Catalyst composition, and ethylene-alpha-olefin polymer and preparation method thereof

A catalyst and composition technology, applied in the field of polyolefin elastomers, can solve problems such as low efficiency of ethylene-α-olefin polymers, and achieve the effects of improving catalytic effect, reducing cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

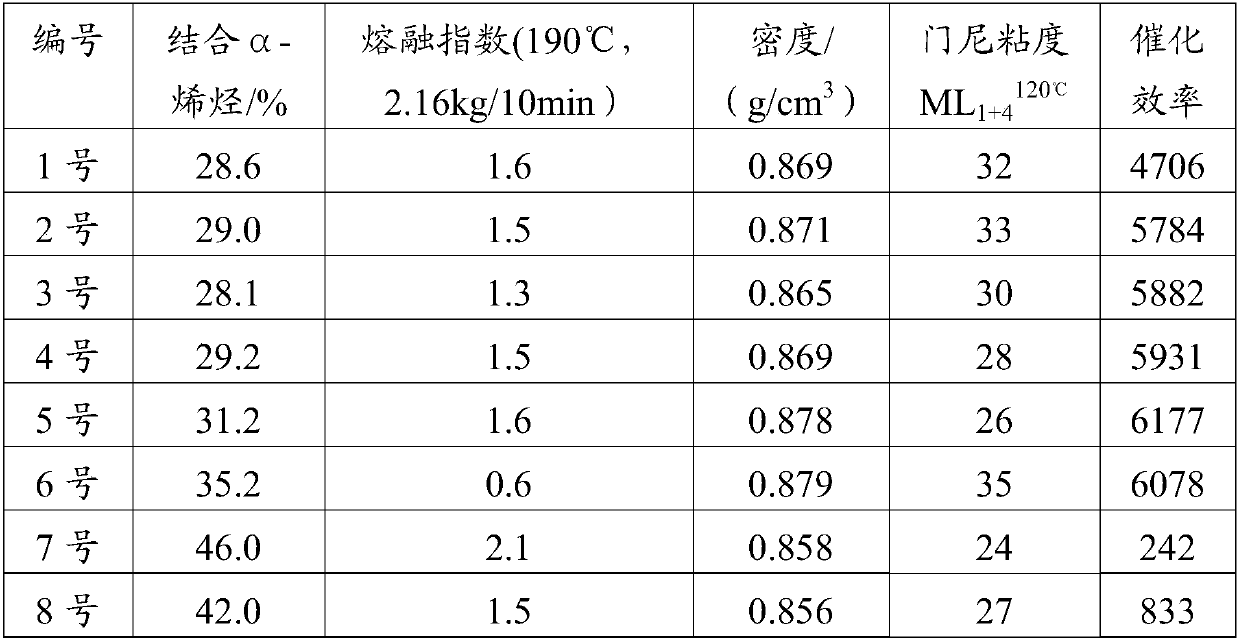

Examples

preparation example Construction

[0055] In a second aspect, an embodiment of the present invention provides a method for preparing an ethylene-α-olefin polymer, the method comprising:

[0056] Adding polymerization solvent and α-olefin to the polymerization kettle, filling ethylene into the polymerization kettle, and adding a molecular weight regulator, so that ethylene is dissolved in the polymerization solvent to saturation;

[0057] Adding the above-mentioned catalyst composition into the polymerization kettle, and at a preset temperature and a preset pressure, ethylene and α-olefin are polymerized to obtain a polymerization mixture;

[0058] adding a terminator to the polymerization mixture, followed by washing, distillation, and drying to obtain an ethylene-α-olefin polymer;

[0059] Wherein, the volume ratio of polymerization solvent to α-olefin is 12.5-50:1;

[0060] The molar ratio of ethylene to molecular weight regulator is 1:0.01~0.03;

[0061] The molar concentration of the vanadium-based cataly...

Embodiment 1

[0080]This embodiment provides an ethylene-α-olefin polymer, which is prepared by the following method: mixing ethylene and hydrogen at a molar ratio of 1:0.02 uniformly through a circulating compressor. The polymerization kettle with a volume of 5 L was vacuum treated for 1 hour, and then 2000 mL of hexane and 100 mL of 1-octene were added into the polymerization kettle. Start the circulation compressor, feed a mixture of ethylene and hydrogen into the polymerization kettle, and dissolve ethylene in hexane to reach saturation. Then add 10 mL of hexane solution containing 0.4 mmol 2,6-di-tert-butyl-p-methyloxyvanadyl dichloride, 4 mmol trichlorotriethyl dialuminum, 2 mmol ethyl trichloroacetate to the polymerization kettle, and make The molar ratio of Al in the alkylaluminum halide, V in the vanadium-based catalyst, and ethyl trichloroacetate is 10:1:5, the temperature of the polymerization kettle is controlled at 50°C, the pressure is 0.5MPa, and the polymerization reaction t...

Embodiment 2

[0082] This embodiment provides an ethylene-α-olefin polymer, which is prepared by the following method: mixing ethylene and hydrogen at a molar ratio of 1:0.01 by a circulating compressor to make a homogeneous mixture. The polymerization kettle with a volume of 5 L was vacuum treated for 1 hour, and then 2000 mL of hexane and 100 mL of 1-octene were added into the polymerization kettle. Start the circulation compressor, feed a mixture of ethylene and hydrogen into the polymerization kettle, and dissolve ethylene in hexane to reach saturation. Then add 10mL hexane solution containing 0.4mmol 2,6-di-tert-butyl-p-methyloxyvanadyl dichloride, 4mmol trichlorotriethyldialuminum, 1.2mmol ethyl trichloroacetate to the polymerization kettle, and The molar ratio of Al in the alkylaluminum halide, V in the vanadium-based catalyst, and ethyl trichloroacetate is 10:1:3, the temperature of the polymerization kettle is controlled at 55°C, the pressure is 0.7MPa, and the polymerization react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com