Pneumatic chucking tool capable of milling two faces of track link section piece

A chain link, double-sided technology, applied in positioning devices, milling machine equipment, manufacturing tools, etc., can solve the problems of high labor intensity, low production efficiency, quality problems, etc., and achieve power saving, high production efficiency, and work efficiency. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

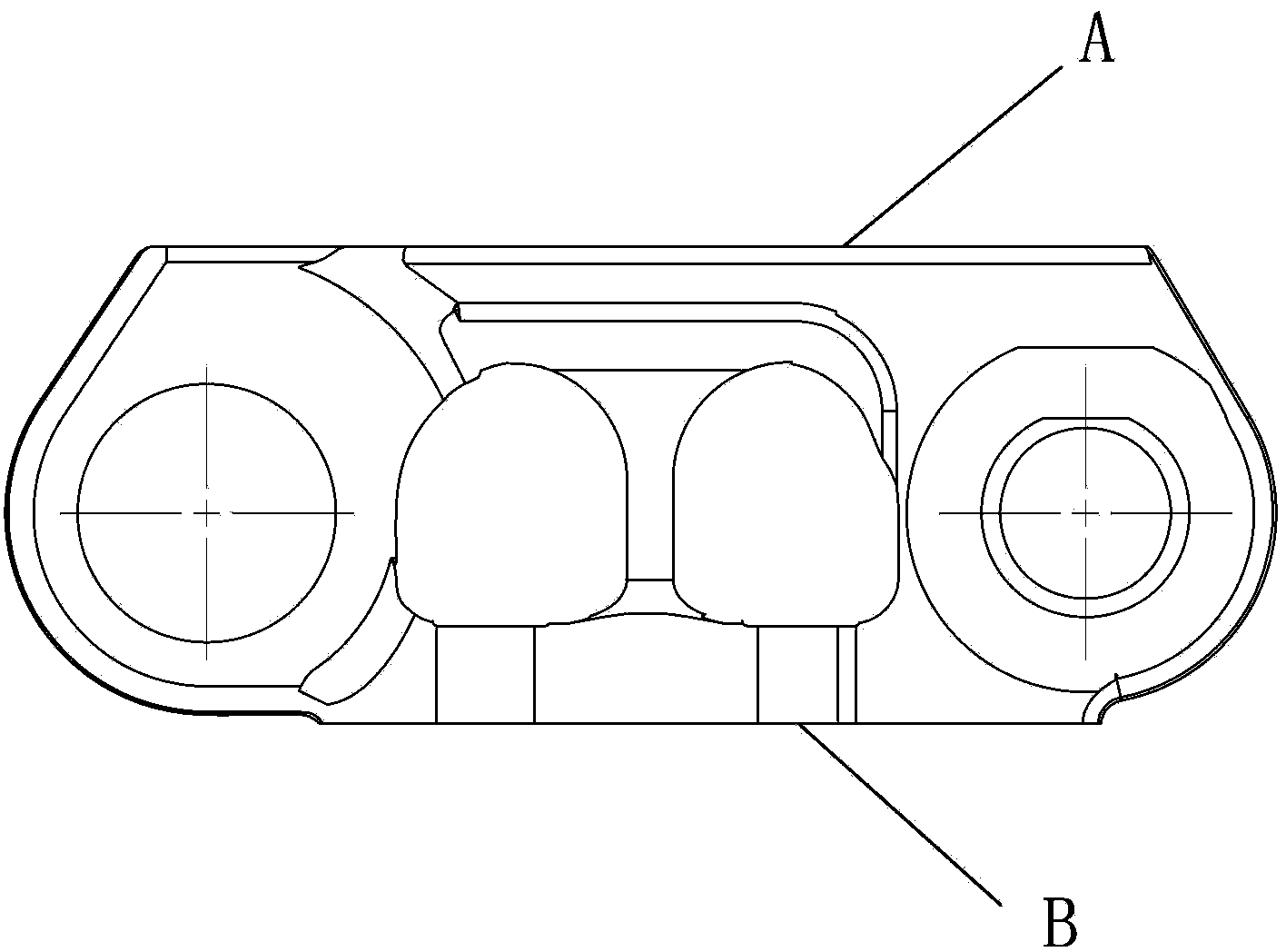

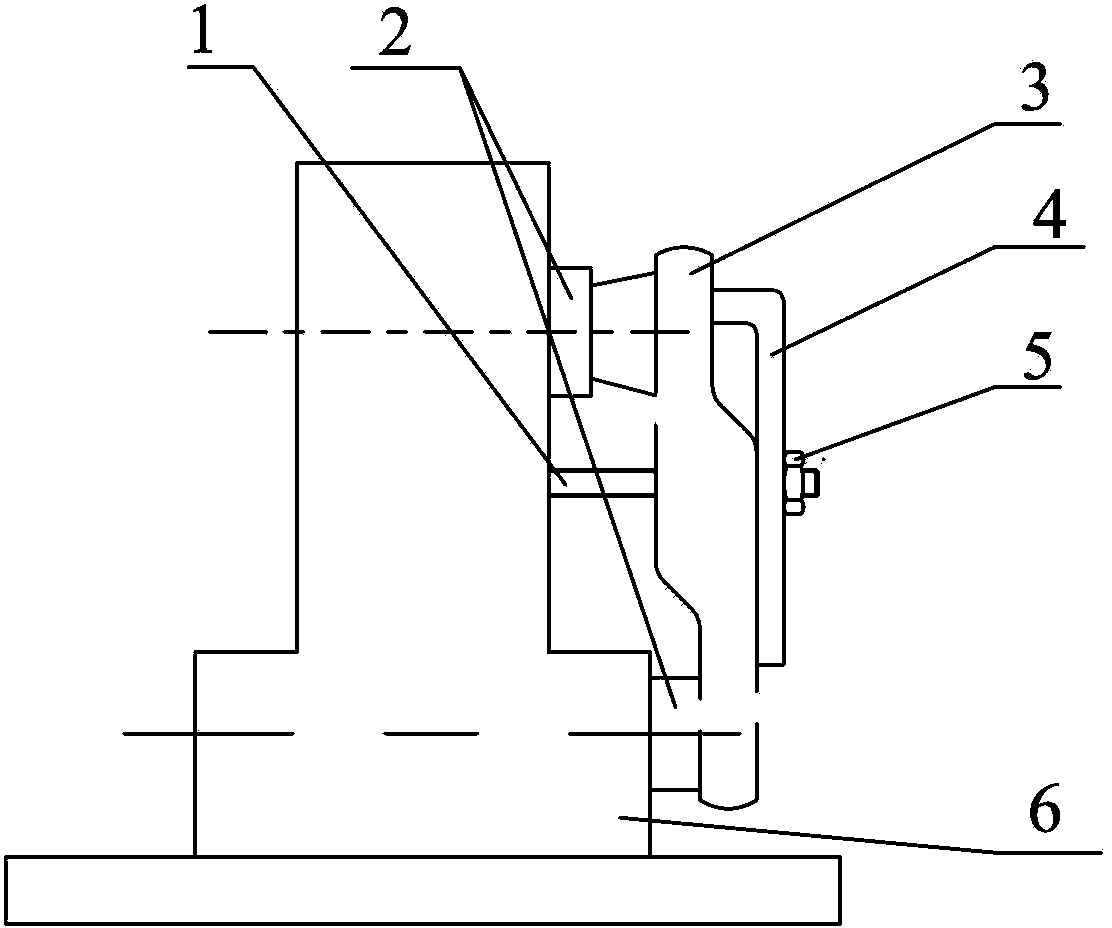

