Spraying method of titanium dioxide photocatalyst and spraying equipment of spraying method

A technology of photocatalyst and titanium dioxide, which is applied in the direction of coating, spraying device, and device for coating liquid on the surface, etc. It can solve the problems of poor spraying of tubular profiles, easy deactivation of catalyst, and low catalytic efficiency. It is not easy to achieve Effects of deactivation, catalytic effect improvement, and high degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

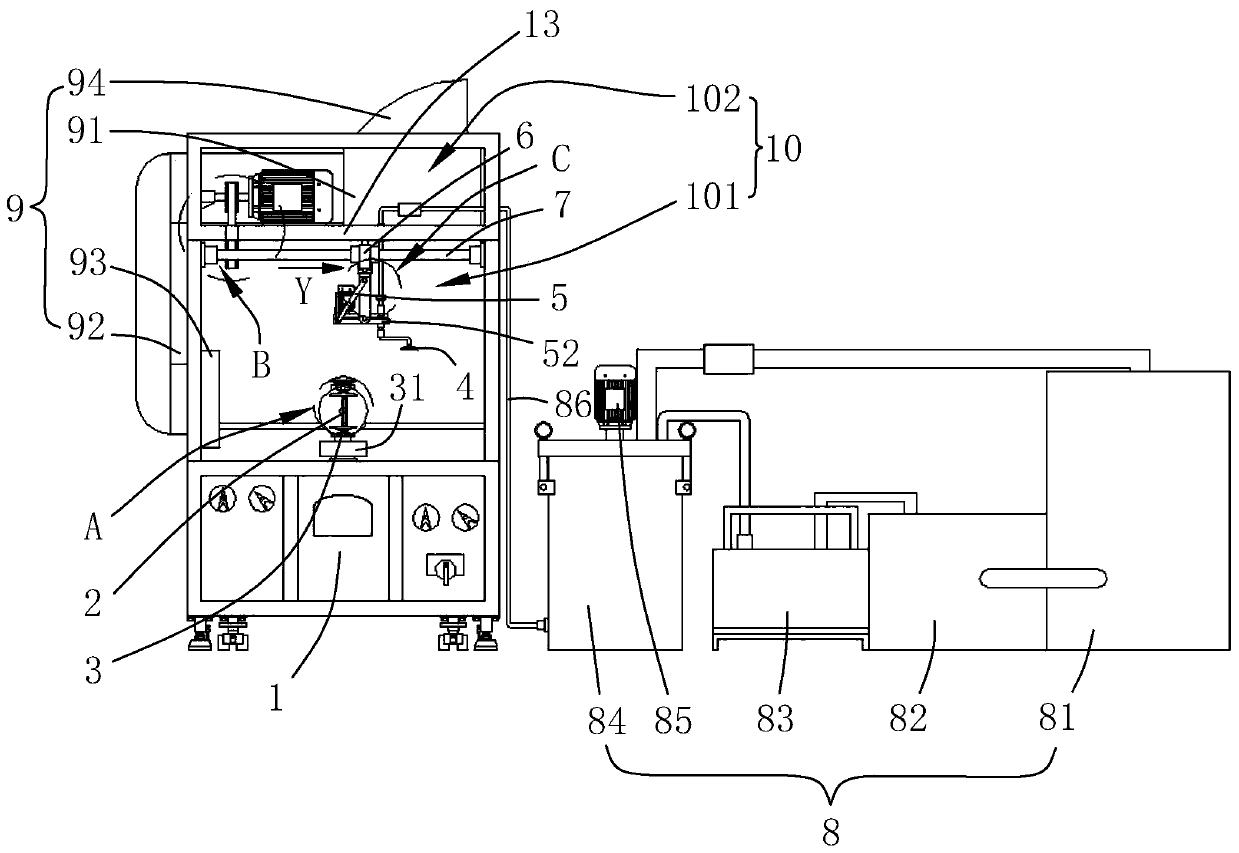

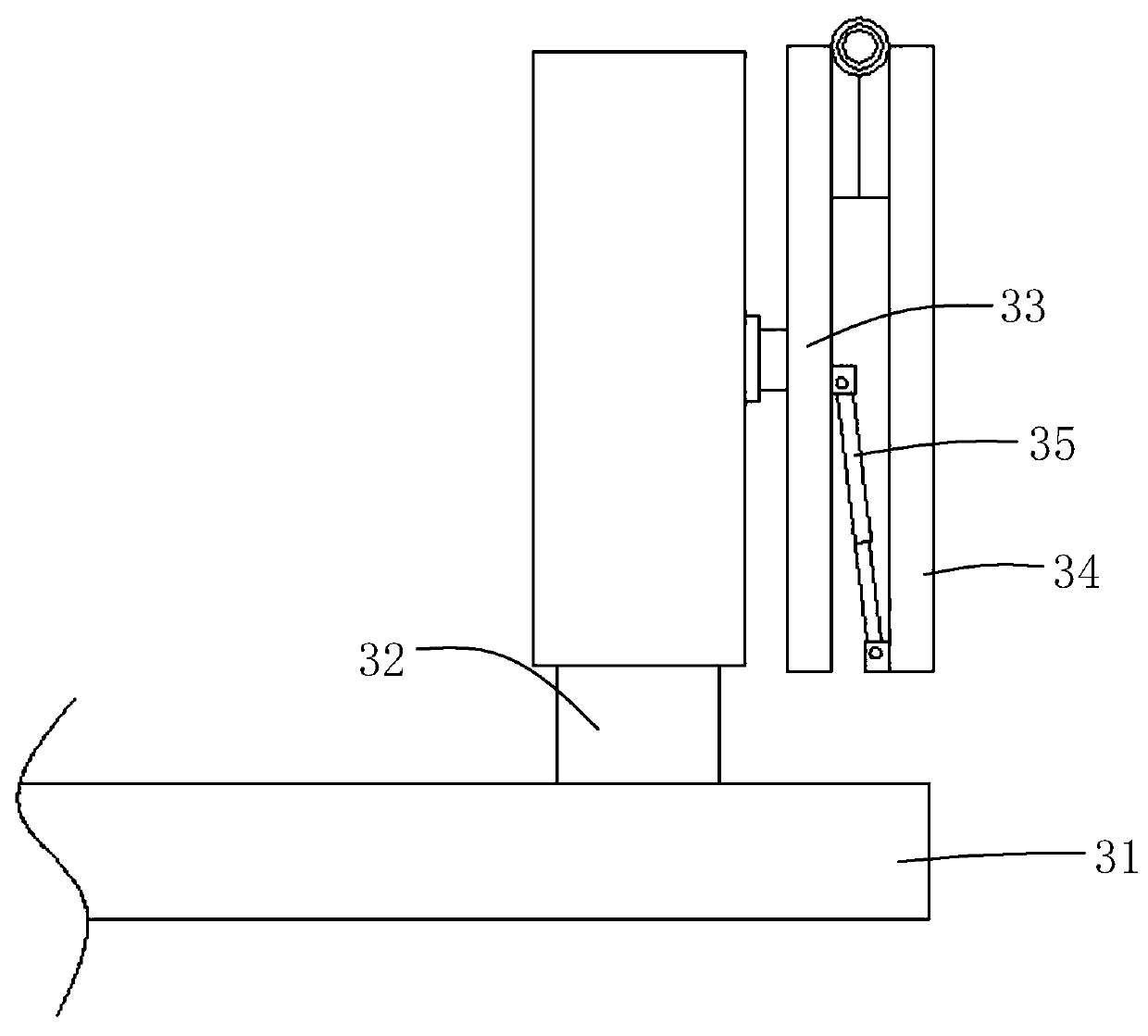

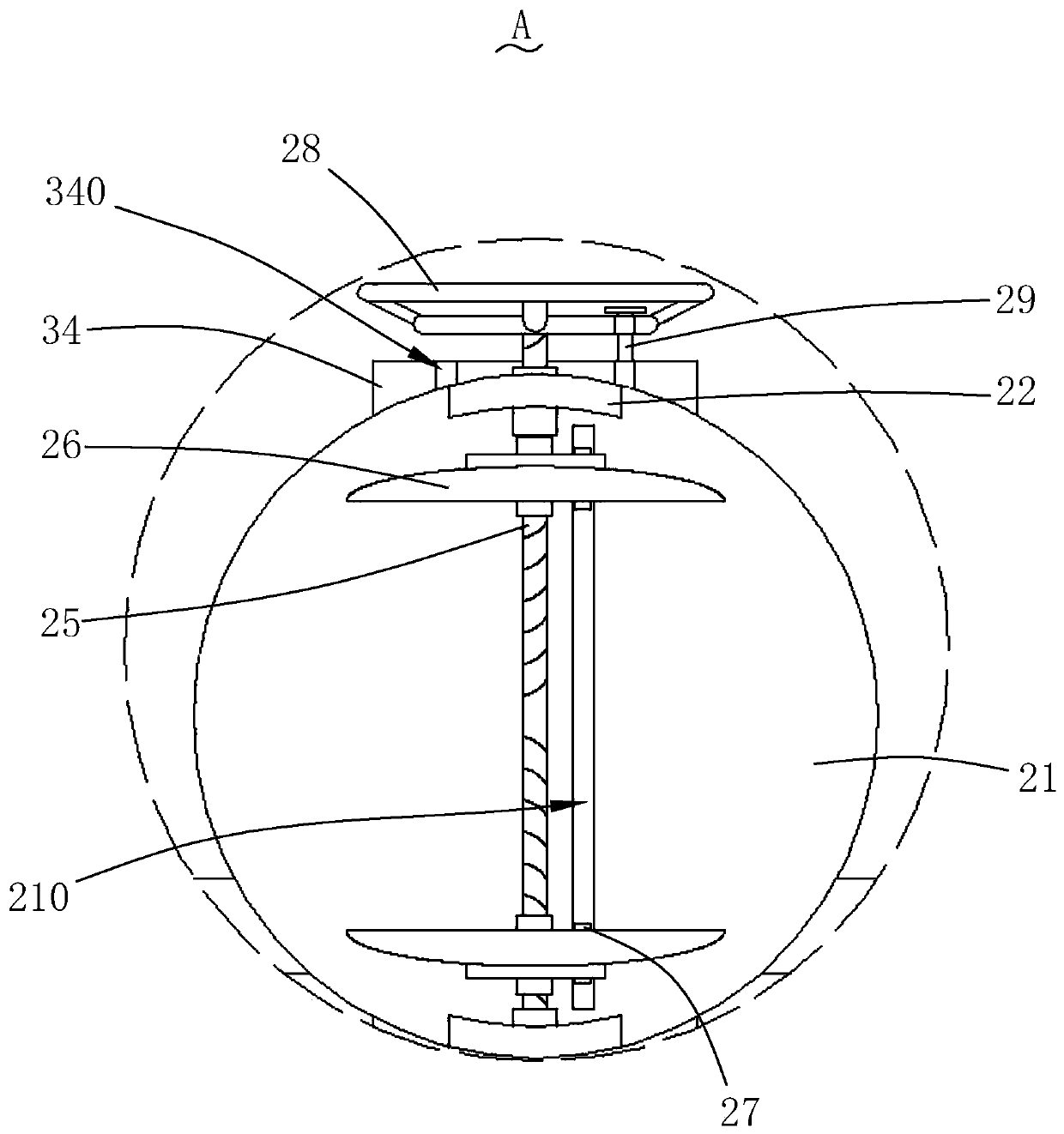

Method used

Image

Examples

Embodiment 1

[0063] Spray the profile with titanium dioxide photocatalyst added with precious metals, then place the profile in a closed container filled with formaldehyde, measure and record the formaldehyde content in the closed container, and irradiate the profile with light to catalyze the action of titanium dioxide photocatalyst, and start to degrade formaldehyde Pollutants, after standing for 8 hours, measure and record the formaldehyde content of the airtight container again, use this profile to repeatedly degrade formaldehyde pollutants, the time and light conditions are the same, record the number of degradations and calculate according to the formaldehyde content before and after each degradation Degradation rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com