Horizontal numerical-control double-end-milling rear axle housing plane clamp

A rear axle housing and horizontal technology, which is applied in the field of horizontal CNC double-end milling rear axle housing steel plate support fixtures, can solve the problems of difficult to guarantee product quality, low efficiency, and the plane cannot be fed multiple times, so as to improve the use of Longevity and the effect of ensuring machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

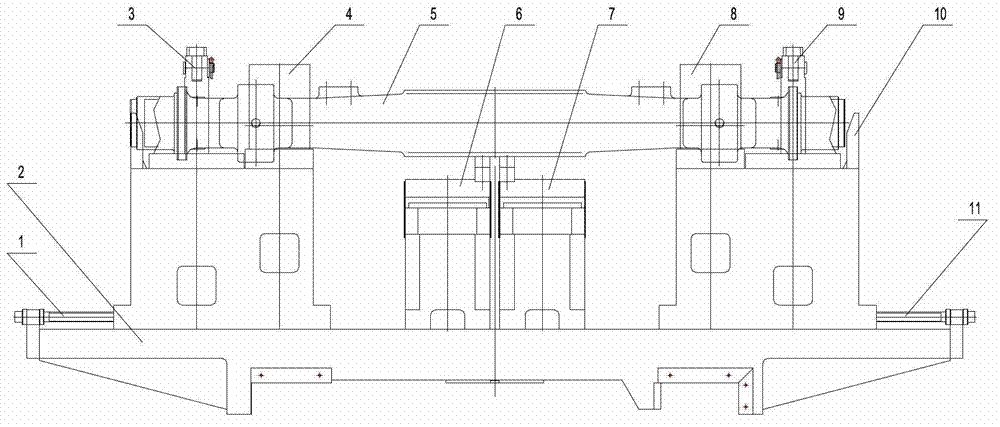

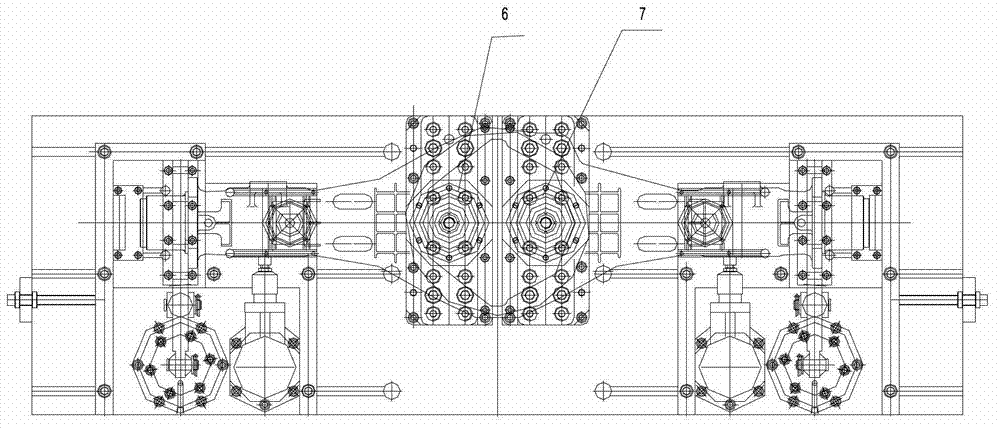

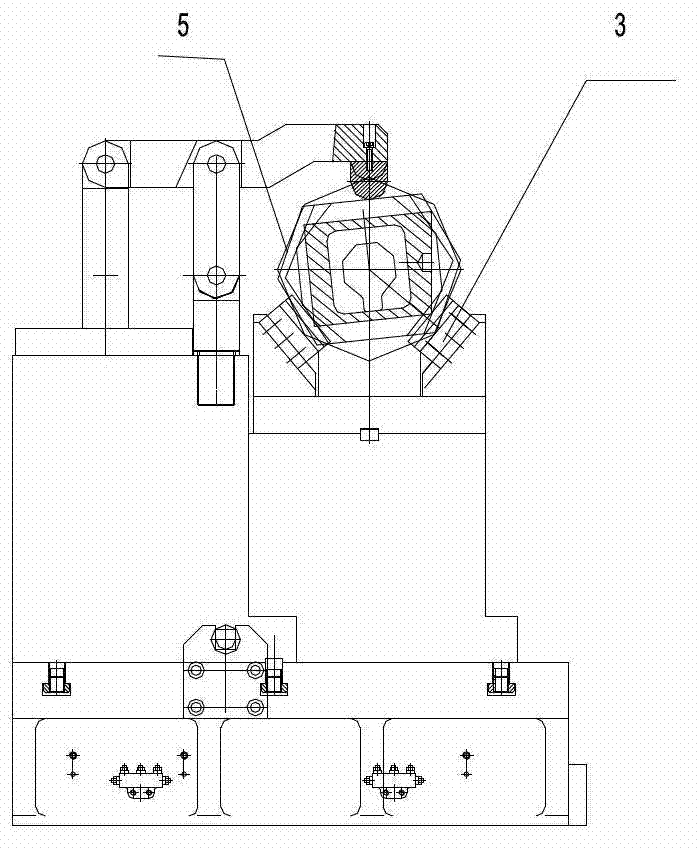

[0016] like figure 1 -3 shows a horizontal CNC double-end milling rear axle housing steel plate support fixture, which includes a fixture base 2, two ends of the fixture base are symmetrically provided with positioning and clamping devices 3 and 9, and the outer ends of the positioning and clamping devices at both ends are respectively There are adjusting screws 1 and 11, which are used to adjust the position of the positioning and clamping device on the fixture base. The lower part of the rear axle housing steel plate support 5 is provided with the rear axle housing steel plate support upper plane angle positioning device 6 and the rear axle housing The lower plane angle positioning device 7 of the steel plate support, and the workpiece end positioning device 10 is provided on the positioning and clamping device at the end of the steel plate support of the rear axle housing.

[0017] Preferably, the inner side of the positioning and clamping device is provided with auxiliary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com