Patents

Literature

47results about "Milling equipments" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

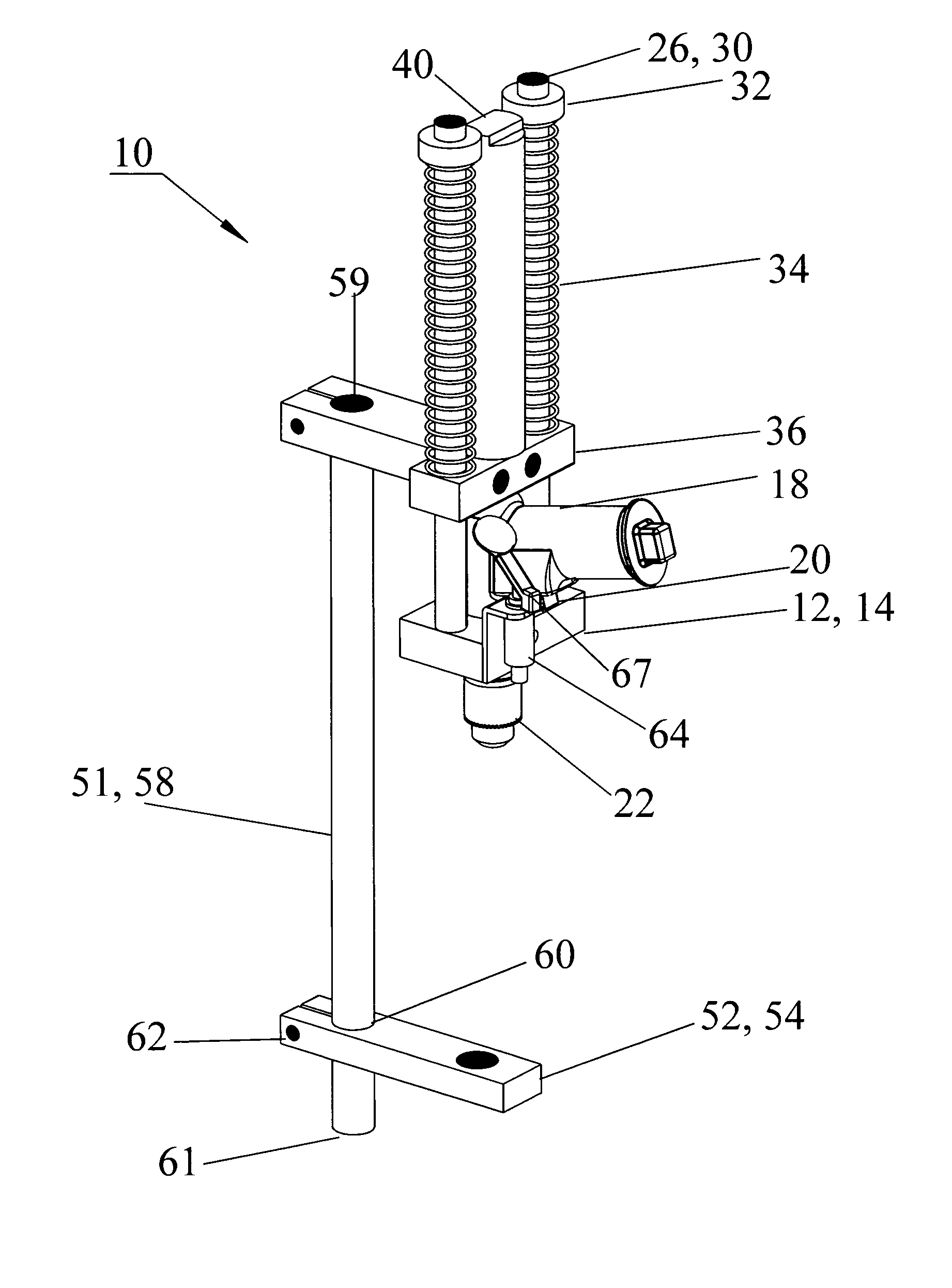

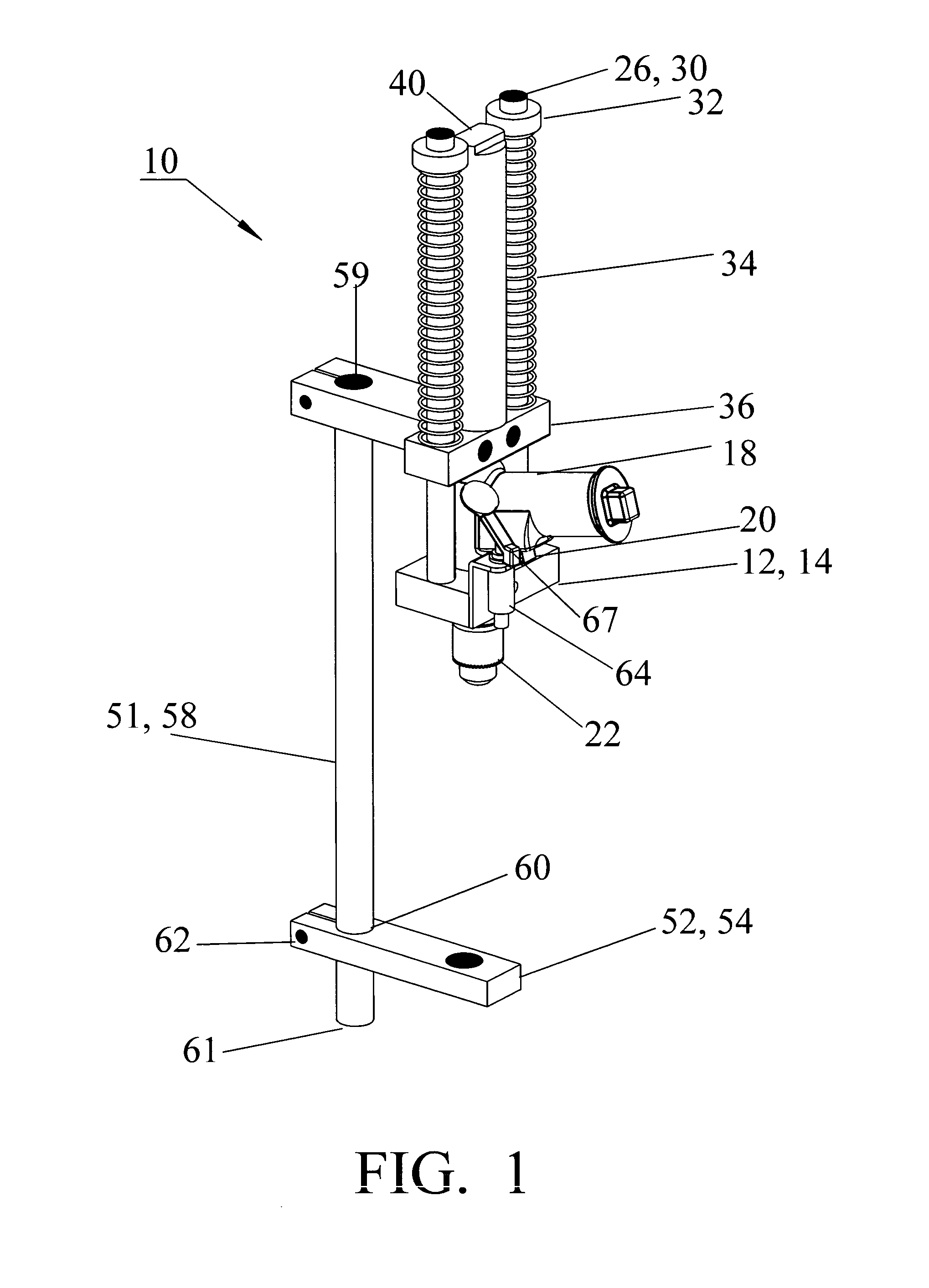

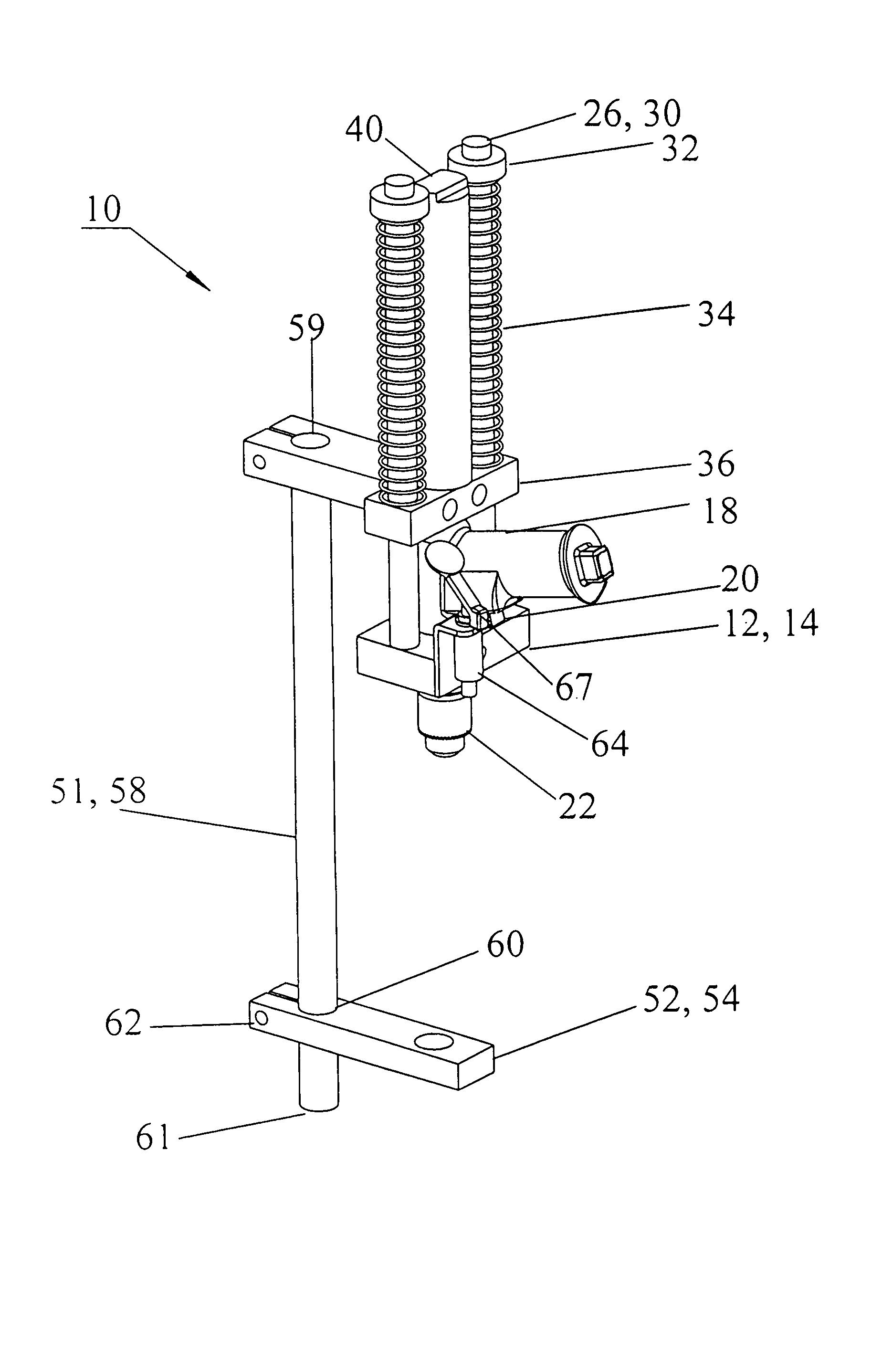

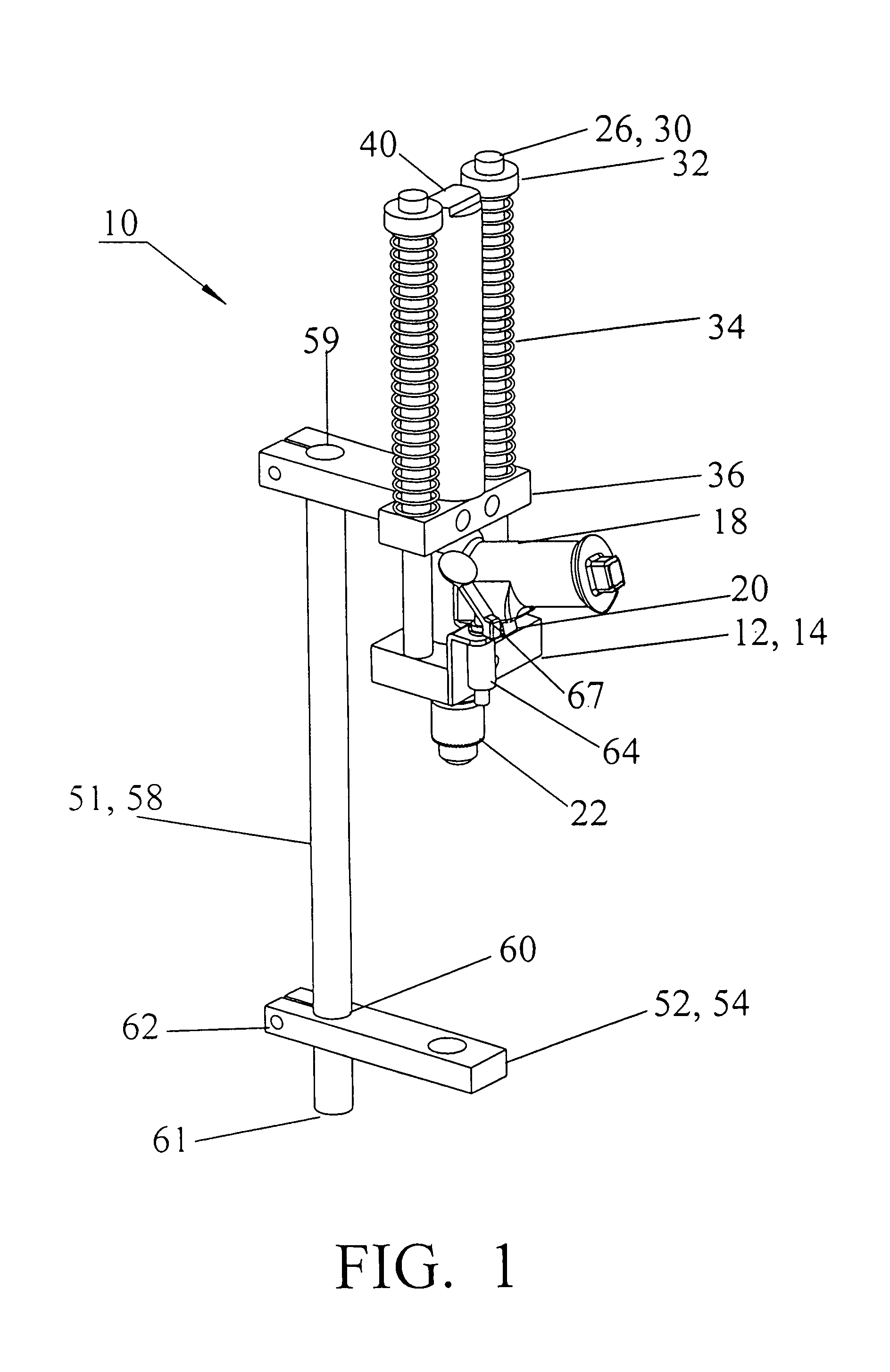

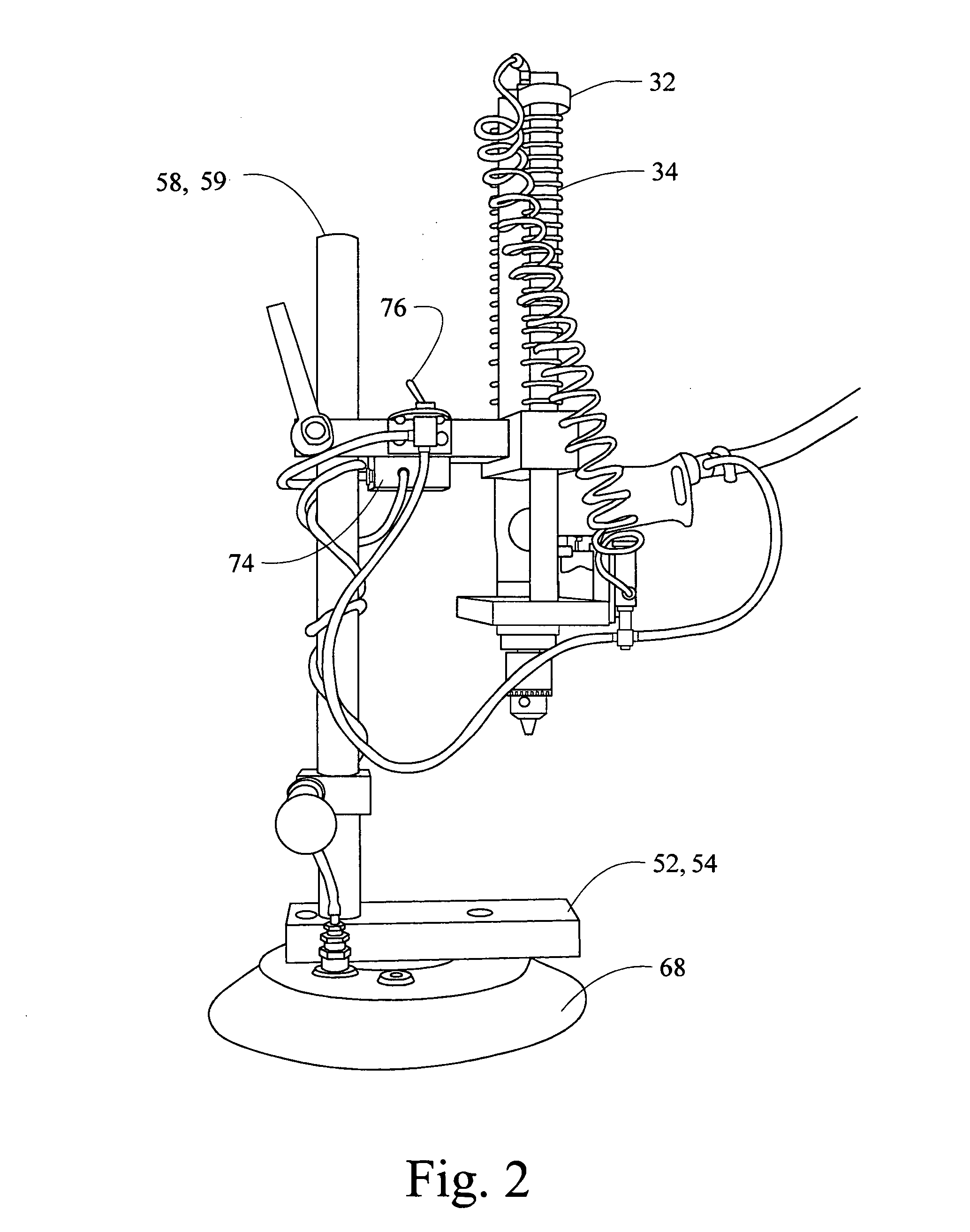

Power assisted drill press

InactiveUS7108459B1Quick and easy securingEasily suppliedDrilling/boring measurement devicesThread cutting machinesEngineeringVariable pressure

A power assisted drill press having a feed cylinder fed by a variable pressure regulator which allows a user to controllably feed a bit and work material together while activating a drill motor to rotate the bit. An embodiment of the power assisted drill press utilizes a suction cup and venturi system for attachment of the press to a surface work material. The drill press uniquely allows a person to variably activate the feed cylinder and also activate the drill motor with a single hand.

