Bitangent circle reactor applied to urea pyrolysis to produce ammonia

A technology of reactor and double tangent circle, which is applied in the preparation/separation of ammonia, ammonia compounds, chemical instruments and methods, etc. It can solve the problems of cost loss, damage to pyrolysis equipment, insufficient pyrolysis, etc., and slow down the passing speed , prolong the residence time, strengthen the effect of catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

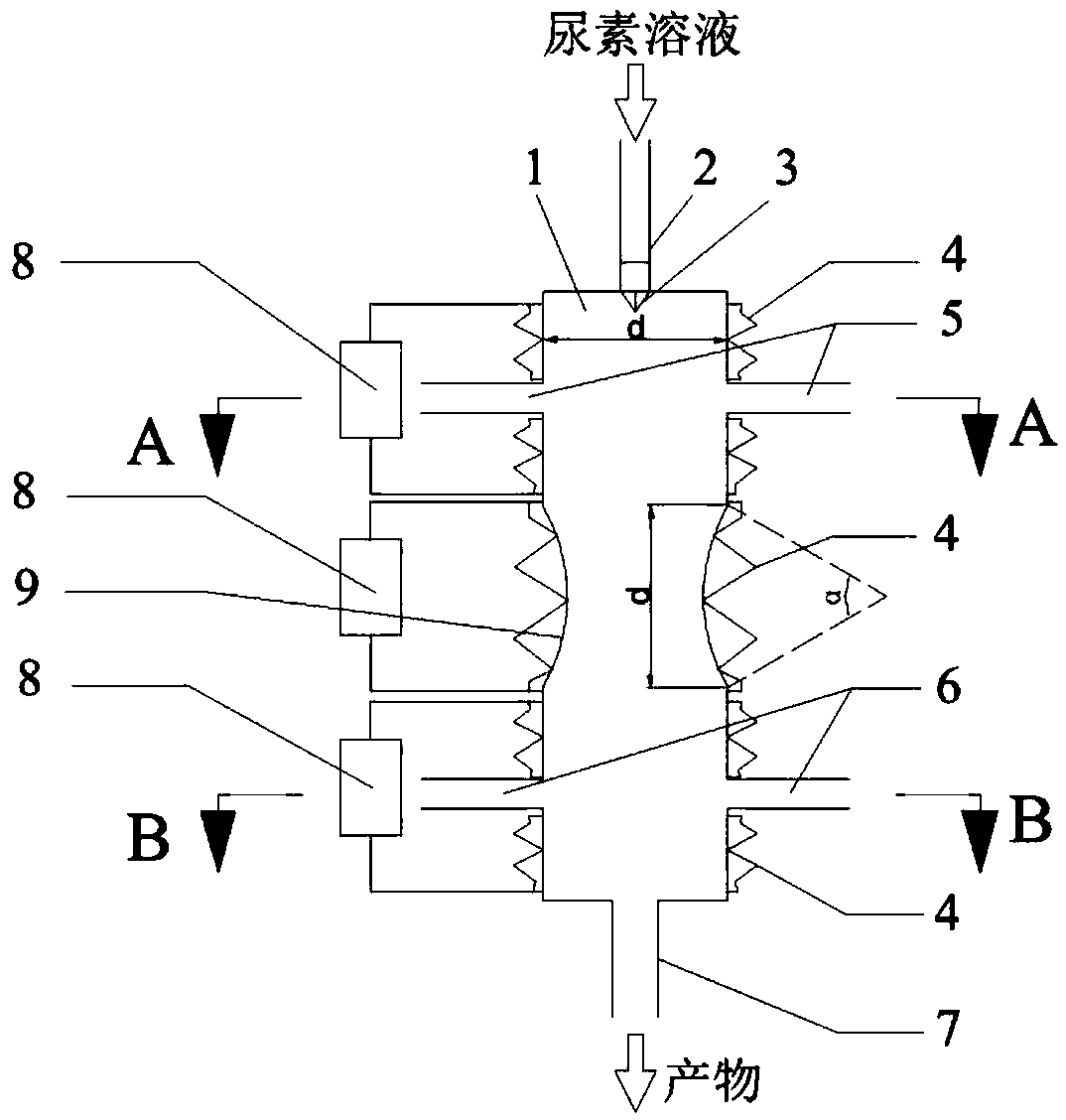

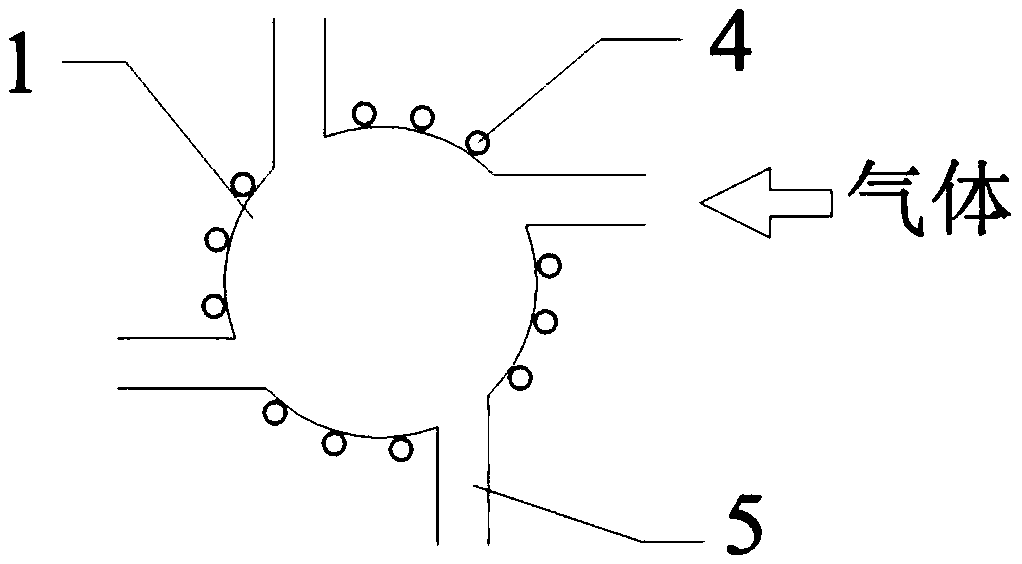

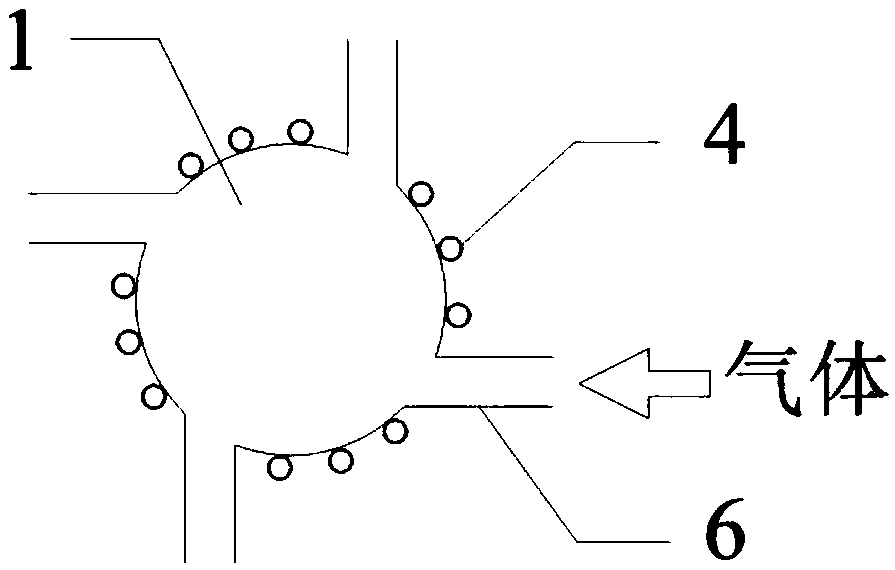

[0026] Such as figure 1 As shown, the double tangential circular reactor for urea pyrolysis ammonia production of the present invention includes a reactor body 1 made of aluminum cylinder, and the upper part of the reactor body 1 is provided with a urea solution inlet 2 connected to its inner cavity , the urea solution inlet extends into the reactor body; the lower part of the reactor body 1 is provided with a decomposition product outlet 7 . The side of the reactor body 1 is provided with two sets of upper and lower gas inlets 5 and 6 arranged in a swirl tangential circle, for introducing air or flue gas into the reactor body 1 . The outside of the reactor body 1 is wrapped with three s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com