System for improving molecular weight distribution of middle-molecular polyisobutene

A technology of molecular weight distribution and polyisobutylene, which is applied in the direction of feeding devices, chemical/physical/physical chemical processes, chemical instruments and methods, etc., can solve the problems of restricting the development of polyisobutylene industry and the inability of products to enter the international high-end application market, etc. To achieve the effect of improving the catalytic effect and reducing the reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

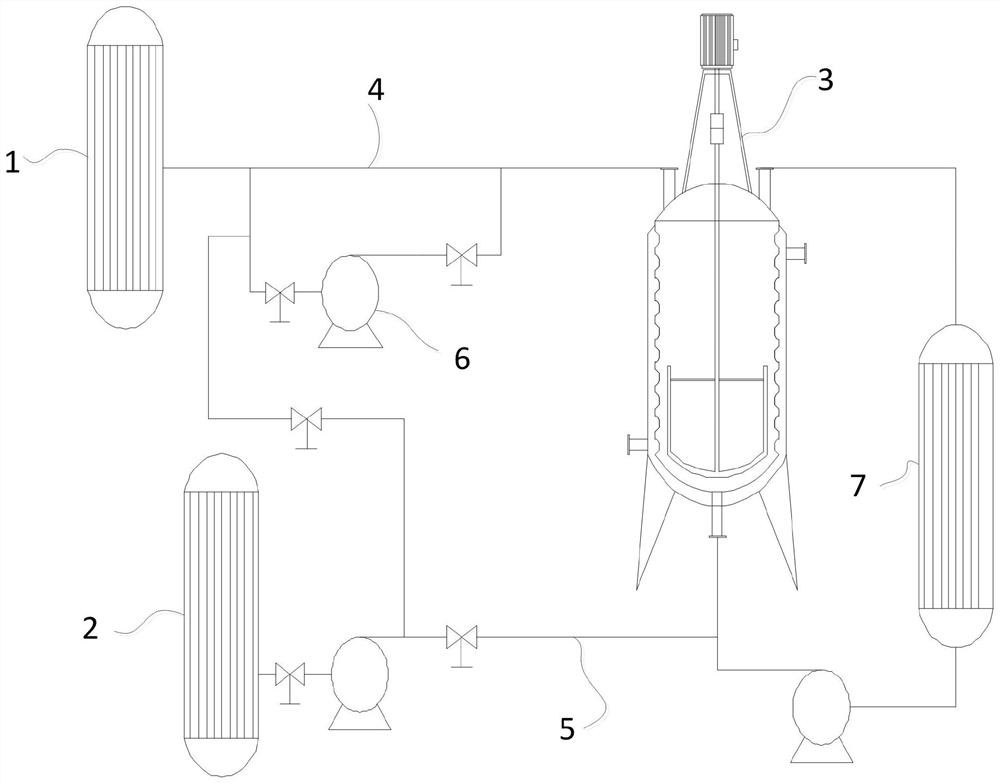

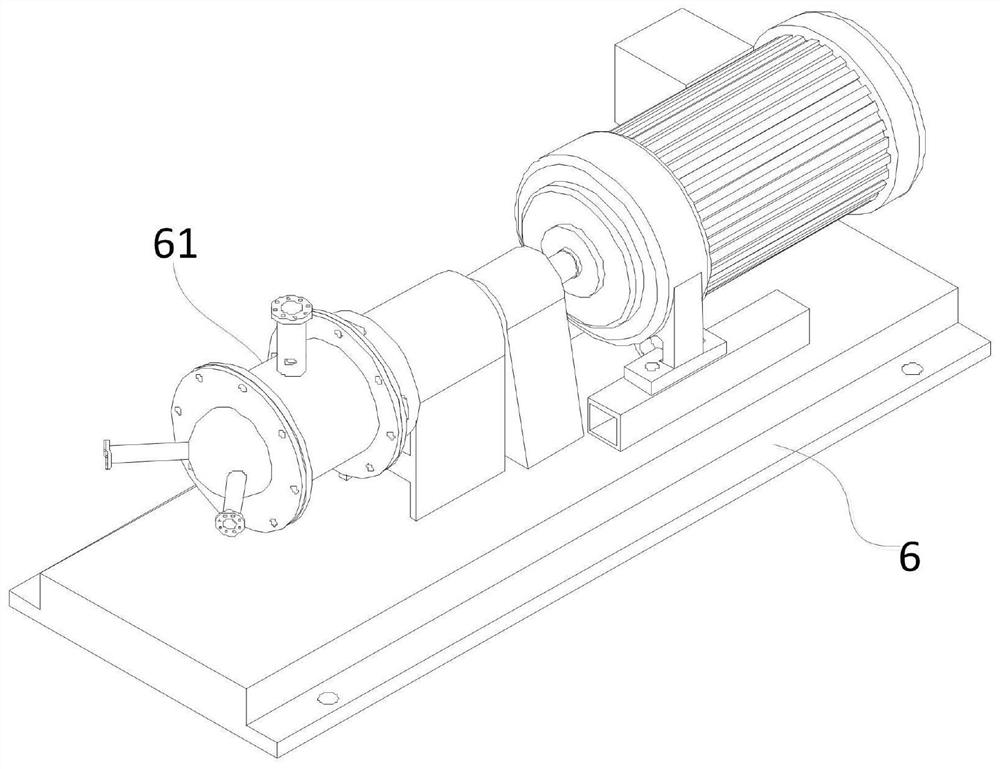

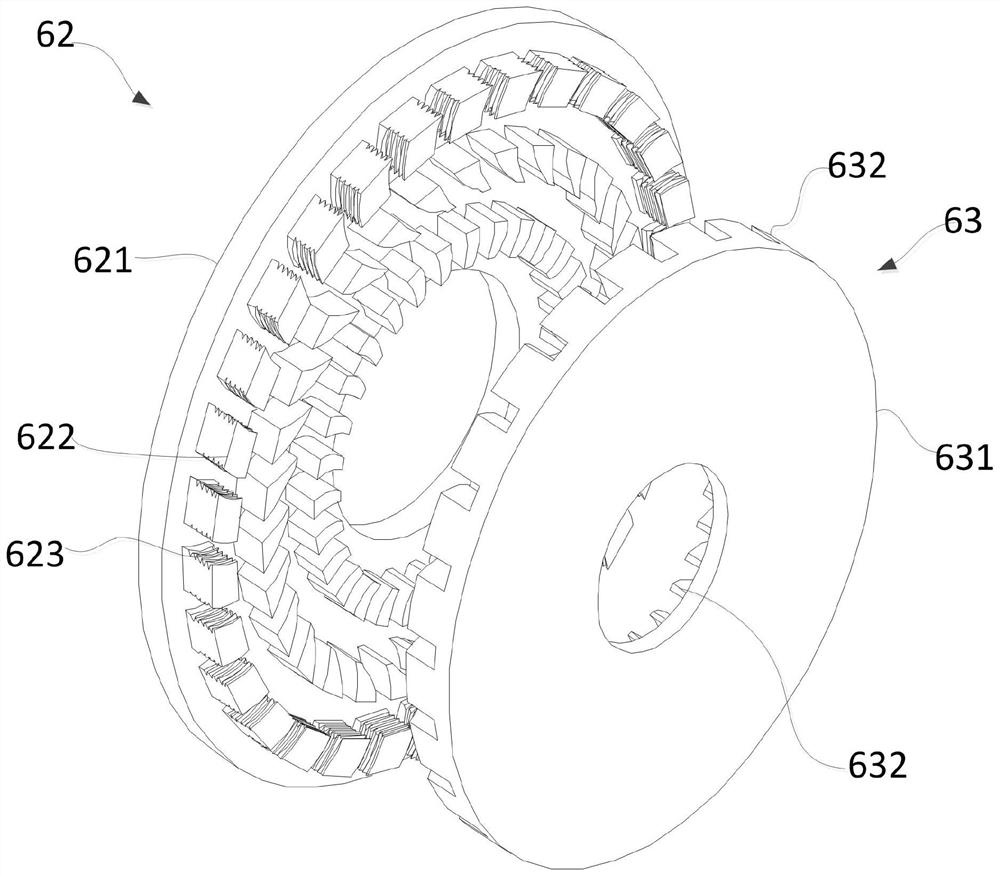

[0024] Example 1, such as Figure 1 ~ 5 As shown, the present embodiment is intended to provide a molecular weight distribution improvement system in which the molecular polyisobutylene molecular weight is distributed, and the molecular weight of the medium polyisobutylene molecular weight is distributed over 3.5 or less. In this regard, the present embodiment from three angles to existing technologies Performance: 1 The raw material mixture is mixed more uniform, and the catalytic effect of the auxiliary catalyst; 3, isobutylene polymerization belongs to the cationic polymerization reaction, which is characterized by fast polymerization speed and instant release a large amount of reaction heat. The polymerization needs to be carried out at low temperatures. If the heat is not quickly removed, the polymer molecular chain will be shorter, and the small molecular weight product is large, and the degree of demand, even the polymerization can not be completed, and the heat accumulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com