Efficient heterogeneous photo-Fenton and membrane bioreactor coupling process

A membrane bioreactor and reactor technology, applied in the field of water treatment, can solve the problems of membrane fouling, increase operating cost, and reduce biological decomposition efficiency, and achieve the effects of improving treatment efficiency, reducing operating pressure, and improving catalytic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

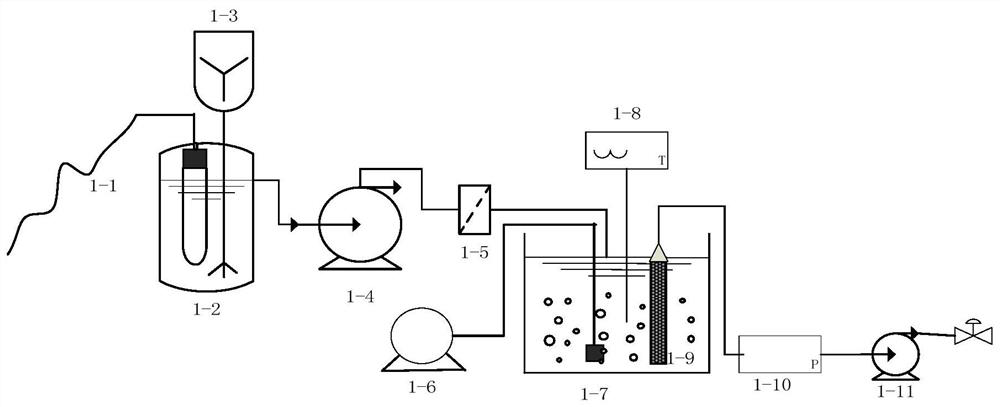

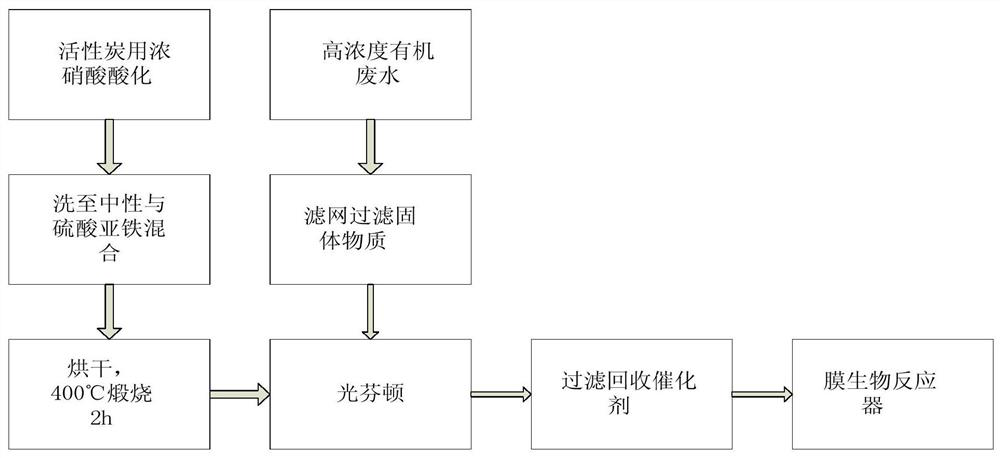

Method used

Image

Examples

Embodiment 1

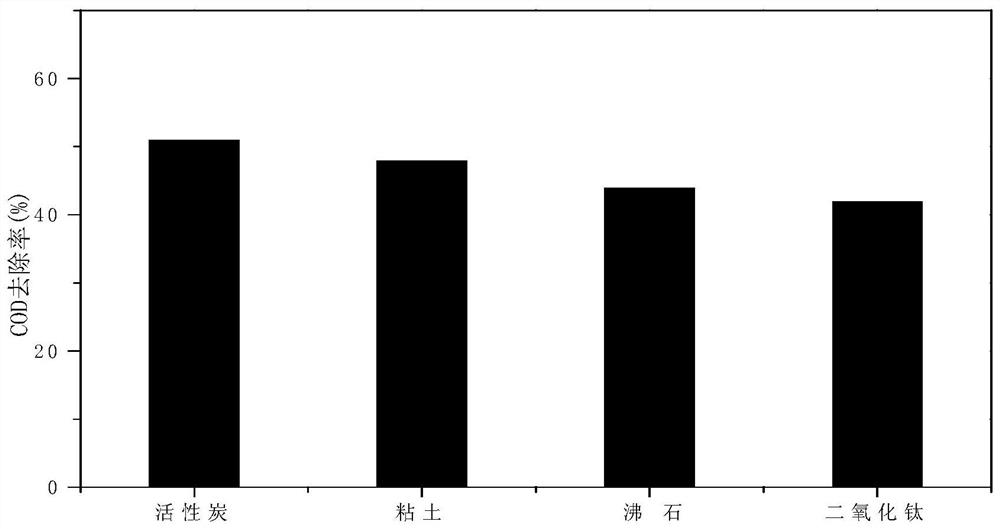

[0039]A new coupling process of heterogeneous photo-Fenton and membrane bioreactor was used to treat printing and dyeing wastewater, and the COD of the photo-Fenton reactor and membrane bioreactor effluent and the change of membrane flux with time were measured. The operating conditions of the photo-Fenton reactor: 5000ml of high-concentration printing and dyeing wastewater, adding 1.8g of catalyst, ultraviolet light for 2h, and recycling the catalyst ten times. The operating conditions of the membrane bioreactor: adopt intermittent pumping mode, pump for 8 minutes, stop for 2 minutes, hydraulic retention time 24 hours, reactor volume 40L, PVDF microfiltration membrane, transmembrane pressure difference between 0.04MPa, sludge concentration between About 5000mg / L. image 3 Photo-Fenton catalysts prepared by activated carbon, clay, zeolite, and titanium dioxide as supporting materials were used to remove COD from printing and dyeing wastewater by photo-Fenton. The results showe...

Embodiment 2

[0041] A new coupling process of heterogeneous photo-Fenton and membrane bioreactor was used to treat leather wastewater, and the COD of the effluent from photo-Fenton reactor and membrane bioreactor was determined. The operating conditions of the photo-Fenton reactor: 5000ml of high-concentration leather wastewater, adding 1.8g of catalyst, UV light for 2h, and recycling the catalyst ten times. The operating conditions of the membrane bioreactor: adopt intermittent pumping mode, pump for 8 minutes, stop for 2 minutes, hydraulic retention time 24 hours, reactor volume 40L, PSF ultrafiltration membrane, transmembrane pressure difference between 0.04, sludge concentration 5000mg / L or so. Depend on Figure 7 It can be seen that the COD removal rate of the photo-Fenton process remains at about 50%, and the coupling system uses ultrafiltration membranes instead of microfiltration membranes, and the COD removal rate reaches from about 90% to more than 97%.

[0042] Only the membr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com