Owner:MUELLER THOMAS L MUELLER TOD BEVERLY H & MUELLER JOSEPH E

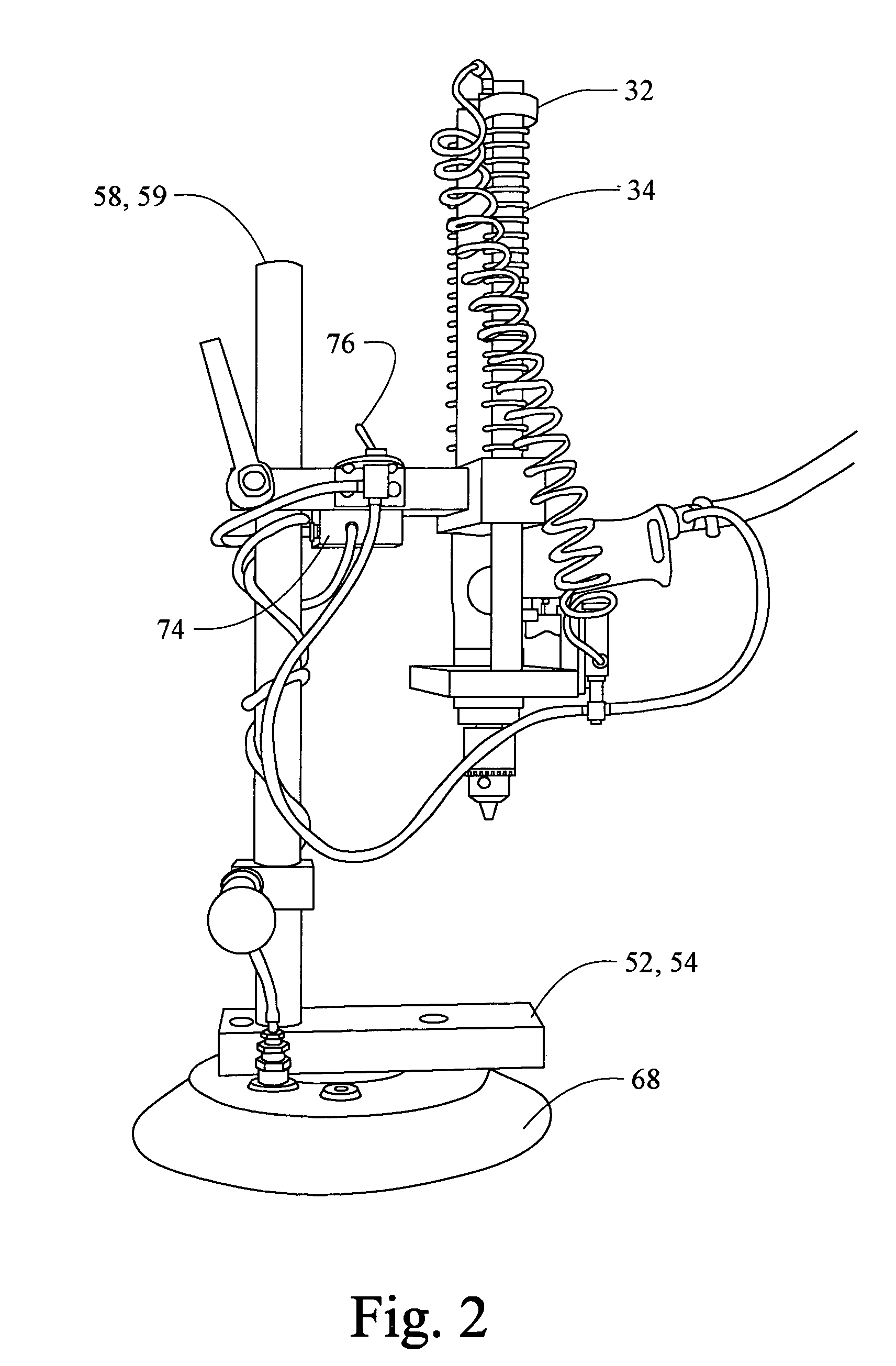

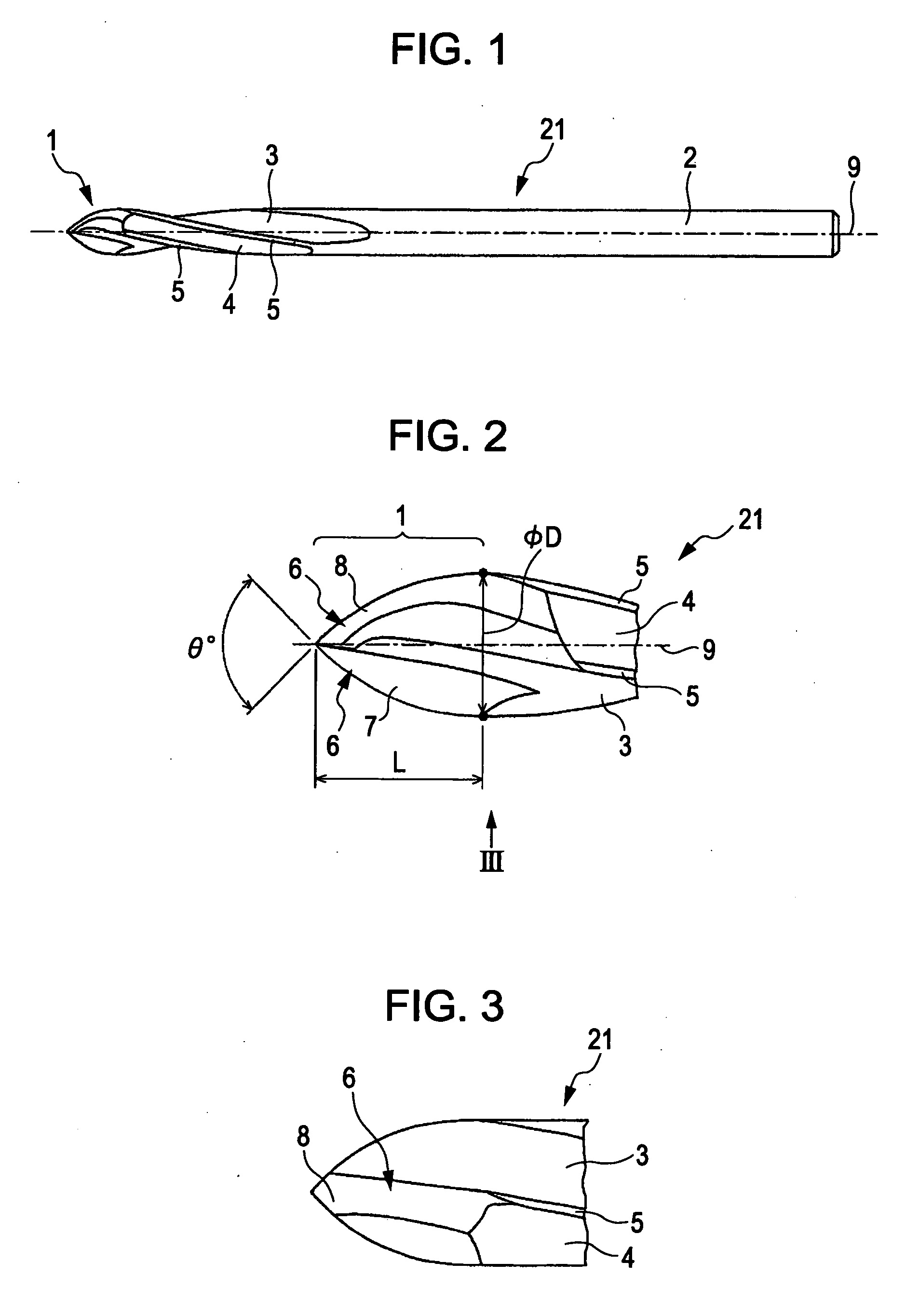

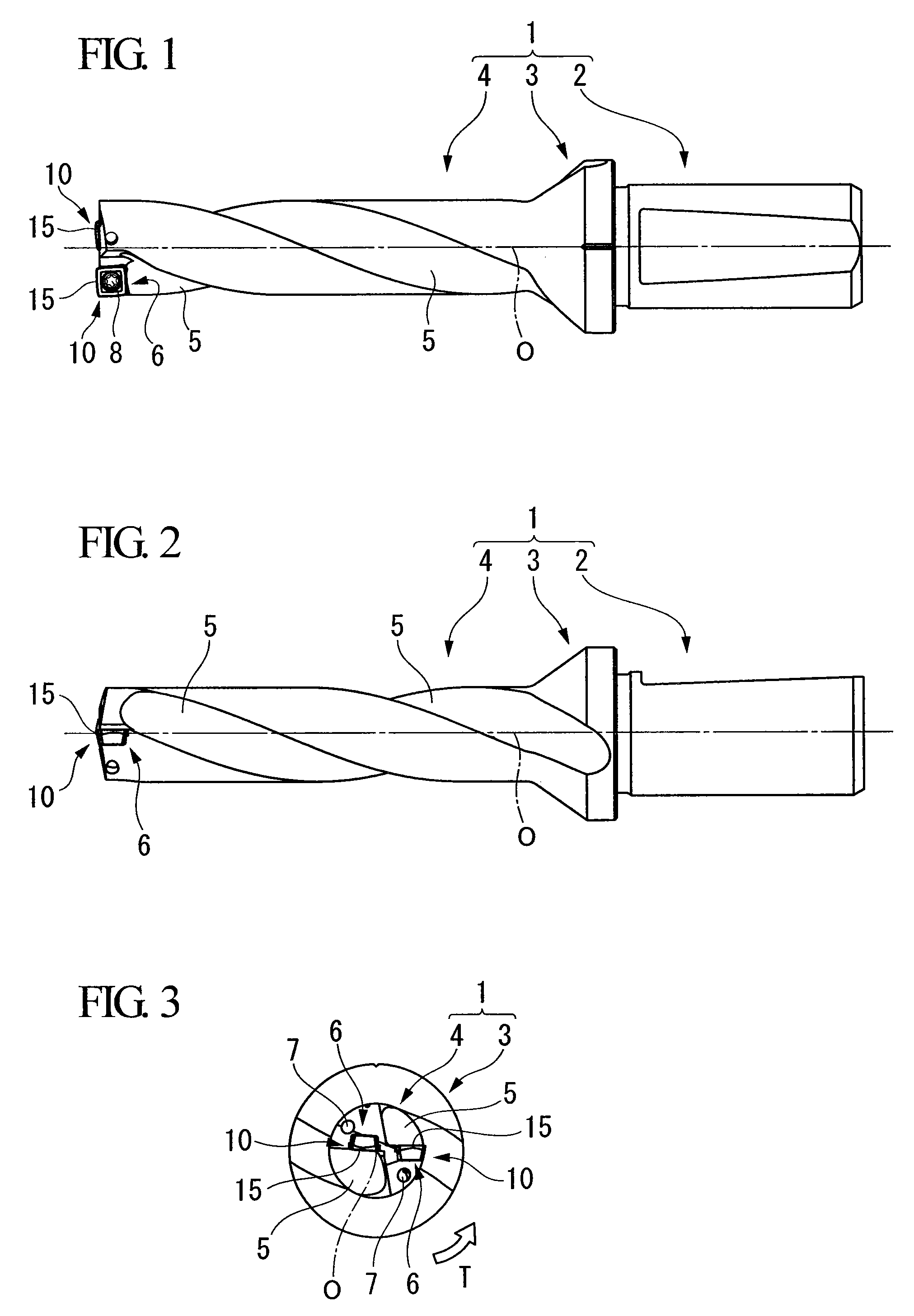

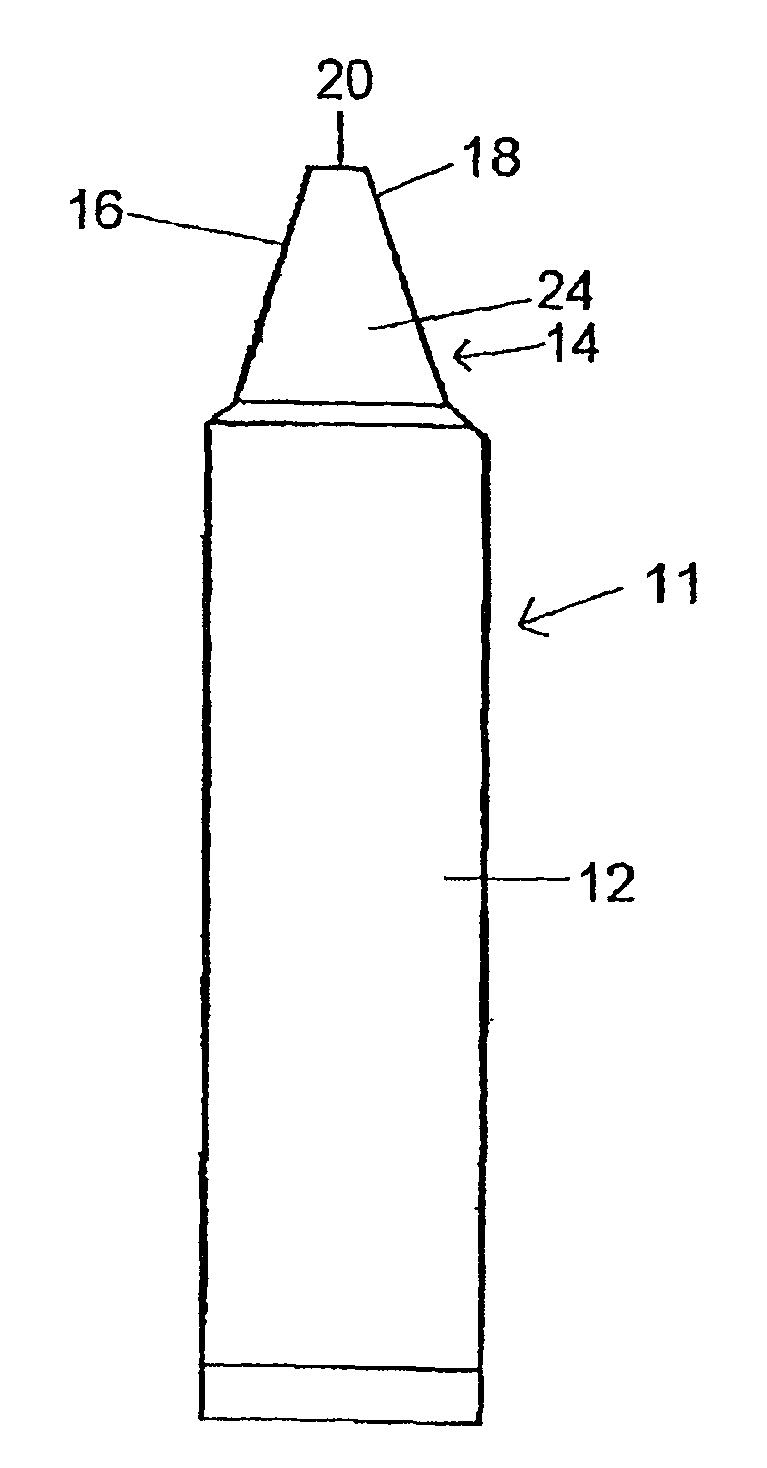

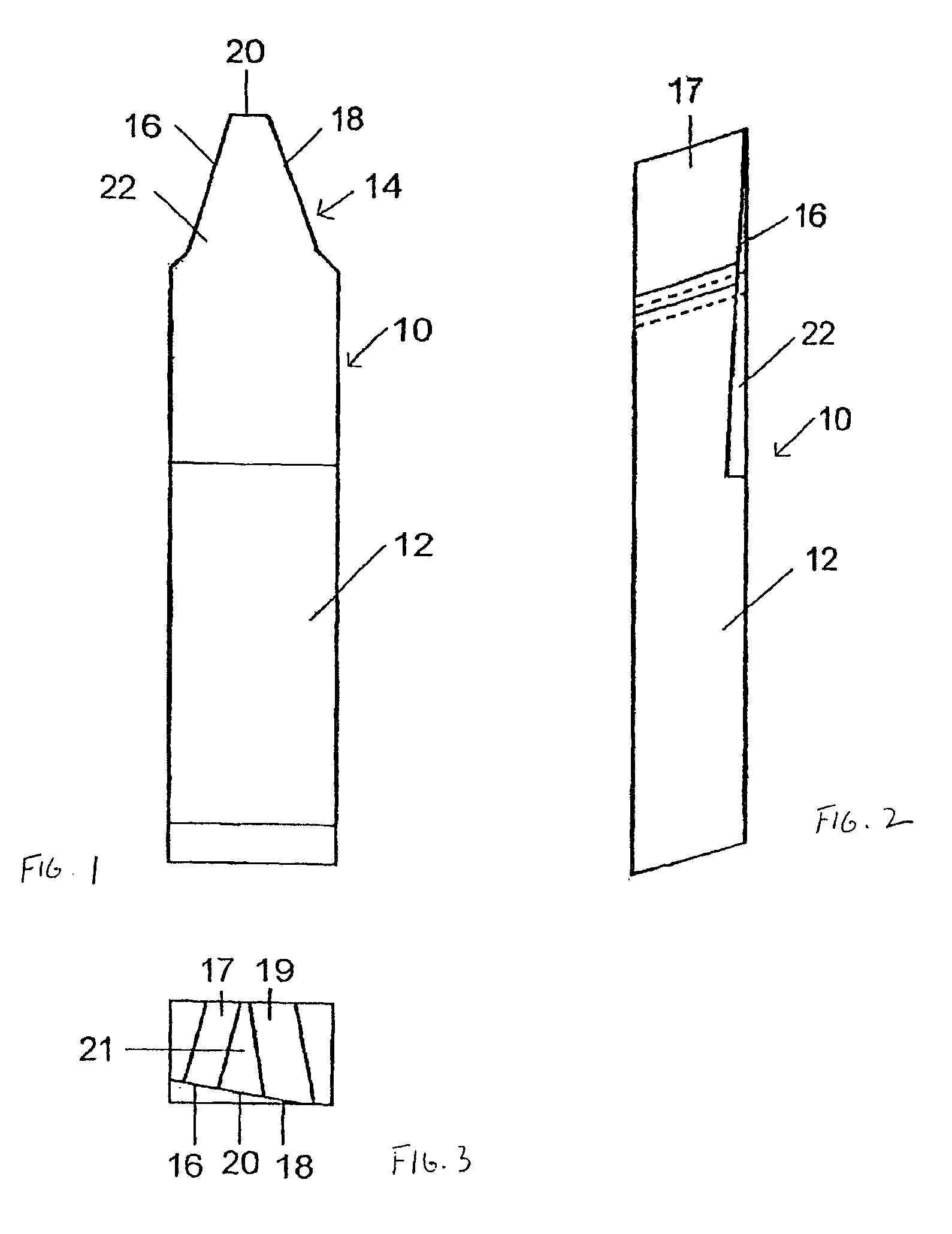

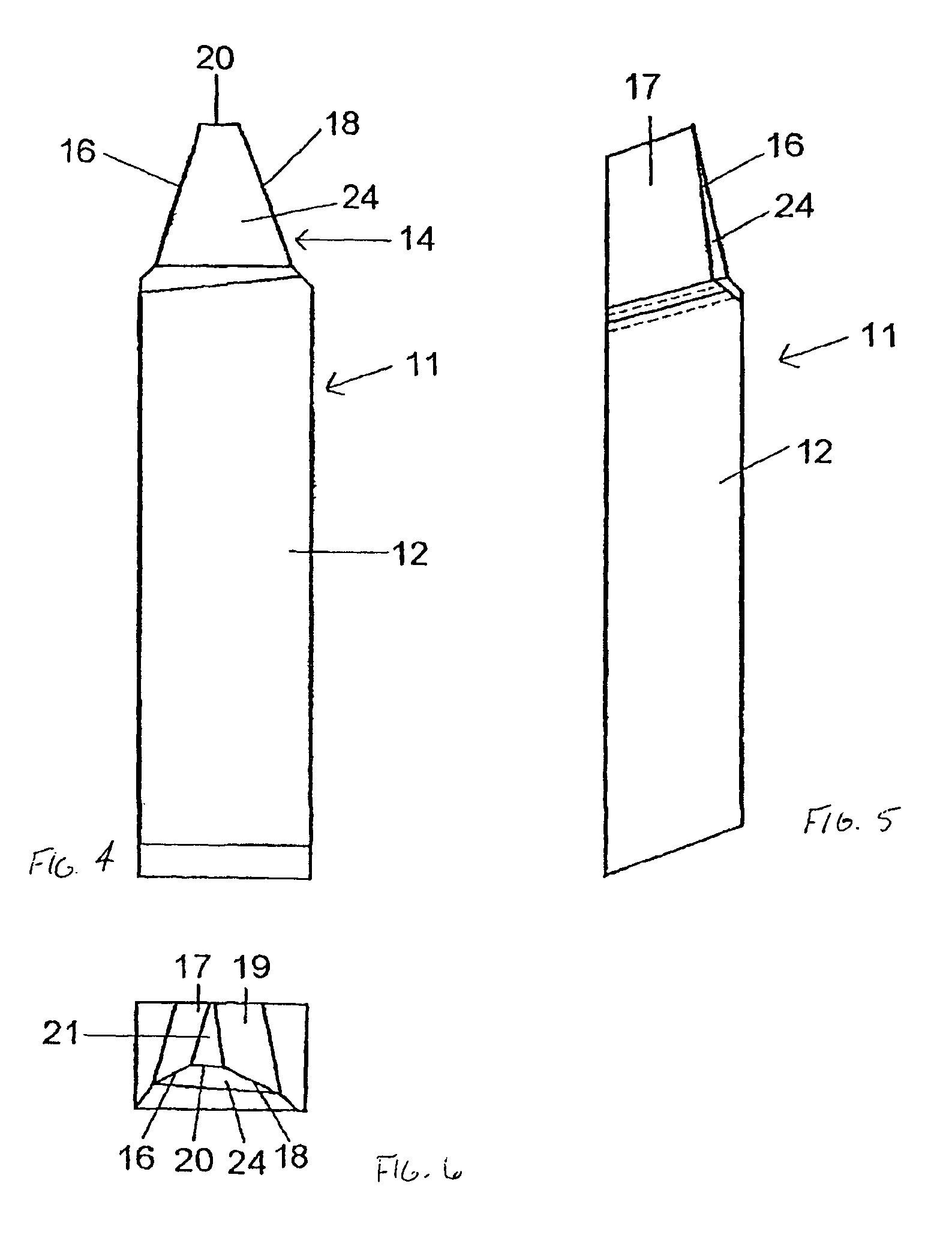

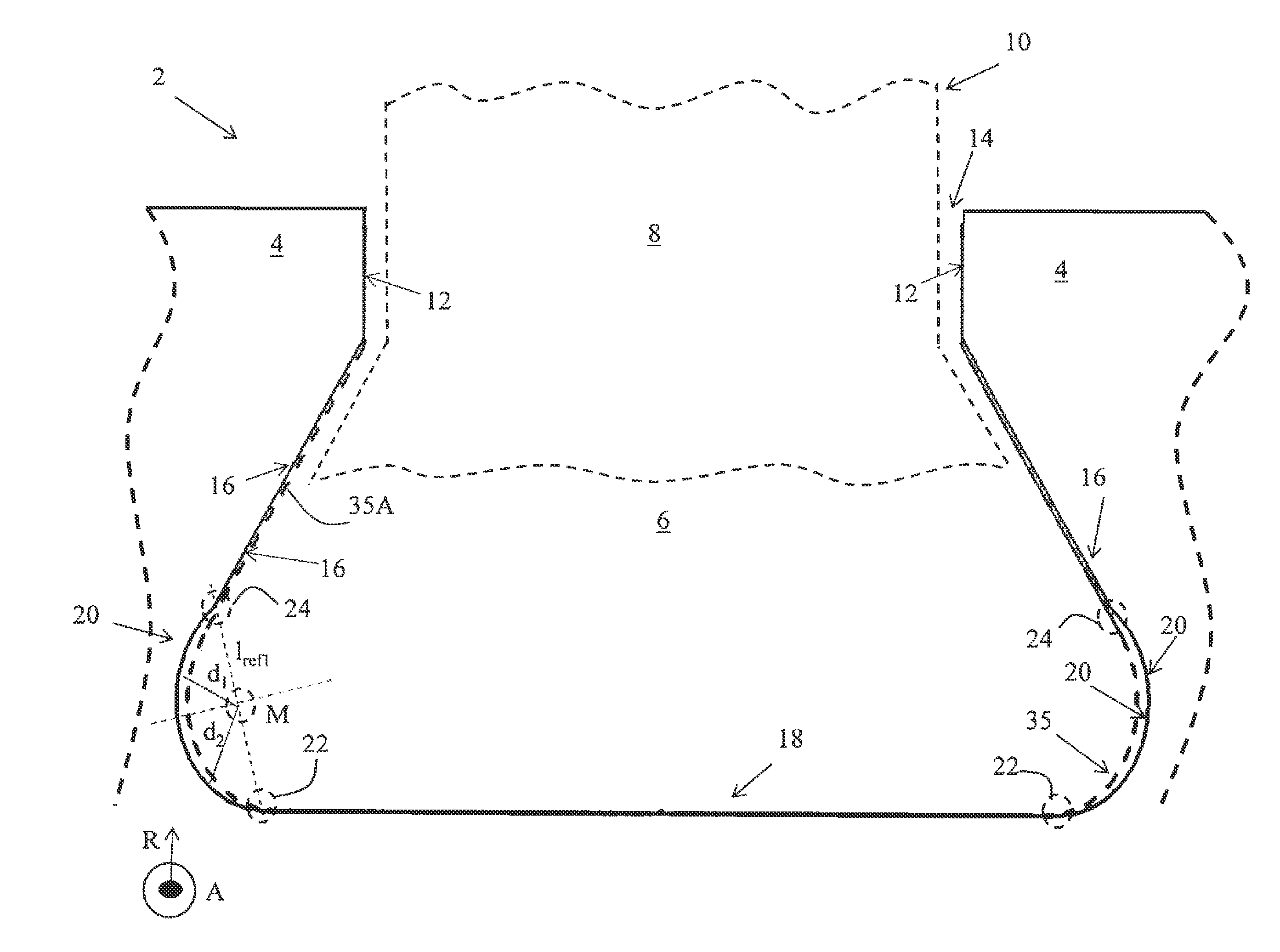

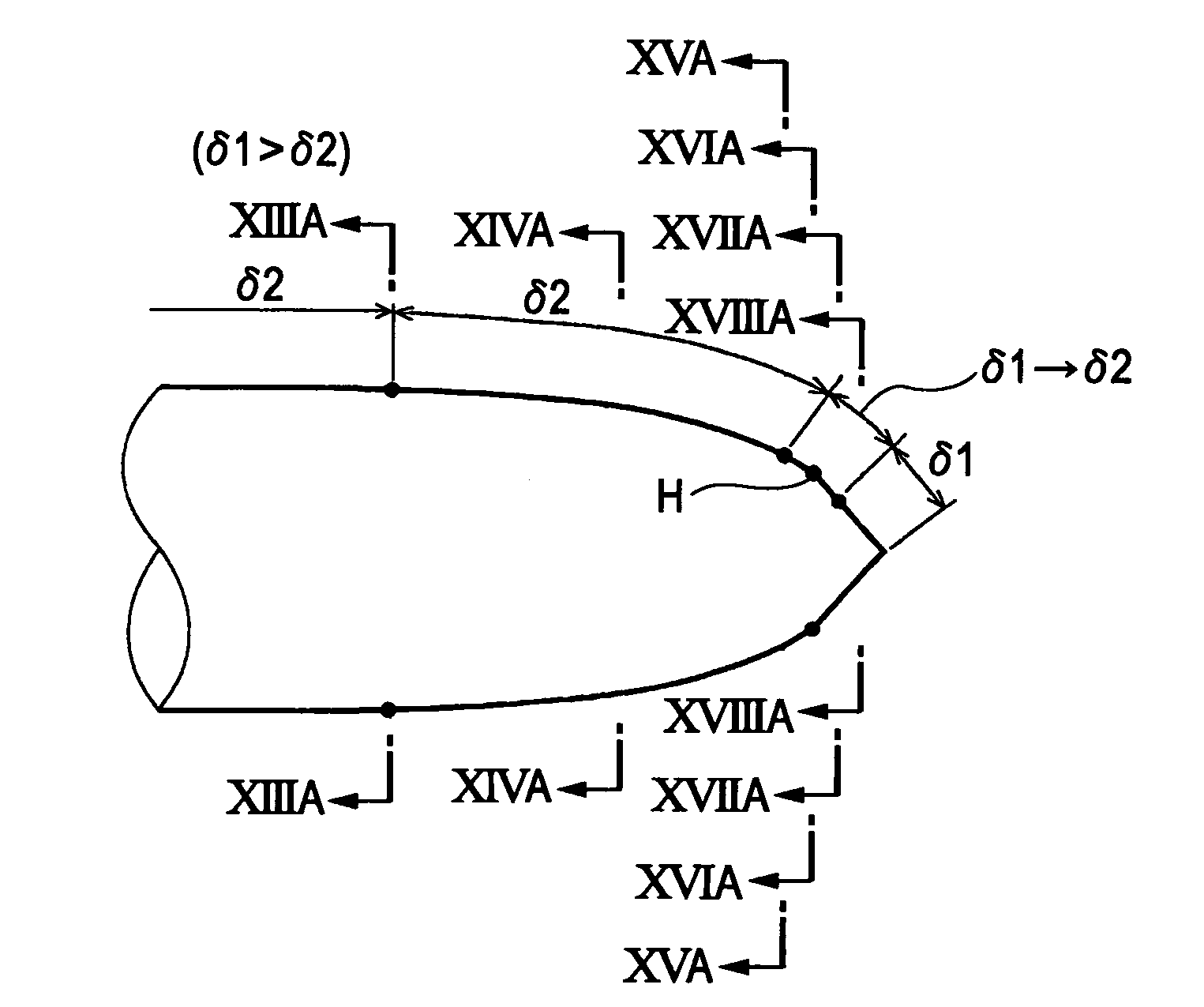

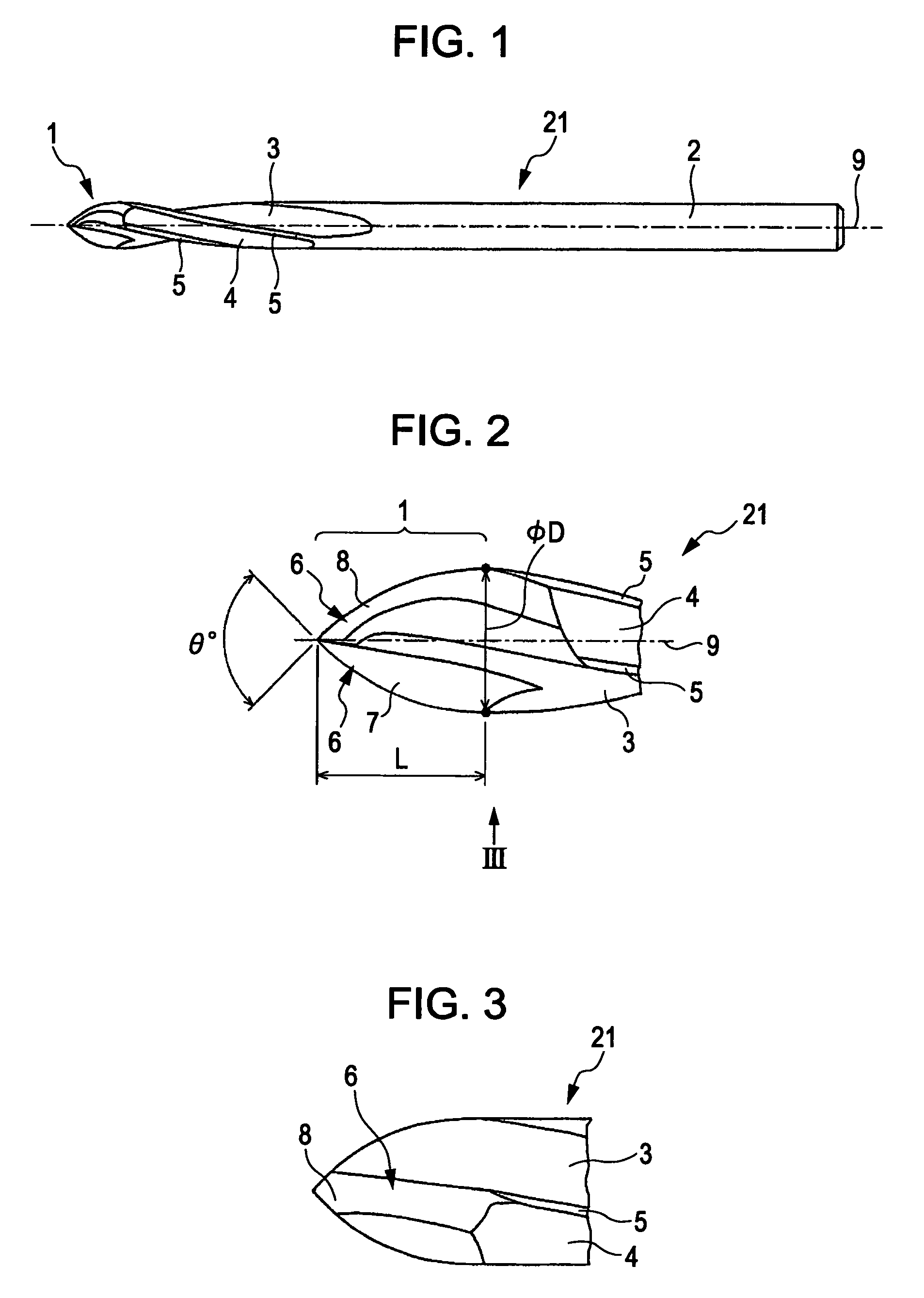

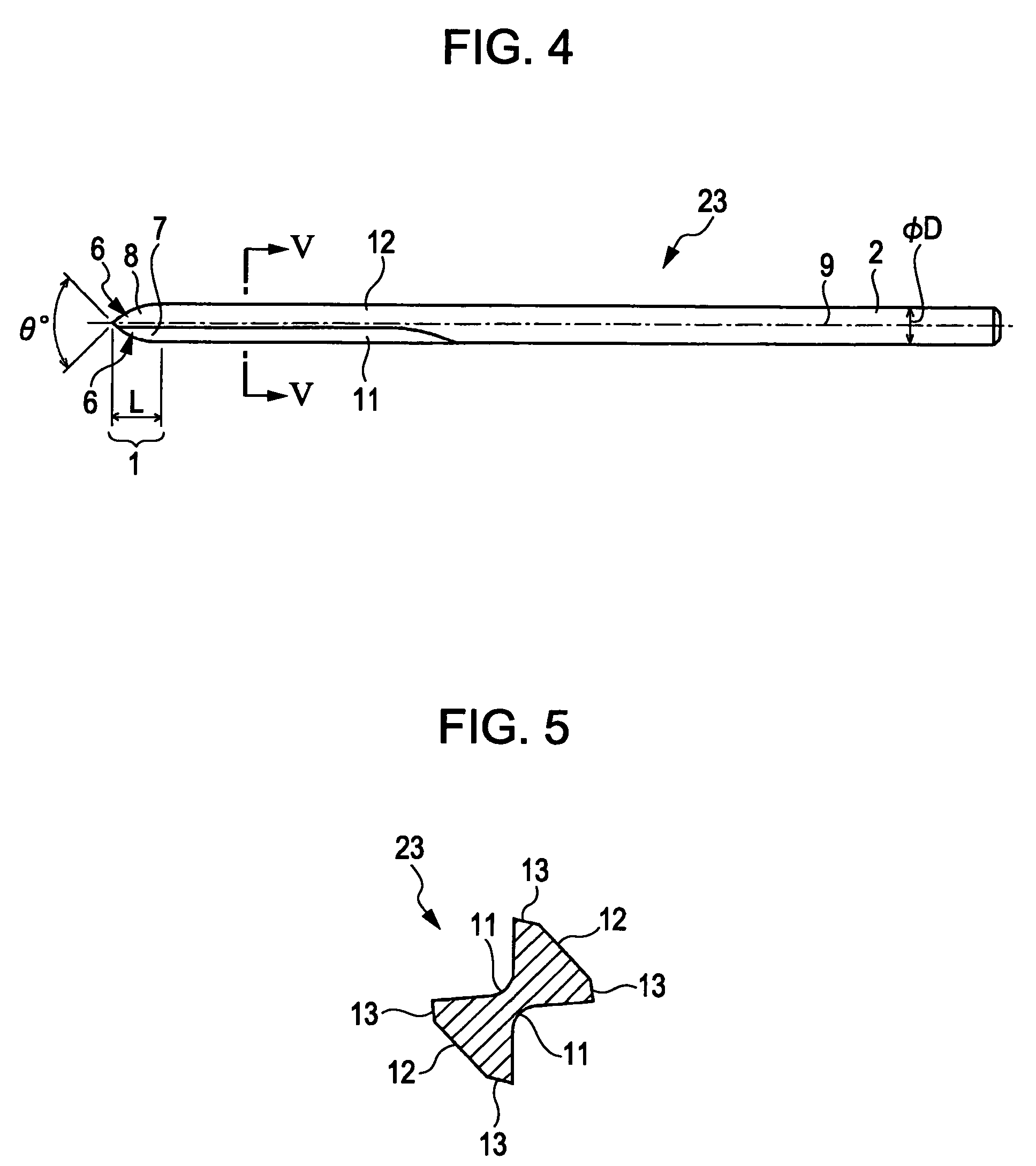

Drill

ActiveUS20100166517A1Reduce pointsReduce cutting loadWood turning toolsTransportation and packagingEllipseEngineering

A drill includes a cutting edge having a ridgeline. The ridgeline has a part of an ellipse and a straight line. It is assumed that the coordinates of a separation point of an ellipse portion from a straight line portion are (x0, y0). The straight line is a tangent to the ellipse at the separation point. It is assumed that a1 is an area from a tip end of the drill to x0, a2 is an area from x0 to the origin of the ellipse, and a3 is a negative area, along the x-axis. The ridgeline of the cutting edge is formed straight along the tangent in the area a1, and is formed along the ellipse in the area a2. A margin is formed in the area a3 continuously from a relief face of the cutting edge.

