Method for synchronously preparing hierarchical pore cobalt and nitrogen co-doped nanorod loaded platinum-cobalt alloy nano oxygen reduction electrocatalyst

A catalyst and reducing agent technology, applied in the field of electrochemical energy conversion electrocatalytic materials, can solve the problem of improving the catalytic effect of nano-catalytic materials for oxygen reduction reaction, limiting the large-scale production of MOFs materials, and the inability of active sites to obtain oxygen mass transfer channels and other problems, to achieve the effect of being suitable for large-scale production, excellent electrochemical performance, and improving catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

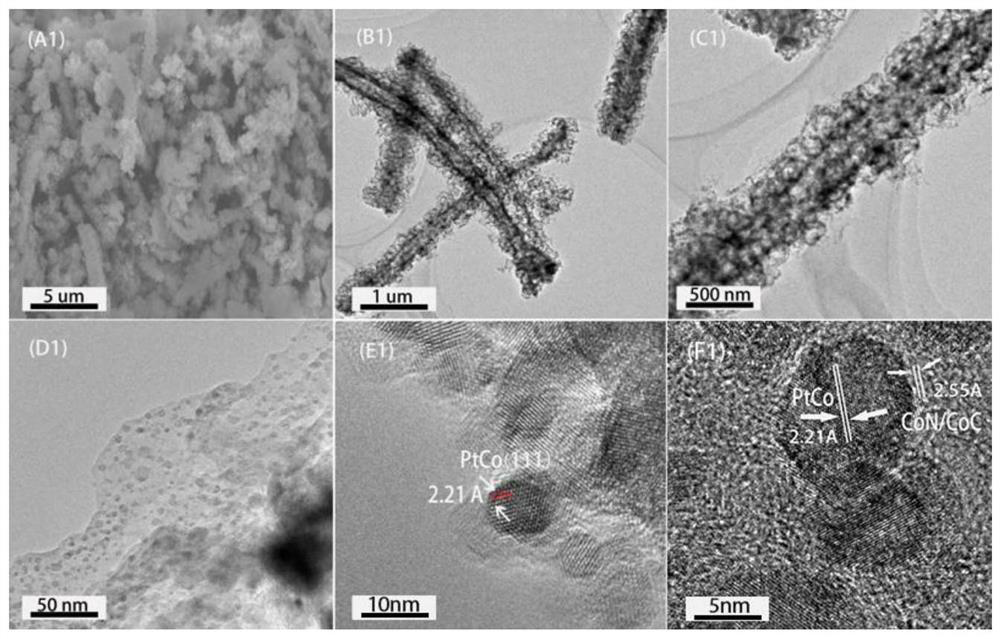

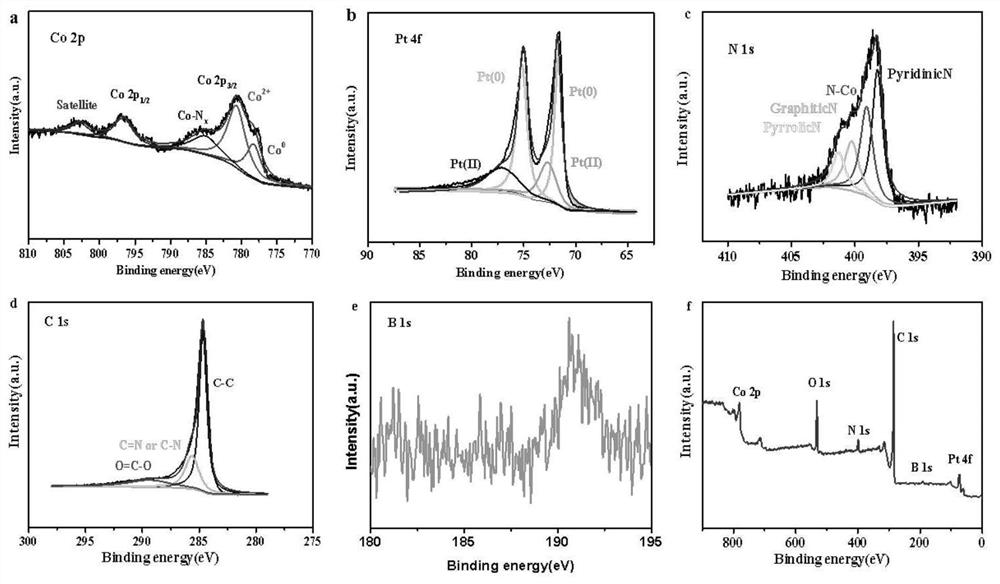

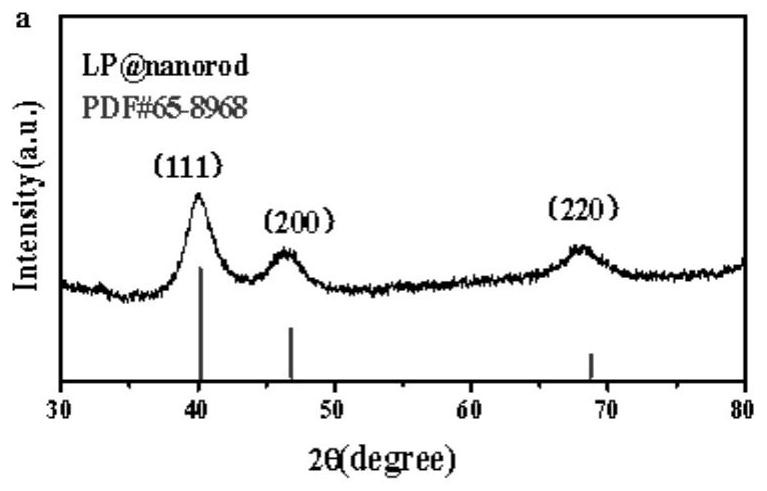

[0033] Embodiment 1 synchronous method prepares PtCo / Co-N-C catalyst

[0034] (1) Mix 168mg of cobalt nitrate hexahydrate and 56mg zinc nitrate hexahydrate under the conditions of room temperature and magnetic stirring and homogenize it with 20mL of ultrapure water; then add 20mL of 2-methylimidazole with a concentration of 10mg / mL solution, stirred for 2h to mix and react to obtain the first mixed solution; in this step, the Co / Zn precursor and 2-methylimidazole will form a chelate with a certain shape;

