Milling machine fixture capable of adjusting angle

A milling machine fixture and adjustable technology, applied in the mechanical field, can solve the problems of time-consuming and laborious clamping process, difficult to improve production efficiency, difficult to guarantee the angle, etc., and achieve the effect of improving processing efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

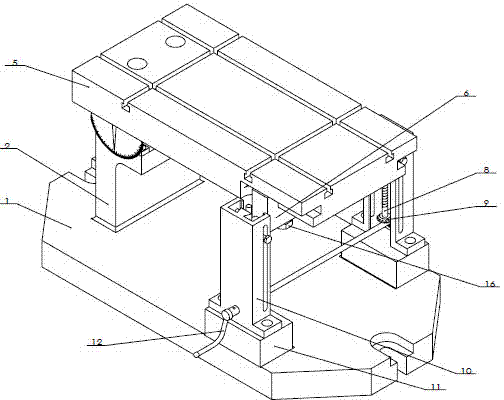

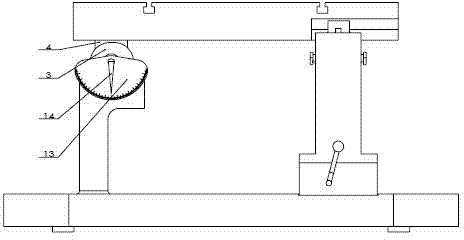

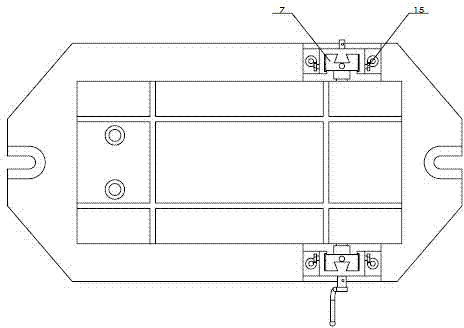

[0010] Fixtures such as figure 2 As shown, it includes the fixture base 1, the side wall 2, the shaft sleeve 3 is installed on the side wall 2 through bolts, the shaft 4 cooperates with the shaft sleeve 3 to form a hinge mechanism, the working plate 5 is connected with the shaft 4 through bolts, and the parts are connected through bolts and pressure plates. Fixed on the working board, the other end of the working board is connected with the shaft 6, the shaft 6 cooperates with the nut 7 with the shaft hole, the nut 7, the lead screw 8, the bevel gear 9, and the guide rail 10 form a nut screw mechanism, and the rocker arm 12 and the Bevel gear connection, by rotating the rocker arm, gear meshing, and thread transmission, the nut is pushed up and down to adjust the angle of the working plate.

[0011] When processing the workpiece, first rotate the rocker arm, read the required angle from the dial, and then tighten the clamping bolts 4×15 and 2×16. If the angle of the part pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com