Owner:SUBARU CORP

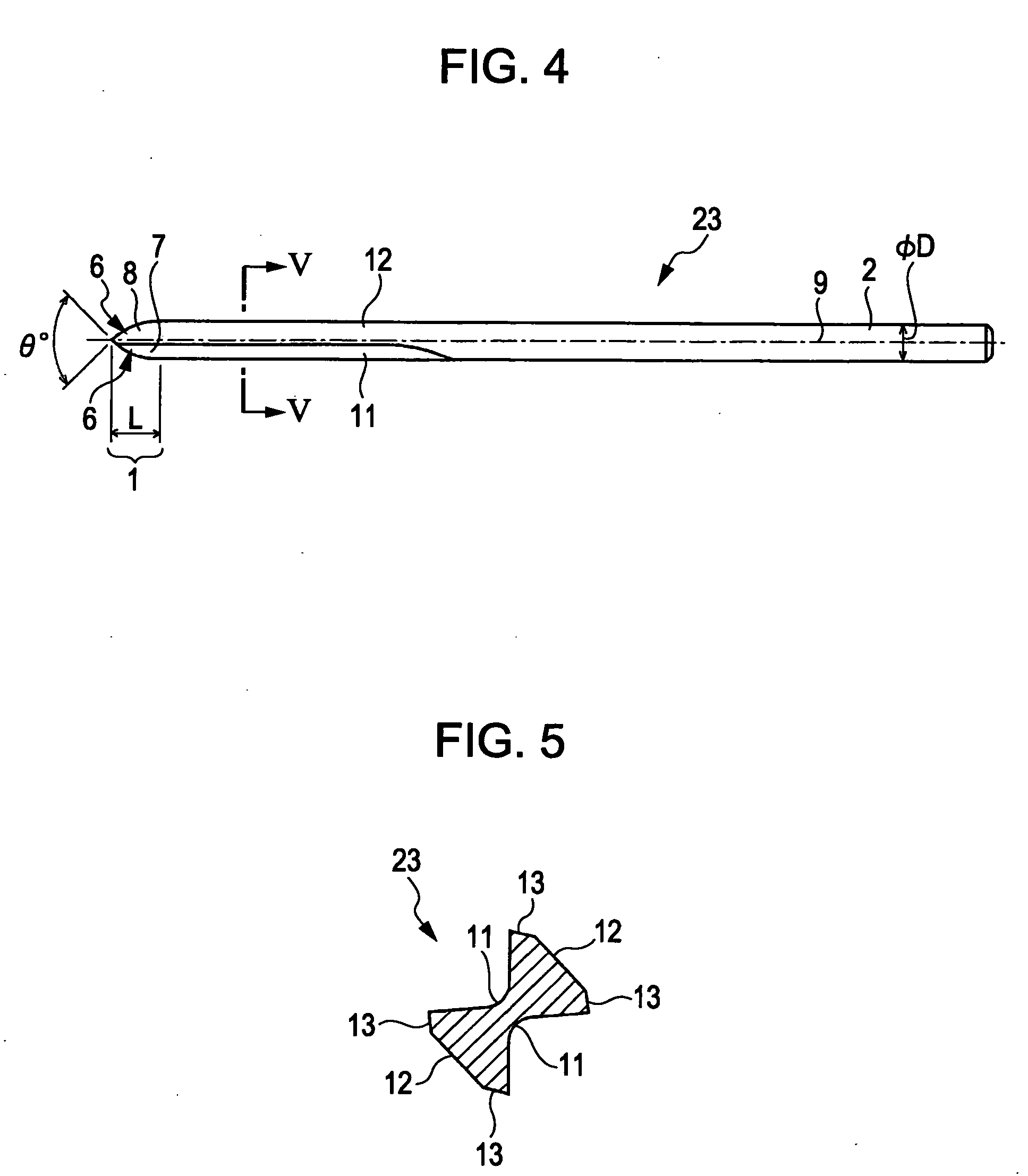

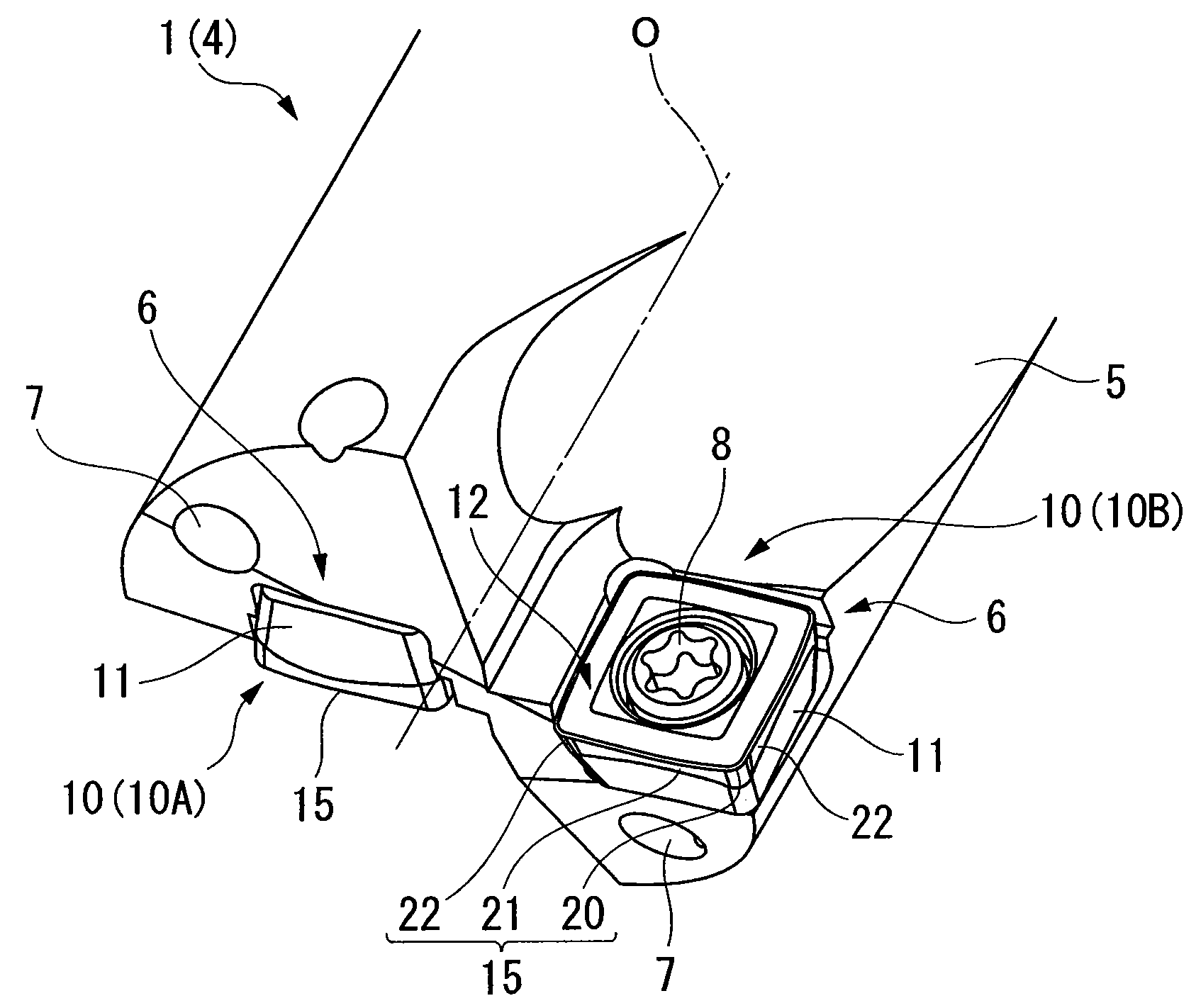

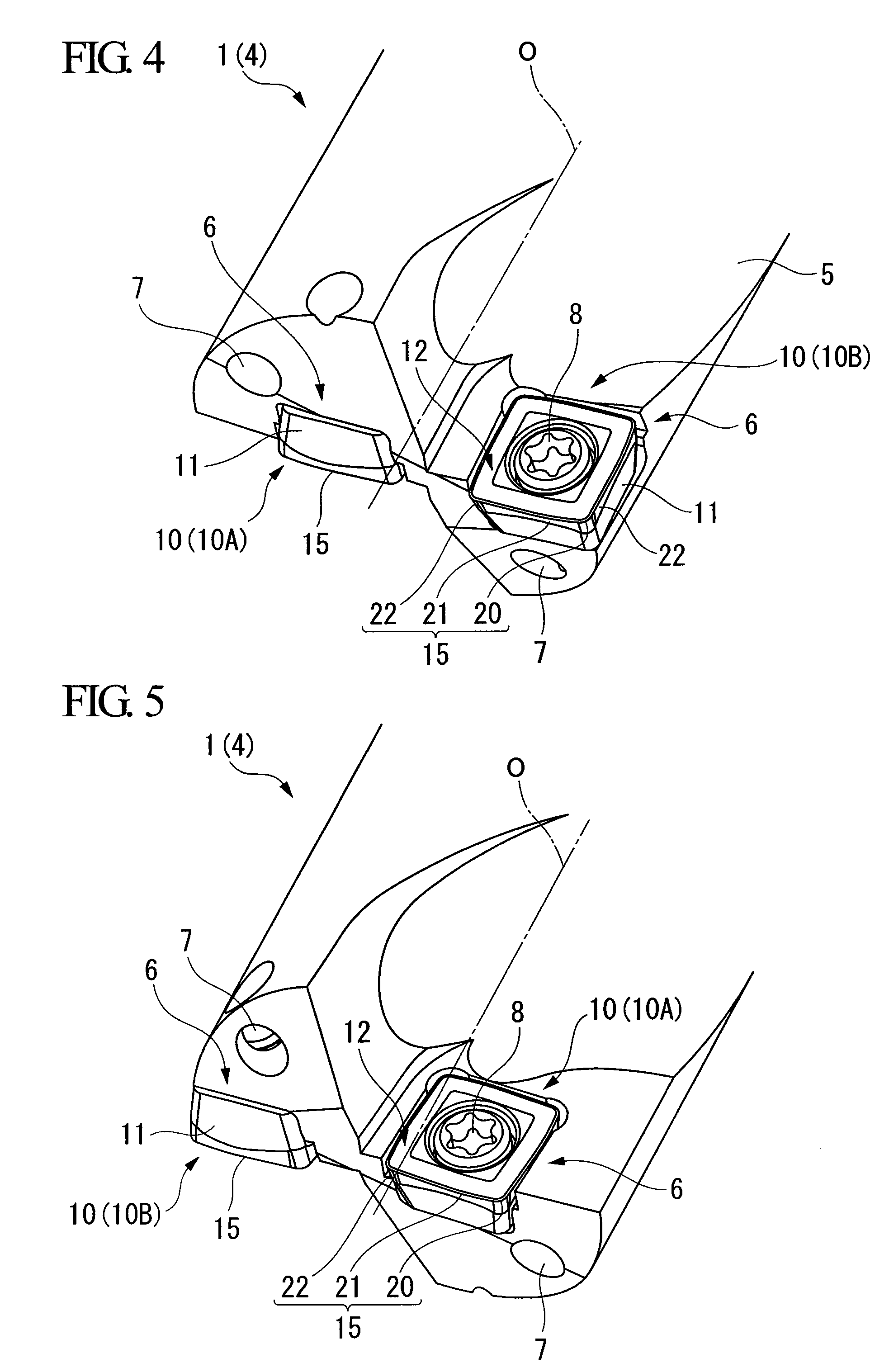

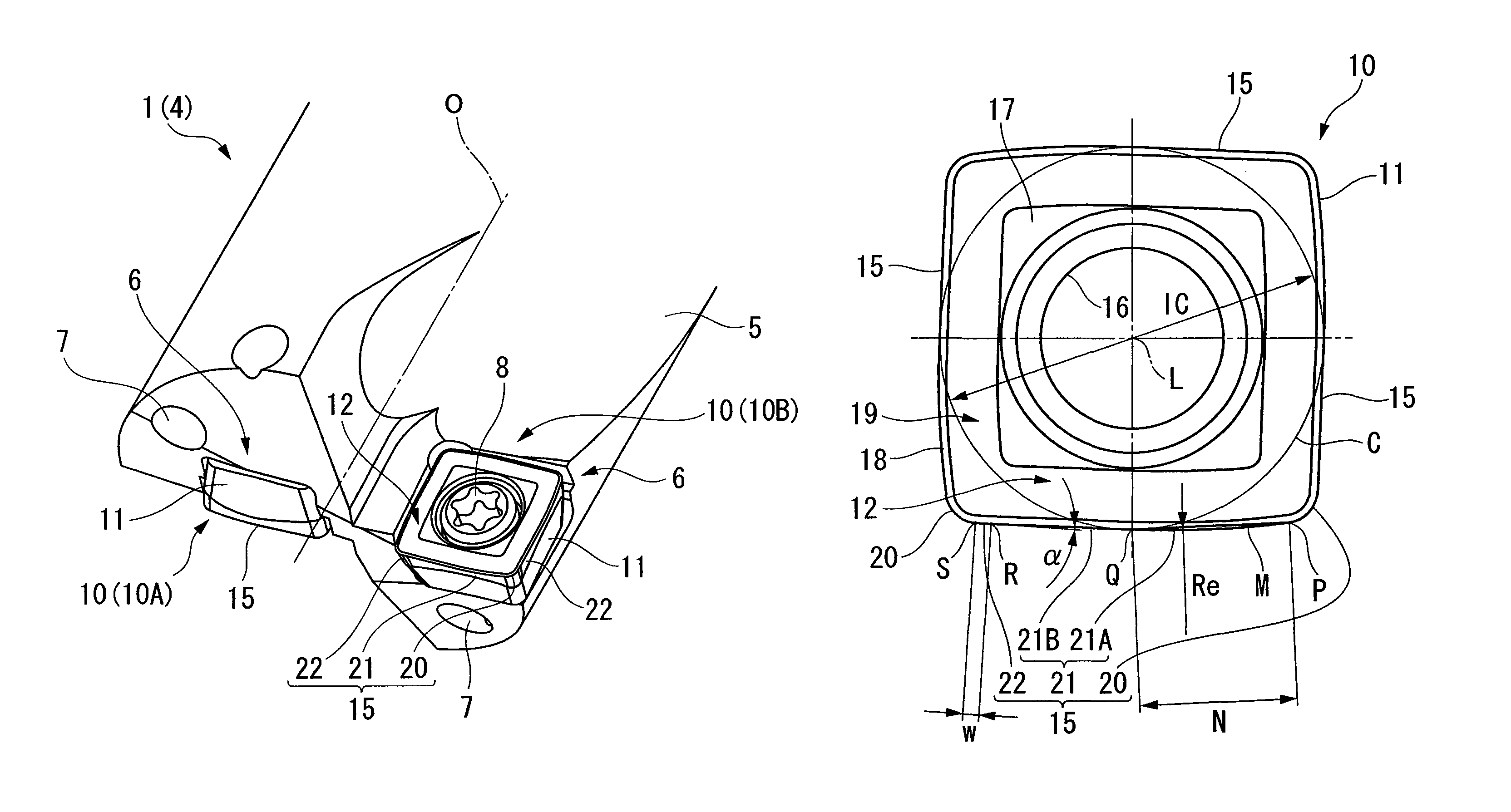

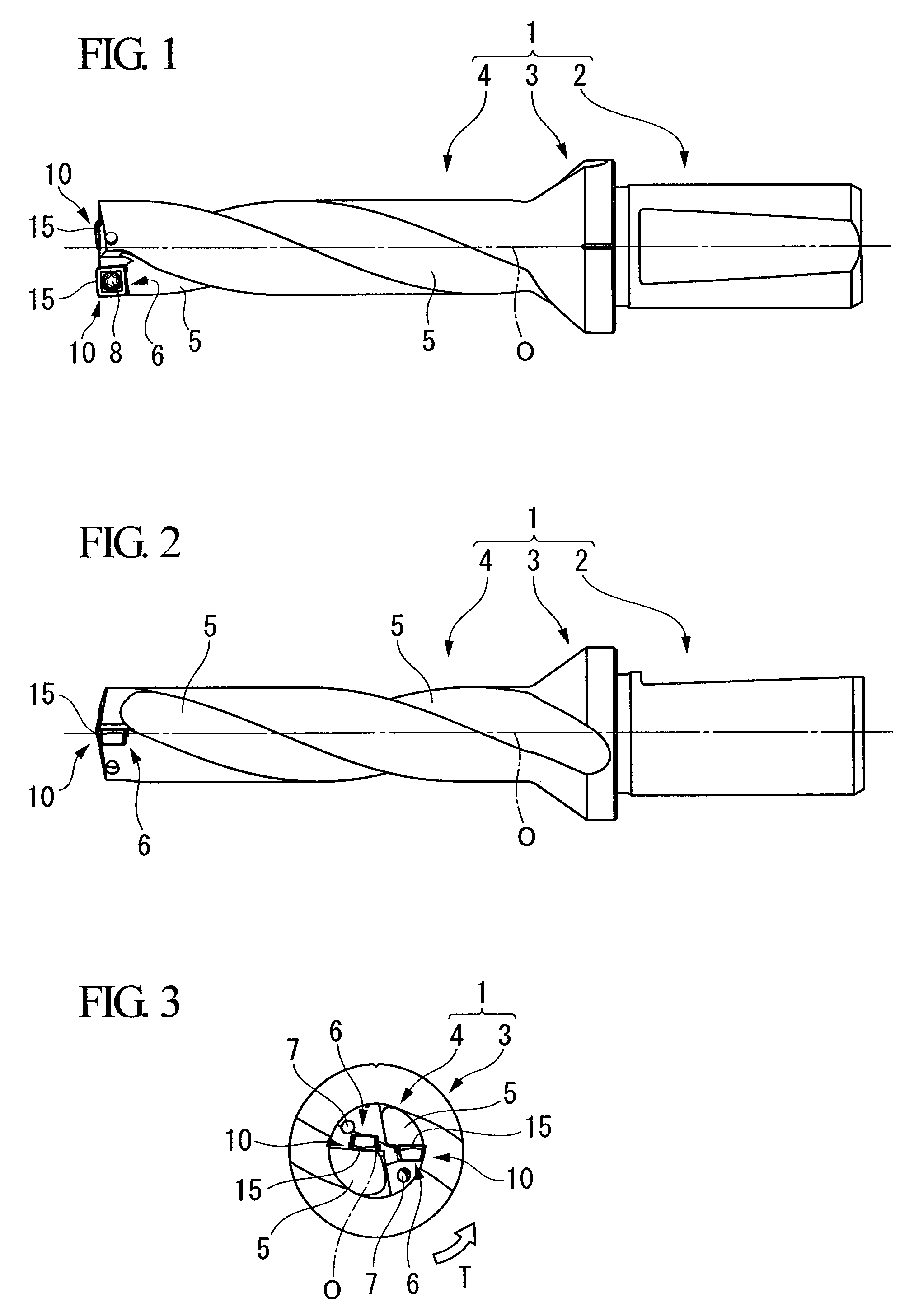

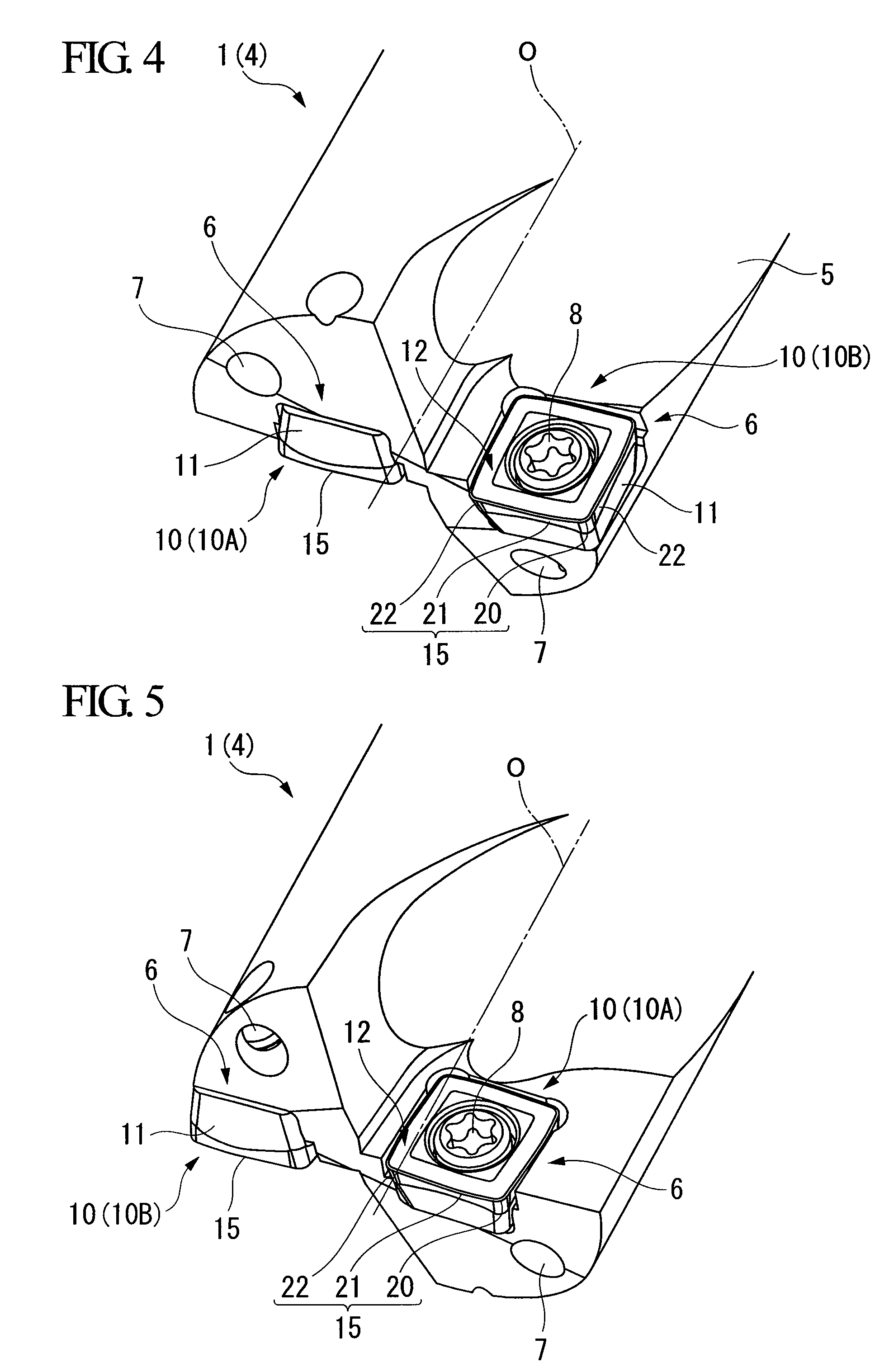

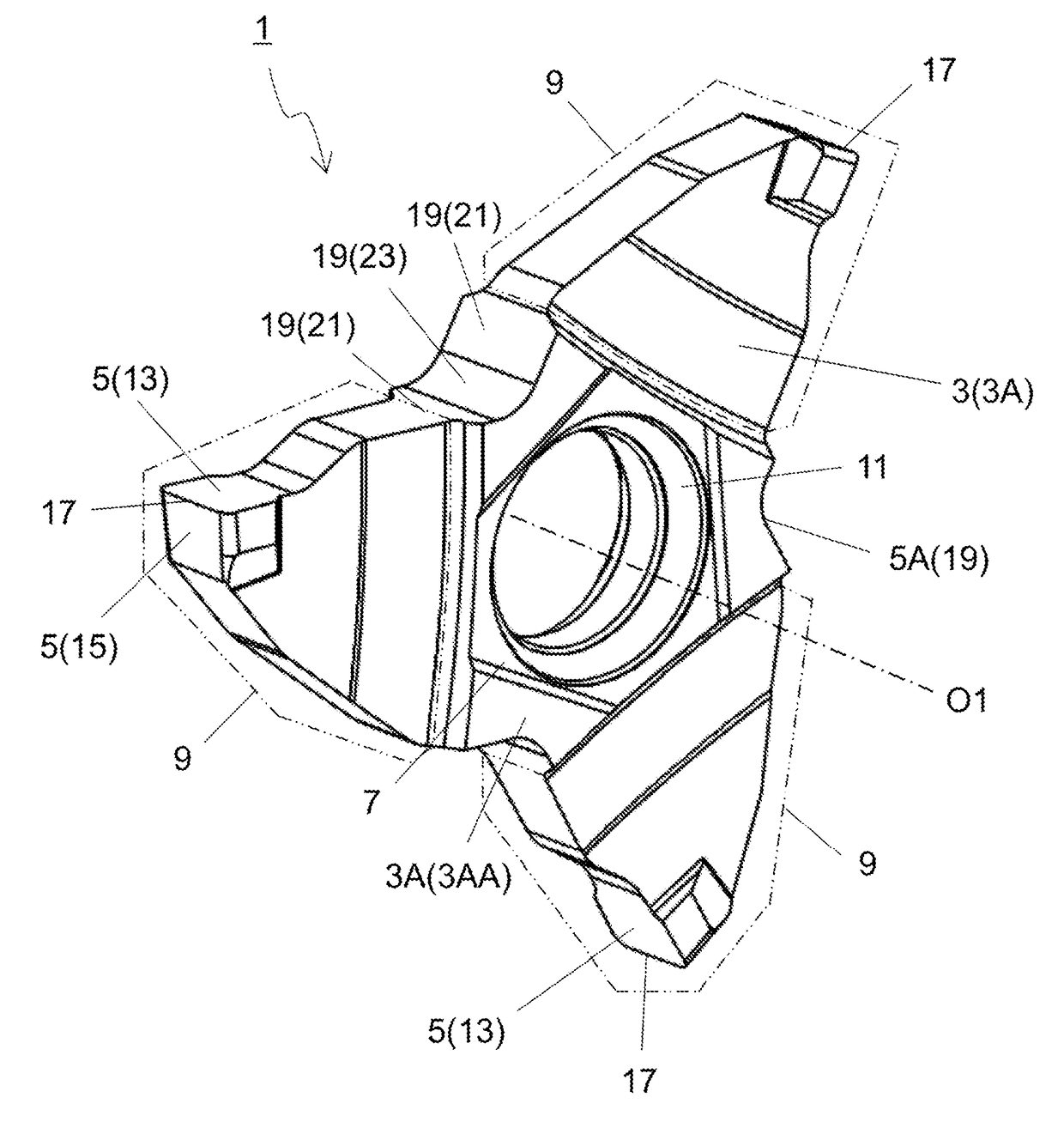

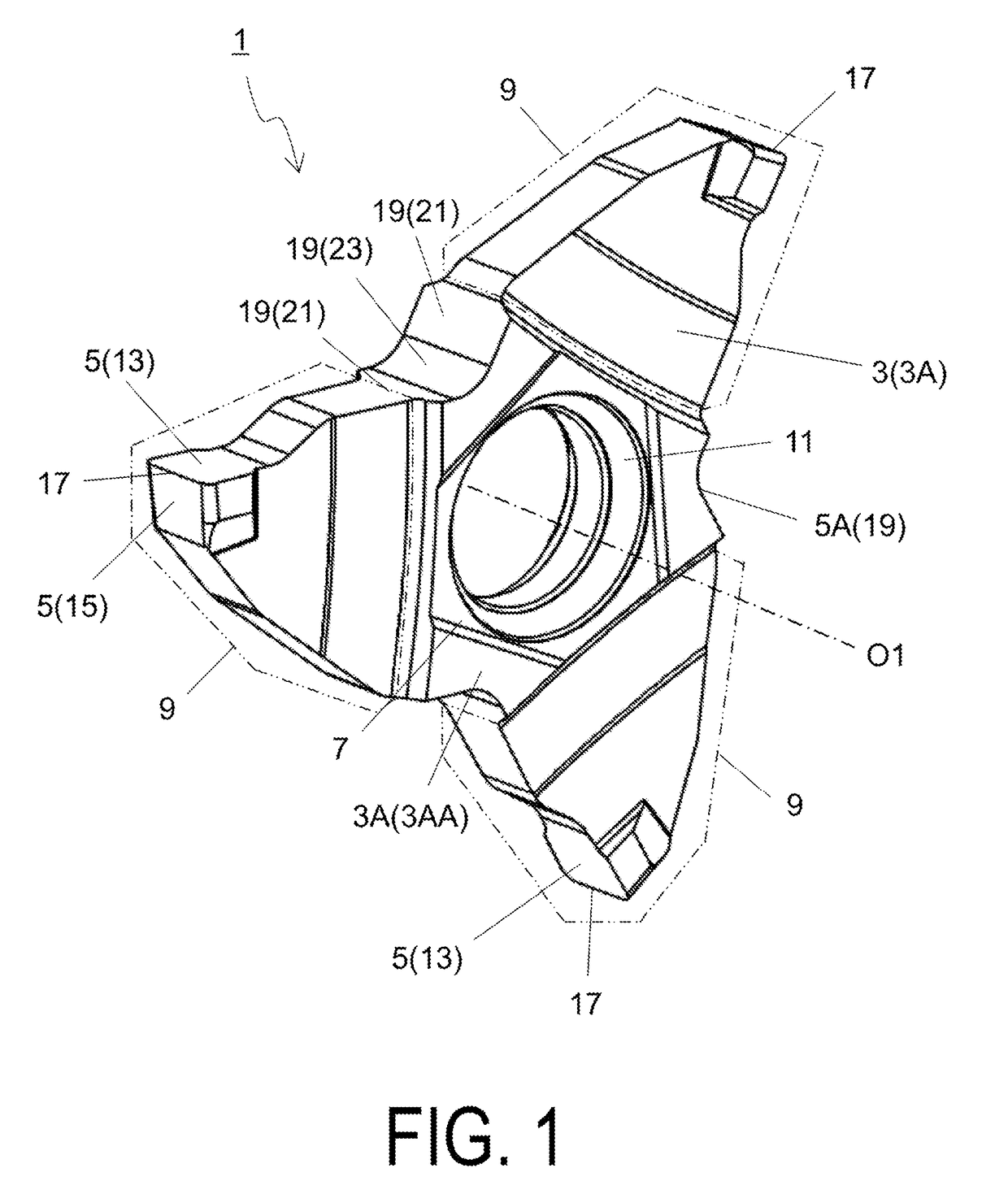

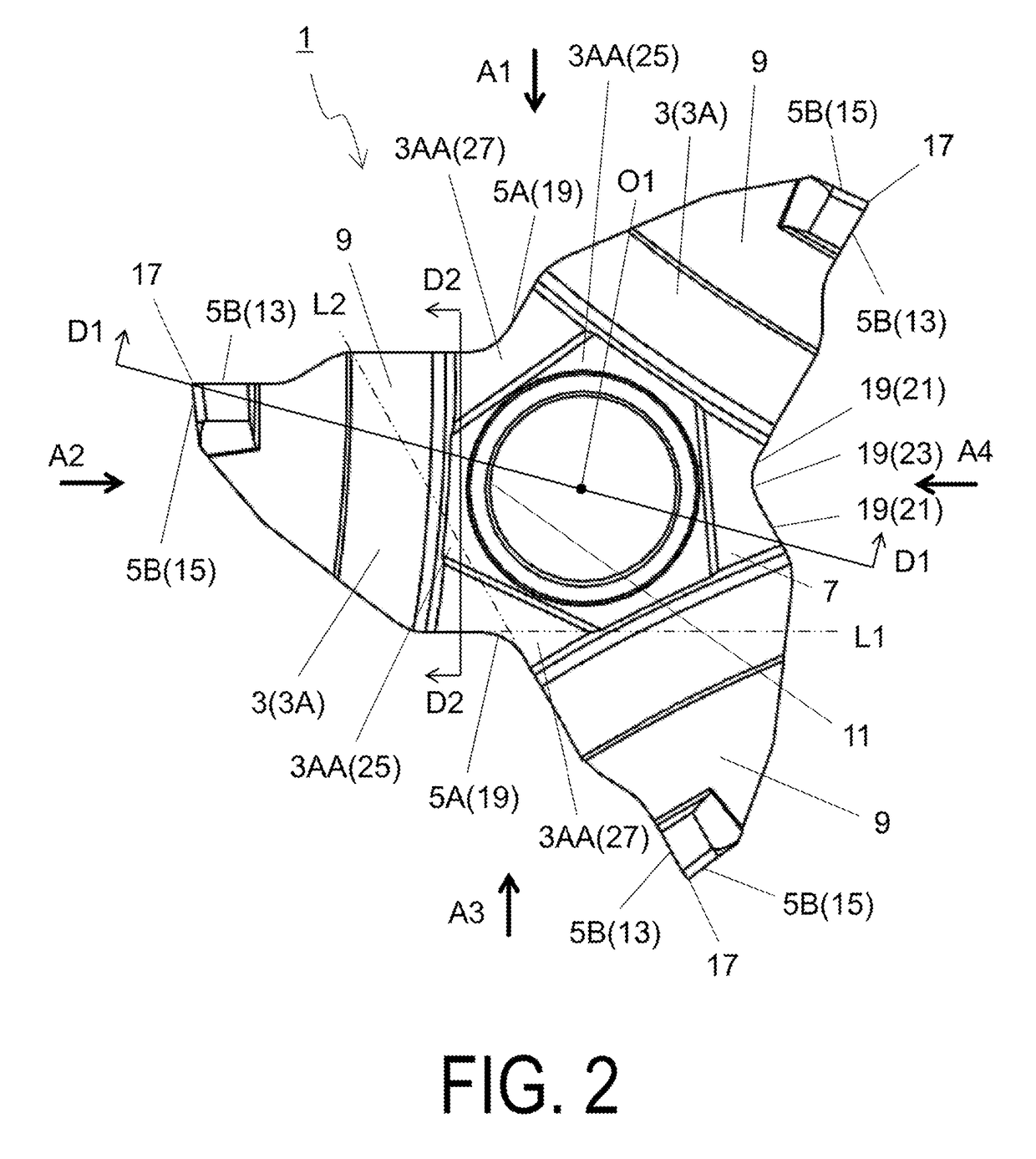

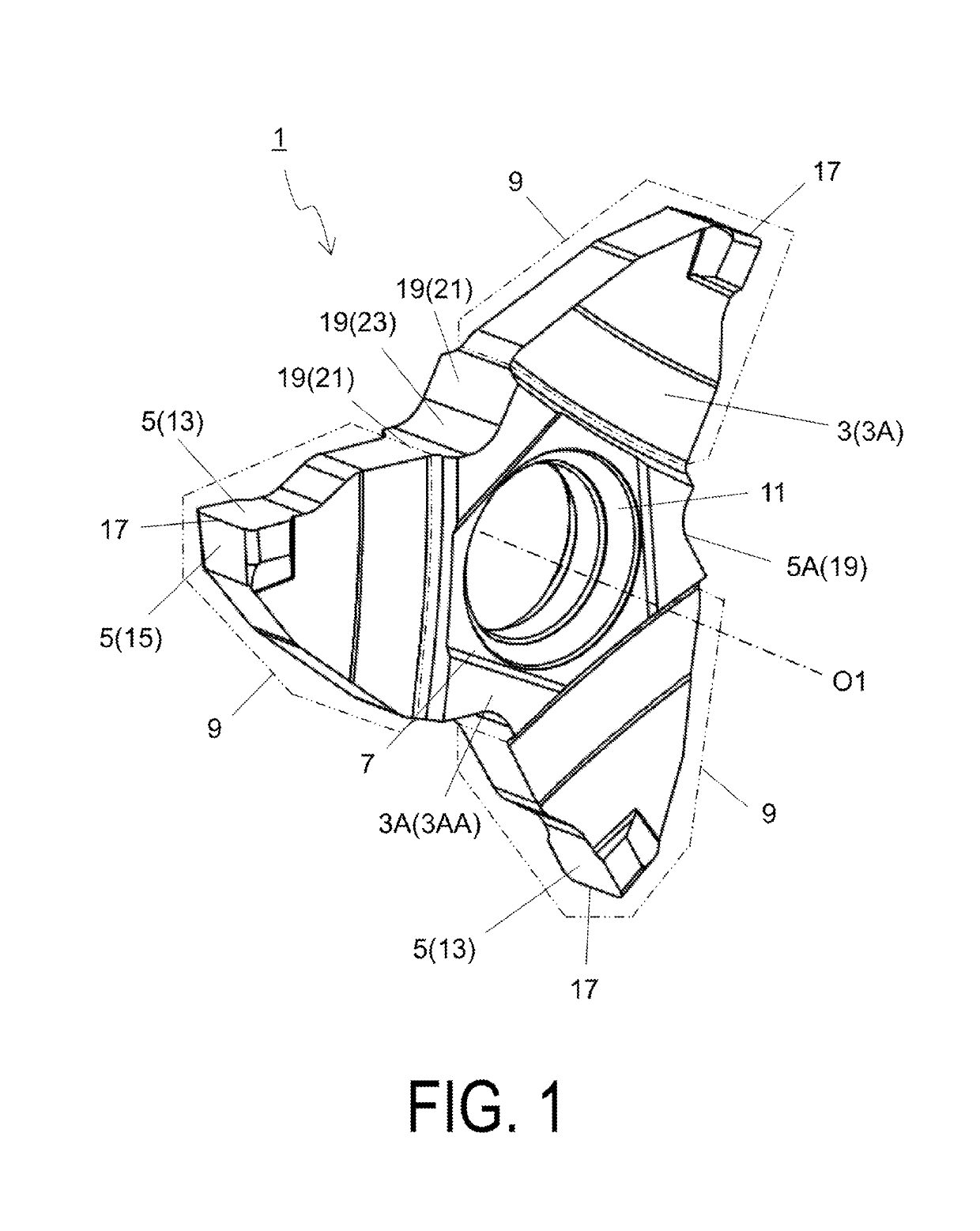

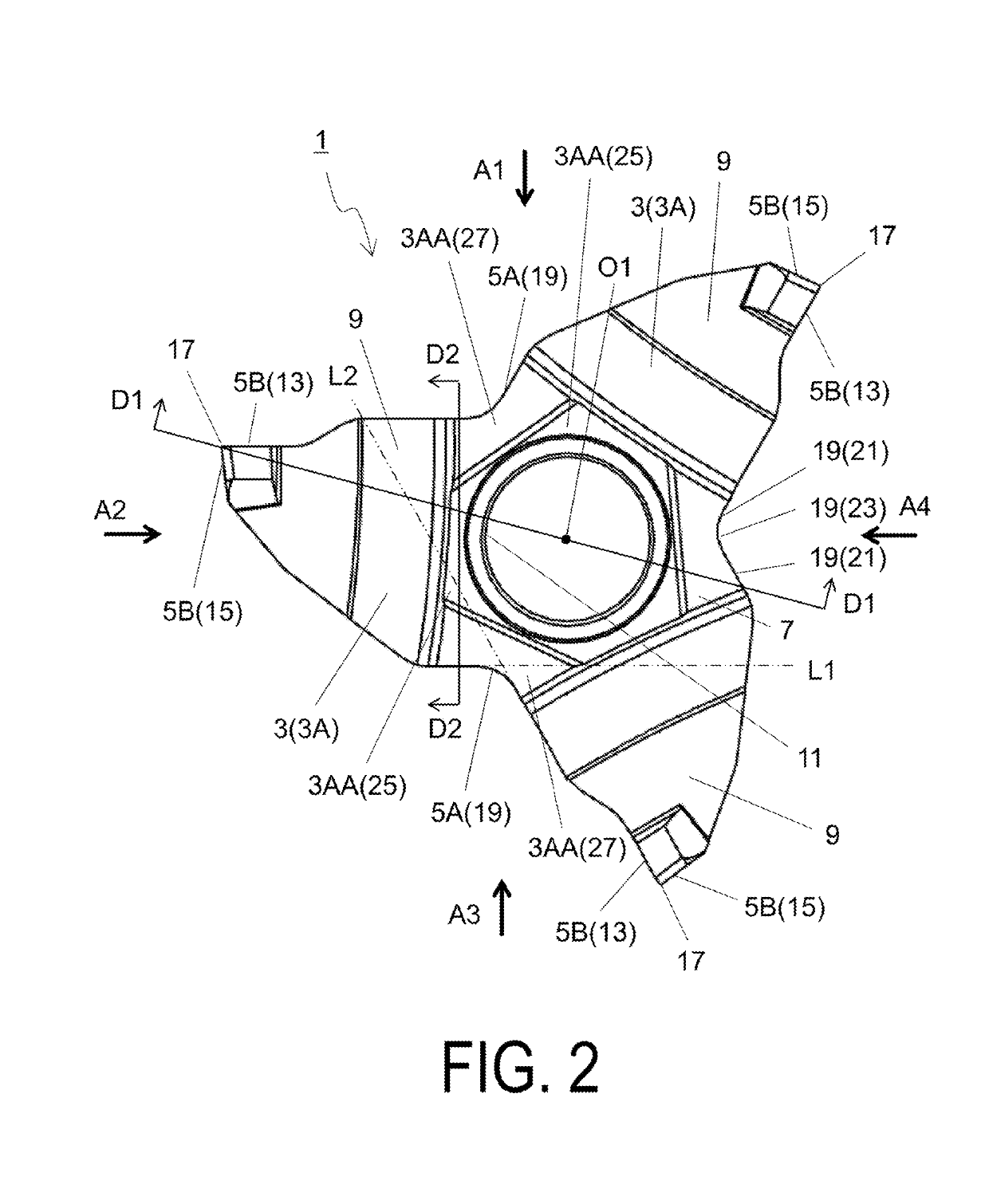

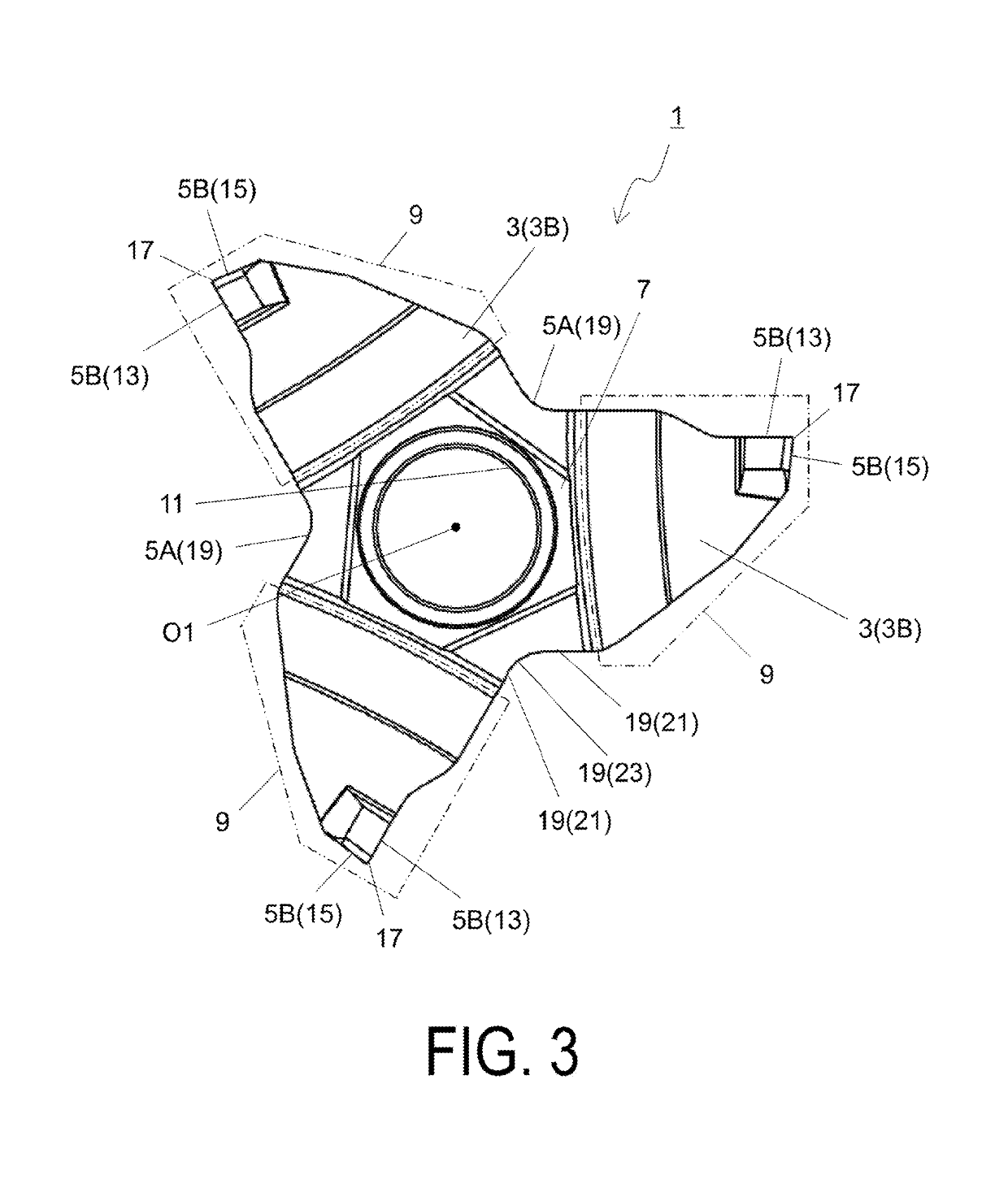

Insert for drill and indexable insert drill

ActiveUS20090245949A1Improve surface qualityHigh concentricityTransportation and packagingCutting insertsCurve shapeEngineering

An insert for a drill in which one of the cutting edges respectively formed at four side ridge portions of a rake face of a square flat plate-shaped insert body is made to protrude toward the tip of the drill body of the indexable insert drill while being detachably attached is provided. Each of the cutting edges has a corner cutting edge located at a corner of the rake face, and a major cutting edge and a wiper edge which extend substantially toward one peripheral direction of the rake face from a corner cutting edge. The major cutting edge has a first major cutting edge portion which has a convexly curved shape and extends from the corner cutting edge, and a second major cutting edge portion which smoothly touches the first major cutting edge portion and extends linearly, as seen from a direction facing the rake face. The wiper edge has a straight shape intersecting the second major cutting edge portion at an obtuse angle.

