Chamfering device and chamfering method for metallic material

A technology of metal materials and chamfering devices, which can be used in metal processing equipment, accessories of tool holders, turning equipment, etc., and can solve problems such as poor working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0061] Hereinafter, the present invention will be described in more detail using examples.

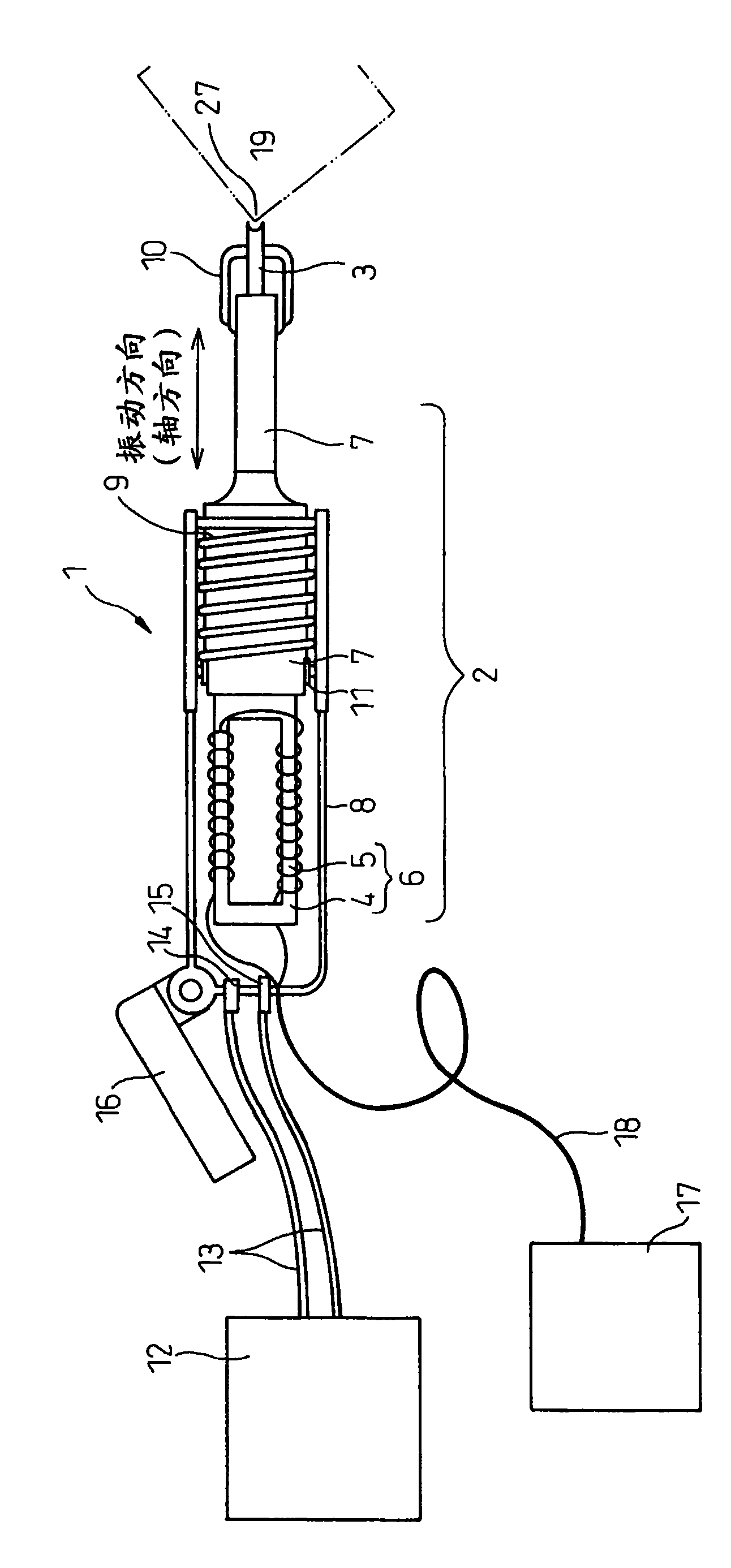

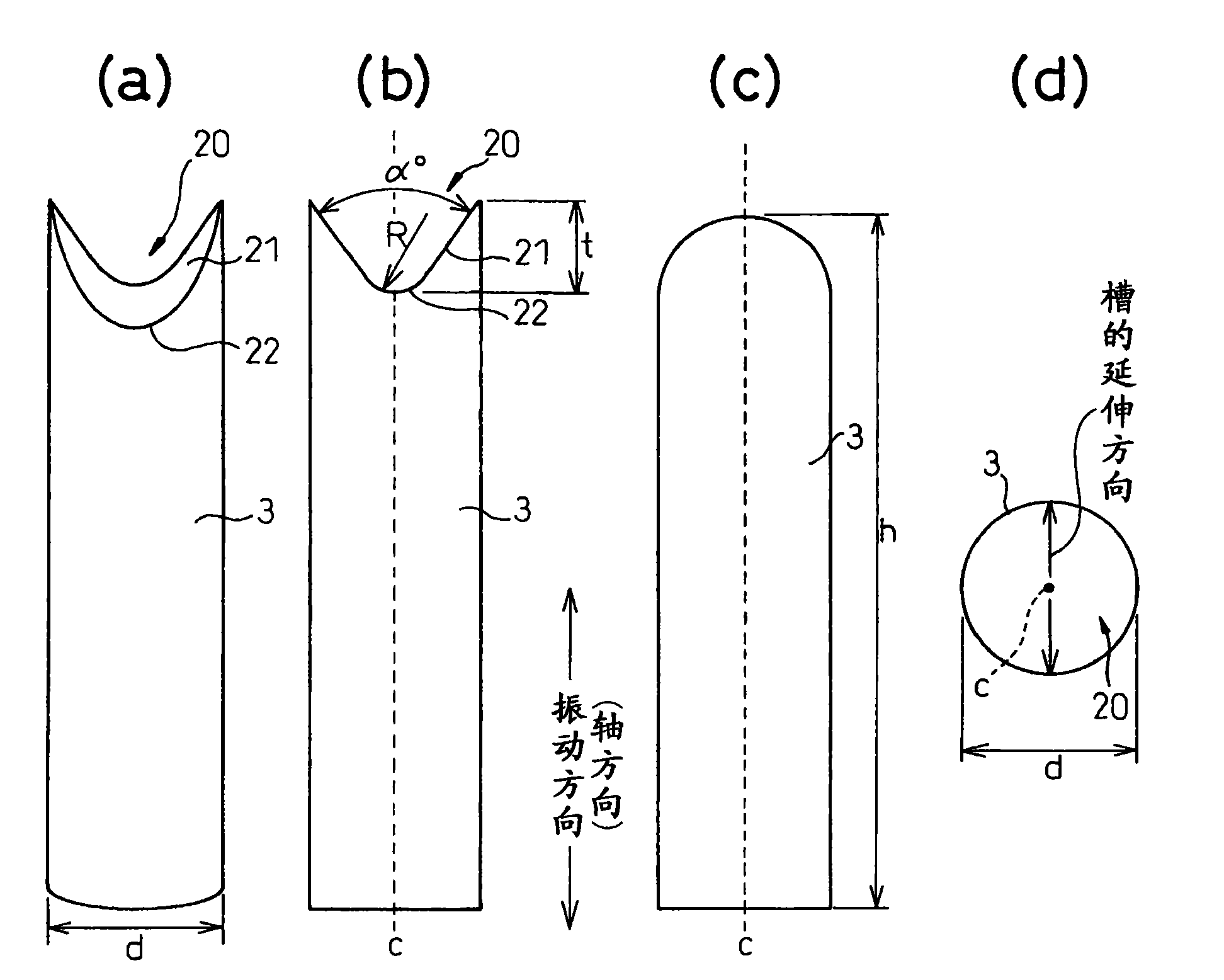

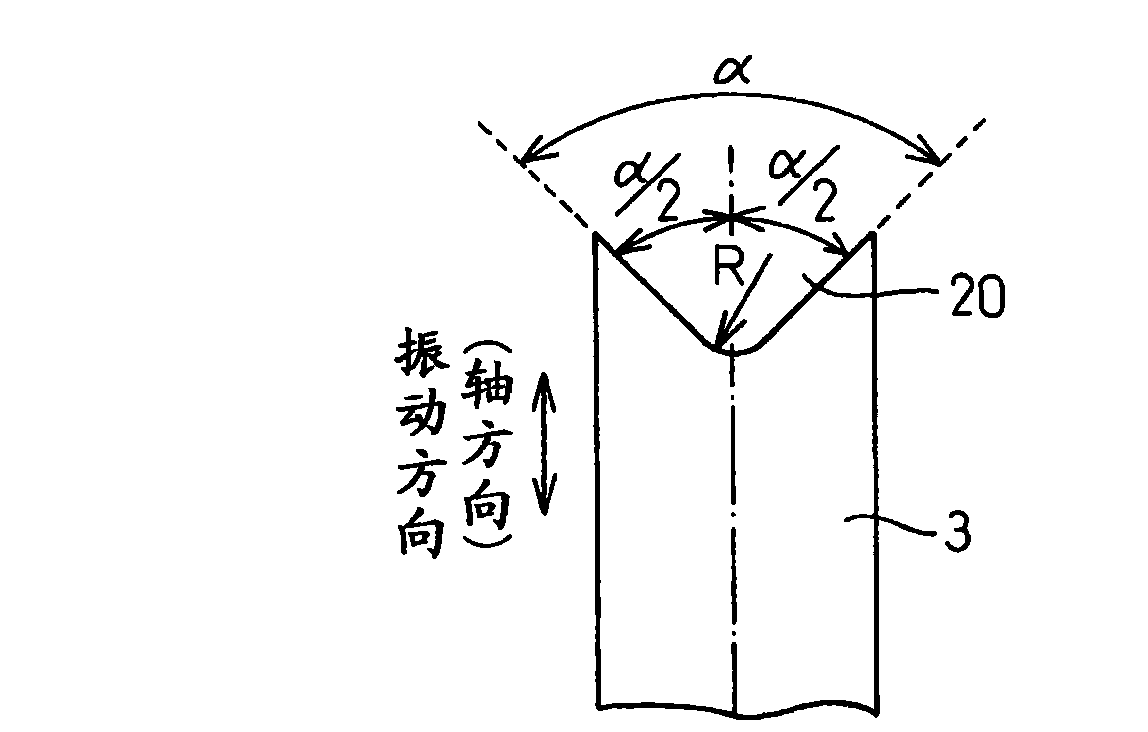

[0062] use figure 1 The shown chamfering device chamfers three corners of five steel parts samples 1 to 5 with a cross-section of about a square (corner angle of about 90°) and strength grades ranging from 400 to 600 MPa. The chamfering pin is made of HRC62 SKH material, a cylindrical rod with a diameter of 4.8mm and a length of 35mm. The opening angle of the groove at the top is 90°, and the radius of curvature of the bottom of the groove is Figure 7 As shown in (a) to (c), it changes from 1R to 3R. respectively with different radii of curvature at the bottom of the groove, as described above Figure 7 The chamfering pins shown in (a) to (c) chamfer the three corners of the above-mentioned steel member sample. For comparison, one corner was left as an unprocessed part while maintaining the corner condition before chamfering. The conditions of chamfering treatment (the radius of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com