Composite sodium supplement additive and application thereof in sodium ion battery

A technology for compound sodium supplementation and additives, applied in secondary batteries, secondary battery repair/maintenance, circuits, etc., can solve the problems of low energy density and poor cycle stability of batteries, and achieve improved industrialization process, low cost, and improved The effect of catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

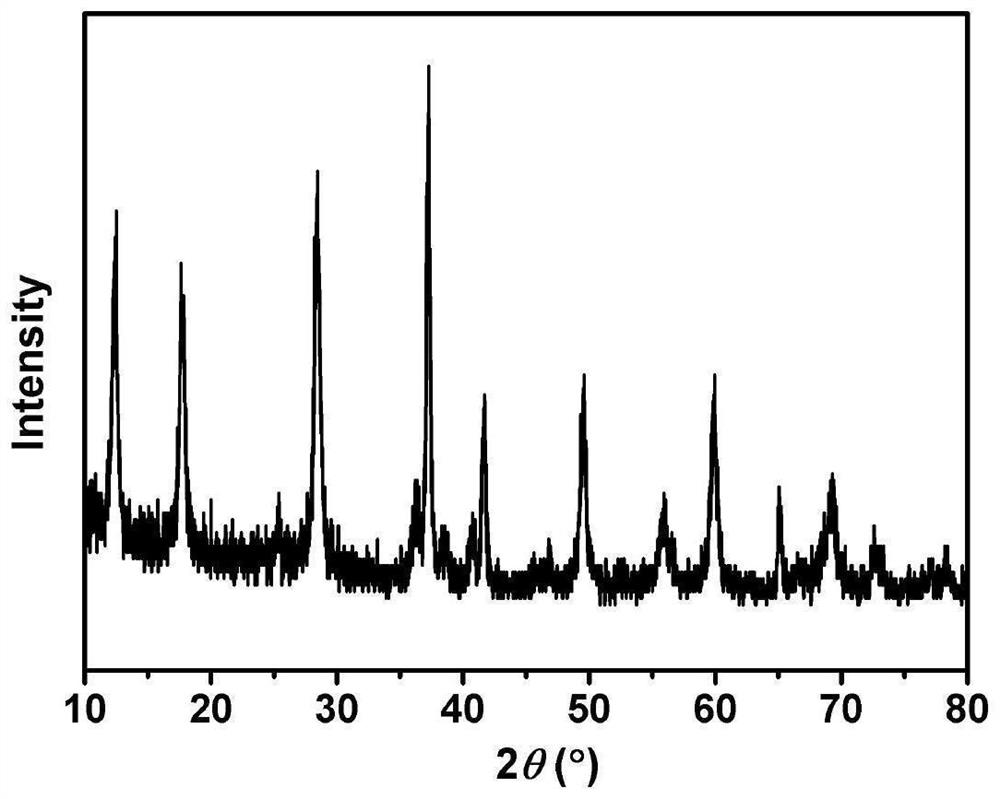

[0061] Preparation Example 1α-MnO 2 Catalyst Synthesis

[0062] Dissolve 3mmol manganese sulfate monohydrate in 15mL deionized water to form A solution, and then dissolve 6mmol potassium permanganate in 15mL deionized water to form B solution. Both A and B are dissolved in a water bath at 90°C at a constant temperature for 2 After hours, pour liquid A into liquid B, ultrasonicate for 0.5 hours, then transfer the mixed liquid into a 100mL hydrothermal reaction kettle, keep it warm at 150°C for 8 hours, then cool it down to room temperature naturally, filter with suction, wash, and dry to obtain α-MnO 2 , where the BET specific surface area test, α-MnO 2 The specific surface area is 54m 2 / g.

preparation example 2

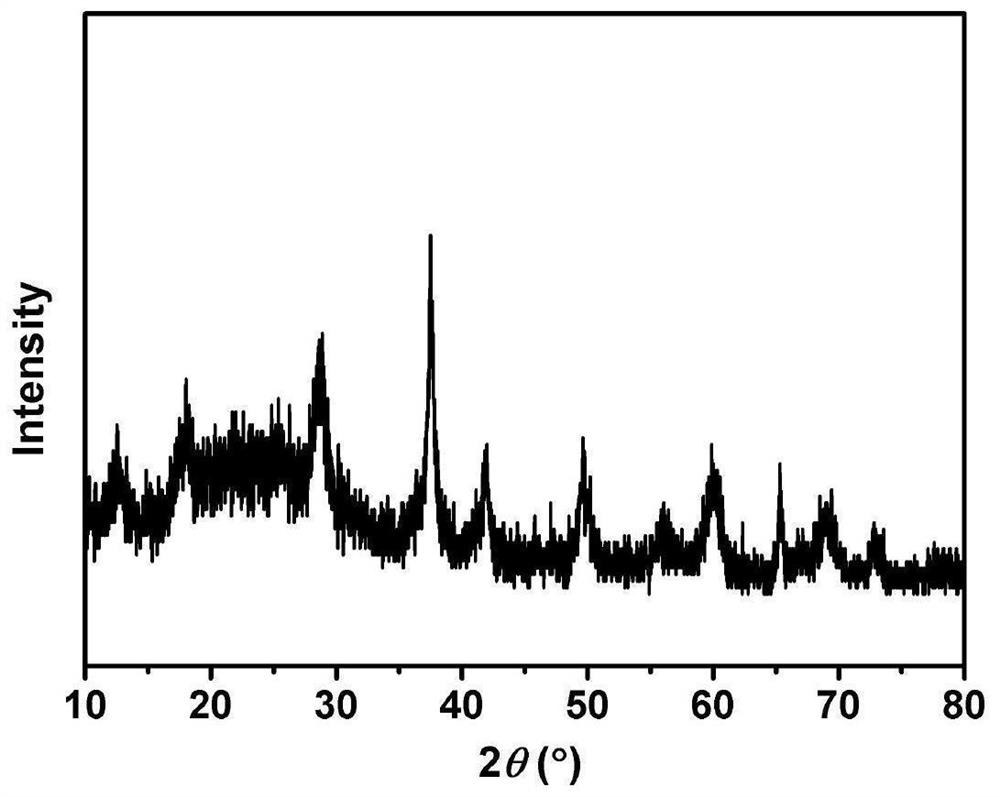

[0063] Preparation example 2α-MnO 2 / Synthesis of CNTs-OH catalyst

[0064] Get 0.2g hydroxylated multi-walled carbon nanotubes (long, specific surface area 174m 2 g) and 2g KMnO 4 Grind in a mortar first, then ultrasonically disperse in 60mL deionized water for 0.5 hours, then add 1mL concentrated sulfuric acid dropwise to the mixed solution, then stir in a water bath in an oil bath at 80°C for 2.5 hours, then cool naturally to room temperature, and filter with suction , washed and dried to obtain α-MnO 2 / CNTs-OH complex. Wherein, according to the thermogravimetric test, the loading of the active component (calculated as metal manganese) accounts for 48wt% of the catalyst.

[0065] After the BET specific surface area test, α-MnO 2 / CNTs-OH specific surface area reaches 198m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com