Owner:MITSUBISHI MATERIALS CORP

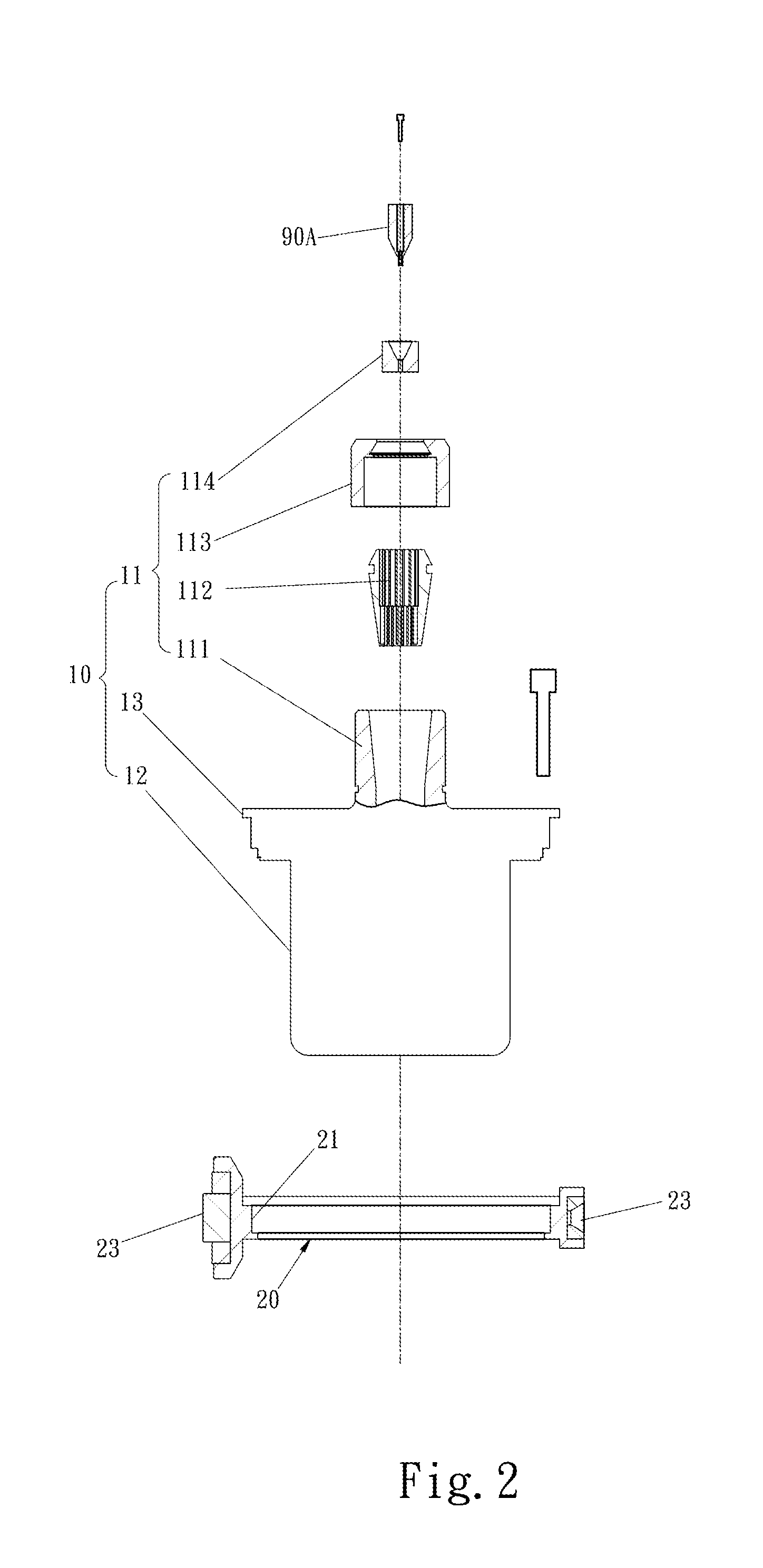

Power assisted drill press

InactiveUS7267512B1Quick and easy securingEasily suppliedDrilling/boring measurement devicesThread cutting machinesVariable pressureDrilling machines

A power assisted drill press having a feed cylinder fed by a variable pressure regulator which allows a user to controllably feed a bit and work material together while activating a drill motor to rotate the bit. An embodiment of the power assisted drill press utilizes a suction cup and venturi system for attachment of the press to a surface work material. The drill press uniquely allows a person to variably activate the feed cylinder and also activate the drill motor with a single hand.

Owner:MUELLER THOMAS L MUELLER TOD BEVERLY H & MUELLER JOSEPH E

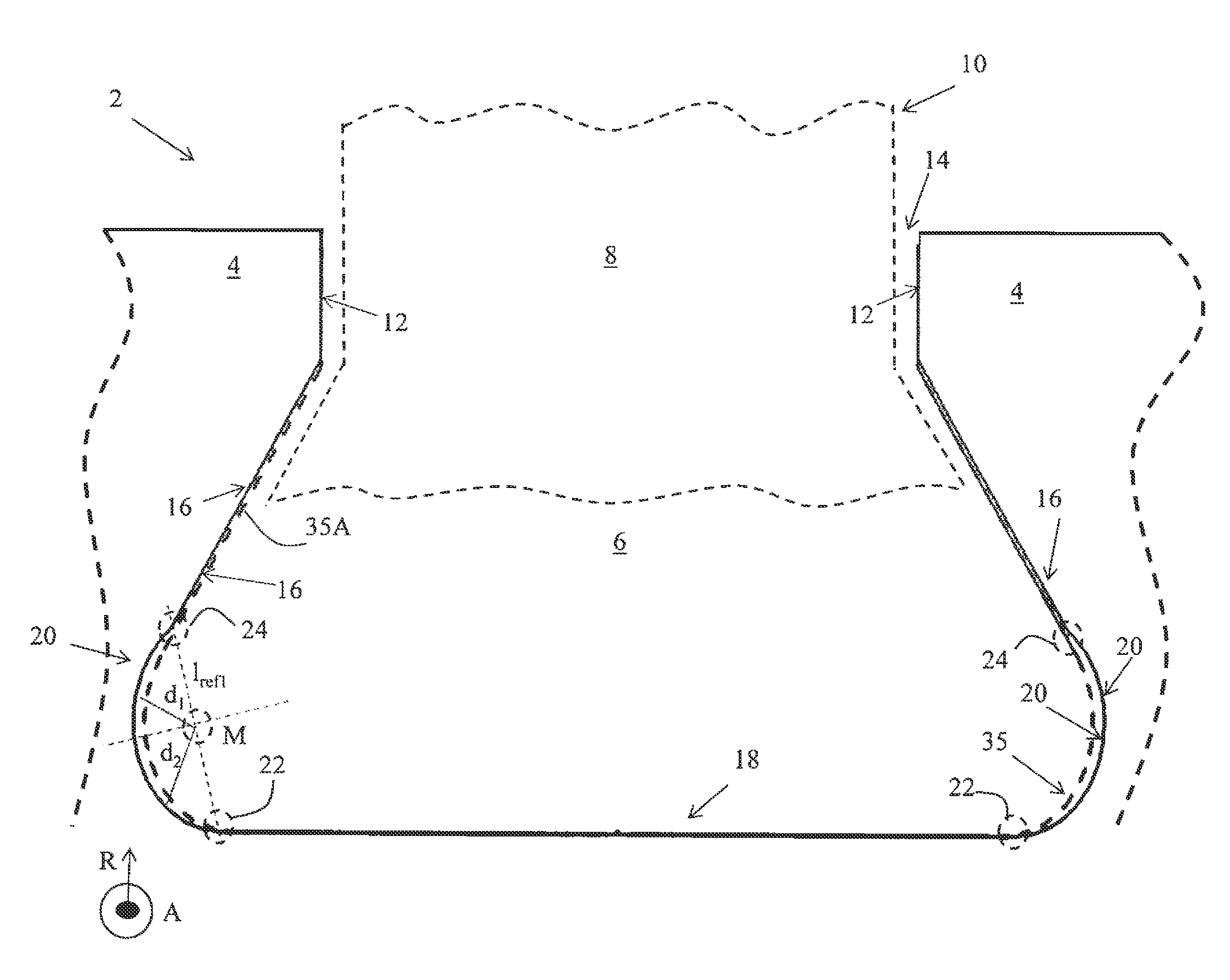

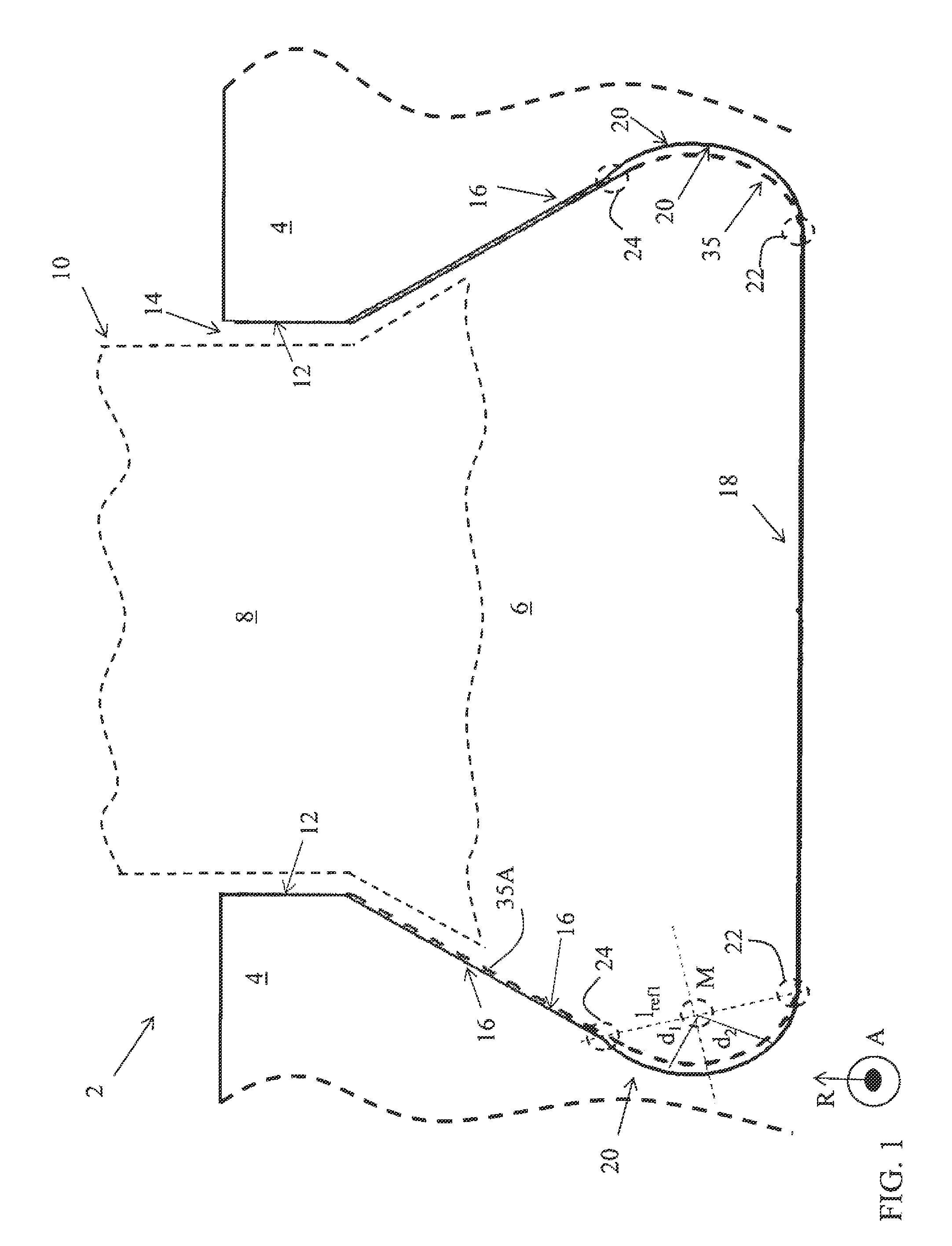

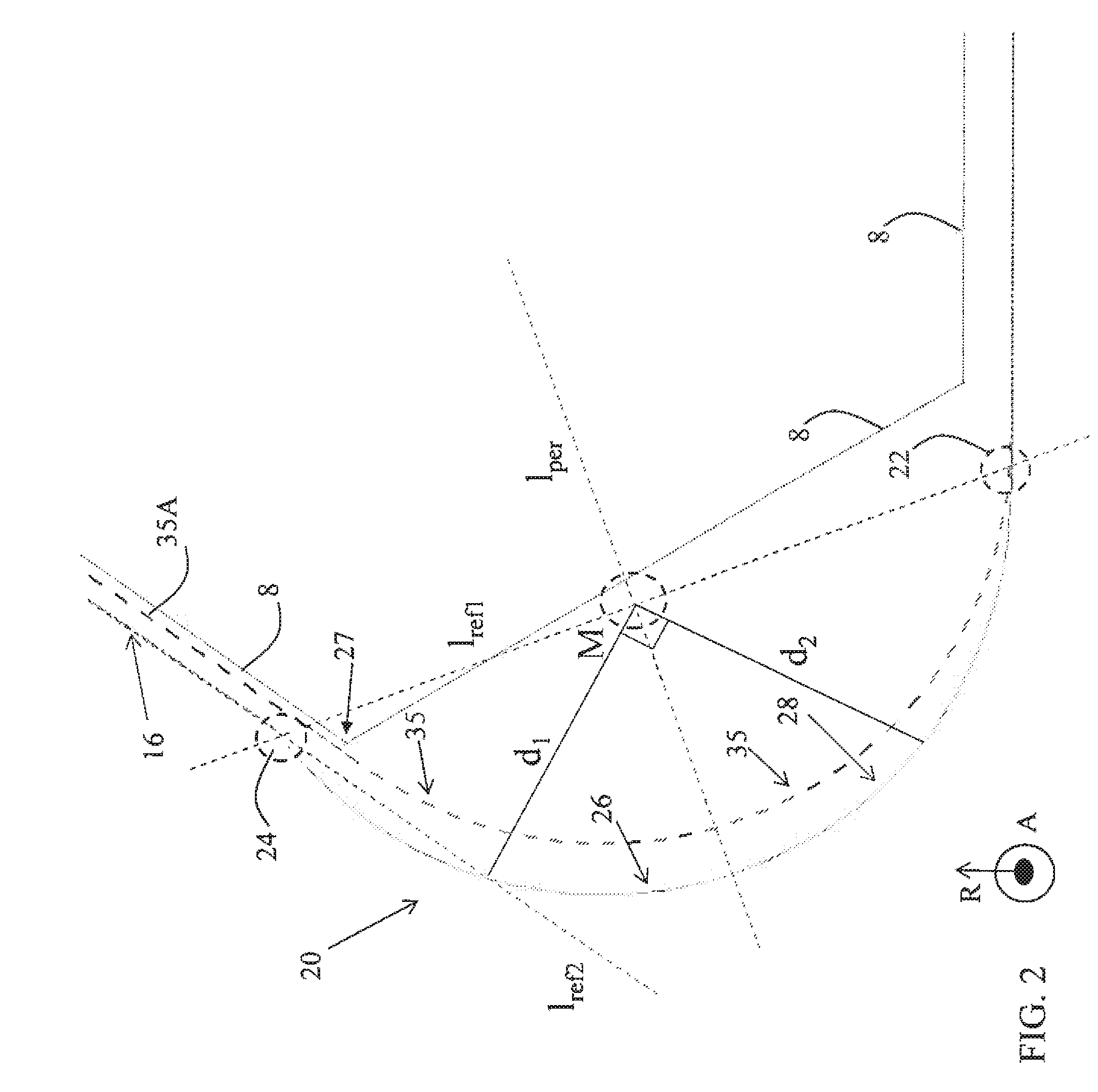

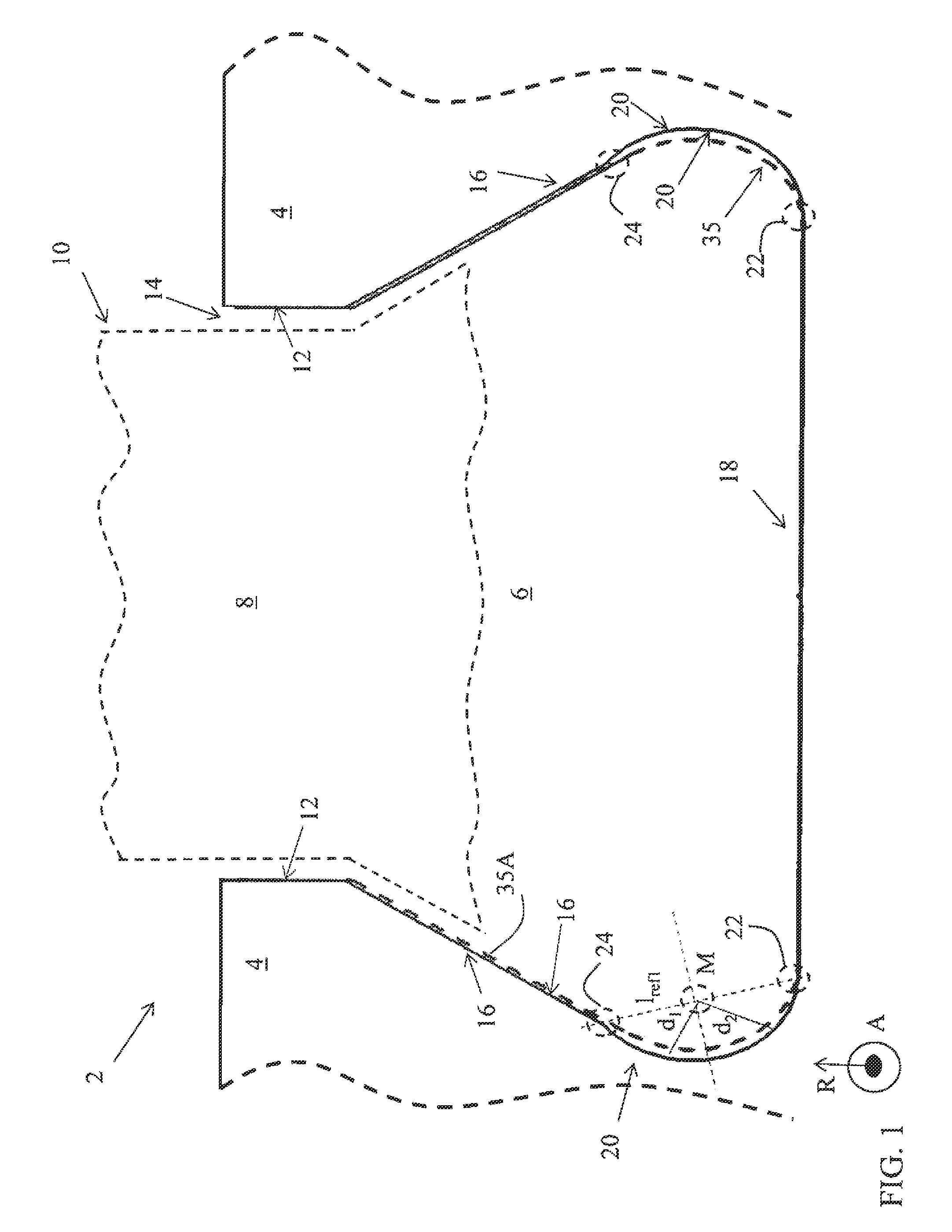

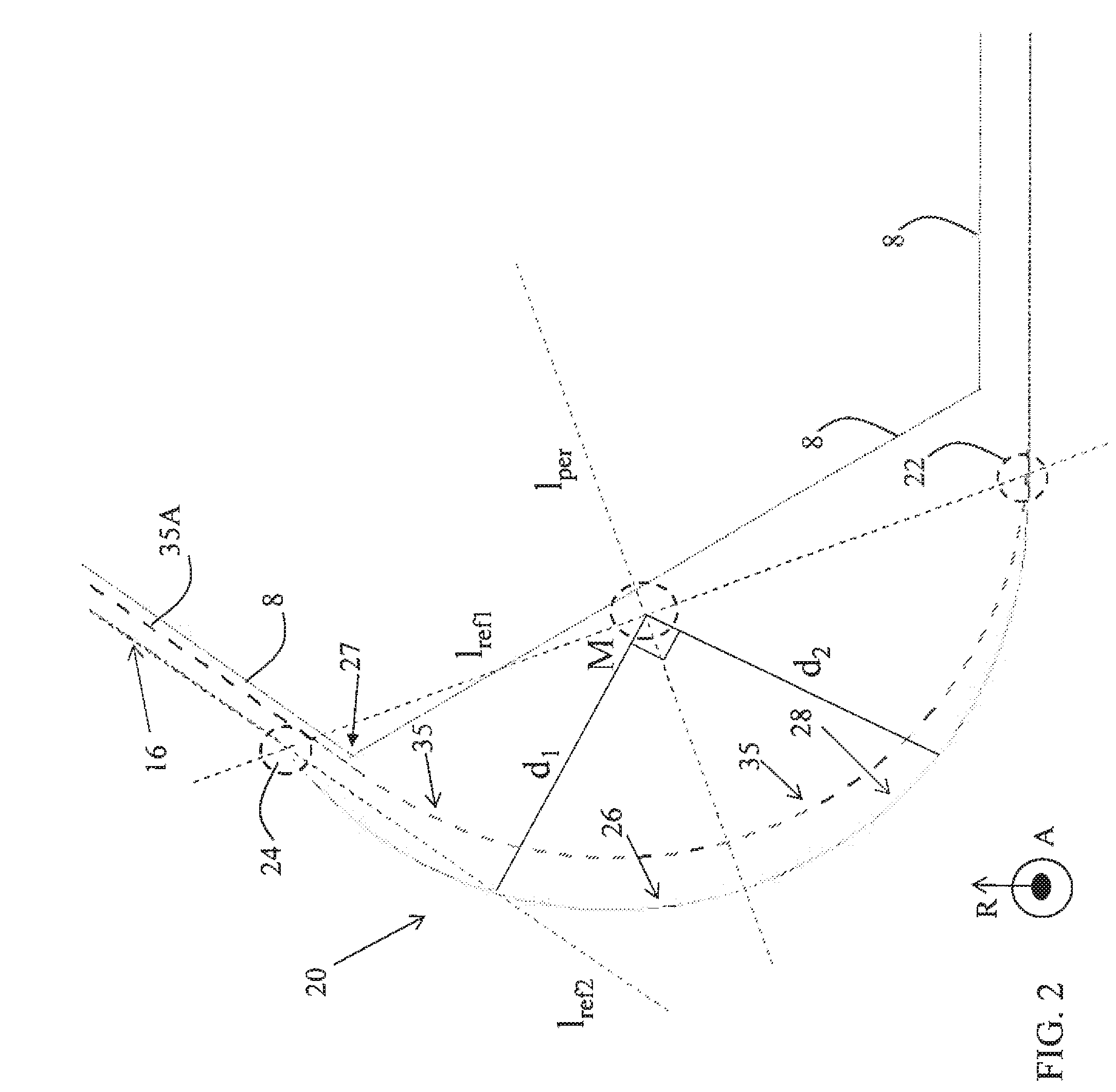

Method, bar blade, and use thereof for milling spiral bevel gears and hypoid gears

ActiveUS7775749B2Extended service lifeMetal working apparatusGear teeth manufacturing toolsGear wheelEngineering

In a method and a bar blade for milling spiral bevel gears and hypoid gears, a shaft of the bar blade has a blade profile that is formed by the cross-section of at least one cutting area, at least two free areas, and at least one top area. The blade profile is provided with a first cutting edge for a first flank, a second cutting edge for a second flank that faces the first flank, and a top cutting edge for the bottom of a tooth space. The first and the second cutting edge are embodied as principal cutting edges for completely cutting the first or second flank. The top cutting edge is configured for completely cutting the bottom of the tooth space such that the tooth space comprising the complete final geometry is created in one milling process by means of one and the same bar blade.

Owner:KLINGELNBERG AG

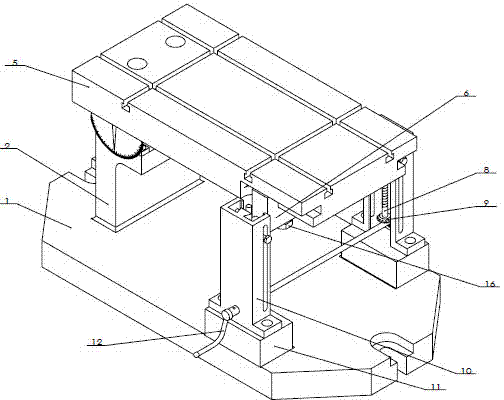

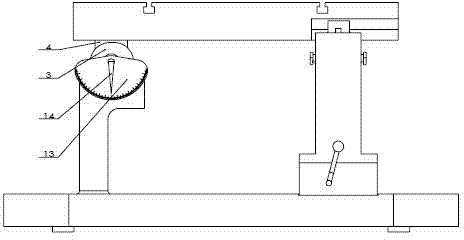

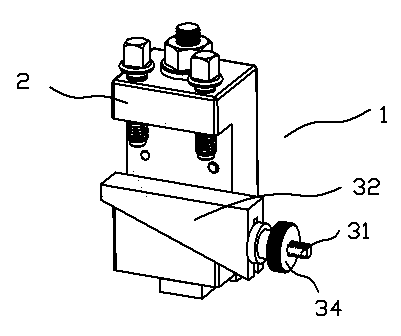

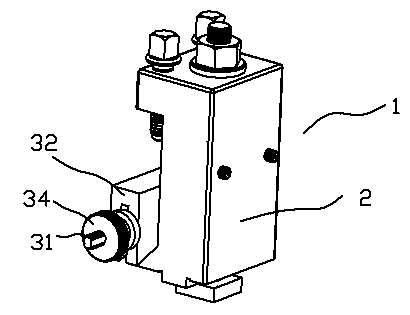

Milling machine fixture capable of adjusting angle

InactiveCN104723135ASimple structureImprove processing efficiencyPositioning apparatusMilling equipmentsMechanical engineering

The invention relates to a milling machine fixture capable of adjusting an angle. The structure is simple, the operation is convenient, the problem that location of a plane with an angle in milling processing is complex in the existing milling processing is solved, the clamping time of a part is greatly shortened, and the processing efficiency is facilitated to be improved. The milling machine fixture capable of adjusting the angle mainly comprises a base, a side wall, a shaft sleeve, a shaft, a working plate, a guide rail, a nut, a screw, a bevel wheel and a rocker arm. The angle of the working plate is adjusted through the change of the height of the nut, so that the milling of planes of different angles and the processing of chutes of plate parts are met.

Owner:UNIV OF JINAN

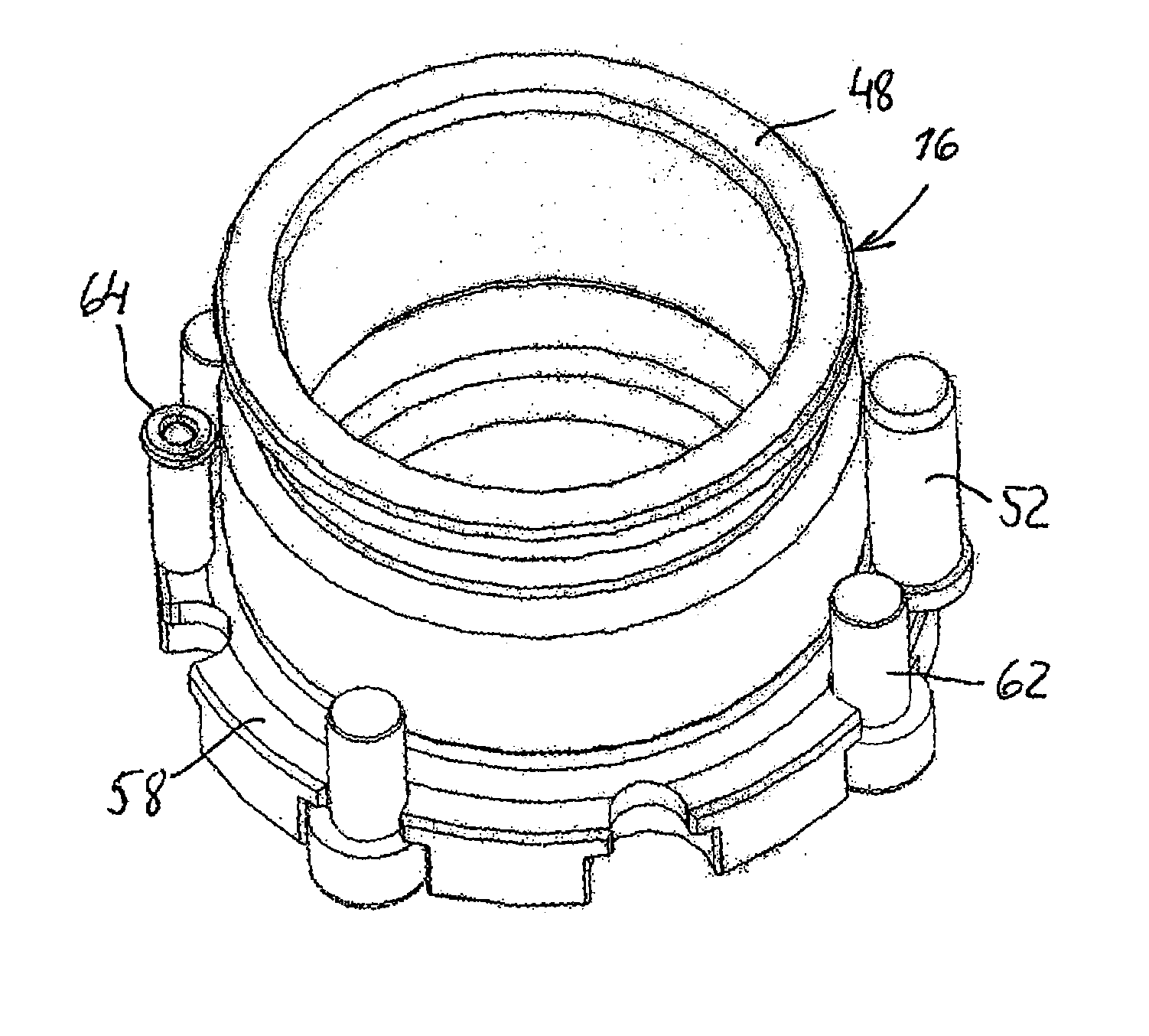

Fixation device for a portable drilling unit

InactiveUS20100040426A1Increase clamping forceDrilling/boring measurement devicesThread cutting machinesDrilling machines

A fixation device for positioning and fixating a portable drilling machine onto a guide bushing on a template, wherein a single locating pin is associated with the guide bushing and extends axially through a separate hole in the drill template adjacent to the guide bushing. A clamping mechanism of the device is configured to concentrically circumscribe a portion of the guide bushing and has a recess for simultaneous engagement with the single locating pin in order to positively lock the housing and a drilling machine attached thereto circumferentially in a predetermined position.

Owner:NOVATOR

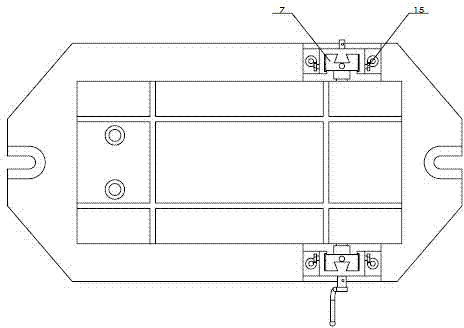

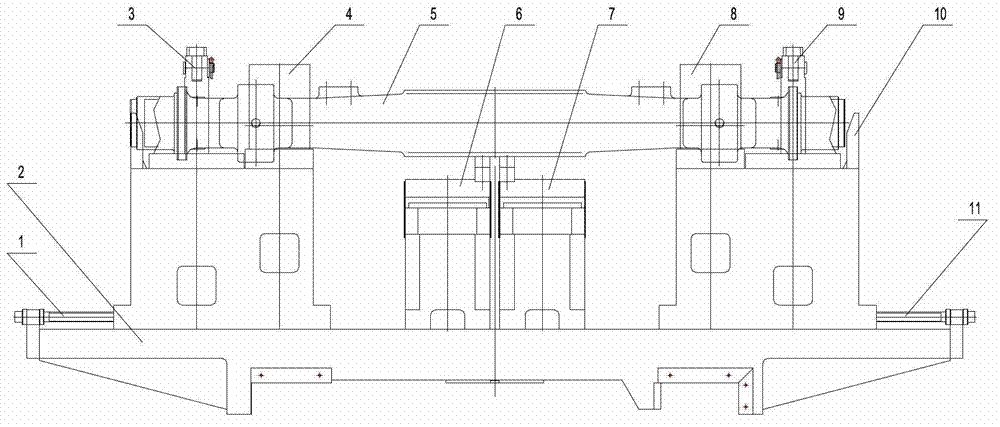

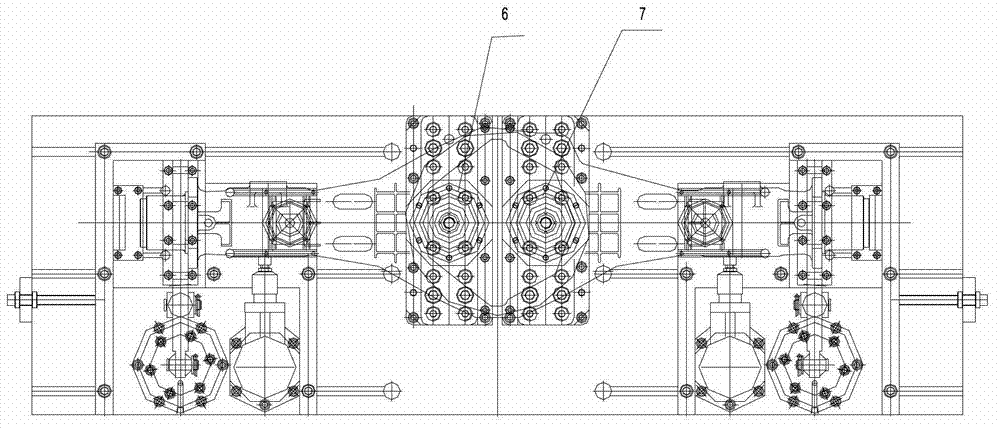

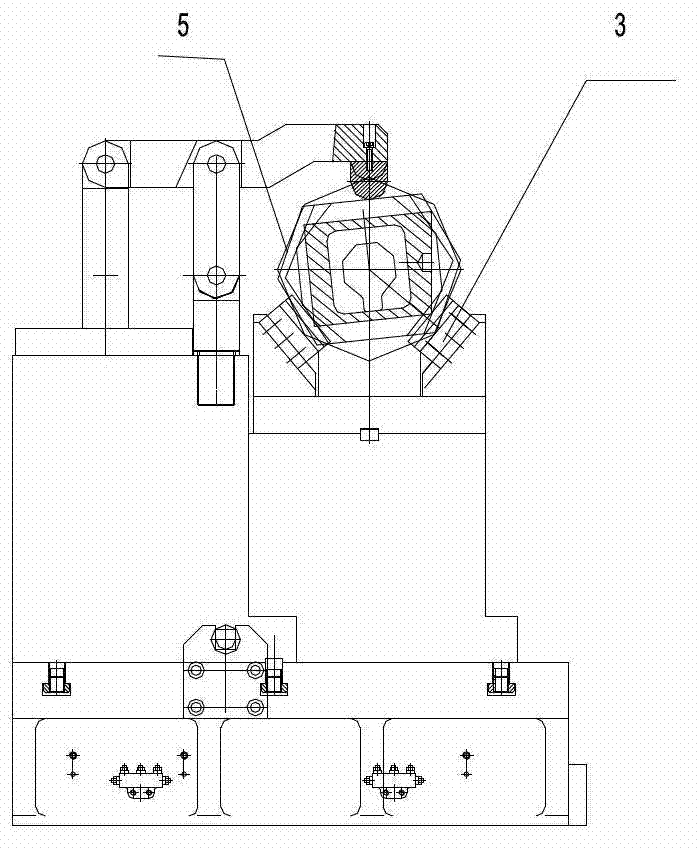

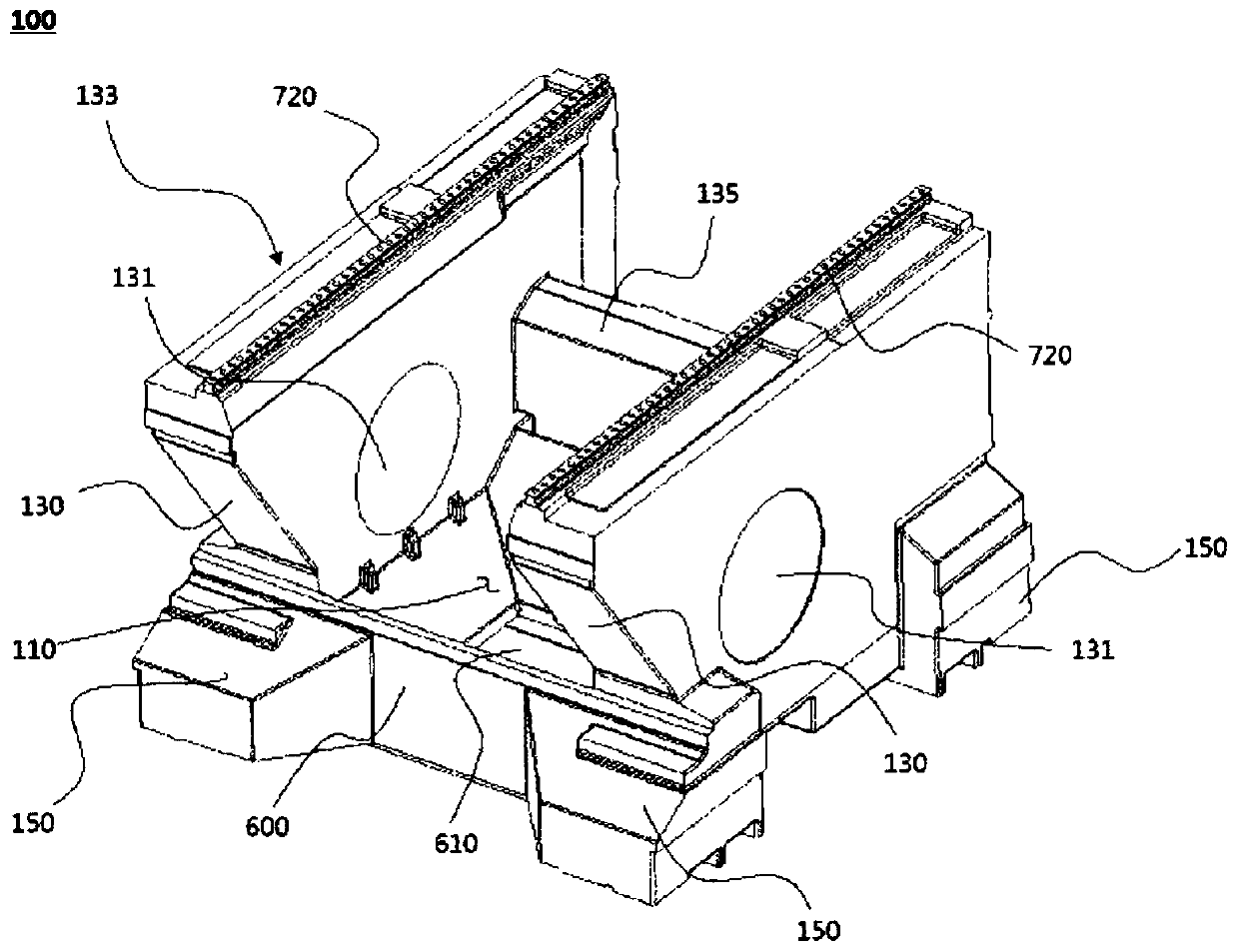

Horizontal numerical-control double-end-milling rear axle housing plane clamp

InactiveCN103586716AExtended service lifeGuaranteed machining accuracyPositioning apparatusMilling equipmentsNumerical controlEngineering

A horizontal numerical-control double-end-milling rear axle housing plane clamp comprises a clamp base. Positioning clamping units are arranged symmetrically at two ends of the clamp base, an adjusting screw is arranged at the outer end of each of the positioning clamping units of the two ends and is used for adjusting positions of the positioning clamping units on the clamp base, a rear axle housing steel plate support upper plane angle positioning unit and a rear axle housing steel plate support lower plane angle positioning unit are arranged on the lower portion of a rear axle housing steel plate support, and work-piece end positioning units are arranged at the ends of the rear axle housing steel plate support on the positioning clamping units. According to the clamp, the whole clamp is mounted on a numerical-control hydraulic sliding platform, multiple times of feeding machining is performed on large-margin planes, the cutter service life is prolonged, and the machining accuracy is guaranteed.

