Method preventing abnormal charging of blade charging machine

A feeding machine, abnormal technology, applied in the direction of tobacco preparation, application, tobacco, etc., can solve the problems of no feeding system status monitoring method, and the inability to strictly guarantee the feeding accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

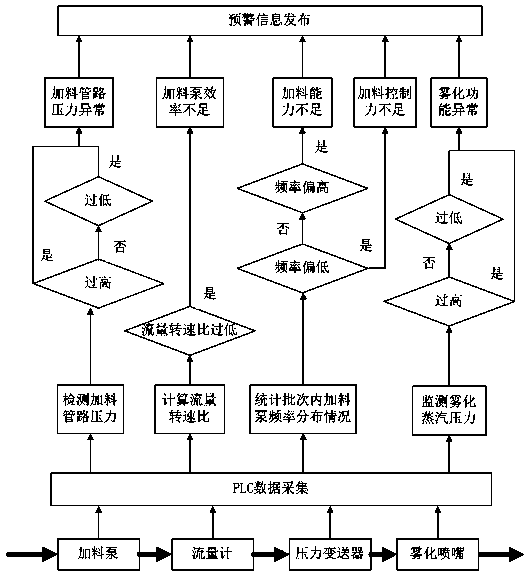

[0051] The invention is described in detail below in conjunction with accompanying drawing:

[0052] A method for preventing abnormal feeding of a blade feeder, comprising the following steps:

[0053] Step 1. Use the PLC controller to realize the data acquisition of the operating frequency of the feeding pump, the feeding flow rate of the flow meter, the pressure of the feeding pipeline and the steam pressure of the atomizing nozzle;

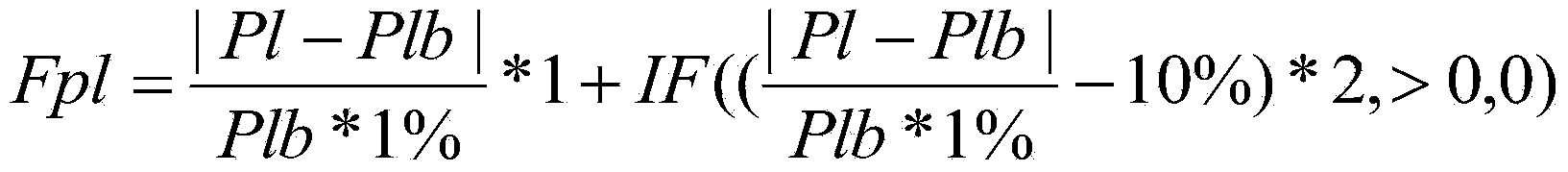

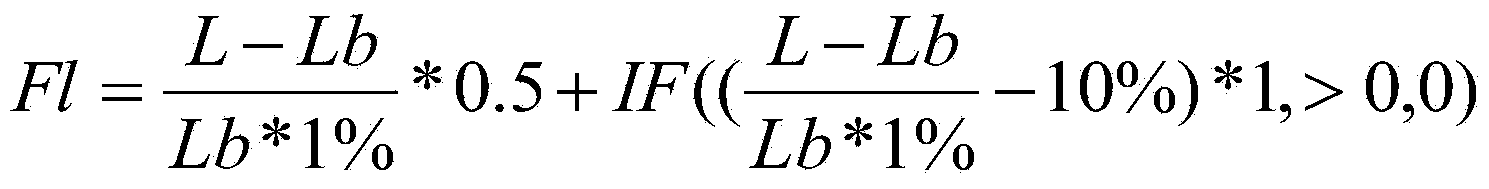

[0054] Step 2 compares the collected feeding pipeline pressure with the theoretical value in the pipeline pressure characteristic curve, and the theoretical value is obtained from the corresponding table according to different types of feed liquids and feed liquid flow rates. If the pipeline pressure is lower or higher than the theoretical value, 1 point will be deducted for every 1% lower (higher) than 5%, and the deduction will be doubled, that is, 2 points will be deducted for every 5% lower. The overall reduction of pipeline pressure is; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com