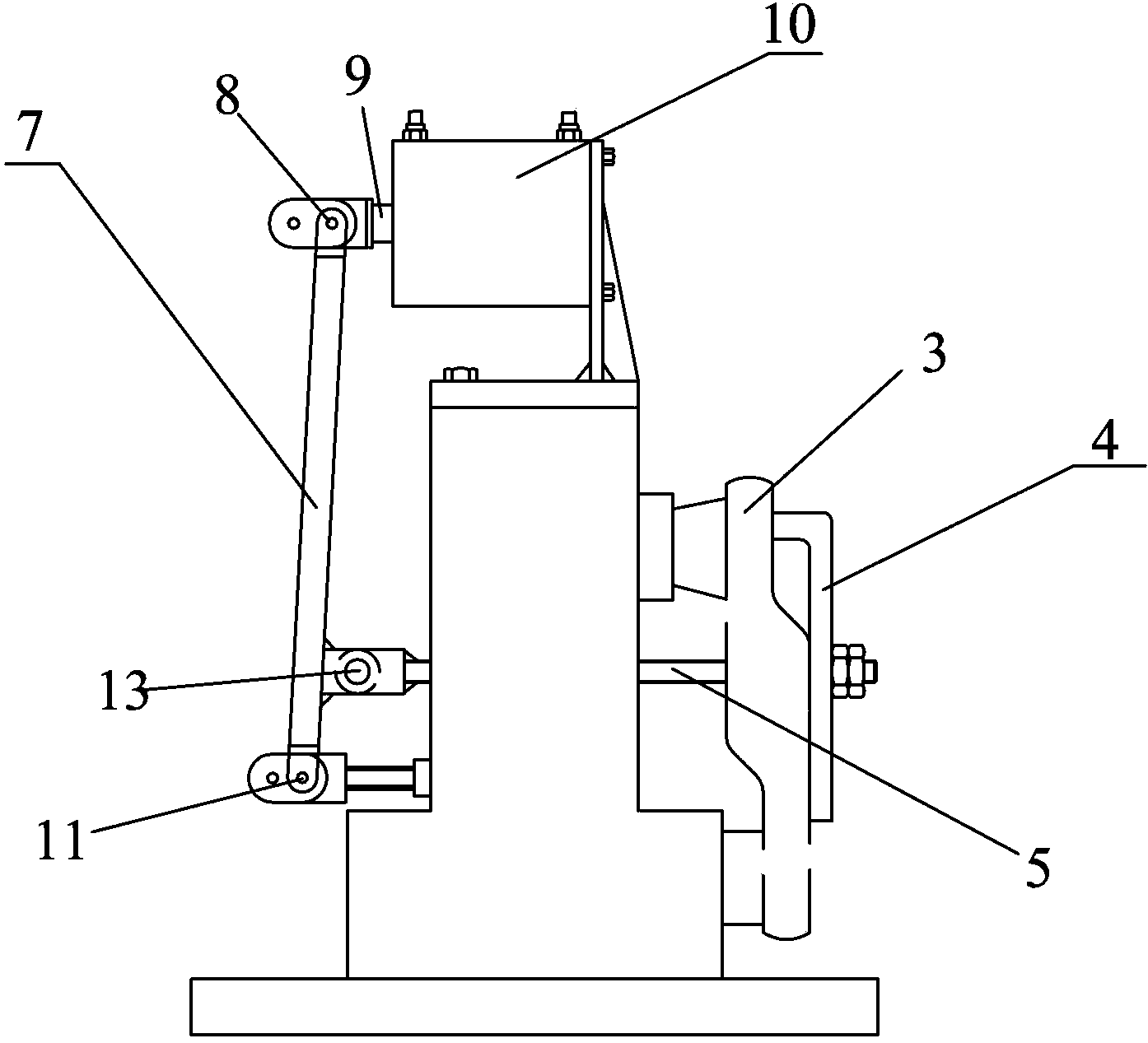

[0017] The present invention studies and updates the existing tooling, develops and designs a set of relatively complete tooling with high efficiency and high yield. Such as image 3 As shown: it includes positioning pins 2 set on the positioning seat 6 at the upper and lower positions, and the screw rod 1 in the middle for piercing the processed chain rail segments. The front end of the screw rod 1 is threaded through the L-shaped pressure plate 4 and then screwed Nut 5. Wherein, the rear end of the screw rod 1 is hingedly connected to the middle part of a lever 7, the lower end of the lever 7 is hingedly connected to the positioning seat 6, and the upper end of the lever 7 is hingedly connected The end of a piston rod 9, the rear part of the piston rod 9 is a telescopic unit. In a preferred manner, the telescopic unit is an air cylinder 10 or a hydraulic cylinder. In the figure, the number 8 is the upper hinge point of the lever 7, the number 11 is the lower hinge point o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com