Owner:YUANAN YONGAN AUTO AXLE

Turbomachine rotor having dovetail slot and method of machining

Owner:GENERAL ELECTRIC CO

Insert for drill and indexable insert drill

ActiveUS7891916B2Improve surface qualityRadial run out alsoTransportation and packagingCutting insertsCurve shapeEngineering

An insert for a drill in which one of the cutting edges respectively formed at four side ridge portions of a rake face of a square flat plate-shaped insert body is made to protrude toward the tip of the drill body of the indexable insert drill while being detachably attached is provided. Each of the cutting edges has a corner cutting edge located at a corner of the rake face, and a major cutting edge and a wiper edge which extend substantially toward one peripheral direction of the rake face from a corner cutting edge. The major cutting edge has a first major cutting edge portion which has a convexly curved shape and extends from the corner cutting edge, and a second major cutting edge portion which smoothly touches the first major cutting edge portion and extends linearly, as seen from a direction facing the rake face. The wiper edge has a straight shape intersecting the second major cutting edge portion at an obtuse angle.

Owner:MITSUBISHI MATERIALS CORP

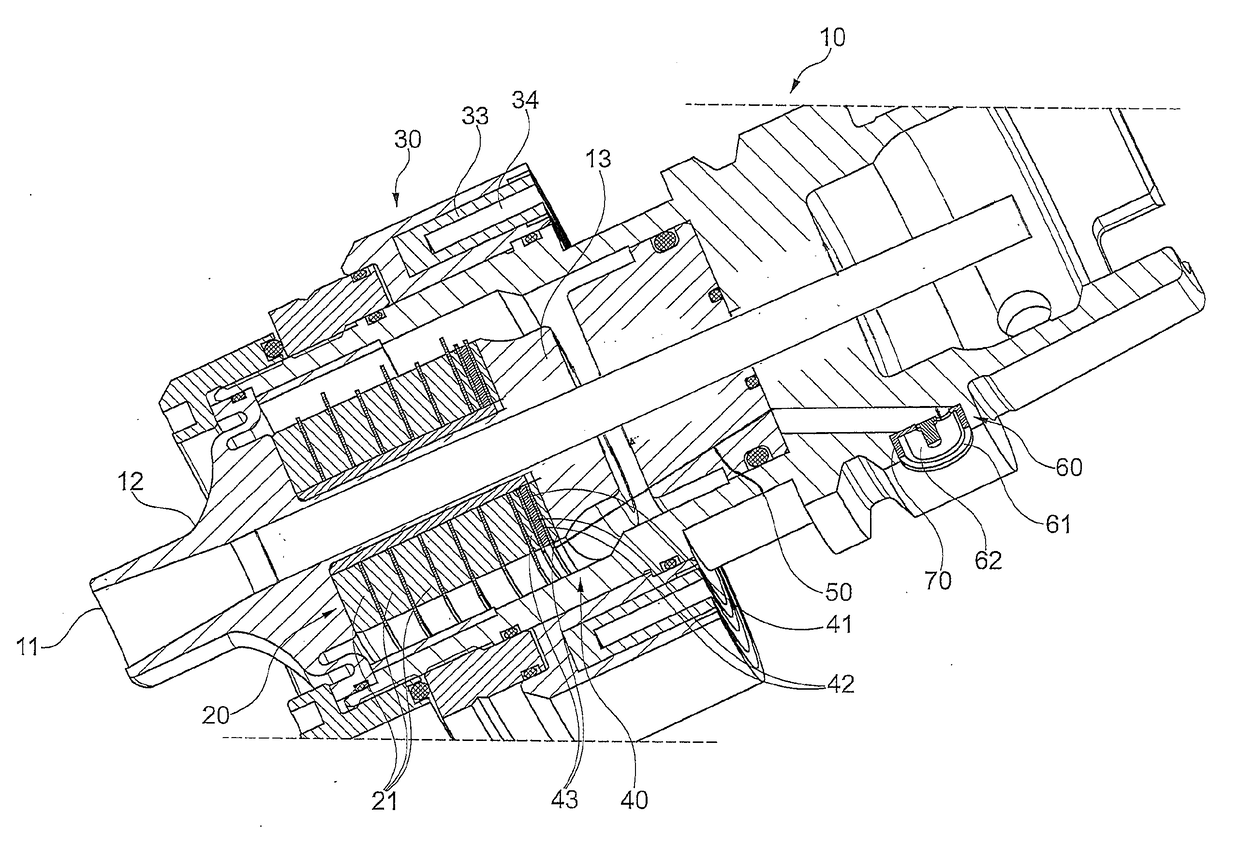

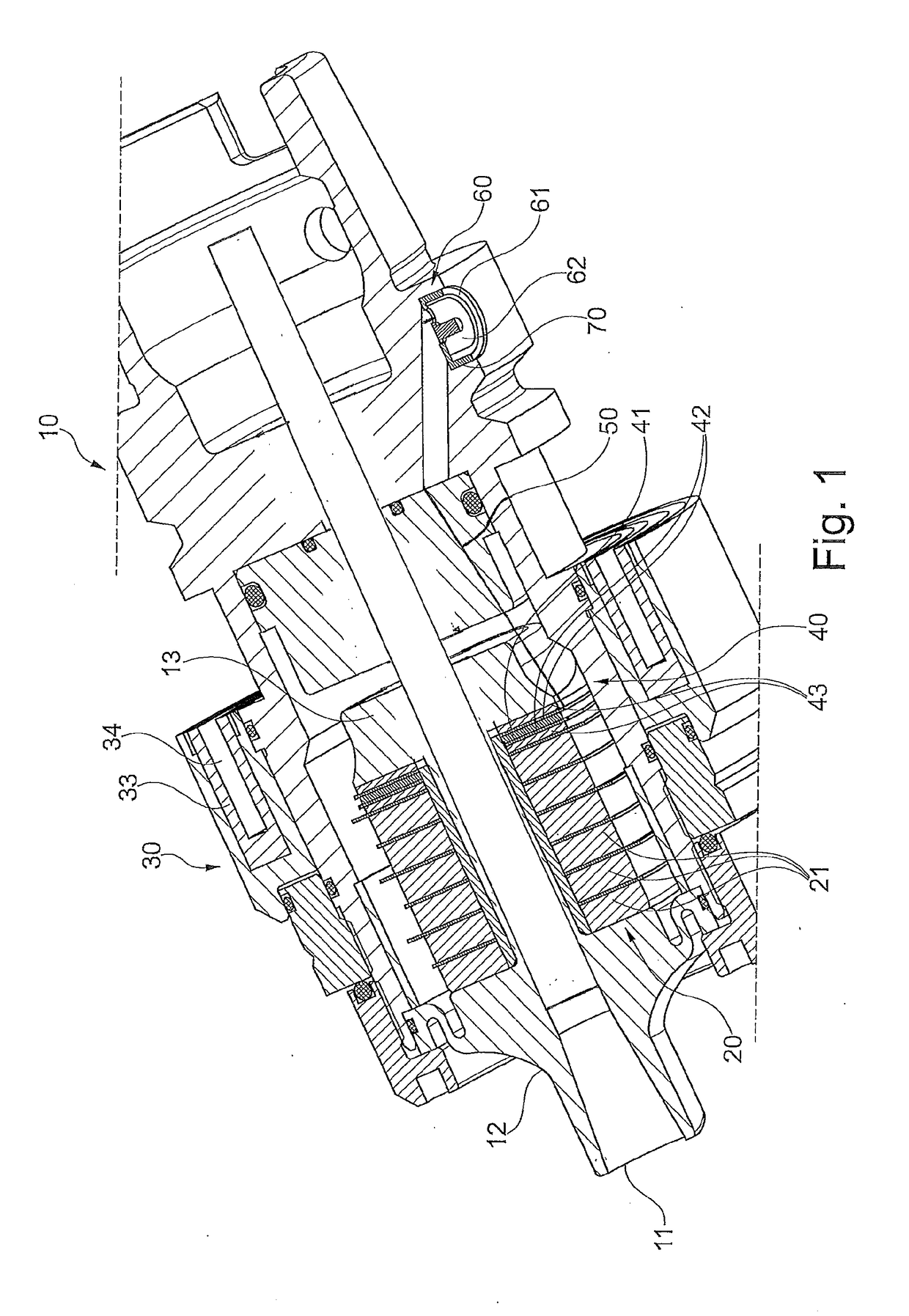

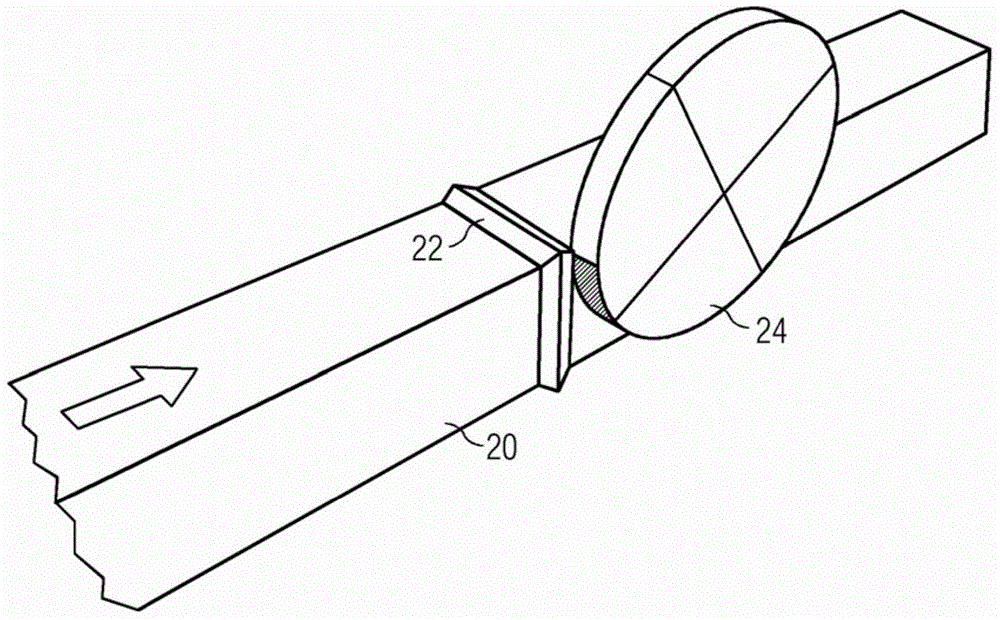

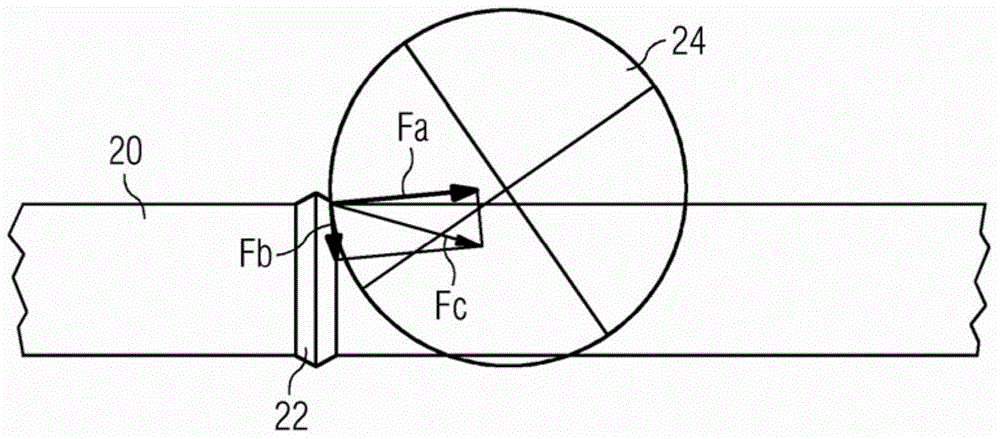

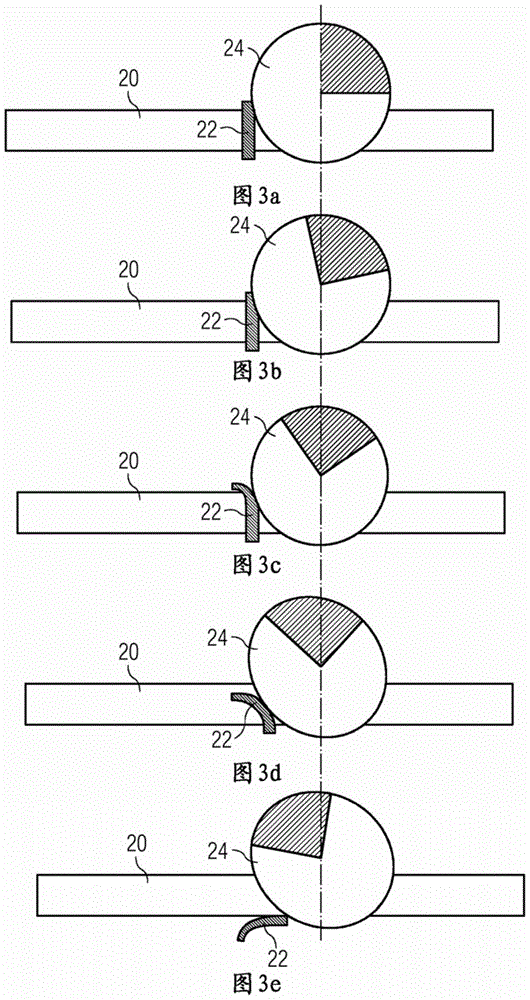

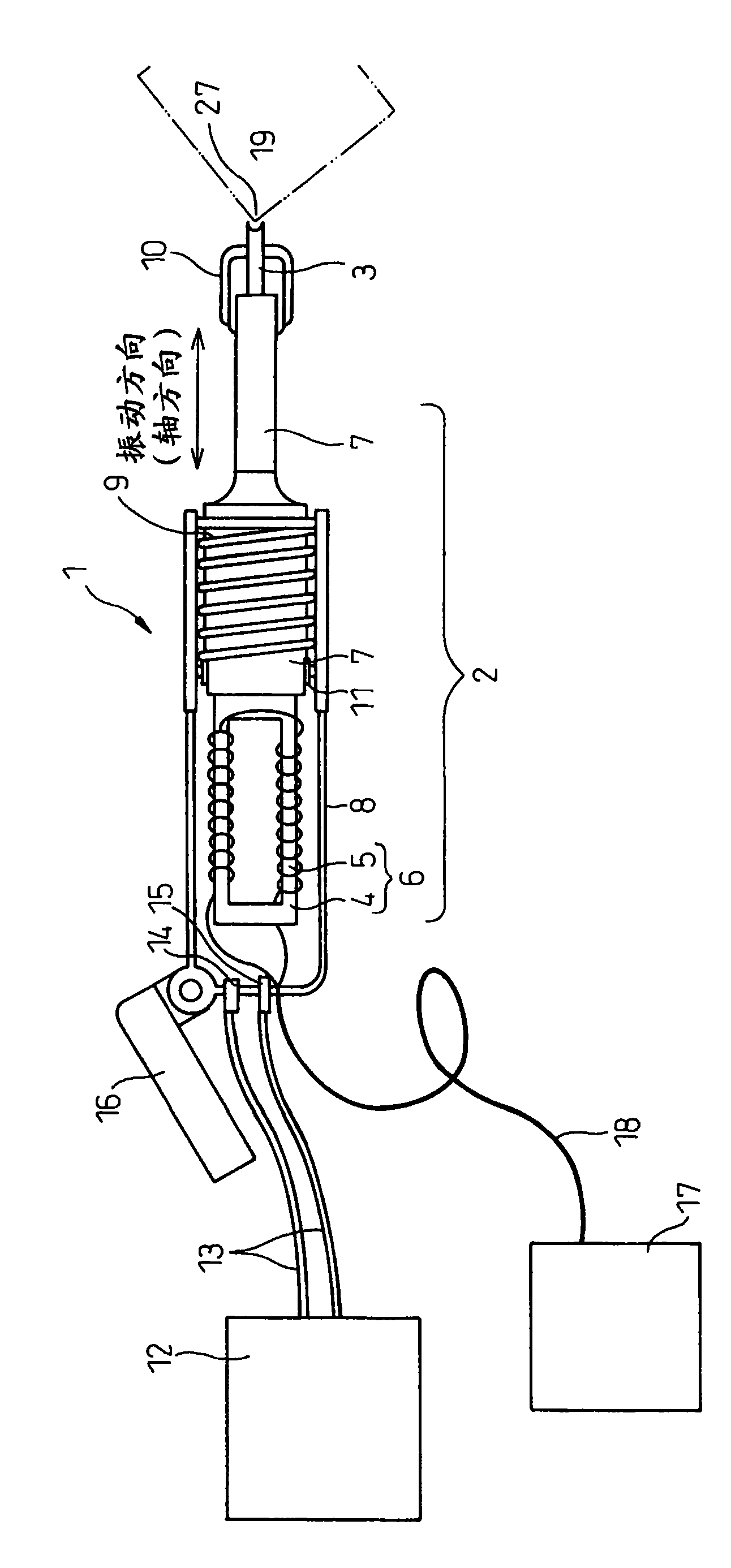

Device for generating an ultrasonic vibration of a tool and for measuring vibration parameters

ActiveUS20180193925A1Improve accuracyReduce the amplitudeSubsonic/sonic/ultrasonic wave measurementUsing electrical meansSignal onUltrasonic machining

The present invention relates to a device for generating an ultrasonic vibration of a tool used for the ultrasonic machining of a workpiece and for measuring ultrasonic vibration parameters of the ultrasonic vibration of the tool having a tool holder for receiving the tool, an ultrasonic transducer in the tool holder for generating the ultrasonic vibration of the tool, a sensor mechanism in the tool holder for producing a sensor signal on the basis of the ultrasonic vibration of the tool, and a sensor signal evaluation device for evaluating the sensor signal.

Owner:SAUER GMBH

Deburring apparatus with driving means for rotatably and reversibly driving the apparatus to and away of a billet

ActiveCN104968468AExtend your lifeReduce maintenance costsWelding/cutting auxillary devicesAuxillary welding devicesEngineering

