Graphene-schiff base iron complex and synthesis method thereof

A technology of Schiff base iron and graphene, applied in chemical instruments and methods, compounds of group 4/14 elements of the periodic table, non-explosive/non-thermal agent components, etc., to achieve the effect of improving the catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

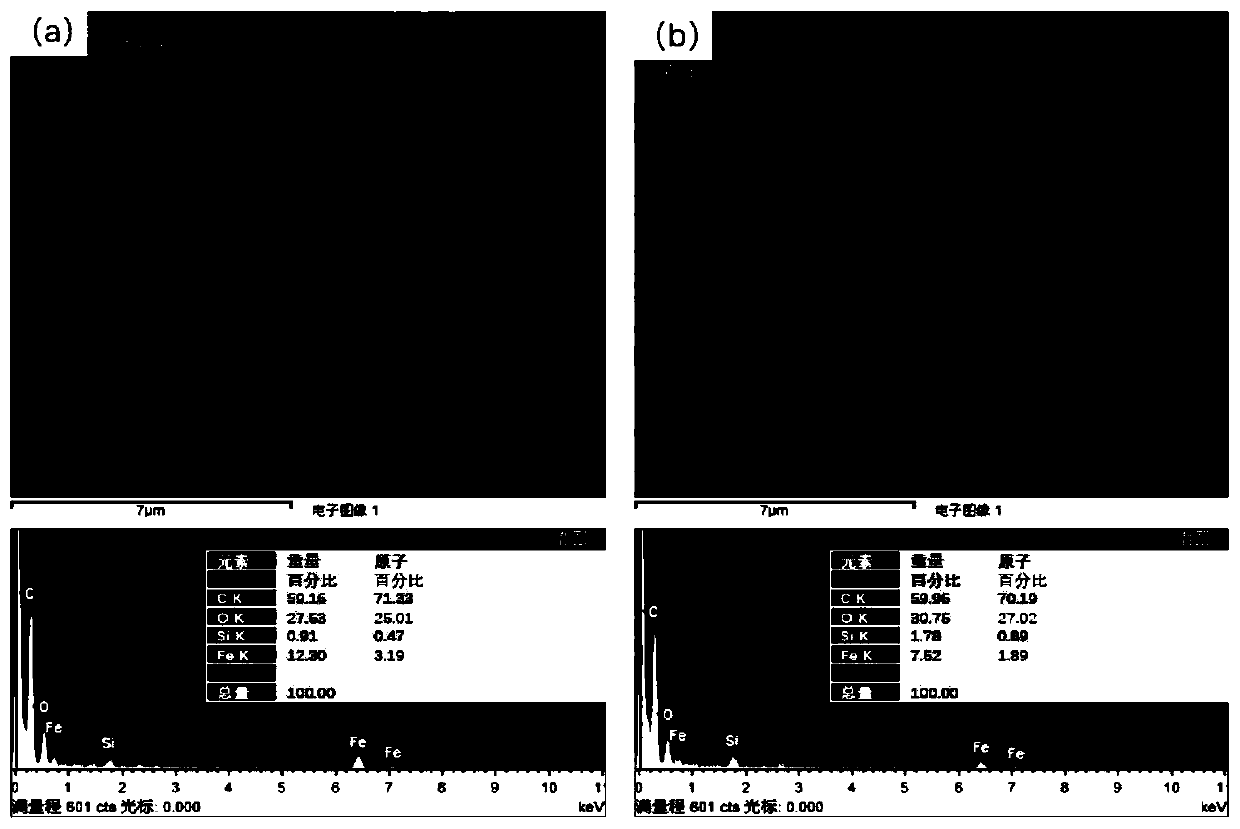

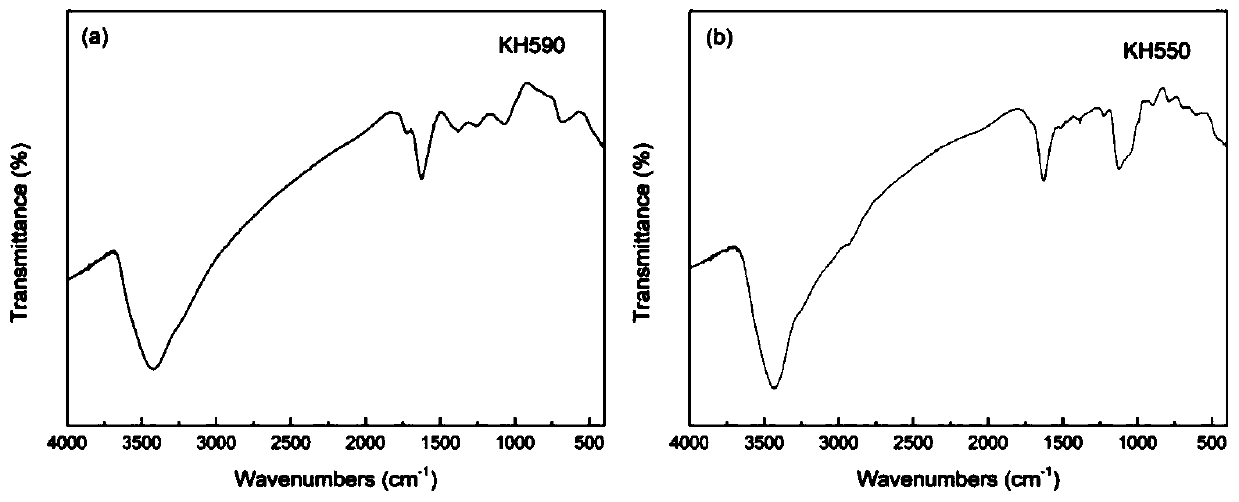

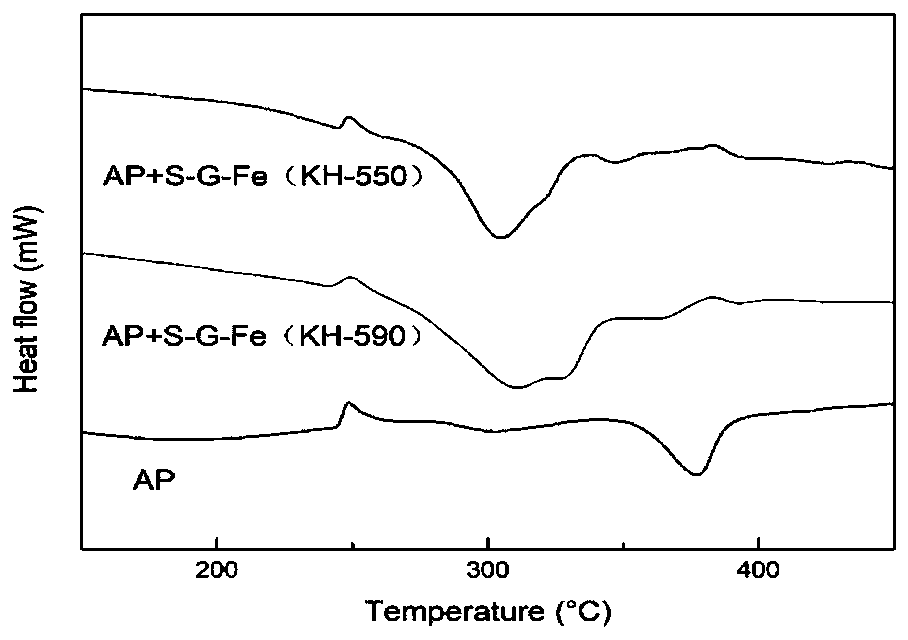

[0023] The morphology was characterized by a Quanta600 scanning electron microscope from Quantachrome in the United States, and the infrared characterization was performed by a Tensor27 Fourier transform infrared spectrometer from Bruker, Germany. ICP elemental analysis was used to characterize the iron content. The catalytic performance of graphene-Schiff base iron complexes on thermal decomposition of AP was characterized by NETZSCH 200F3 differential scanning calorimeter.

[0024] Synthesis of Graphene-Schiff Base Iron Complexes

[0025] (1) Synthesis of surface modified graphene oxide:

[0026] Ultrasonic dispersion of graphene oxide in absolute ethanol (1 mg·ml -1 , 1h), the dispersed graphene oxide ethanol dispersion was placed in a three-necked flask, and an appropriate amount of γ-mercaptopropyltrimethoxysilane (KH590) and γ-aminopropyltriethoxysilane (KH550 ) ethanol solution, reacted under reflux conditions (78° C.) for 2 h, cooled to room temperature after the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com