[0035] (2) Add 20 mL of sodium borohydride aqueous solution with a concentration of 10 mg / mL into the first mixed solution, and react for 2 hours while stirring to obtain the first black suspension; in this step, the addition of sodium borohydride will change the chemical The environment of the reaction (such as: changing the pH value, reducing the valence state of the metal ion), so that the coordination environment of the metal ion changes, the induced structure changes, a...

Embodiment 2

[0042] Embodiment 2 prepares Co-N-C nanorods

[0043] (1) Mix 168mg of cobalt nitrate hexahydrate and 56mg zinc nitrate hexahydrate under the conditions of room temperature and magnetic stirring and homogenize it with 20mL of ultrapure water; then add 20mL of 2-methylimidazole with a concentration of 10mg / mL Aqueous solution, stirred for 2h to mix and react to obtain the first mixed solution;

[0044] (2) Add 20mL of sodium borohydride aqueous solution with a concentration of 10mg / mL to the first mixed solution, and react for 2h while stirring to obtain the first black suspension, that is, an amorphous Co-B-O suspension

[0045] (3) Wash the first black suspension with ultrapure water, then centrifuge, wash with ethanol after centrifugation, and centrifuge again, repeat 3 times, and finally vacuum-dry the product obtained by centrifugation at 60°C for 8 hours, and then dry The final sample was annealed at a high temperature of 950° C. in an atmosphere of hydrogen-argon mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com