Owner:PRIMETALS TECH AUSTRIA GMBH

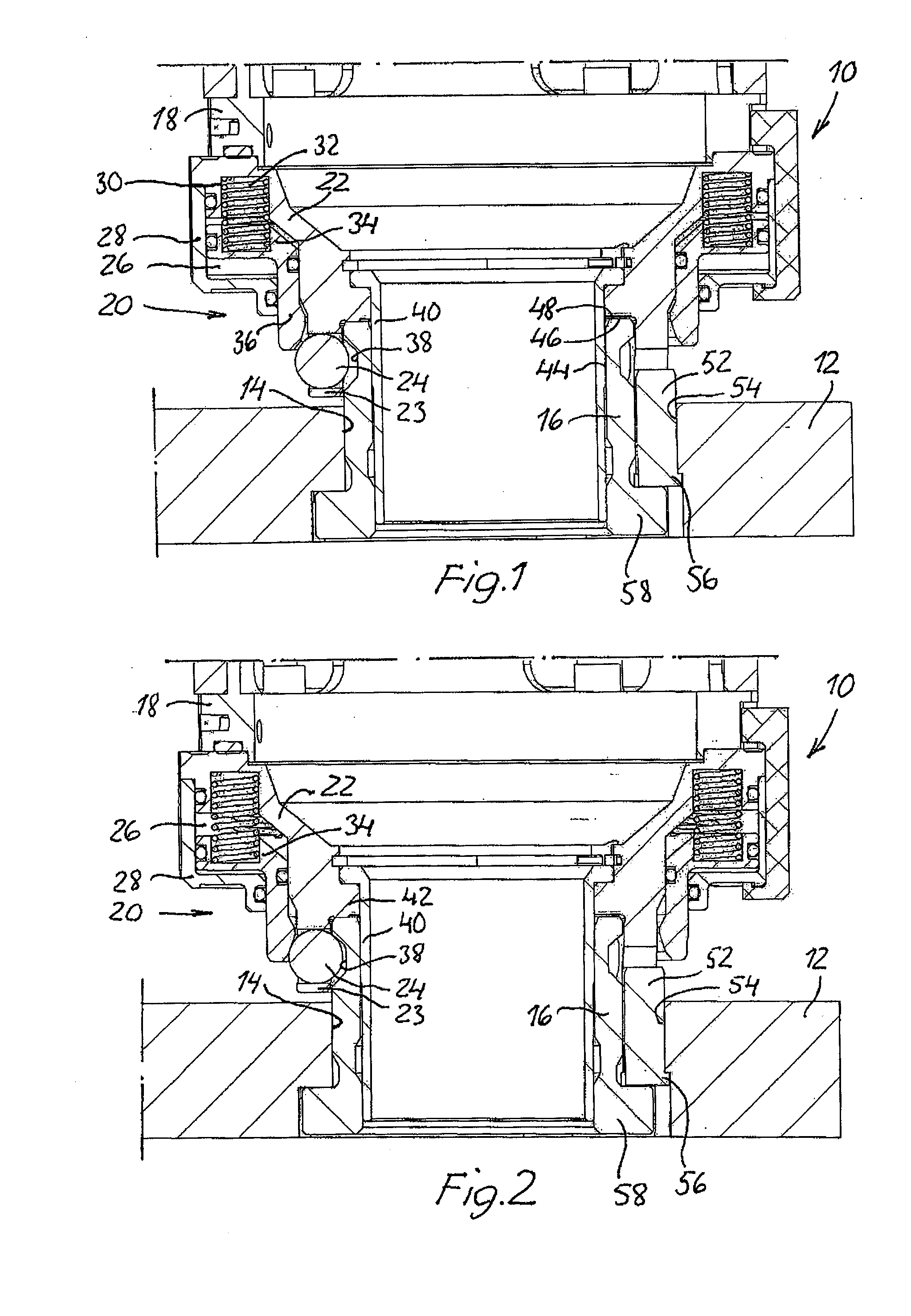

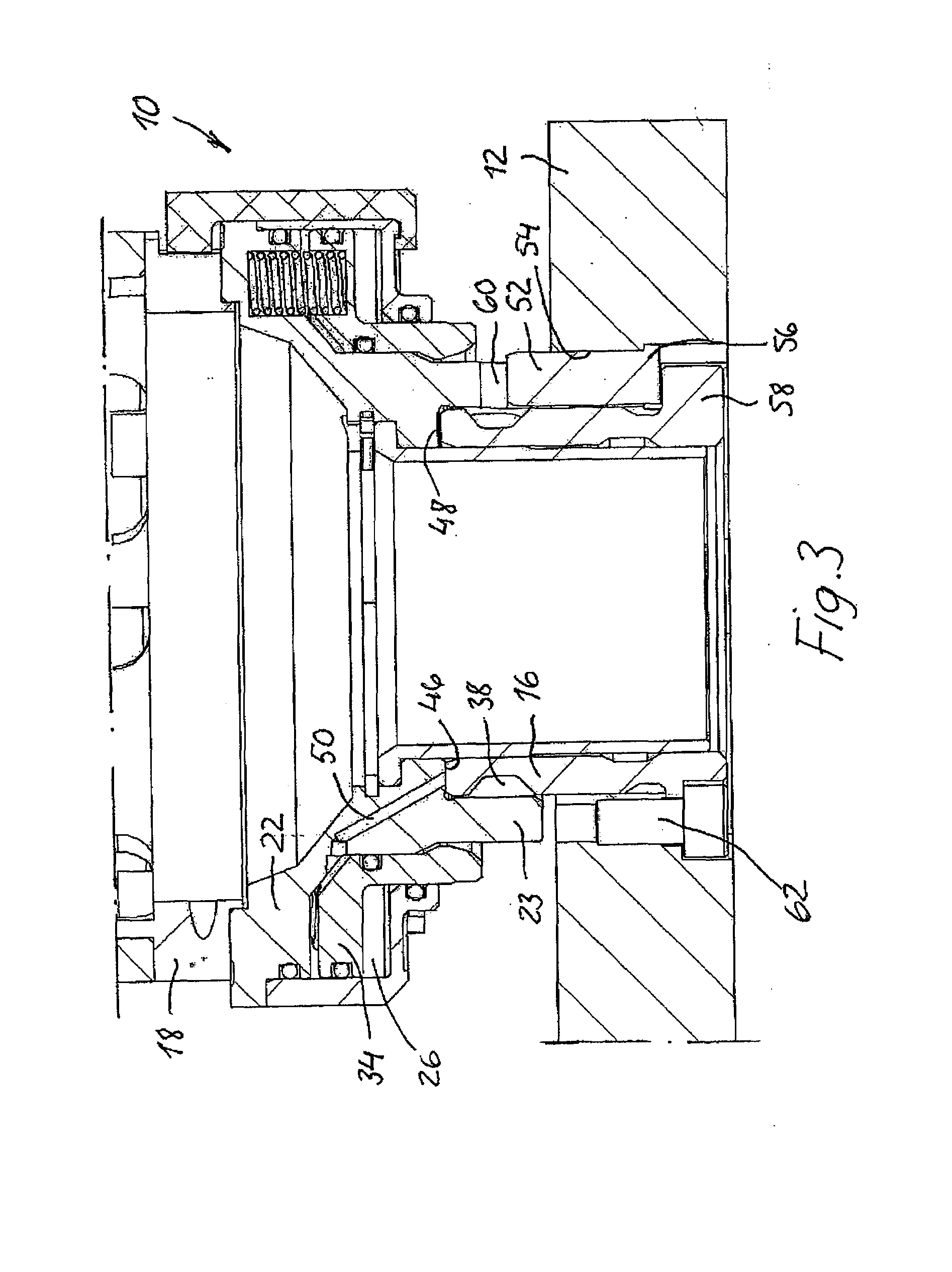

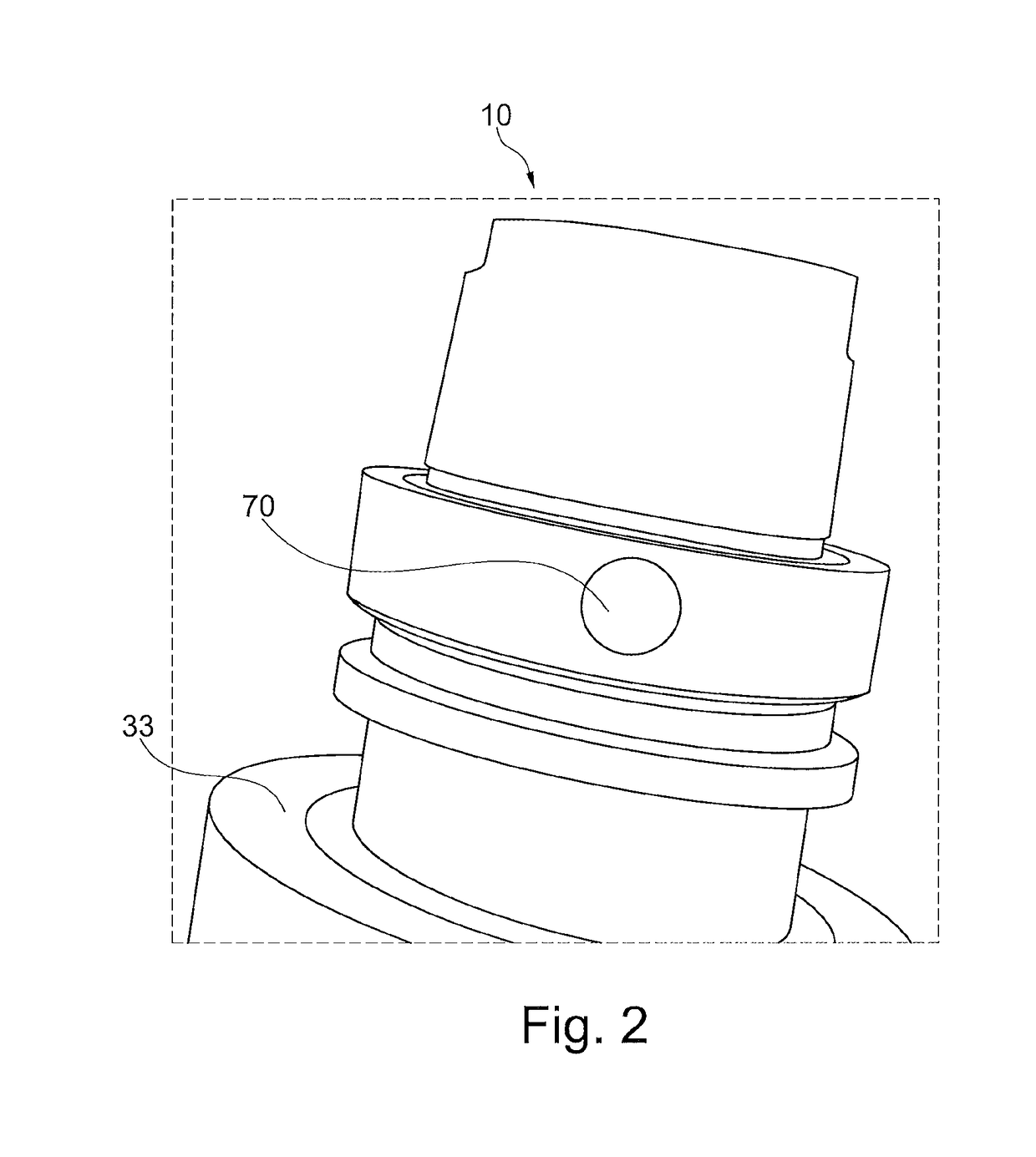

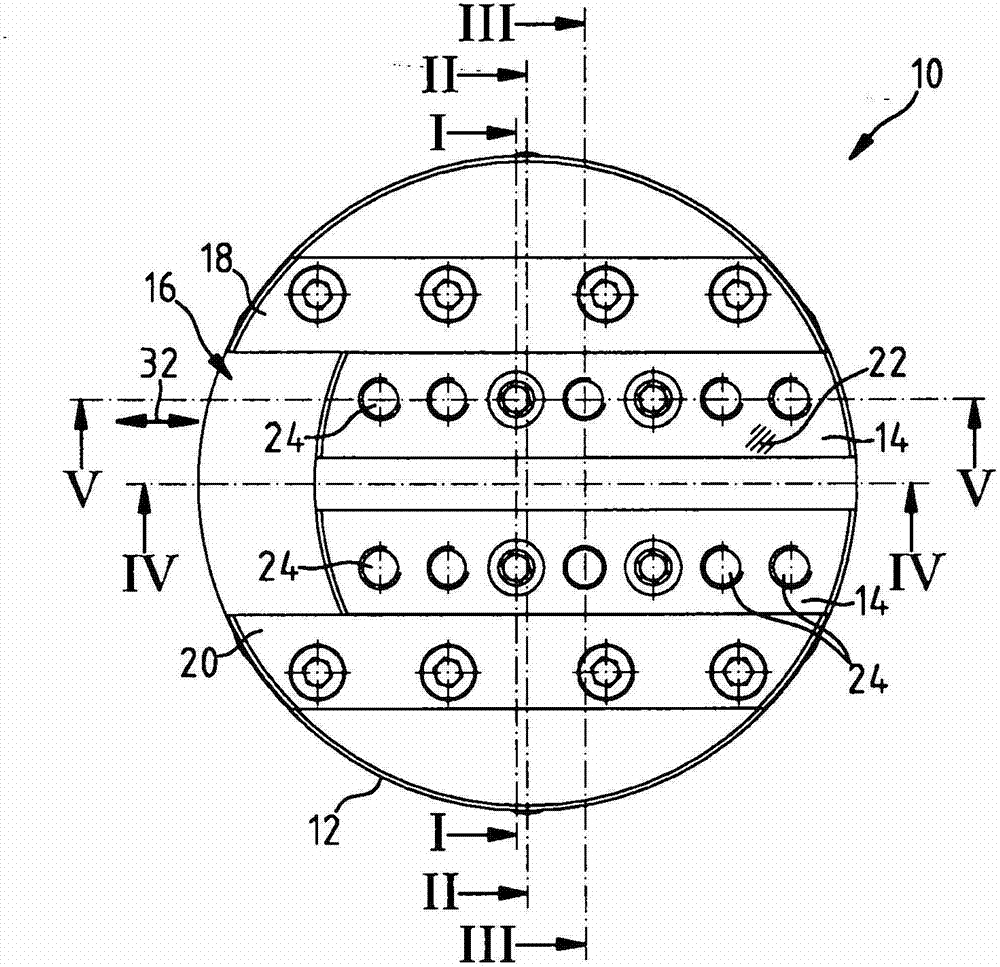

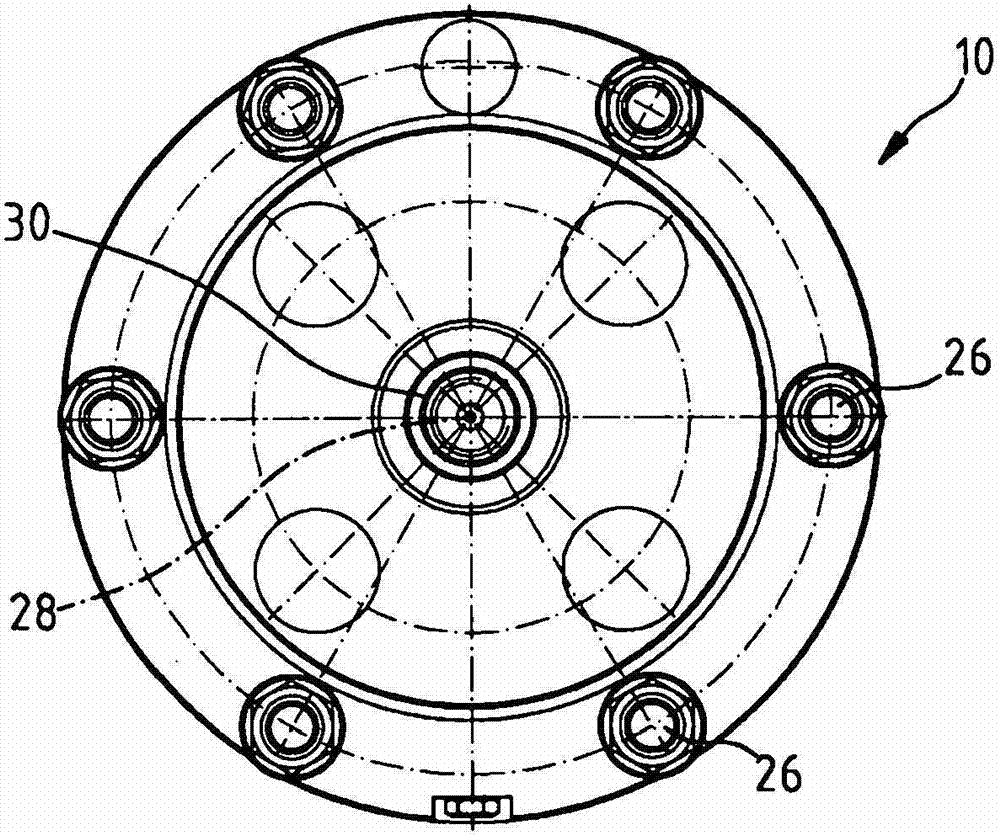

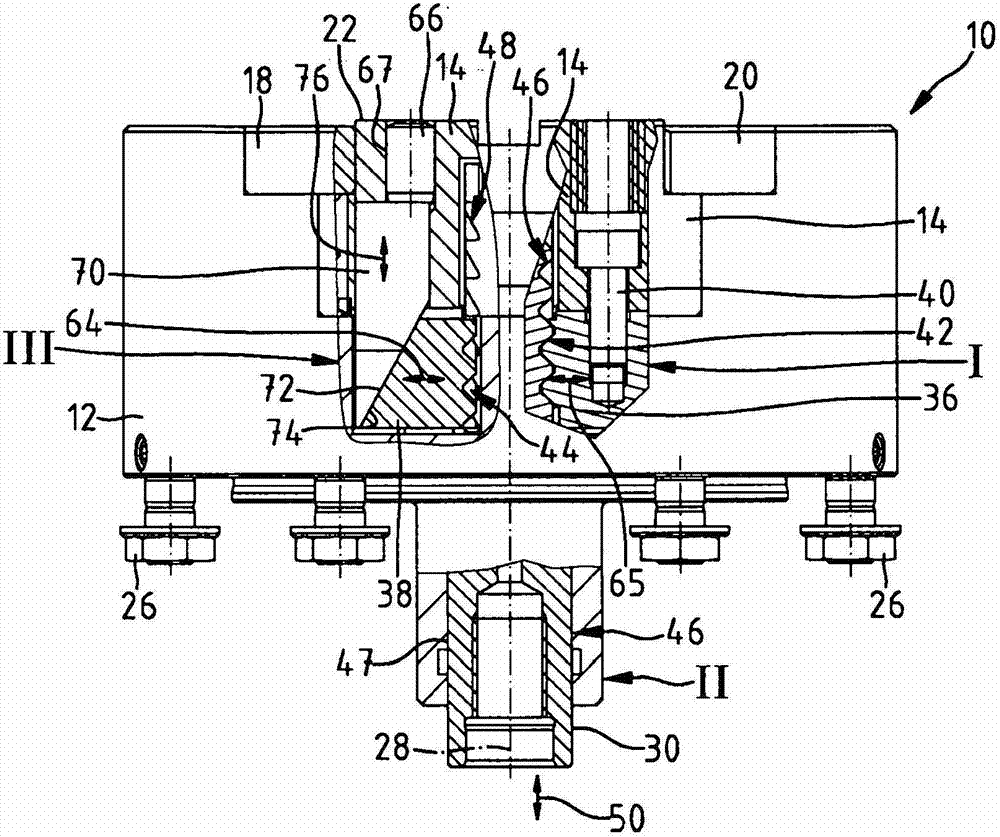

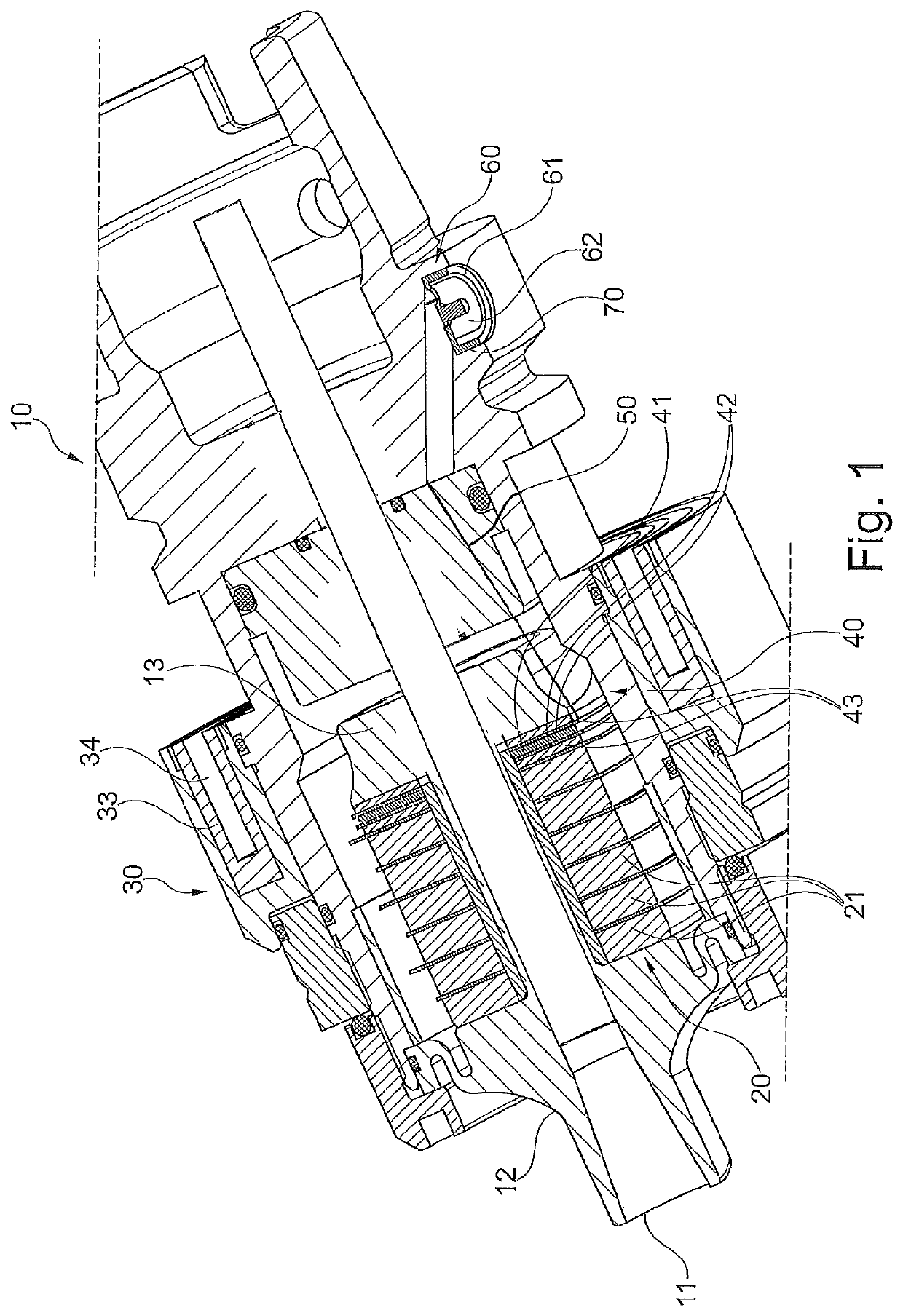

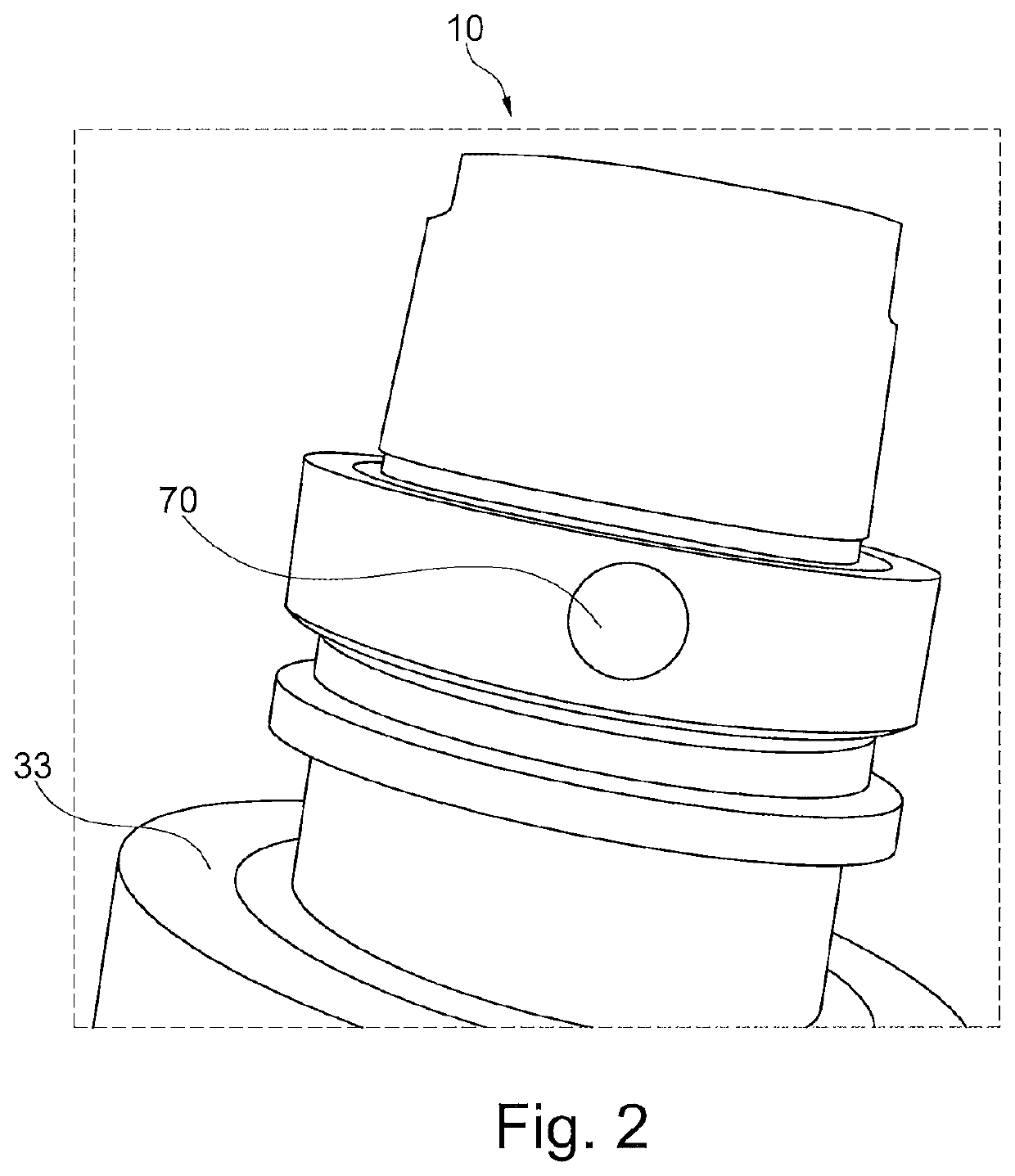

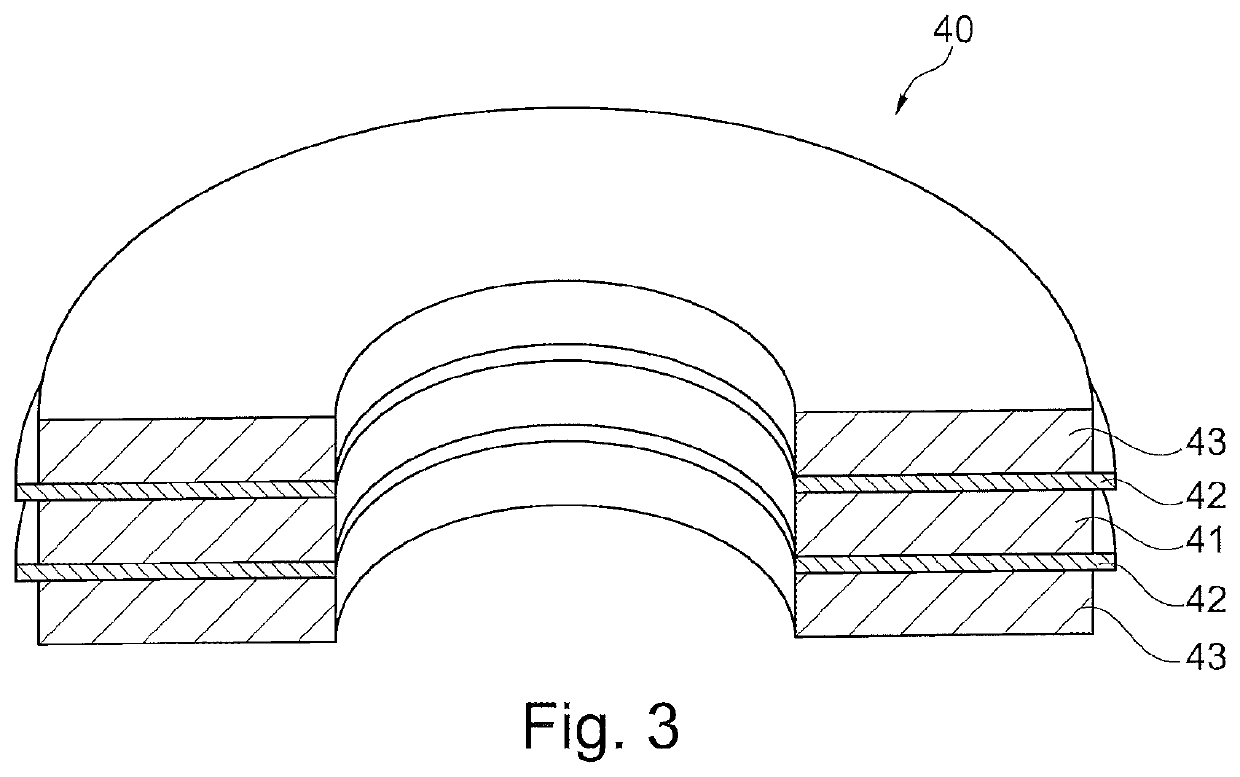

Tool head for use in machine tools

ActiveCN103097059ACompensation clearanceNo high costBoring headsMilling equipmentsEngineeringMachine tool

The invention relates to a tool head (10) for use in machine tools, comprising a main body (12) which can be rotated around an axis of rotation (28). The tool head (10) has a slide (14). The slide (14) can be moved by means of a pull rod (30) axially oriented in the main body (12). The slide (14) can be fitted with at least one tool or one tool holder. At least one adjustable toothed plate (36, 38) is fixedly arranged on the slide (14). The toothed plate (36, 38) comprises a helical gearing (42, 44) functioning as a gear means for engaging with a helical gearing (44, 48) of the pull rod (30) which is complementary thereto. According to the invention, the slide (14) has an adjustment unit (66) for moving the at least one toothed plate (36, 38) and the helical gearing (42, 44) thereof into the complementary helical gearing (44, 48) of the pull rod (30).

Owner:KOMET GROUP GMBH

Turbomachine rotor having dovetail slot and method of machining

Owner:GE INFRASTRUCTURE TECH INT LLC

Cutting insert, cutting tool, and method for manufacturing machined product

A cutting insert according to one aspect has a flat plate shape including a first main surface having a polygonal shape, a second main surface located opposite to the first main surface, and an outer peripheral surface located between the first main surface and the second main surface. The cutting insert includes a cutting portion located in regions including at least a corner portion of the first main surface, and a main body portion located in a region other than the corner portion. A thickness of the main body portion is larger than a thickness of the cutting portions, and the main body portion includes a recessed portion or a protruding portion located in the outer peripheral surface thereof.

Owner:KYOCERA CORP

Drill

ActiveUS9168593B2Improve performanceImprove cutting performanceWood turning toolsTransportation and packagingEllipseEngineering

A drill includes a cutting edge having a ridgeline. The ridgeline has a part of an ellipse and a straight line. It is assumed that the coordinates of a separation point of an ellipse portion from a straight line portion are (x0, y0). The straight line is a tangent to the ellipse at the separation point. It is assumed that a1 is an area from a tip end of the drill to x0, a2 is an area from x0 to the origin of the ellipse, and a3 is a negative area, along the x-axis. The ridgeline of the cutting edge is formed straight along the tangent in the area a1, and is formed along the ellipse in the area a2. A margin is formed in the area a3 continuously from a relief face of the cutting edge.

Owner:SUBARU CORP

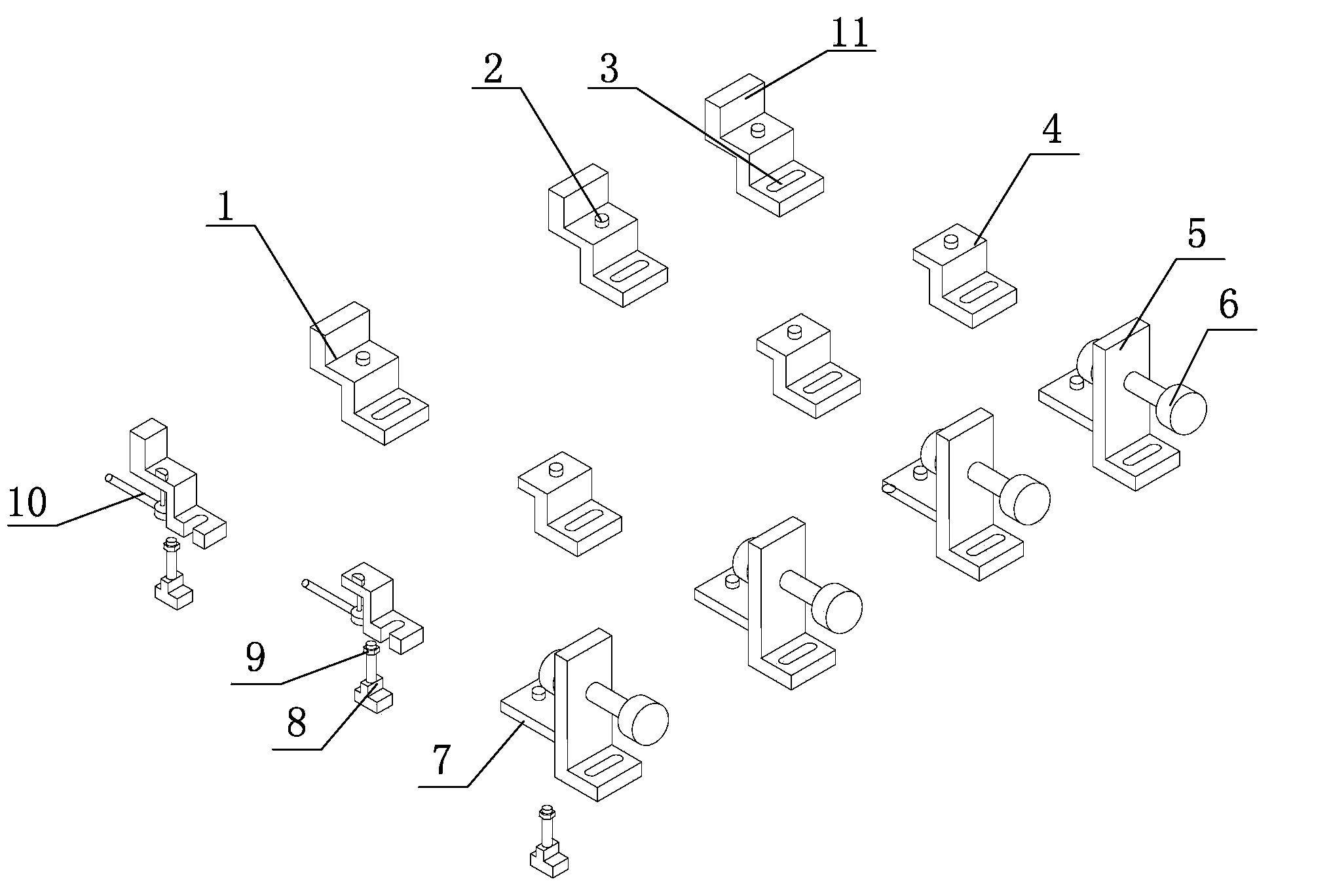

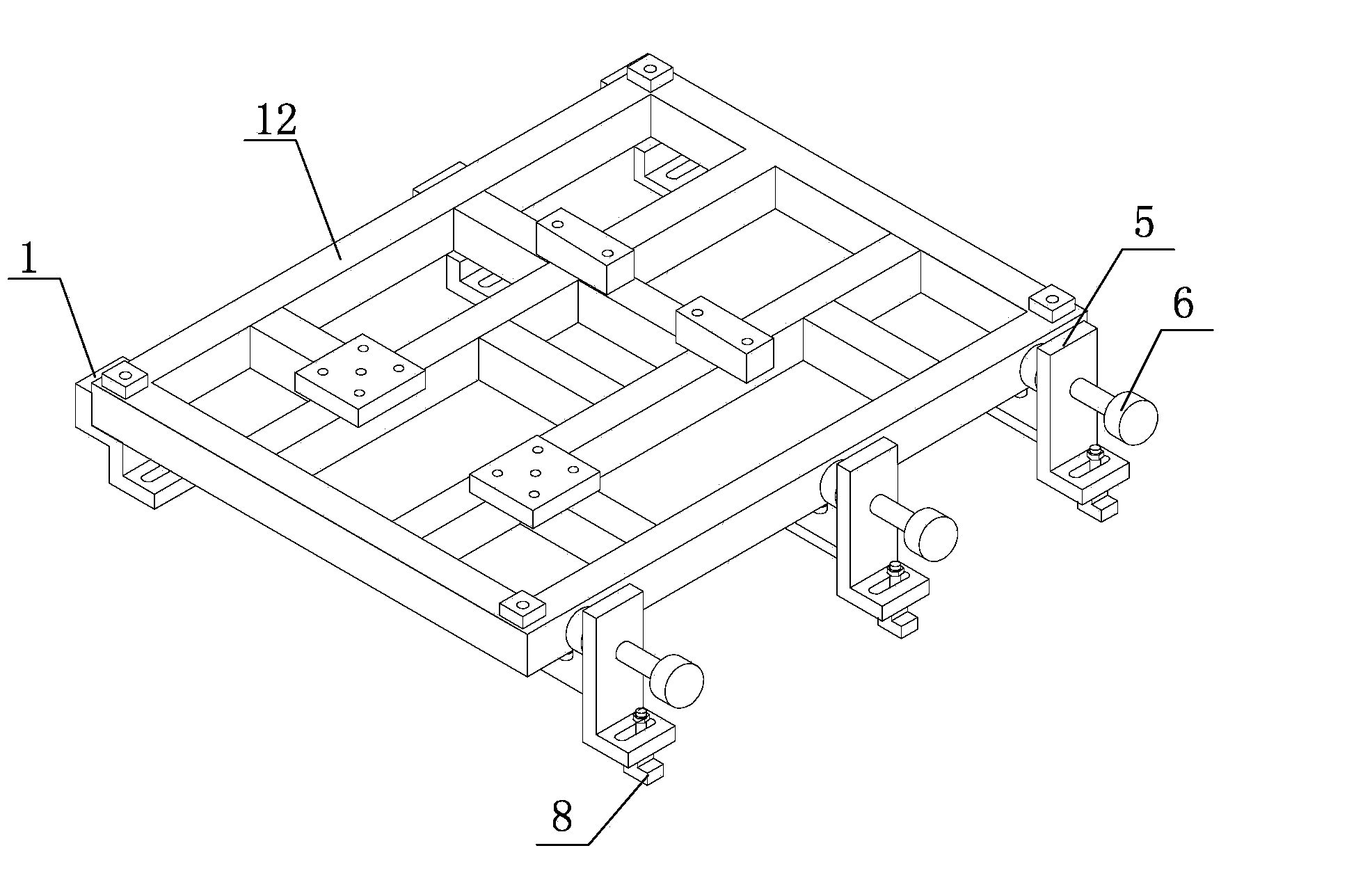

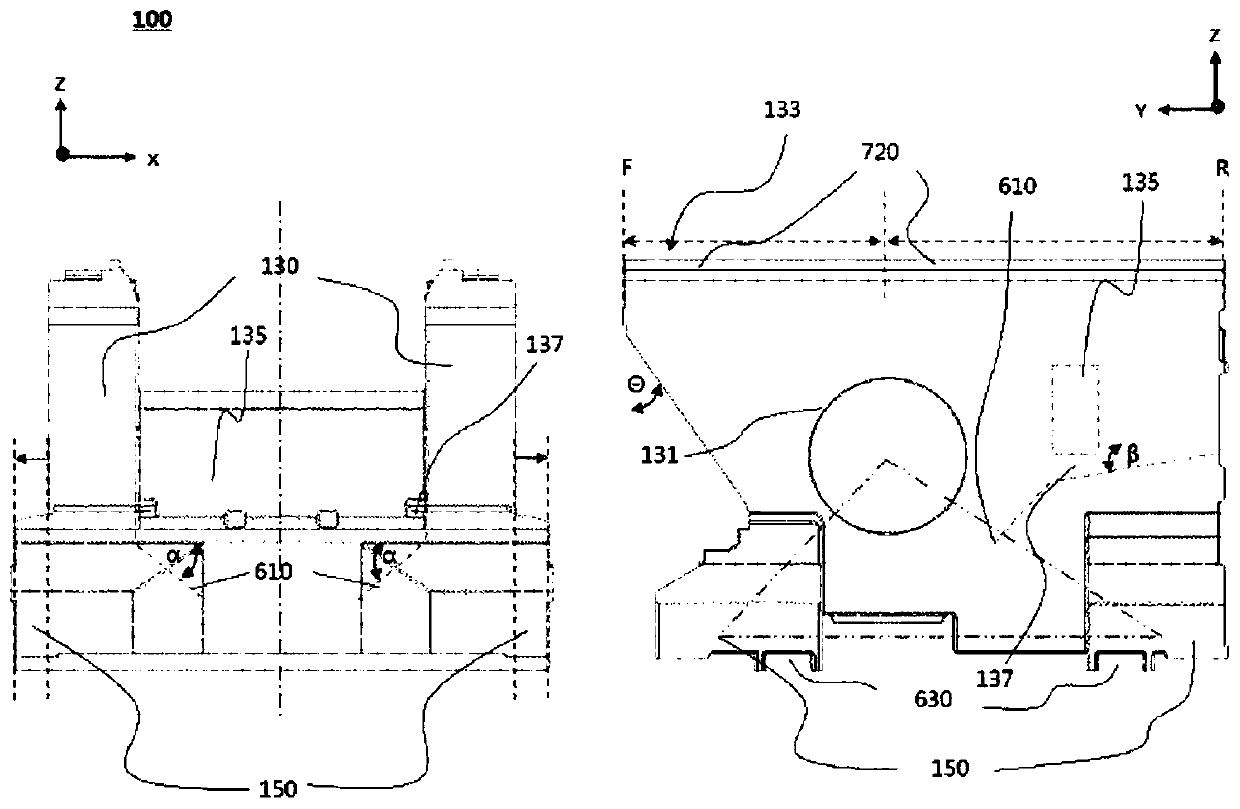

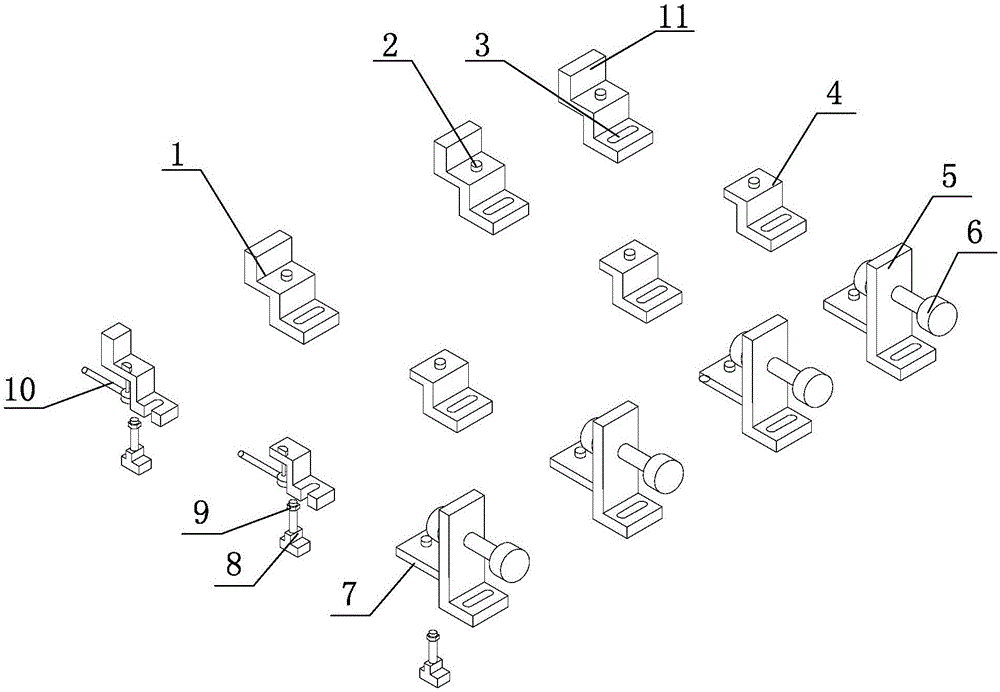

Large aluminum piece milling and positioning clamp

ActiveCN103639755AAvoid deformationEven by forcePositioning apparatusMilling equipmentsEngineeringMechanical engineering

The invention relates to a large aluminum piece milling and positioning clamp which comprises a plurality of first positioning blocks, a plurality of second positioning blocks and a plurality of third positioning blocks. The first positioning blocks, the second positioning blocks and the third positioning blocks are arranged side by side and provided with first steps, wherein the first steps are provided with kidney-shaped holes. The first positioning blocks and the second positioning blocks are provided with second steps, wherein ejection rods are installed on the second steps, and the bottom ends of the ejection rods are connected with a handle. The second steps of the first positioning blocks are provided with stopping blocks. The third positioning blocks consist of L-shaped positioning plates and flat plates which are connected fixedly, wherein the positioning plates are provided with adjusting bolts, and the flat plates are provided with flat plates. The large aluminum piece milling and positioning clamp further comprises a positioning part, wherein the positioning part is provided with a locking bolt. The large aluminum piece milling and positioning clamp is simple in structure, flexible and convenient to use and high in clamping efficiency, and the accuracy is easy to ensure.

