Tool head for use in machine tools

A combination and cutter head technology, which is applied in the direction of milling machine equipment, toolholder accessories, manufacturing tools, etc., can solve the problems of wear and adjustment gaps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

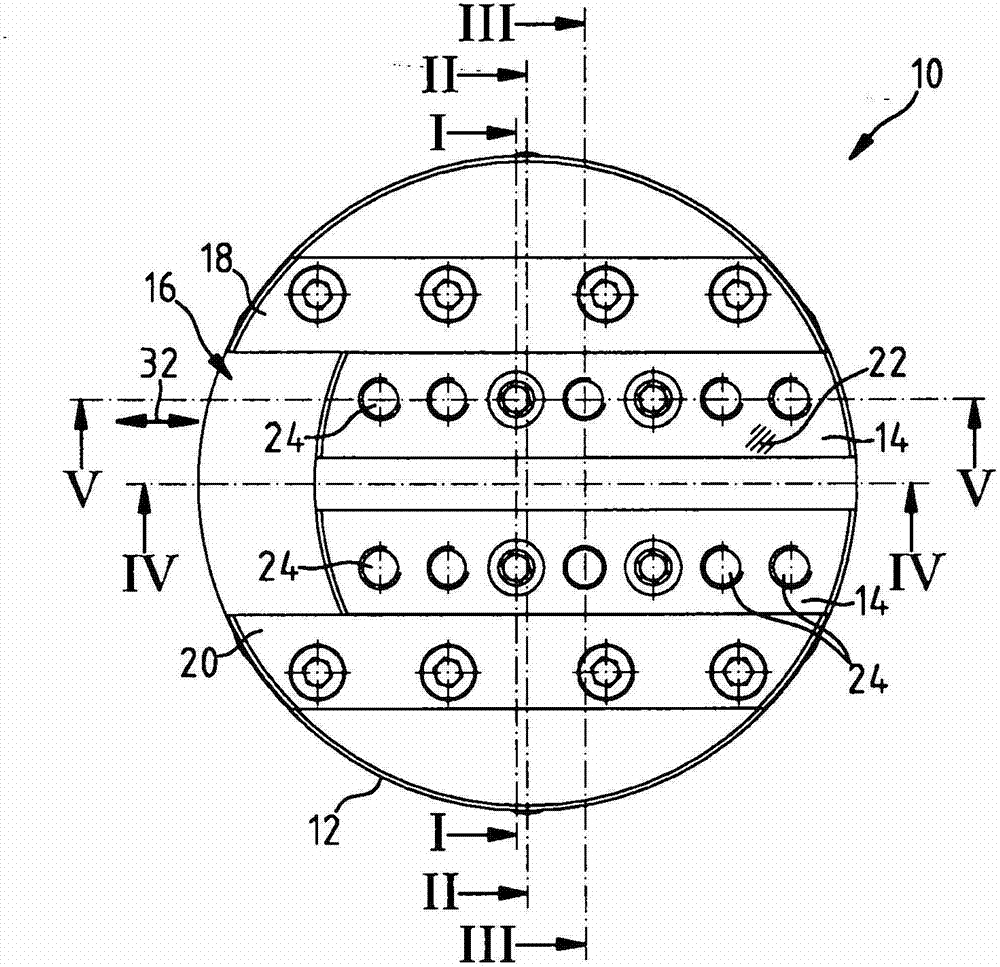

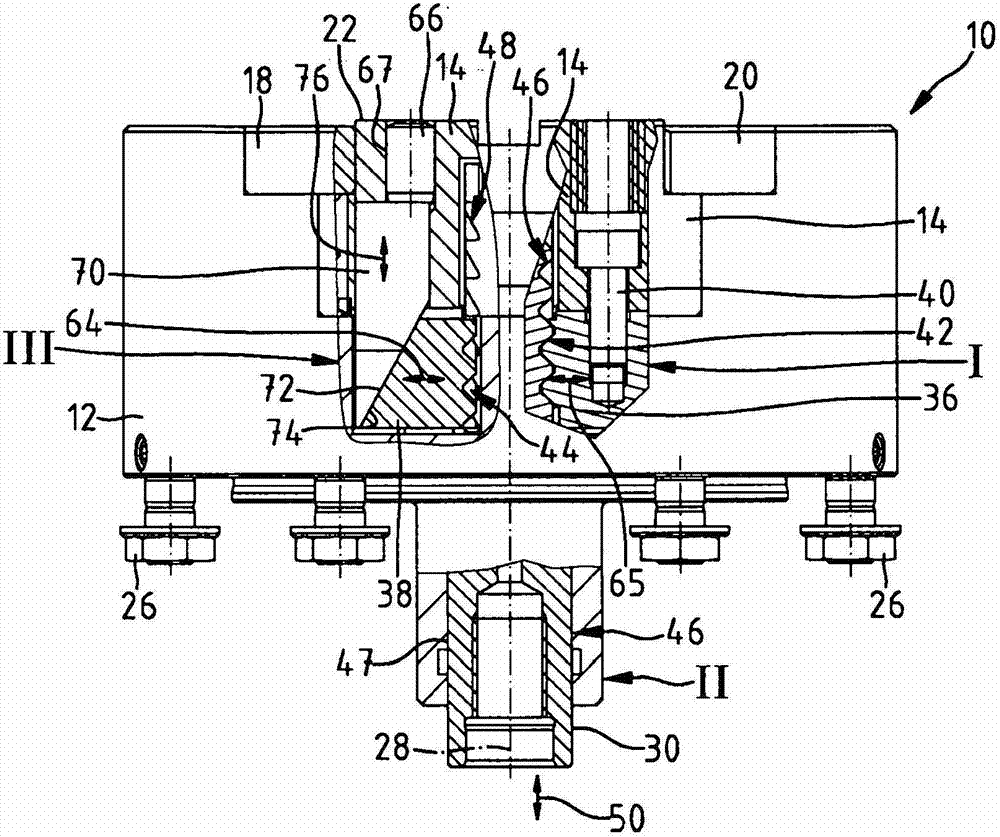

[0024] figure 1 The combined cutter head 10 shown in has a base body 12 . A movable slide 14 is mounted on the base body 12 . The carriage 14 is guided linearly movable in a sliding bearing 16 formed on the base body 12 . The carriage 14 is held in the slide bearing 16 by means of a first web 18 and by means of a second web 20 .

