A tool that can press and install multiple parts at the same time

A technology of parts and tooling, which is applied in the field of mechanical processing fixtures, can solve the problems of limited number of clamping parts, low machine tool utilization rate and processing efficiency, and achieve the effect of shortening clamping time, improving machine tool utilization rate and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

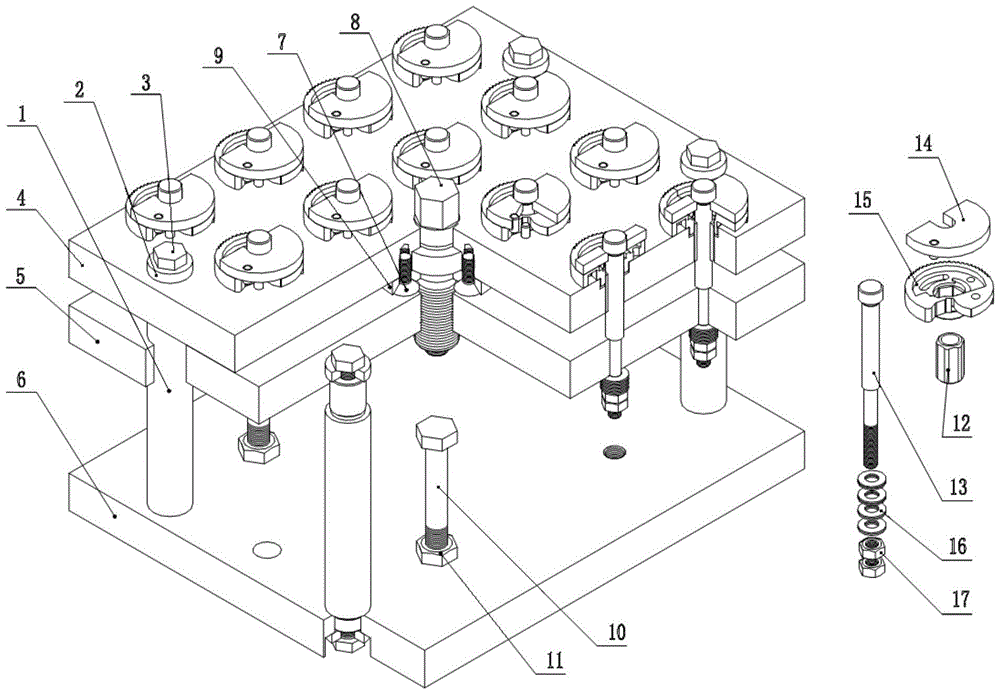

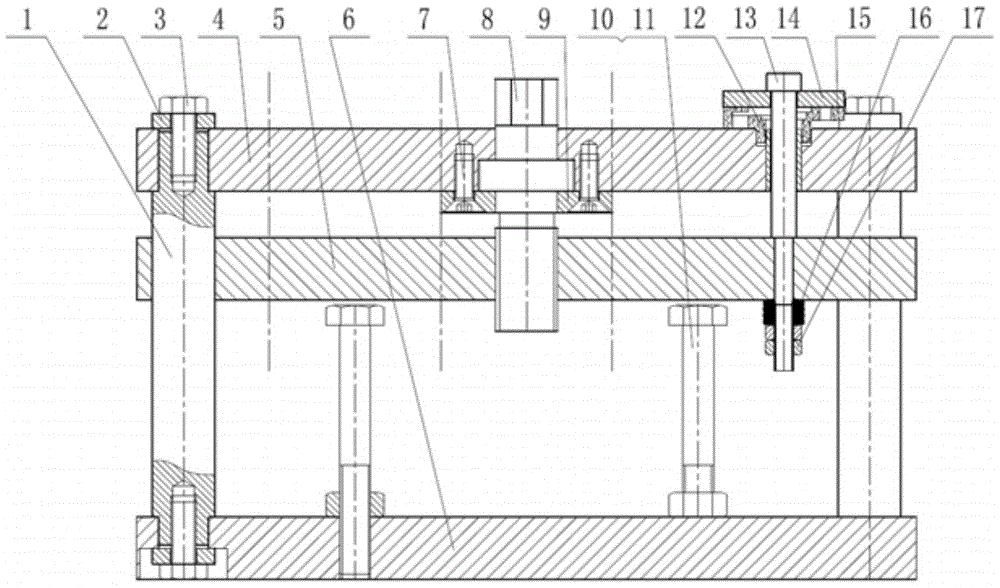

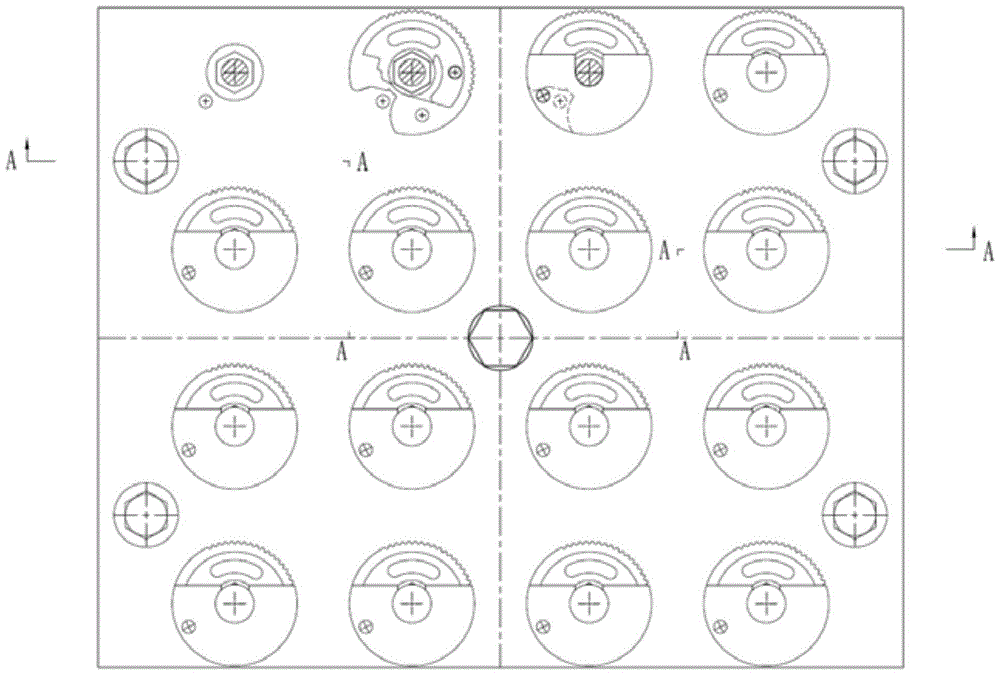

[0016] see figure 1 , figure 2 with image 3 , the present embodiment press-fits sixteen parts at the same time, and the structure of the tooling is: the tooling plate 4 and the bottom plate 6 are fastened by four guide columns 1 to form a frame structure by gaskets 2 and bolts 3; In the step hole of the mounting part 15, the small end of the step hole is a hexagonal through hole, and the hexagonal through hole is closely matched with the hexagonal positioning pin 12 with a through hole in the center; The holes are loosely matched, the central through hole of the hexagonal positioning pin 12 is loosely matched with the middle section of the pressing shaft 13; the moving plate 5 is installed between the tooling plate 4 and the bottom plate 6, and the moving plate 5 is driven by the screw rod 8 to move up and down, and on the guide column The moving guide is obtained on the moving plate 5; the moving plate through holes that are loosely matched with the lower section of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com