Owner:WUXI HANGHU TECH

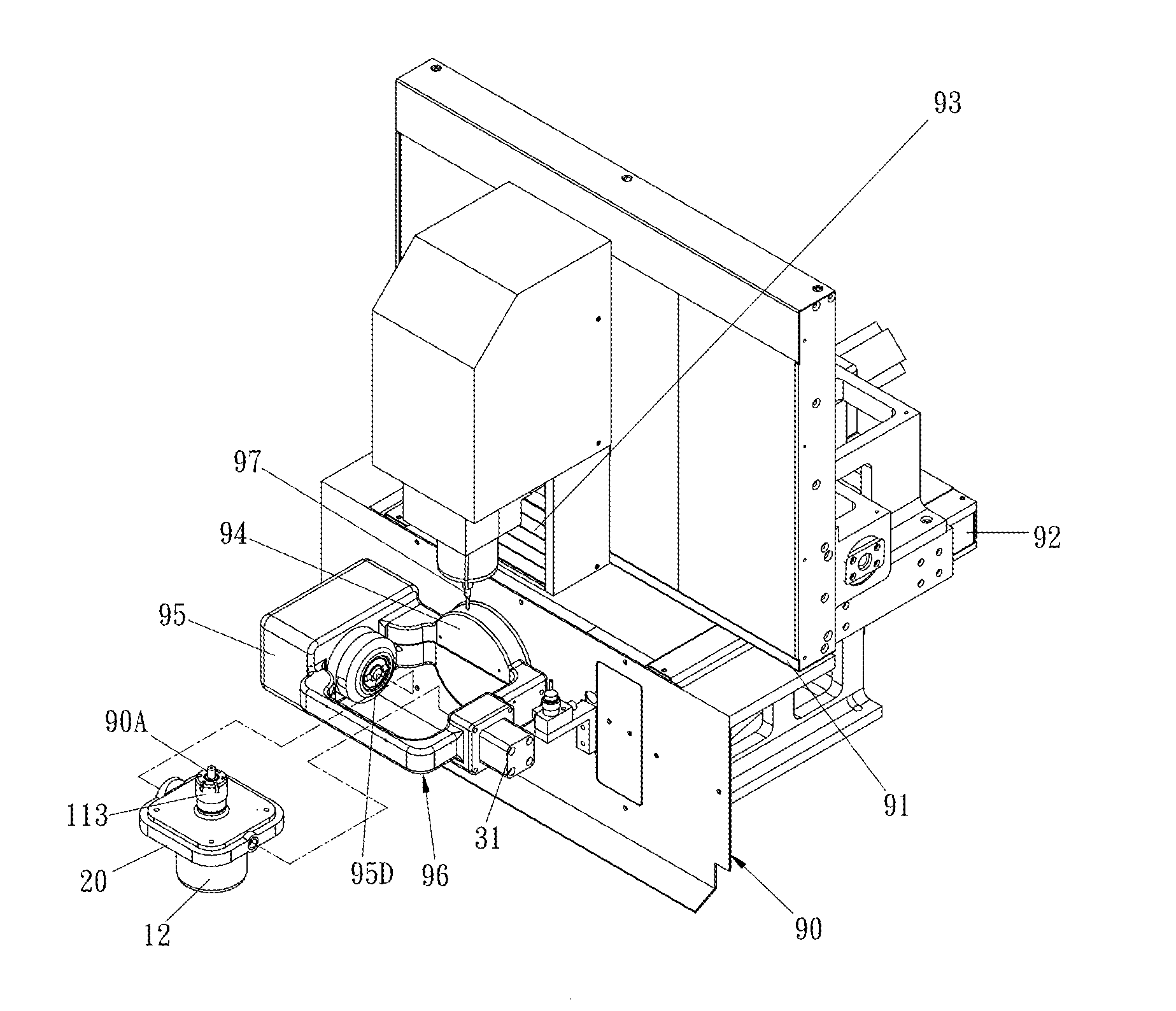

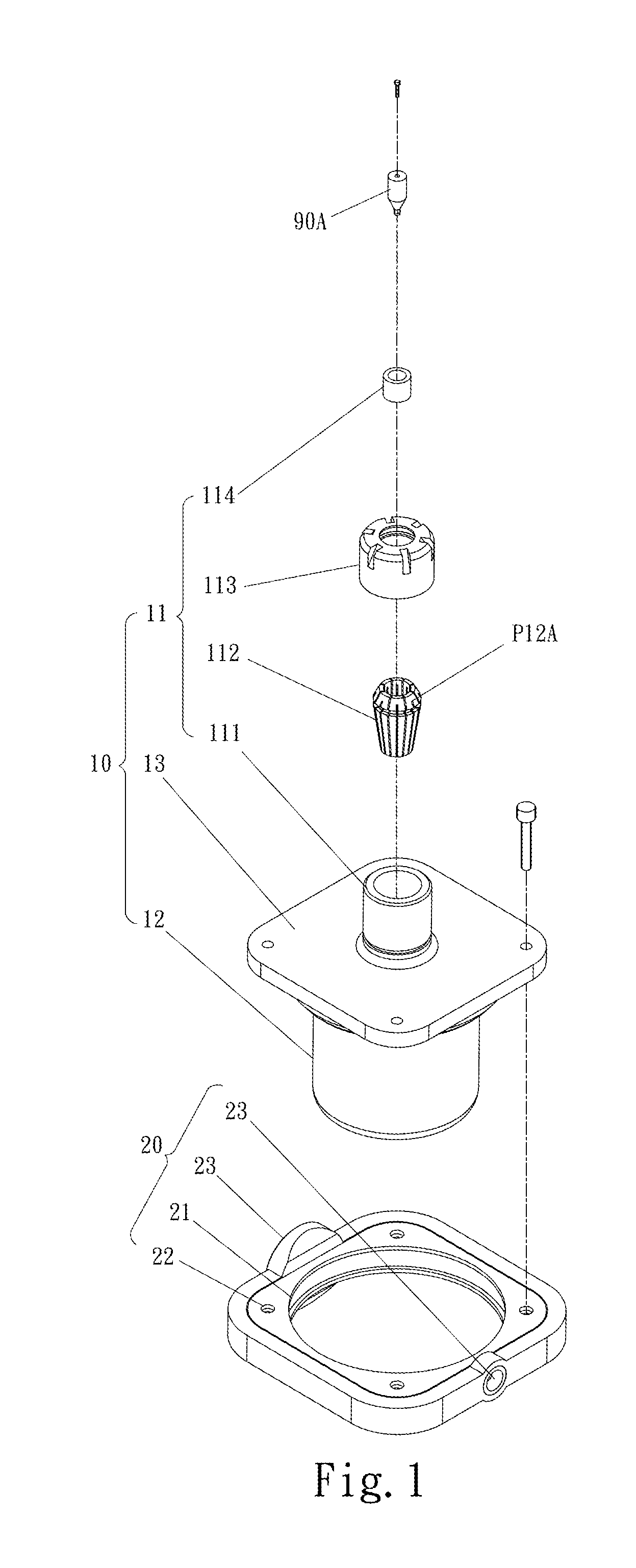

Ultrasonic positioning device for five-axis machine

InactiveUS20160091307A1Suitable for processingEasy to useMaterial analysis using sonic/ultrasonic/infrasonic wavesUsing subsonic/sonic/ultrasonic vibration meansUltrasonic vibrationEngineering

An ultrasonic positioning device for a five-axis machine includes an ultrasonic device and a positioning plate. The ultrasonic device is adapted to fix a material and generates ultrasonic vibrations to the material. The positioning plate is adapted to fix the ultrasonic device and pivotally connected the five-axis machine for the material to be controlled by the five-axis movement on the five-axis machine. By cooperating with the ultrasonic vibrations, a processing portion of the five-axis machine can process the material.

Owner:CHUAN LIANG IND

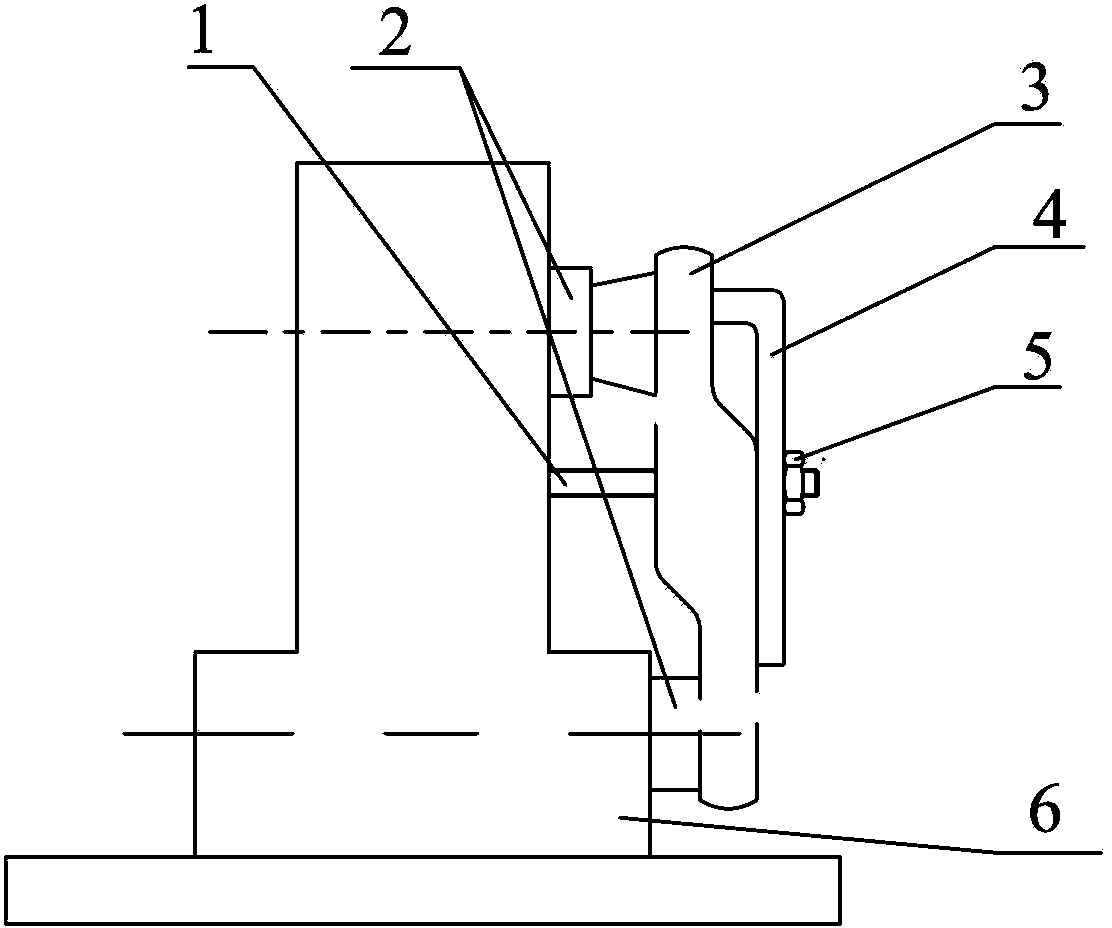

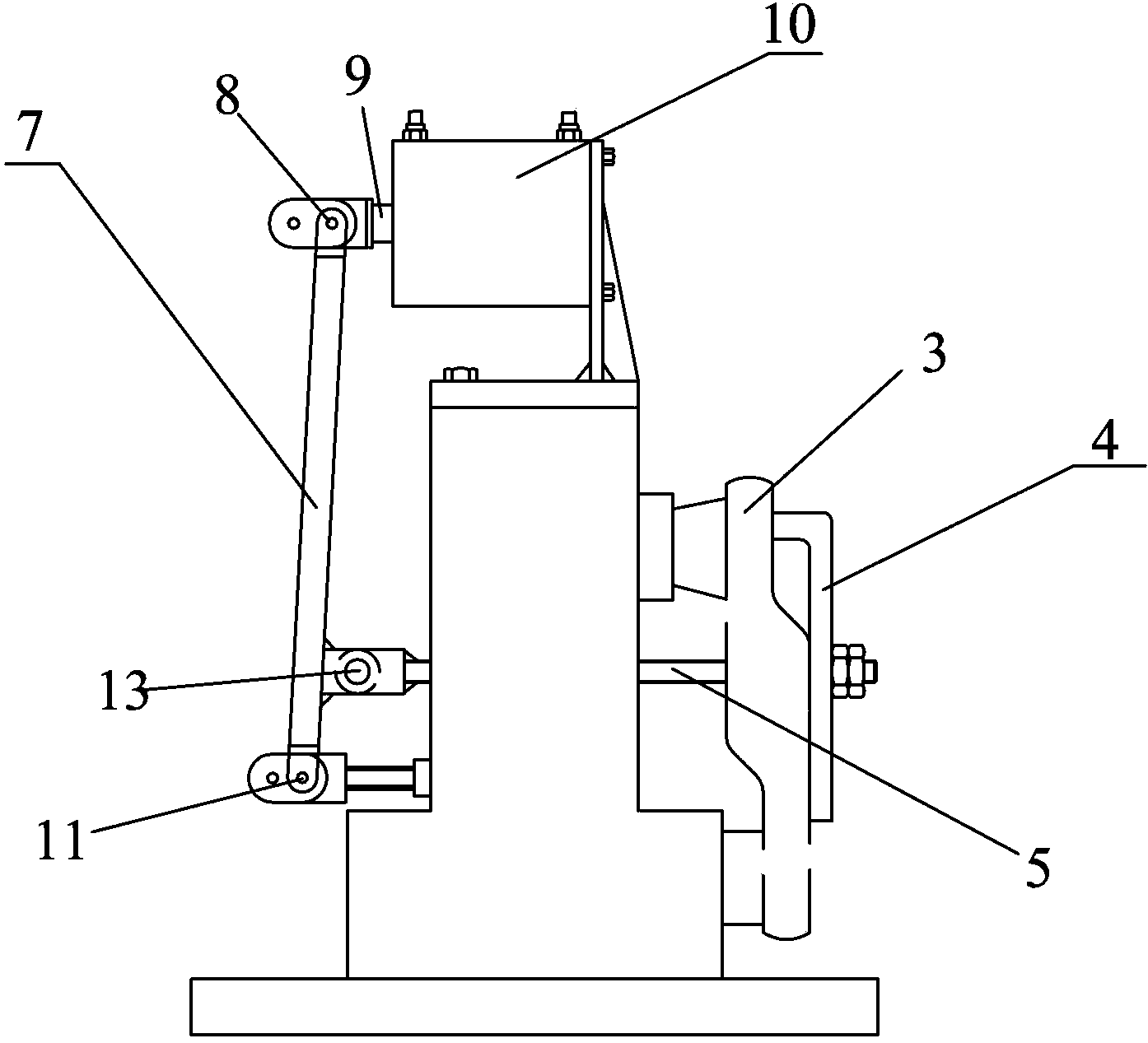

Pneumatic chucking tool capable of milling two faces of track link section piece

InactiveCN103659309ASave powerReduce labor intensityPositioning apparatusMilling equipmentsElectricityEngineering

The invention discloses a pneumatic chucking tool capable of milling two faces of a track link section piece. The pneumatic chucking tool comprises positioning pins 2 and a screw 1, wherein the positioning pins 2 are arranged on a positioning base 6 and located at the upper portion of the pneumatic chucking tool and the lower portion of the positioning base 6 respectively, and the screw 1 is arranged in the middle of the positioning base 6 and used for penetrating the track link section piece to be machined. The front end of the screw 1 penetrates through an L-shaped pressing plate 4 and is then connected with a nut 5 in a rotating mode. The rear end of the screw 1 is hinged to the middle of a lever 7. The lower end of the lever 7 is fixedly hinged to the positioning base 6. The upper end of the lever 7 is hinged to one end of a piston rod 9. A telescopic unit is arranged at the rear portion of the piston rod 9. By means of the pneumatic chucking tool, pressing is conducted according to the principle that the lever is pushed through three hinge points and an air cylinder, labor intensity is greatly lowered, and work efficiency is improved by more than one time; meanwhile, electricity is saved for an enterprise, losses are reduced, chucking can be conveniently conducted and is more stable compared with manual chucking, and product quality is guaranteed.

Owner:DALIAN SHENGLONG MACHINERY

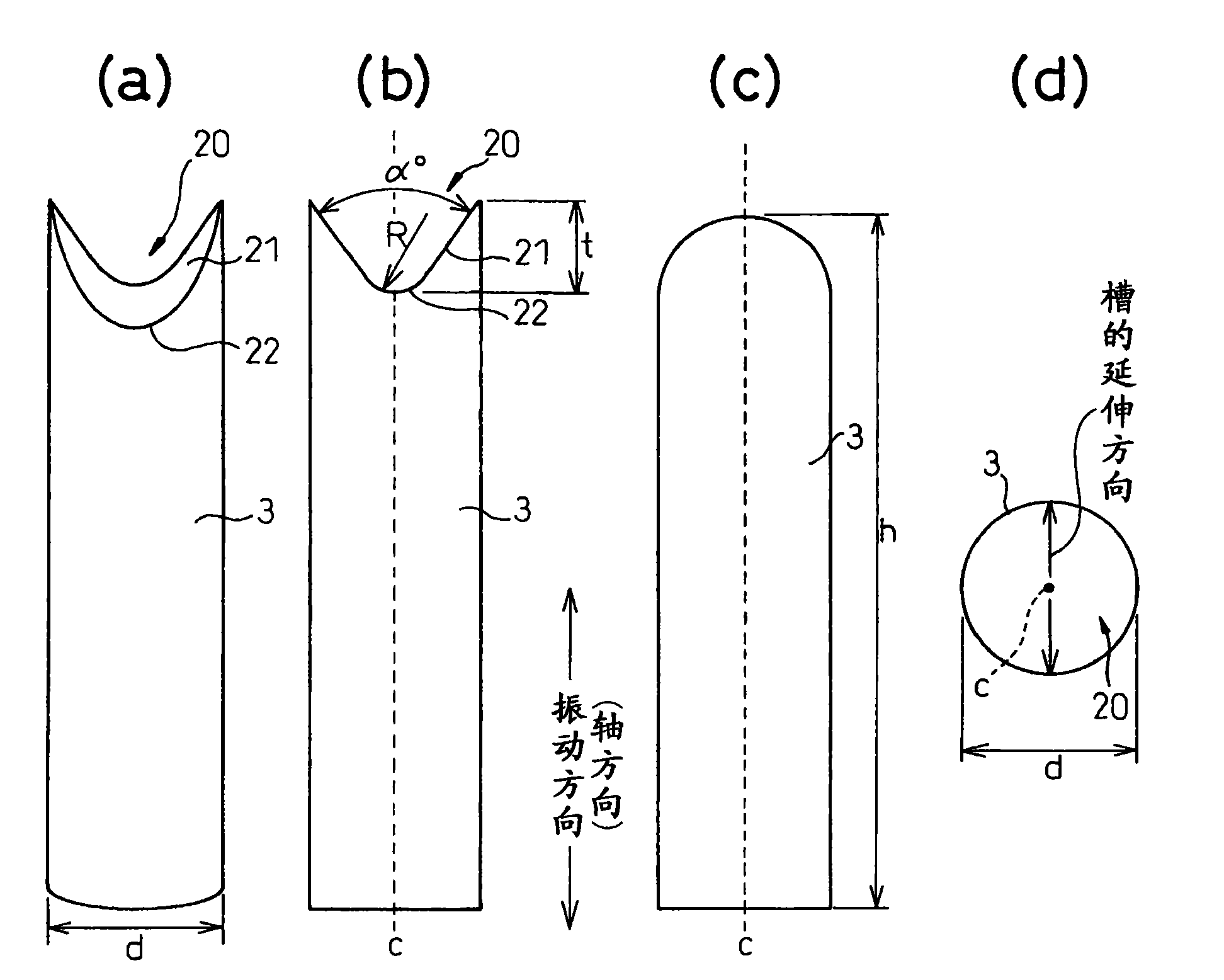

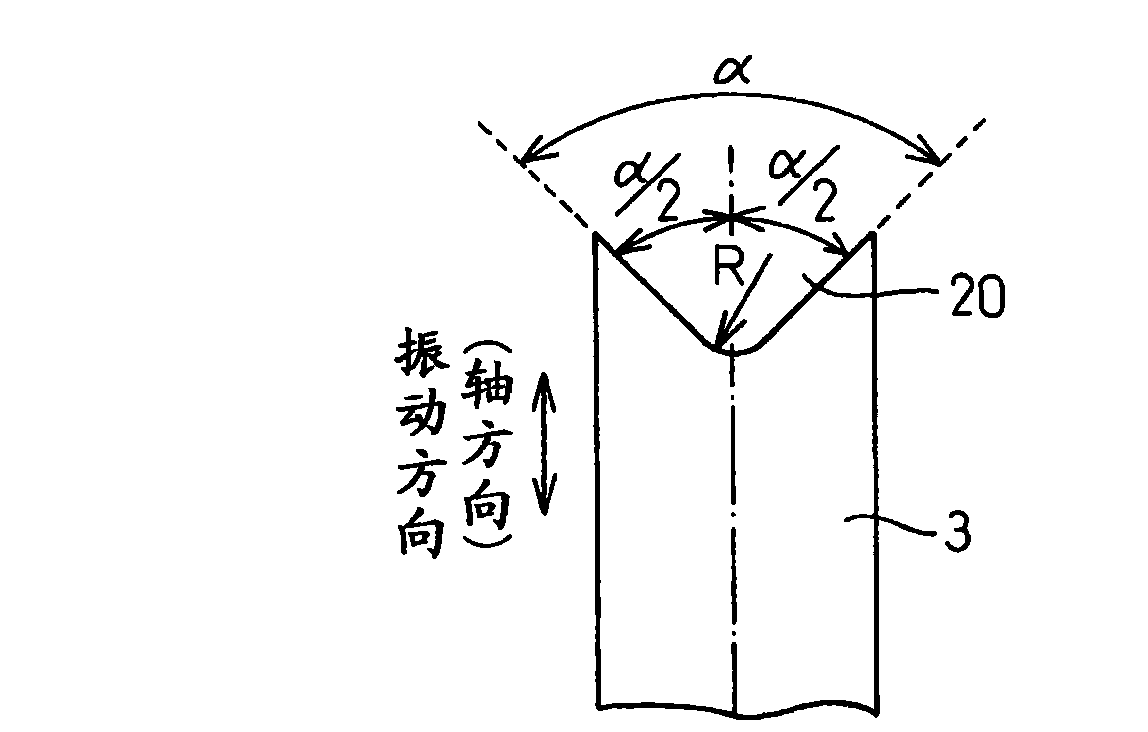

Chamfering device and chamfering method for metallic material

InactiveCN101668598ATurning machine accessoriesMilling equipmentsWorking environmentMetallic materials

Provided is a chamfering device capable of executing the corner portion of a metallic material or a metallic structure member under economical, efficient and satisfactory working environments. The chamfering device for the metallic material comprises a chamfering oscillation terminal extending at the leading end portion of the oscillating direction of an oscillating device and in the direction perpendicular to the oscillating direction and including a bottom portion having a section of a radius of curvature (R) normal to that extending direction and a groove opened toward leading end side, andthat oscillating device for vibrating the oscillation terminal in the axial direction thereof in a frequency of 10 Hz to 50 KHz and in a power of 0.1 to 4 KW.

Owner:NIPPON STEEL CORP

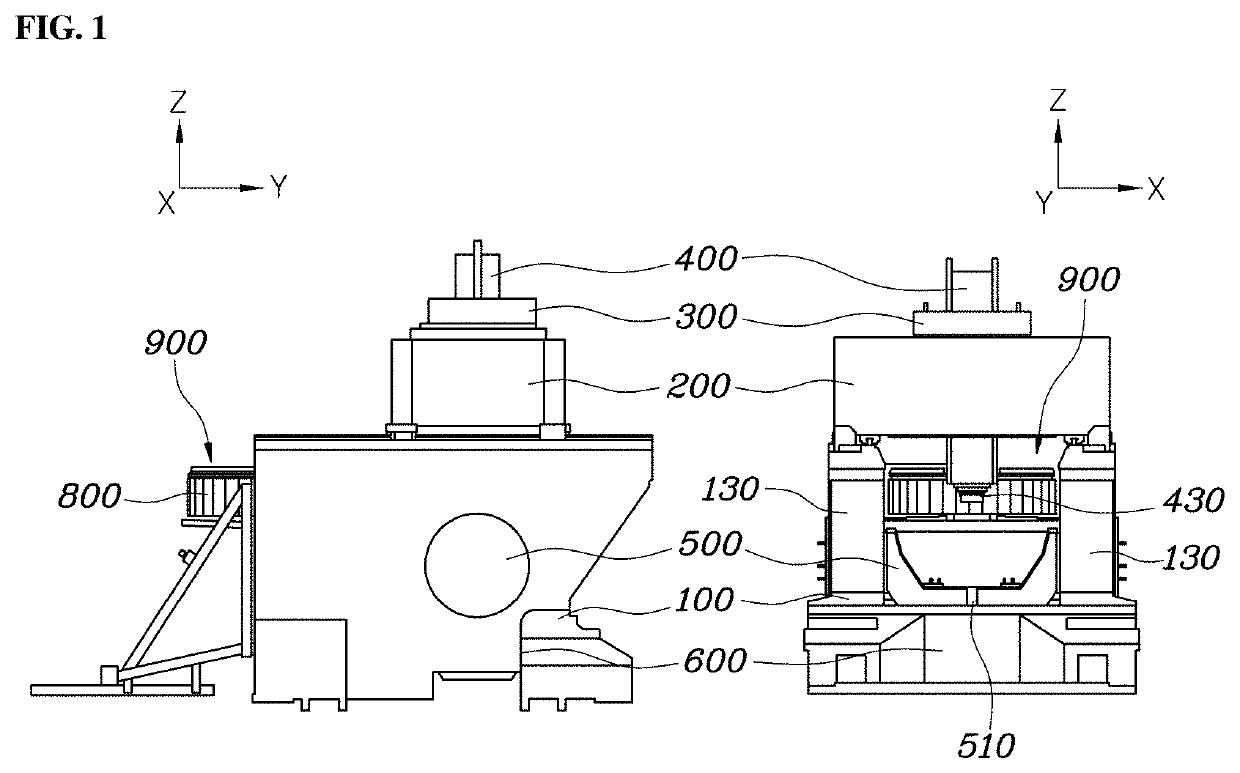

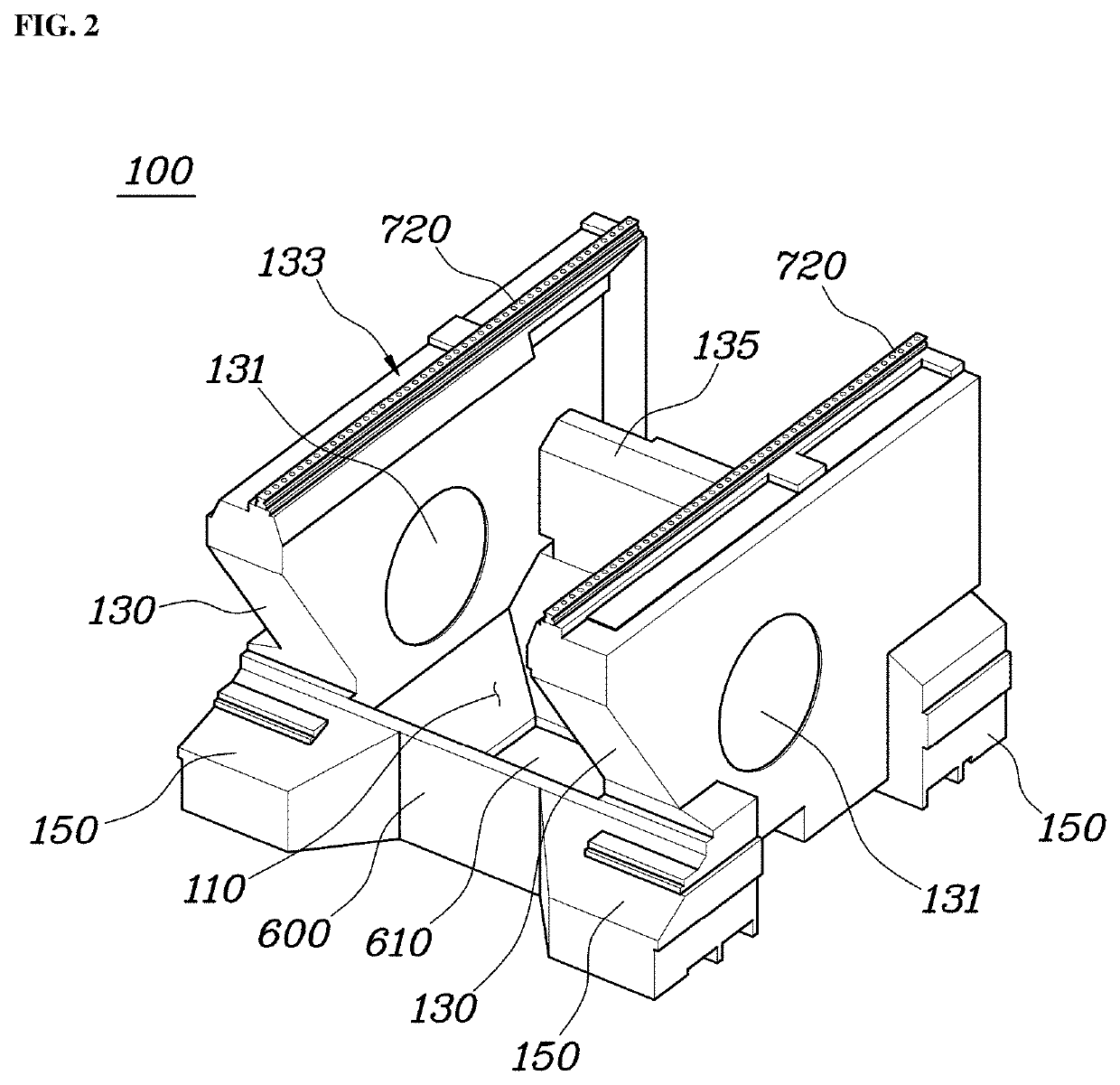

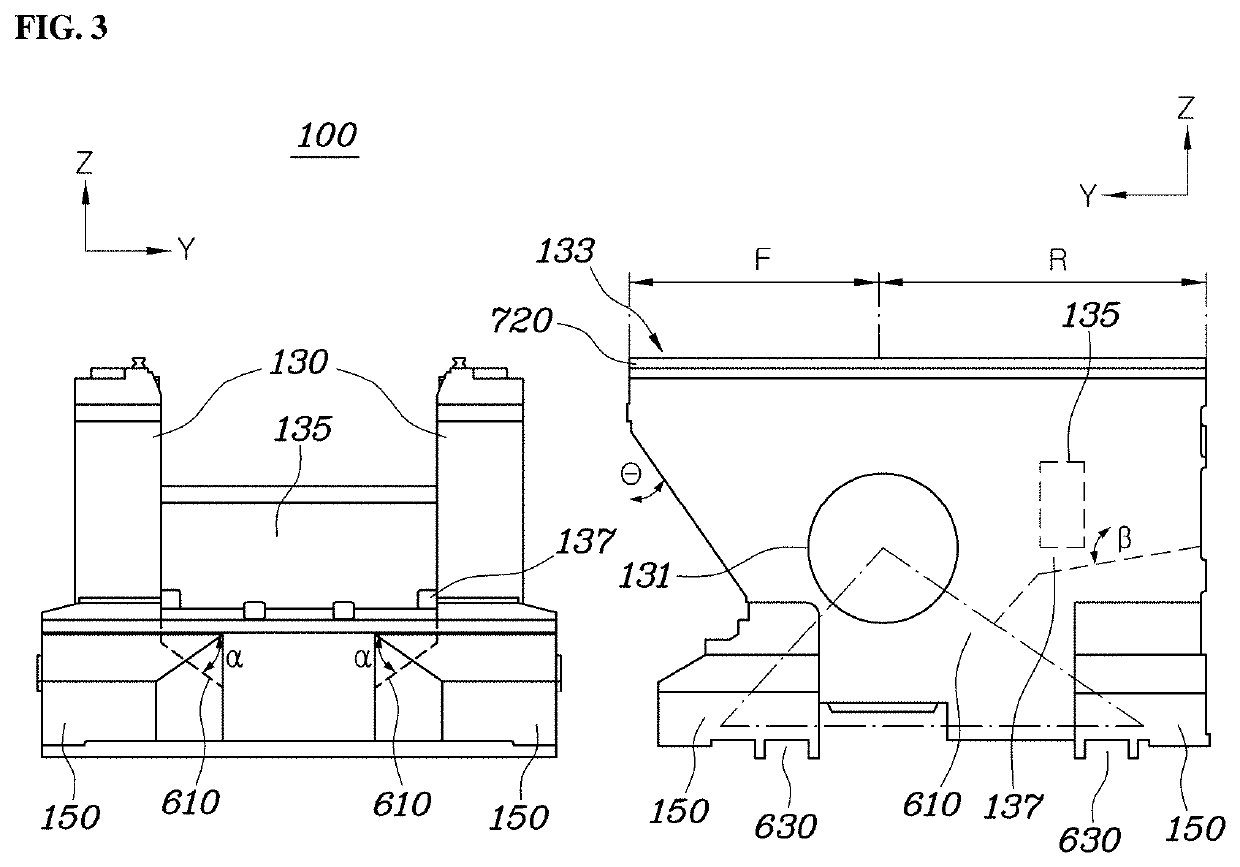

Machine tool

ActiveUS20200298358A1High precisionReduce errorsTool changing apparatusLarge fixed membersSoftware engineeringMachine tool

Disclosed is a machine tool including: a base having a pair of first-axial slides facing each other at both sides of a mounting space; a saddle coupled to the first-axial slides of the base to slide in a first axis direction and having a pair of second-axial slides facing each other; a crosspiece coupled to the second-axial slides of the saddle to slide in a second axis direction and having a pair of third-axial slides facing each other; a vertical ram coupled to the third-axial slides of the crosspiece to slide in a direction perpendicular; and a table disposed in the mounting space of the base to be able to rotate relative to the base.

Owner:HYUNDAI WIA

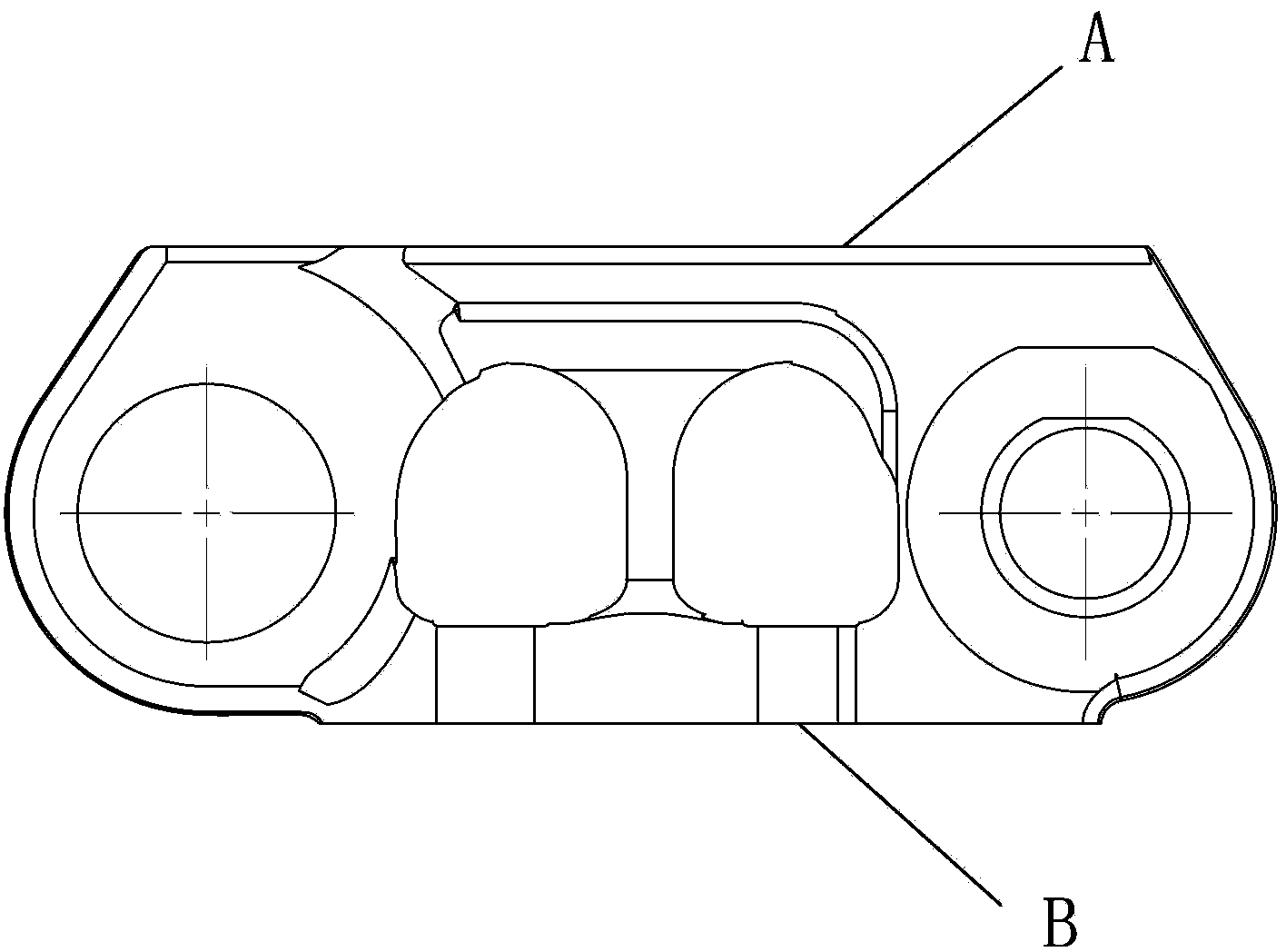

Valve core end surface milling clamp

InactiveCN103659322APrecise positioningPrevent rotationPositioning apparatusMilling equipmentsMechanical engineeringPhysics

The invention provides a valve core end surface milling clamp which is simple in structure and convenient to use and can improve the processing efficiency. A valve core comprises a valve plate and two core shafts on the two sides of the valve plate. The valve core end surface milling clamp comprises a compound die composed of two half dies. The compound die is provided with a valve plate hole which is composed of half round holes in the two half dies. A core shaft hole is formed in each side of the valve plate hole and composed of half circles on the two half dies, and the axes of the core shaft holes are perpendicular to the axes of the round holes. A rotation-preventing column is arranged inside the valve plate hole. One half die is connected with a movable jaw of a jaw vice, and the other half die is connected with a fixed jaw of the jaw vice.