[0025] The slide 14 has a slide working surface 22 which can hold a tool holder for a cutting tool. For connection to the tool holder, a plurality of threaded holes 24 for receiving fastening screws are provided on the slide 14 .

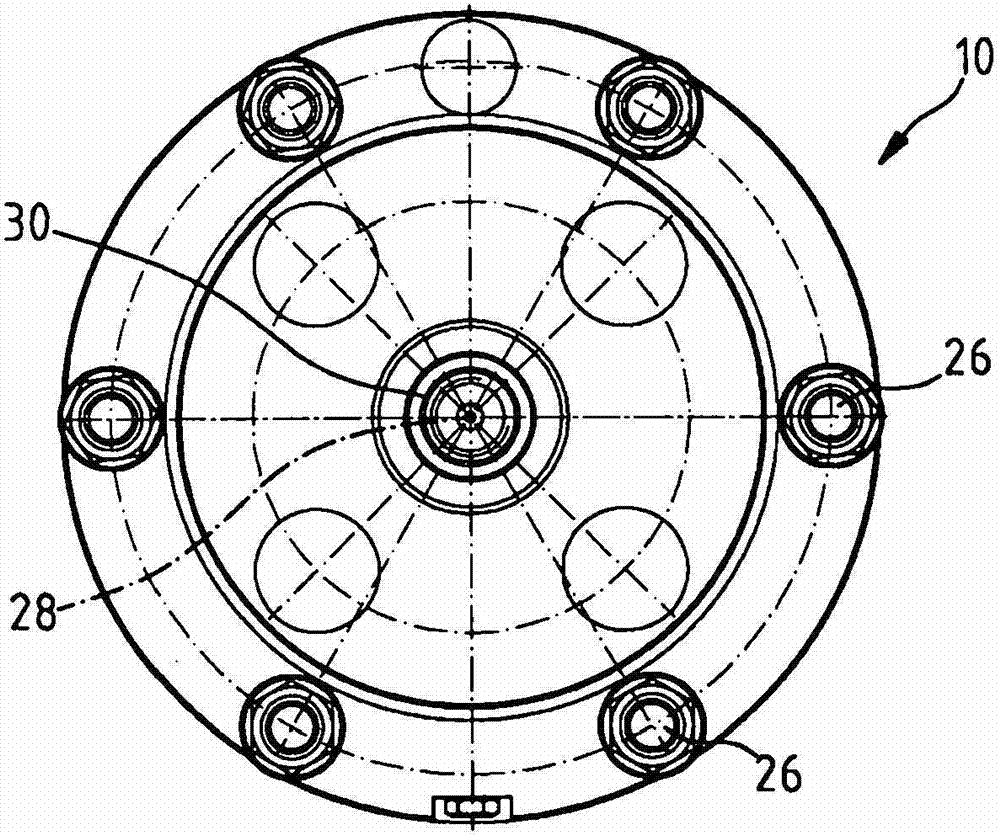

[0026] figure 2 Shown is the back of the modular cutter head 10 . A connecting element 26 is arranged on the rear side of the combination cutter head 10 . By means of a connecting element 26 , the combination cutterhead 10 can be connected to a rotating machine spindle of a machine tool, not further shown. On the machine spindle of the machine tool, the combined cutter head 10 can be rotated at a high rotational sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com