Valve core end surface milling clamp

A valve core end face, milling technology, applied in the direction of clamping, milling machine equipment, manufacturing tools, etc., can solve the problems of difficult positioning and clamping, and achieve the effect of reliable positioning, low cost and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

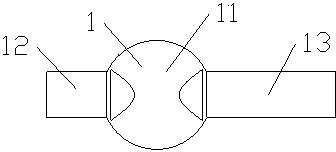

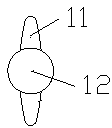

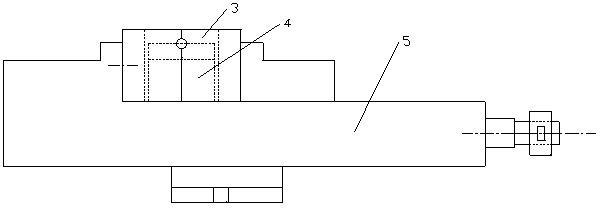

[0017] see Figure 3-4 The shown valve core end face milling fixture includes a clamping mold 3 composed of two half molds 2 with the same structure. Described clamping mold has a valve plate hole 31 that is made up of semicircle hole 21 on two half molds, on the both sides of valve plate hole, there is respectively a mandrel hole 32 whose axis is perpendicular to the axis of the circular hole, the mandrel hole It consists of semicircles 22 on two mold halves. An anti-rotation column 4 is arranged in the hole of the valve plate; the top surface of the anti-rotation column is an arc surface with a high center and a low periphery. One half-mold 2 is connected with the movable jaw 51 of the vice 5, and the other half-mold 2 is connected with the fixed jaw 52 of the vice. The closing mold that valve plate hole 31 faces upwards is clamped by vice.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com