Deburring apparatus with driving means for rotatably and reversibly driving the apparatus to and away of a billet

A driving device and deburring technology, which is applied to auxiliary devices, milling machine equipment, welding equipment, etc., can solve the problems of hard-to-replace worn cutting devices and difficult-to-cut devices, and achieve the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

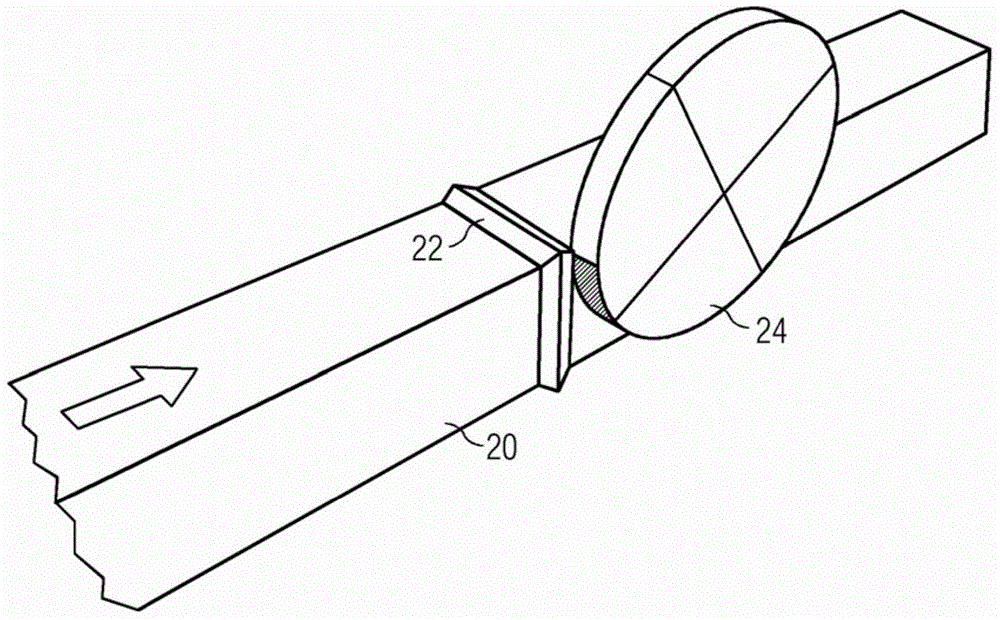

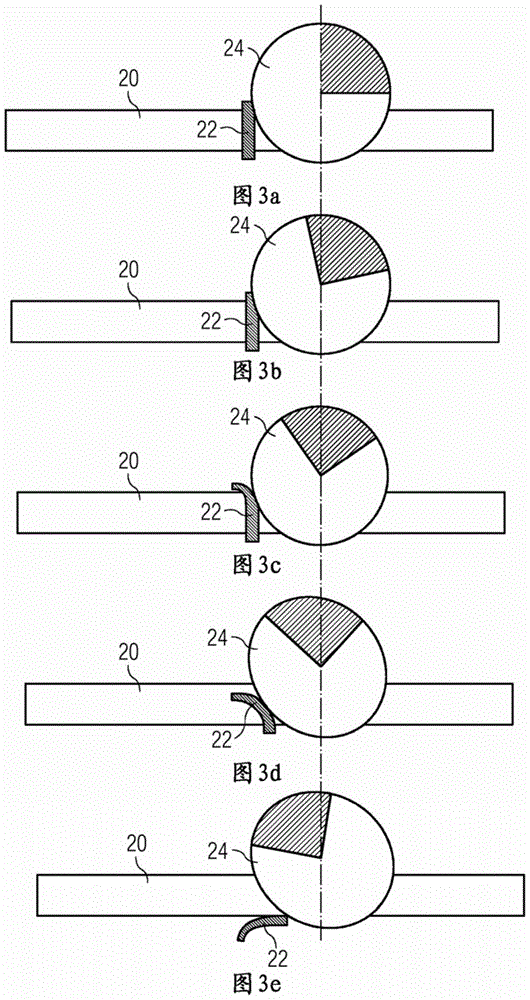

[0056] figure 1 It is a schematic diagram showing how the burr 20 existing on the welding position of two blanks is cut. The device according to the invention comprises an idler disk which is free to rotate about its axis when an appropriate torque is applied.

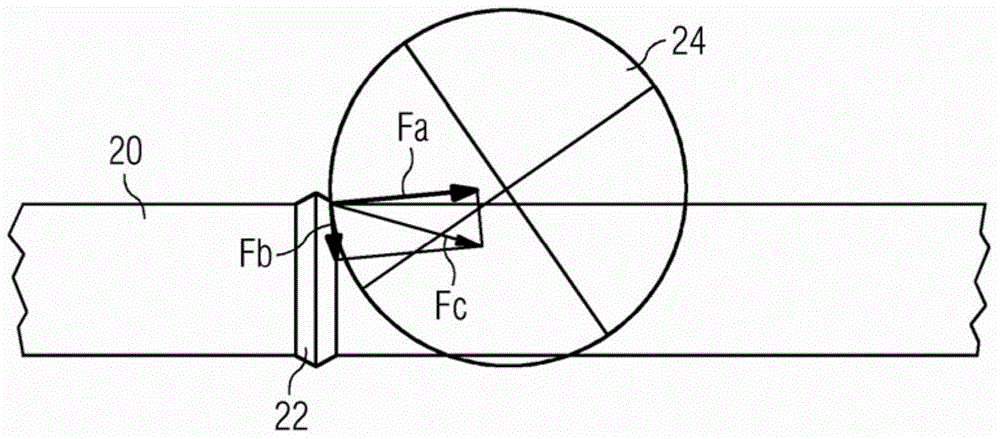

[0057] Such as figure 2As can be seen, the disc is positioned such that the reaction force experienced by the cutting disc when it contacts the burr causes the disc to rotate. Thus, no rotary drive mechanism (eg, a motor) is required for cutting. The reaction force Fc has a horizontal component Fa and a vertical component Fb. The cutting disc torque is the product of the vertical component Fb of the reaction force and the radius of the cutting disc.

[0058] Also, considering that each cutting disc is idling and only rotates when it contacts a burr, or that is, each cutting disc rotates at a speed that is a result of the stock speed, there is no need to adjust the stock speed to the cutting speed . This makes th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com