruments and methods, oxidized water/sewage treatment, water pollutants, etc. cost and other issues, to achieve the effect of improving biodegradability, improving catalytic effect, and saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

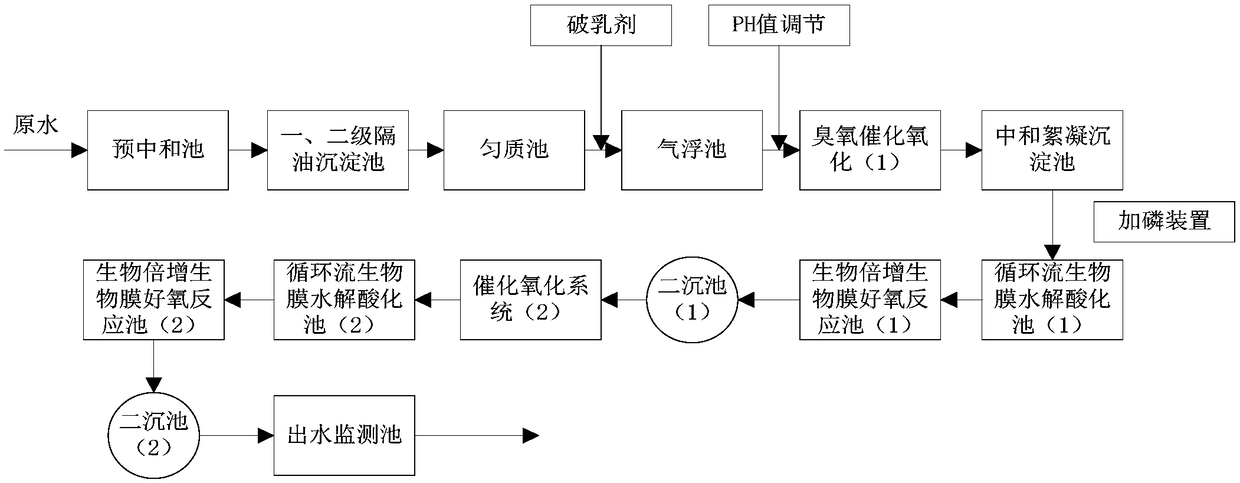

Method used

Image

Examples

Embodiment 1

[0030] After the organic silicon wastewater is pretreated, the pH value of the wastewater is adjusted to 6.8, so that the COD concentration of the organic silicon wastewater is controlled at 990mg / L;

[0031] serial number

index

value

1

pH

6

2

COD

990mg / l

3

BOD

≈0

[0032] Raw water with a pH of 6-8 enters the first-stage ozone catalytic oxidation tower, and the effluent is tested for COD. At this time, the detected value of COD is 835 mg / l, the value of BOD is 251 mg / l, the value of B / C is 0.301, and the removal rate of COD is 15.65%.

[0033] Among them, the first-stage ozone catalytic oxidation tower is filled with ozone catalytic oxidizer, which includes ZSM-5 molecular sieve, manganese oxide, copper oxide and ferric oxide with a mass ratio of 1:0.4:0.3:0.15.

[0034] The effluent is introduced into a section of circulating flow biofilm hydrolysis acidification tank and biomultiplication biofilm aerobic reaction...

Embodiment 2

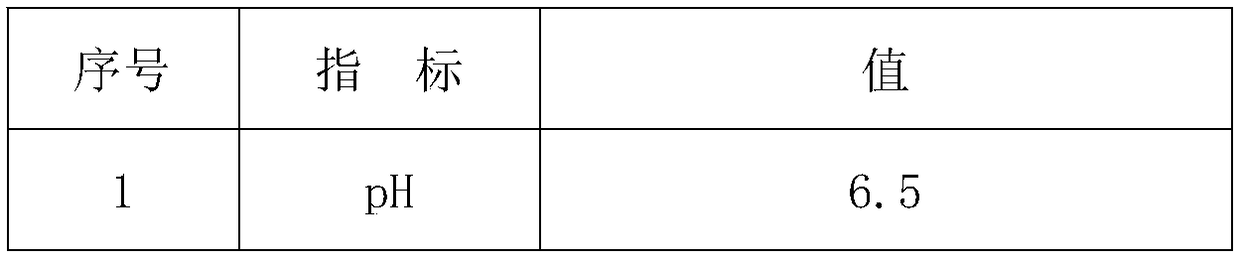

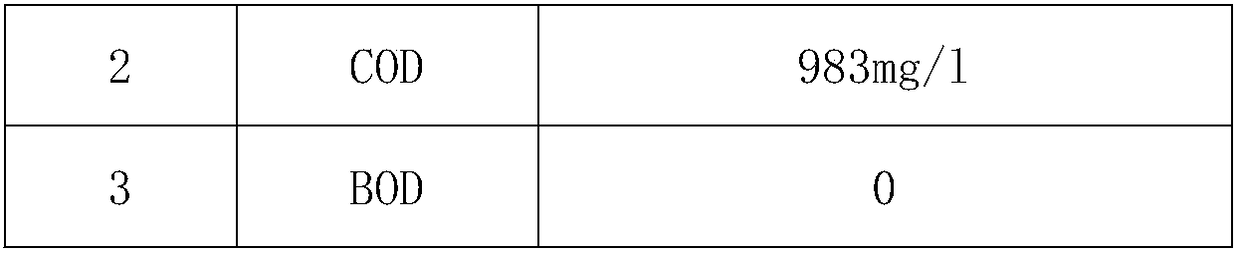

[0041] After the organic silicon wastewater is pretreated, the pH value of the wastewater is adjusted to 6.5, so that the COD concentration of the organic silicon wastewater is controlled at 983mg / L;

[0042]

[0043]

[0044] The raw water pH=6.5 enters the first-stage ozone catalytic oxidation tower, and the effluent is tested for COD. At this time, the detected value of COD is 820mg / l, the value of BOD is 261mg / l, the value of B / C is 0.318, and the removal rate of COD is 16.58%.

[0045] Among them, the first-stage ozone catalytic oxidation tower is filled with ozone catalytic oxidizer, which includes ZSM-5 molecular sieve, manganese oxide, copper oxide and ferric oxide with a mass ratio of 1:0.5:0.35:0.15.

[0046] The effluent is introduced into a section of circulating flow biofilm hydrolysis acidification tank and biomultiplication biofilm aerobic reaction tank, in which effluent COD=128mg / l, COD removal rate is 84.4%, BOD=0, B / C=0.

[0047] The effluent is precip...

Embodiment 3

[0053] 1) After the organic silicon wastewater is pretreated, the pH value of the wastewater is adjusted to 6.8, so that the COD concentration of the organic silicon wastewater is controlled at 976mg / L;

[0054] serial number

index

value

1

pH

6.8

2

COD

976mg / l

3

BOD

0

[0055] Raw water with a pH of 6.8 enters the first-stage ozone catalytic oxidation tower, and the effluent is tested for COD. At this time, the detected value of COD is 776mg / l, the value of BOD is 295mg / l, the value of B / C is 0.38, and the removal rate of COD is 20.50%.

[0056] Among them, the first-stage ozone catalytic oxidation tower is filled with ozone catalytic oxidizer, which includes ZSM-5 molecular sieve, manganese oxide, copper oxide and ferric oxide with a mass ratio of 1:0.6:0.45:0.15.

[0057] The effluent is introduced into a section of circulating flow biofilm hydrolysis acidification tank and biomultiplication biofilm aerobic reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com