Machine tool

A technology for machine tools and sliding parts, applied in the field of machine tools, can solve problems such as affecting positioning accuracy, deterioration of workpiece quality, and irregularity, and achieve the effects of simplifying structure, improving accuracy, and being easy to handle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] A machine tool according to an exemplary embodiment of the present invention will be described below with reference to the drawings.

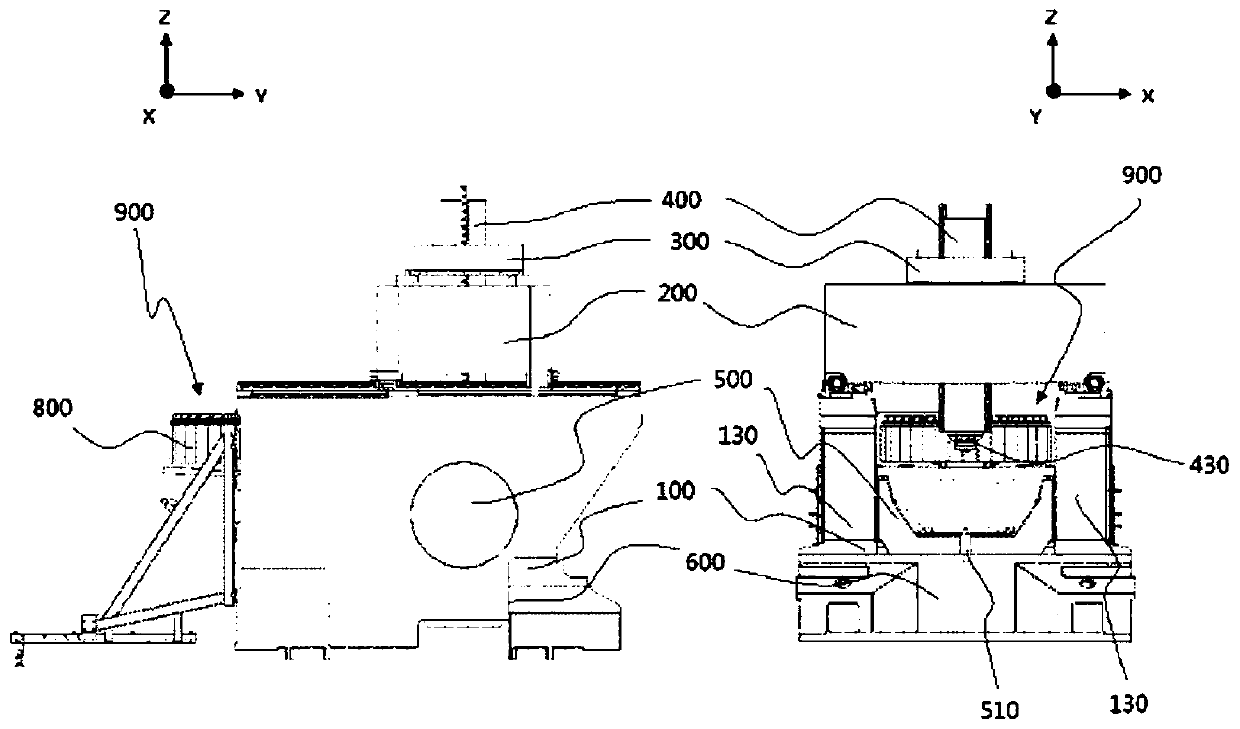

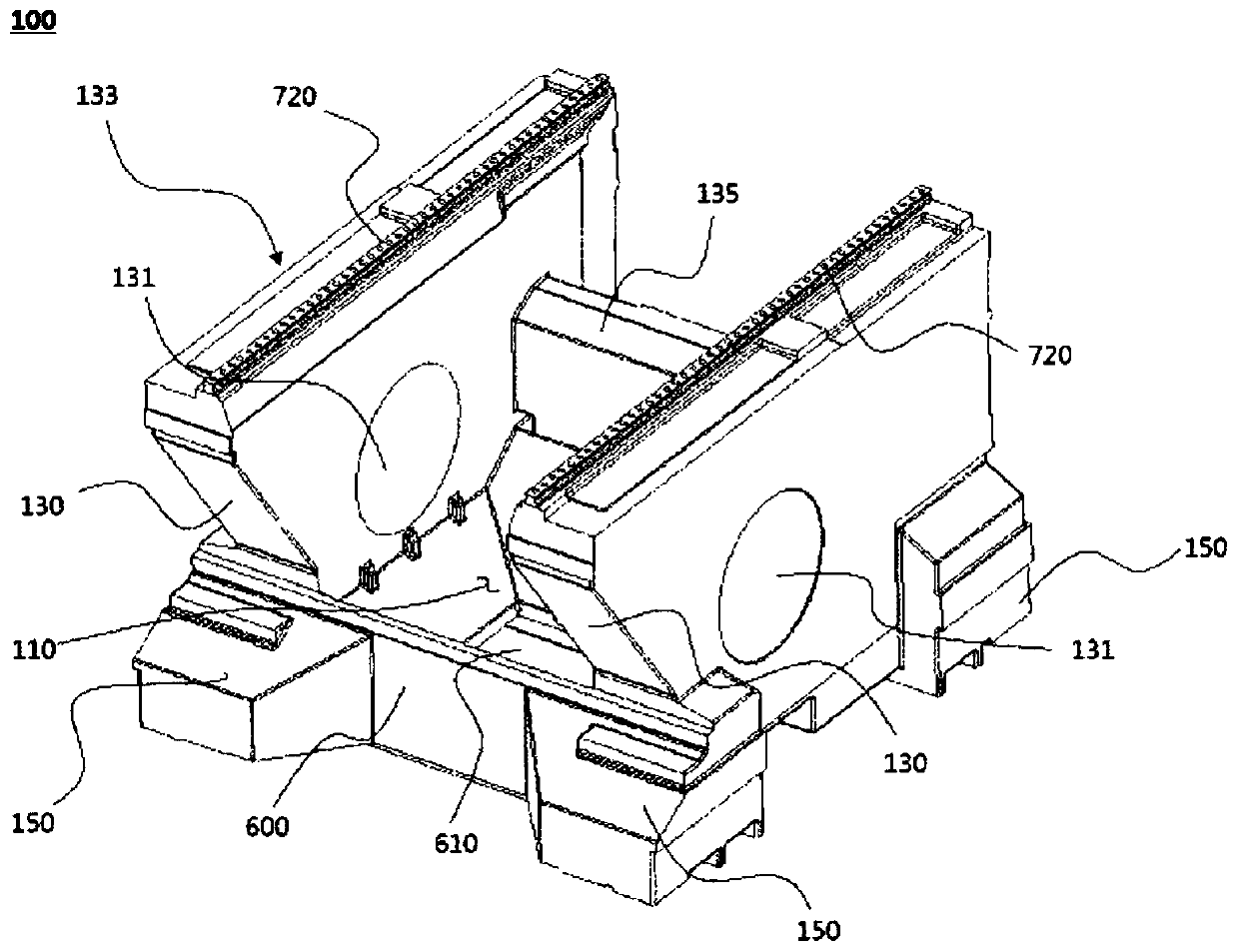

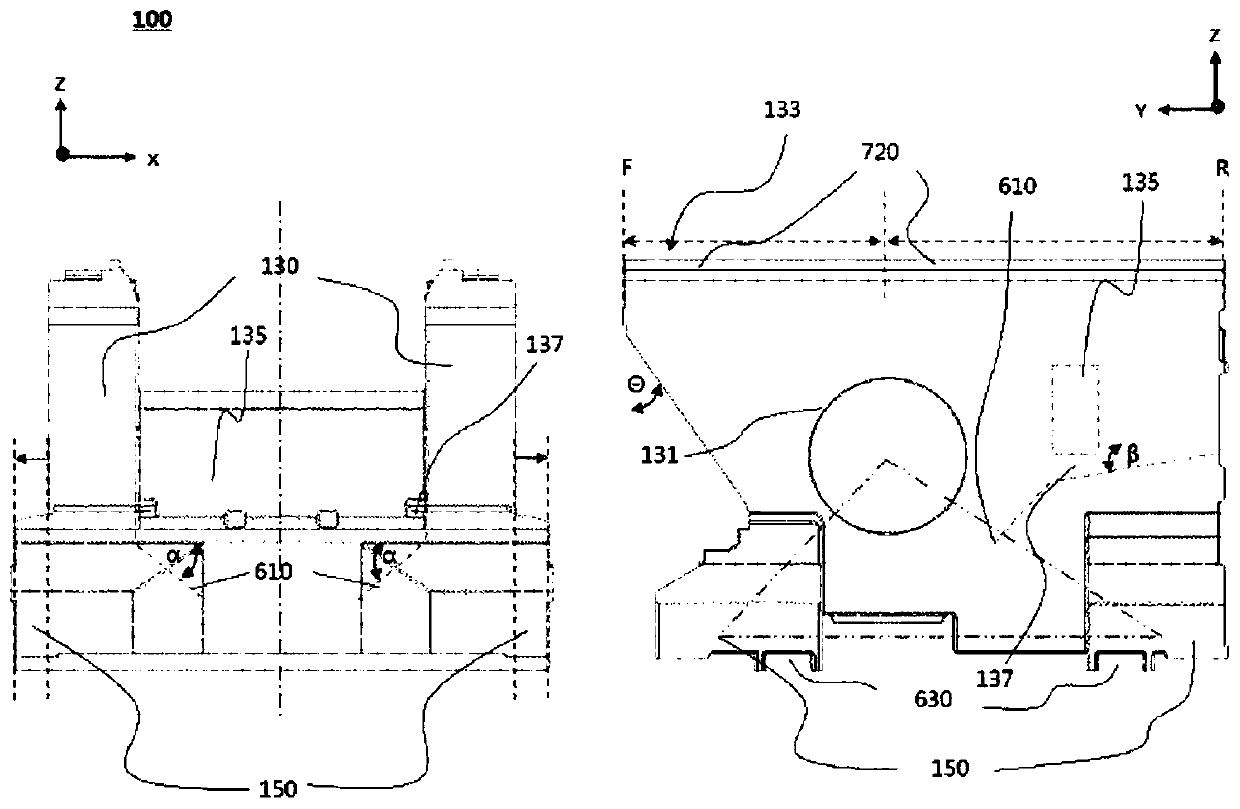

[0035] figure 1 is a view showing a machine tool according to an embodiment of the present invention, figure 2 is showing figure 1 A view of the pedestal 100, image 3 yes figure 2 front and side views. also, Figure 4 is showing figure 1 A view of the Saddle 200, Figure 5 is showing figure 1 A view of the rung 300, Figure 6 is showing figure 1 A view of the vertical push rod 400.

[0036] In this specification, the first axis can be the Y axis, the second axis can be the X axis, and the third axis can be the Z axis, but the directions can be changed freely according to the design or environment, so they are referred to as the first axis in this specification First axis, second axis and third axis.

[0037] Such as figure 1 and figure 2 As shown, the machine tool according to the embodiment of the present invention inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com