Owner:溧阳市瑞丰金属制品有限公司

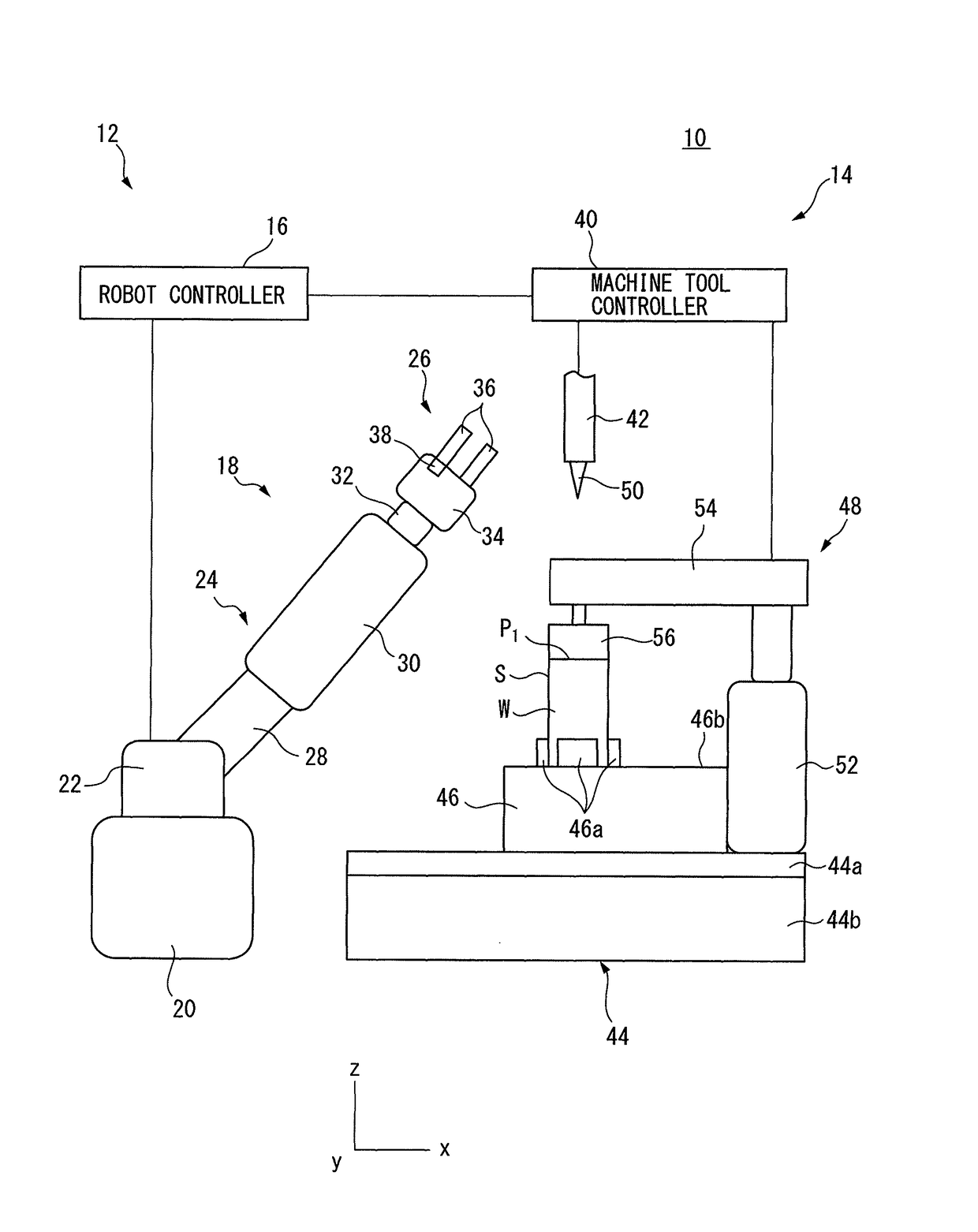

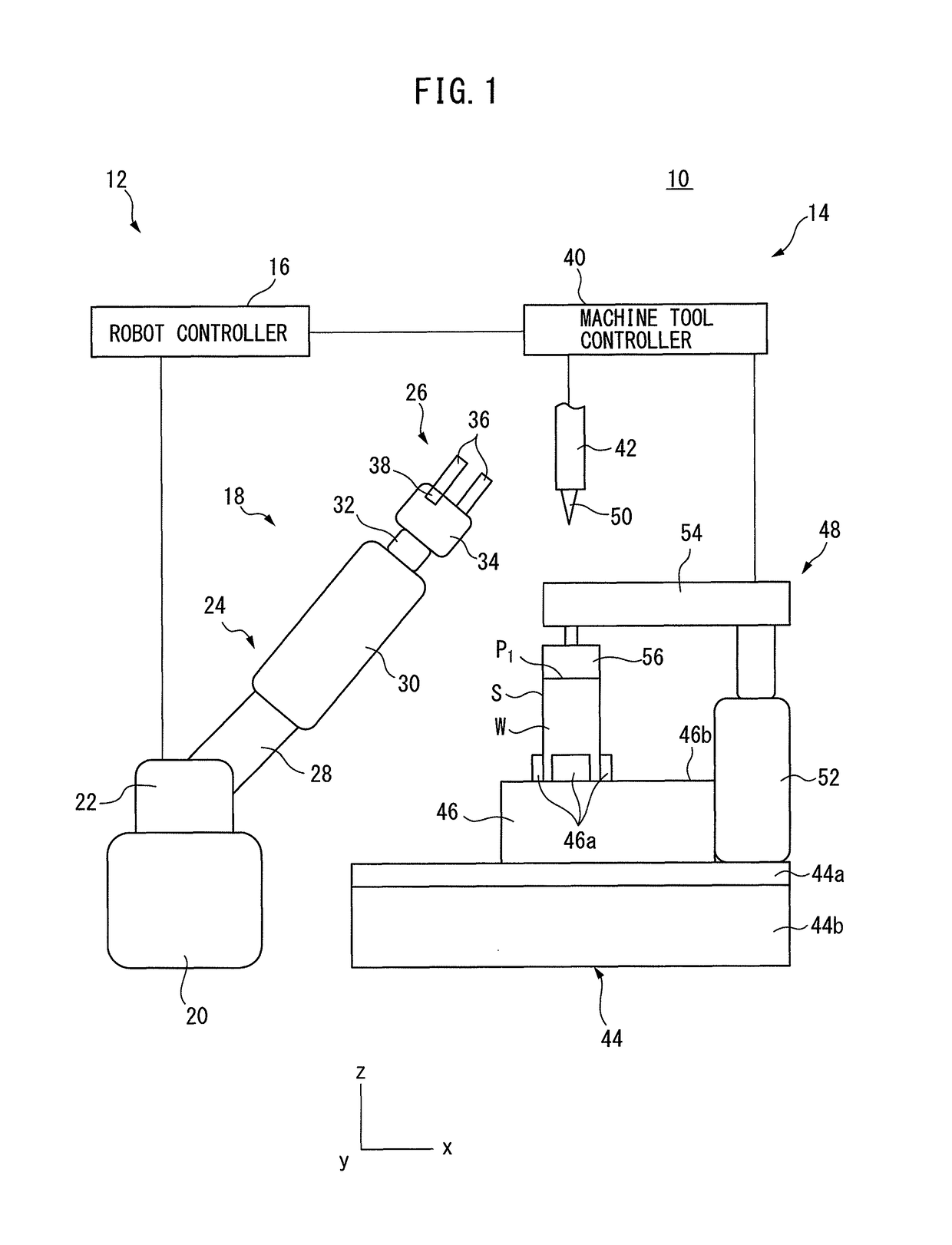

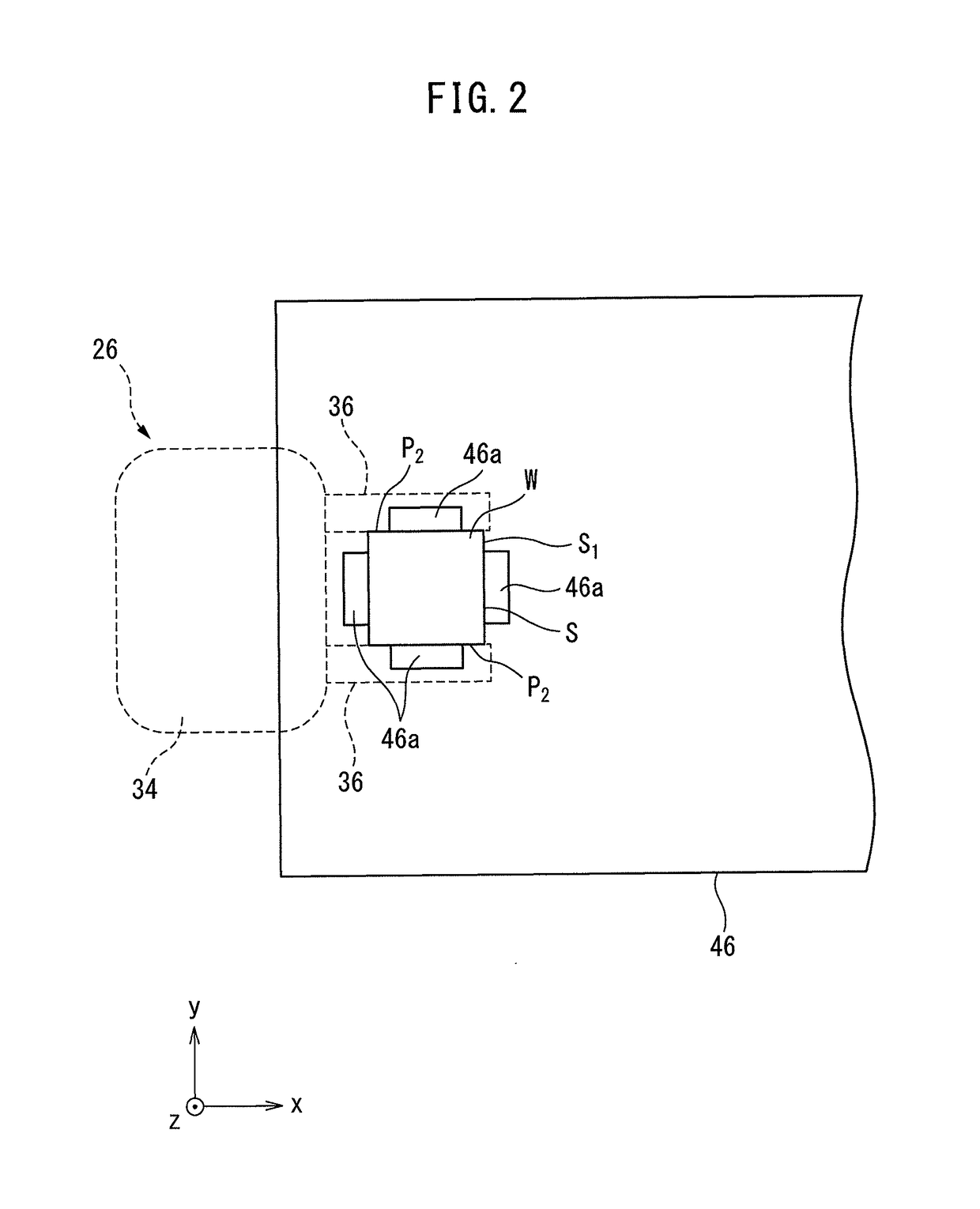

Method of machining workpiece by cooperation of machine tool and robot

A method for machining a workpiece which can prevent a reduction in machining accuracy and production efficiency. The method includes pressing a clamp part against a first portion of the workpiece, to clamp the workpiece in cooperation with a workpiece receiving part, causing the clamp part to move away from the first portion, to release the workpiece, which has been clamped by the clamp part, operating a robot to cause a robot hand to grasp a second portion of the workpiece, which is different from the first portion, to restrict the movement of the workpiece relative to the workpiece receiving part without a change in the posture of the workpiece, and operating a machine tool to machine the first portion while restricting the movement of the workpiece relative to the workpiece receiving part.

Owner:FANUC LTD

Device for generating an ultrasonic vibration of a tool and for measuring vibration parameters

ActiveUS10809123B2Improve accuracyReduce the amplitudeSubsonic/sonic/ultrasonic wave measurementUsing electrical meansSignal onUltrasonic machining

The present invention relates to a device for generating an ultrasonic vibration of a tool used for the ultrasonic machining of a workpiece and for measuring ultrasonic vibration parameters of the ultrasonic vibration of the tool having a tool holder for receiving the tool, an ultrasonic transducer in the tool holder for generating the ultrasonic vibration of the tool, a sensor mechanism in the tool holder for producing a sensor signal on the basis of the ultrasonic vibration of the tool, and a sensor signal evaluation device for evaluating the sensor signal.

Owner:SAUER GMBH

Cutting insert, cutting tool, and method for manufacturing machined product

A cutting insert according to one aspect has a flat plate shape including a first main surface having a polygonal shape, a second main surface located opposite to the first main surface, and an outer peripheral surface located between the first main surface and the second main surface. The cutting insert includes a cutting portion located in regions including at least a corner portion of the first main surface, and a main body portion located in a region other than the corner portion. A thickness of the main body portion is larger than a thickness of the cutting portions, and the main body portion includes a recessed portion or a protruding portion located in the outer peripheral surface thereof.

Owner:KYOCERA CORP

Auxiliary clamp of milling machine

InactiveCN103567775ALarge clamping forceGuaranteed precisionPositioning apparatusMilling equipmentsEngineeringMechanical engineering

The invention discloses an auxiliary clamp of a milling machine. The auxiliary clamp comprises a main body and a pushing portion matched with the main body and used for clamping workpieces, wherein the main body comprises a first inclined surface, the pushing portion comprises a second inclined surface, the first inclined surface is matched with the second inclined surface, and a pushing screw horizontally penetrates through the main body and the pushing portion to be connected with a manual knob. By means of the first inclined surface of the main body and the second inclined surface of the pushing portion, clamping on the workpieces can be achieved through meshing of the first inclined surface and the second inclined surface. Furthermore, by arranging the manual knob, users can increase clamping force during machining continuously, and machining precision is ensured further.

Owner:刘康

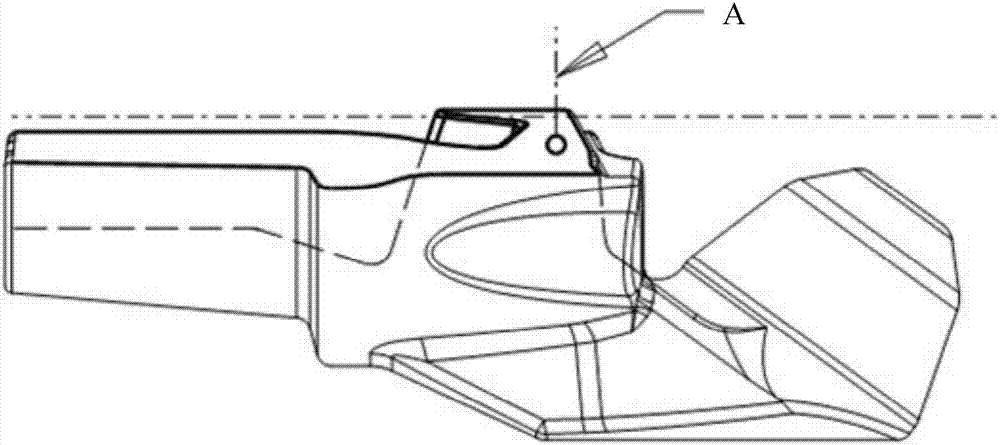

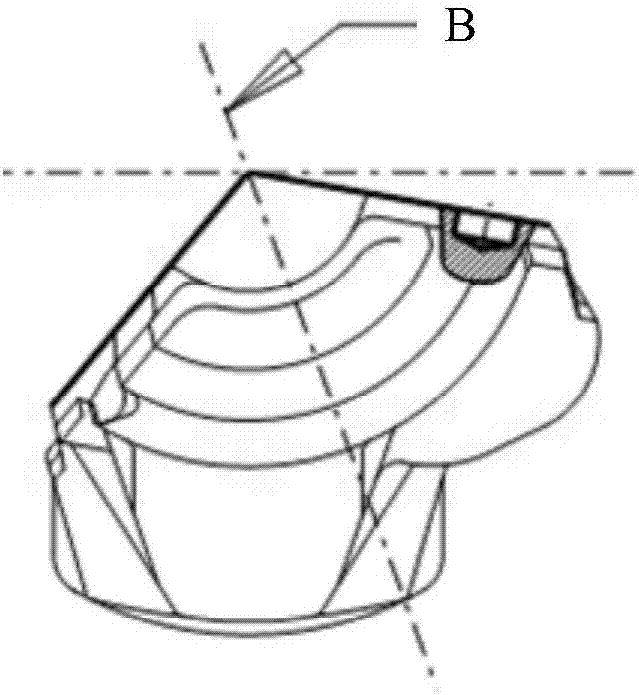

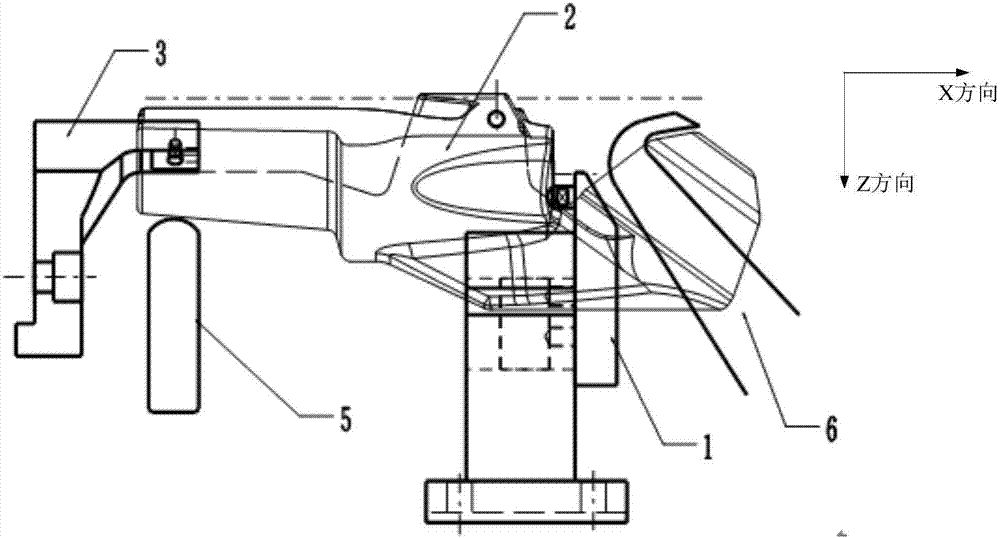

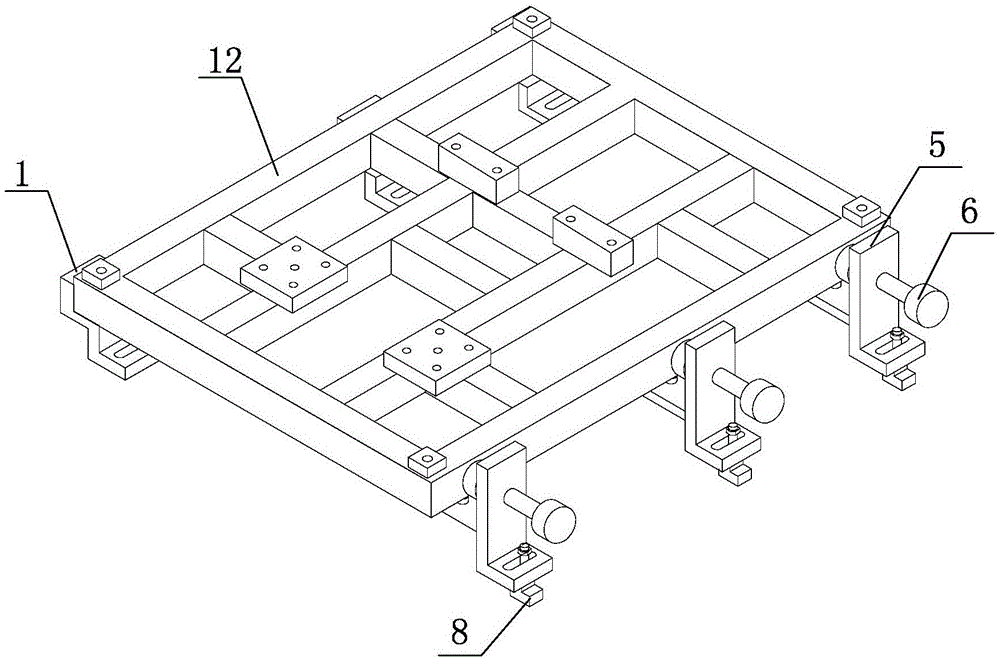

Three-cone drill bit palm reference plane, hole processing fixture

ActiveCN105328488BUniform millingEnsure consistencyWork clamping meansPositioning apparatusTip positionDegrees of freedom

The invention relates to a datum plane and hole processing clamp for tricone bit legs. A blowhole positioning seat and a leg tip positioning component are relatively arranged in front and back. A clamping arm is arranged on the right side of the blowhole positioning seat, and a support screw is arranged on the left side of the blowhole positioning seat. A pressing block is arranged on the left side of the support screw, and bit legs are positioned on the support screw, the blowhole positioning seat and the leg tip positioning component. Leg tip support positioning points used for limiting the rotational degree of freedom of the bit legs on the X direction are arranged on the blowhole positioning seat and positioned at the non-trimming parts of the bit legs. Positioning points used for limiting the moving degree of freedom of the bit legs on the X direction and positioned at the non-trimming parts of the bit legs. The clamping arm is used for straining the root of a shaft head of each bit leg in a contacting manner, the support screw is used for supporting the front end part of each bit leg, and the pressing head of the pressing block is used for being pressed in a pulp hole in the end surface of a screw thread at the front end part of each bit leg. The positioning points completely avoid the trimming part of each bit leg, and the influence of the residual trimming of a bit leg forge piece on datum plane and hole processing of the bit legs is solved.

Owner:SHAREATE TOOLS

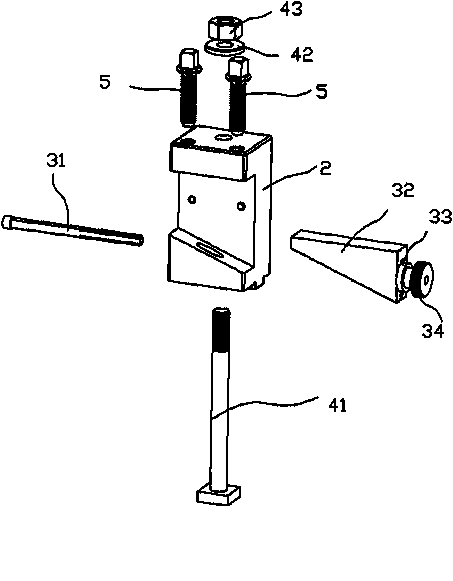

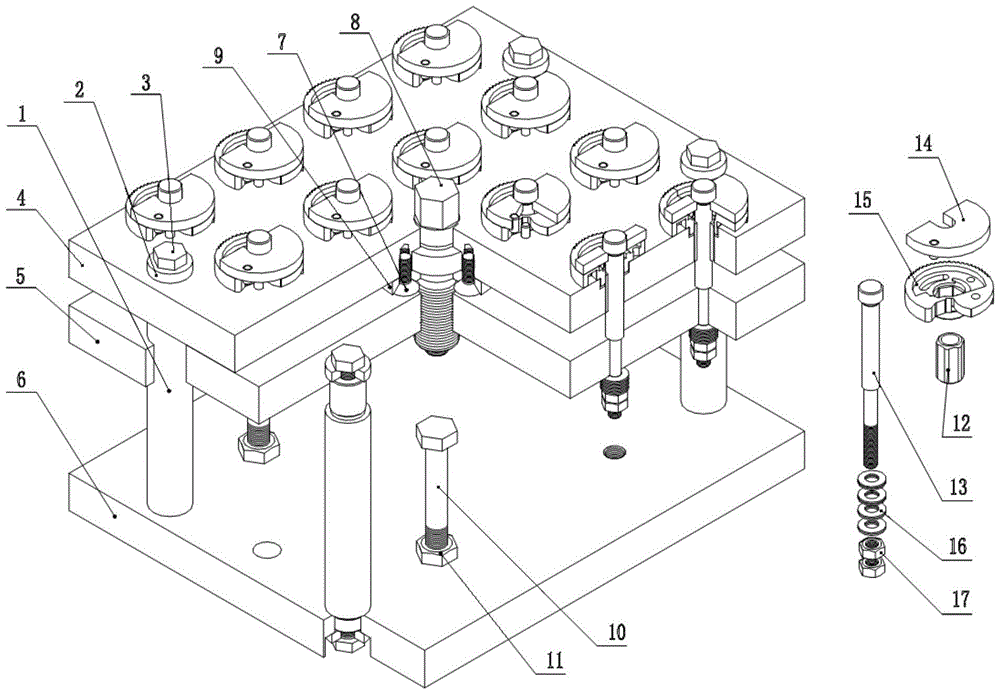

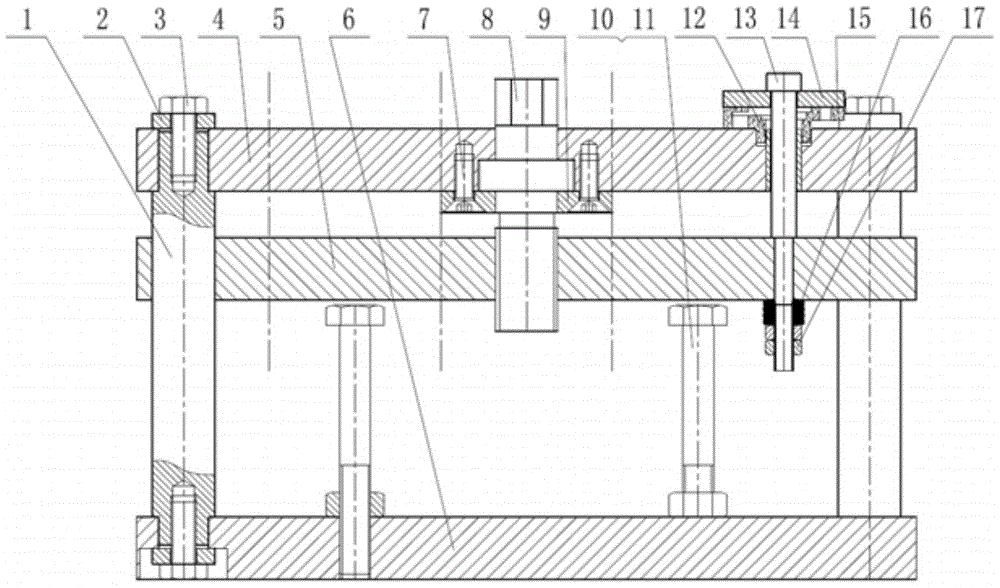

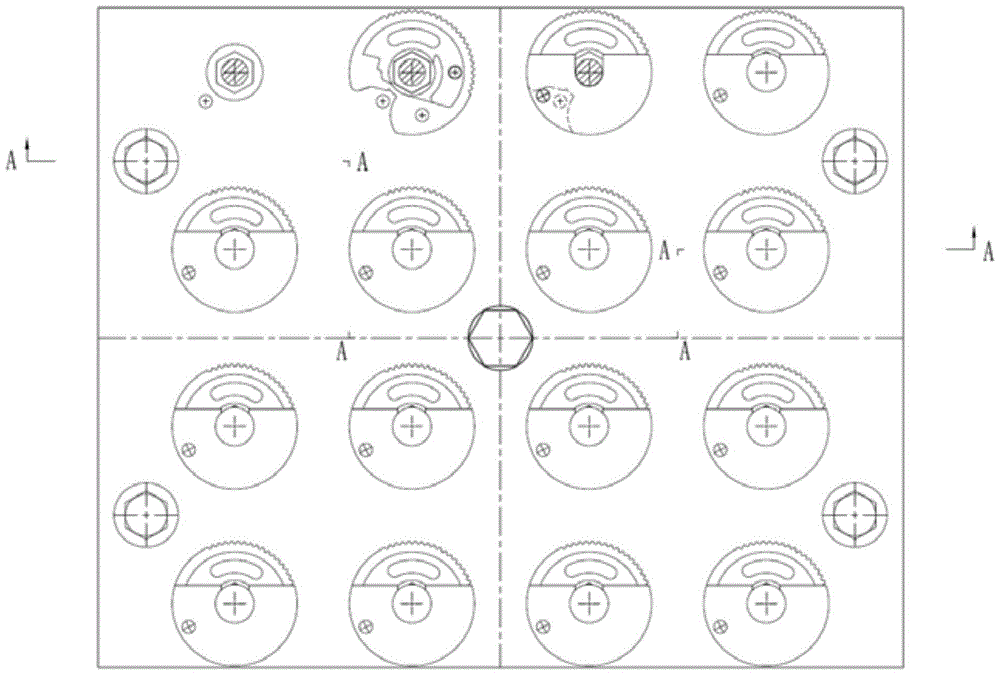

A tool that can press and install multiple parts at the same time

ActiveCN104723143BReduce setup timeIncrease usagePositioning apparatusMilling equipmentsEngineeringScrew thread

Owner:合肥波林新材料股份有限公司

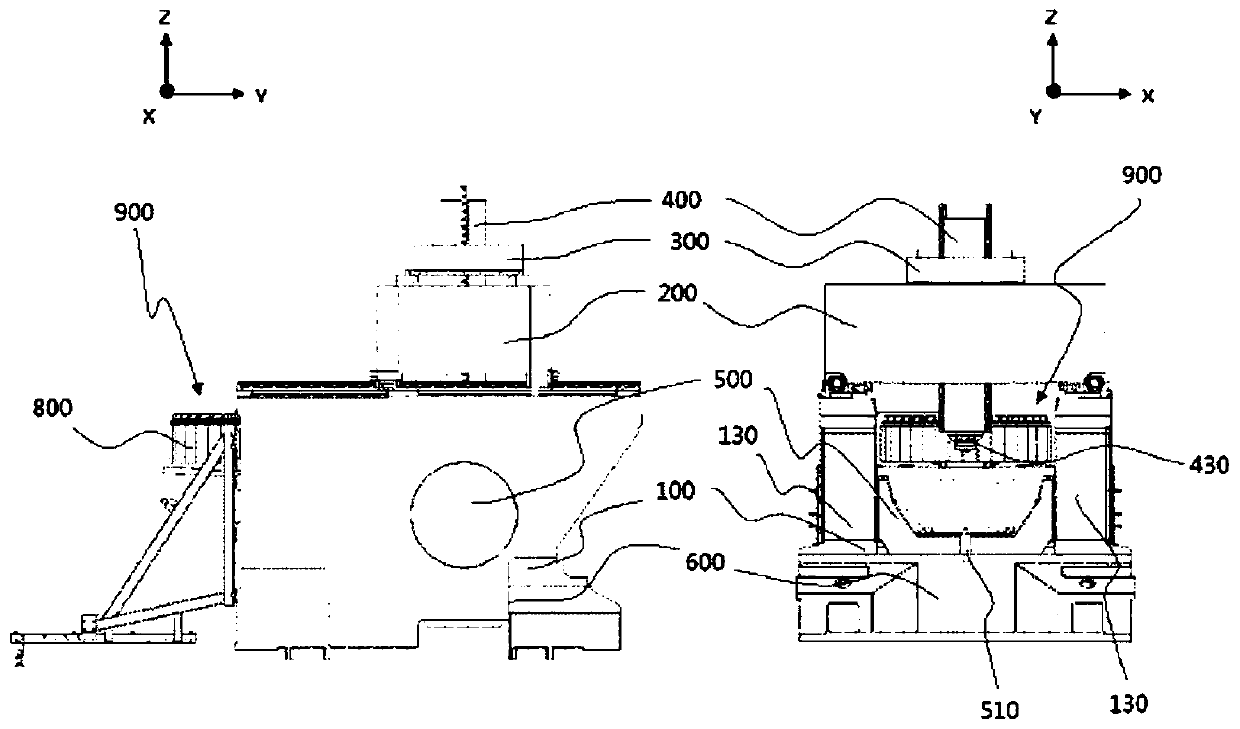

Machine tool

PendingCN111372719AHigh precisionReduce mistakesTool changing apparatusLarge fixed membersStructural engineeringMachine tool

Disclosed is a machine tool comprising: a base having a mounting space in which a workpiece is mounted, shaft holes formed in opposite wall surfaces thereof, and a pair of first shaft sliding parts facing each other on opposite sides of the mounting space; a saddle coupled to the first shaft sliding parts of the base so as to slide on a first shaft and having a pair of second shaft sliding parts facing each other in a direction intersecting the first shaft; a crosspiece coupled to the second shaft sliding parts of the saddle so as to slide on a second shaft and having a pair of third sliding parts facing each other in a direction perpendicular to a plane on which the first shaft and the second shaft are formed; a vertical ram coupled to the third shaft sliding parts of the crosspieces so as to slide in a direction perpendicular to a plane defined by the first shaft and the second shaft and having a tool for machining the workpiece mounted at an end thereof; and a table disposed in themounting space of the base and installed on the base so as to be rotatable relative to the base through shaft holes of the base.

Owner:HYUNDAI WIA

Positioning device for large aluminum parts milling

ActiveCN103639755BAvoid deformationEven by forcePositioning apparatusMilling equipmentsEngineeringMechanical engineering

The invention relates to a large aluminum piece milling and positioning clamp which comprises a plurality of first positioning blocks, a plurality of second positioning blocks and a plurality of third positioning blocks. The first positioning blocks, the second positioning blocks and the third positioning blocks are arranged side by side and provided with first steps, wherein the first steps are provided with kidney-shaped holes. The first positioning blocks and the second positioning blocks are provided with second steps, wherein ejection rods are installed on the second steps, and the bottom ends of the ejection rods are connected with a handle. The second steps of the first positioning blocks are provided with stopping blocks. The third positioning blocks consist of L-shaped positioning plates and flat plates which are connected fixedly, wherein the positioning plates are provided with adjusting bolts, and the flat plates are provided with flat plates. The large aluminum piece milling and positioning clamp further comprises a positioning part, wherein the positioning part is provided with a locking bolt. The large aluminum piece milling and positioning clamp is simple in structure, flexible and convenient to use and high in clamping efficiency, and the accuracy is easy to ensure.

Owner:WUXI HANGHU TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com