Stabilizing structure of tool bar of automatic screwdriver

A technology of stable structure and screwdriver, applied in screwdrivers, wrenches, manufacturing tools, etc., can solve the problems of high labor intensity, trouble, low nailing efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

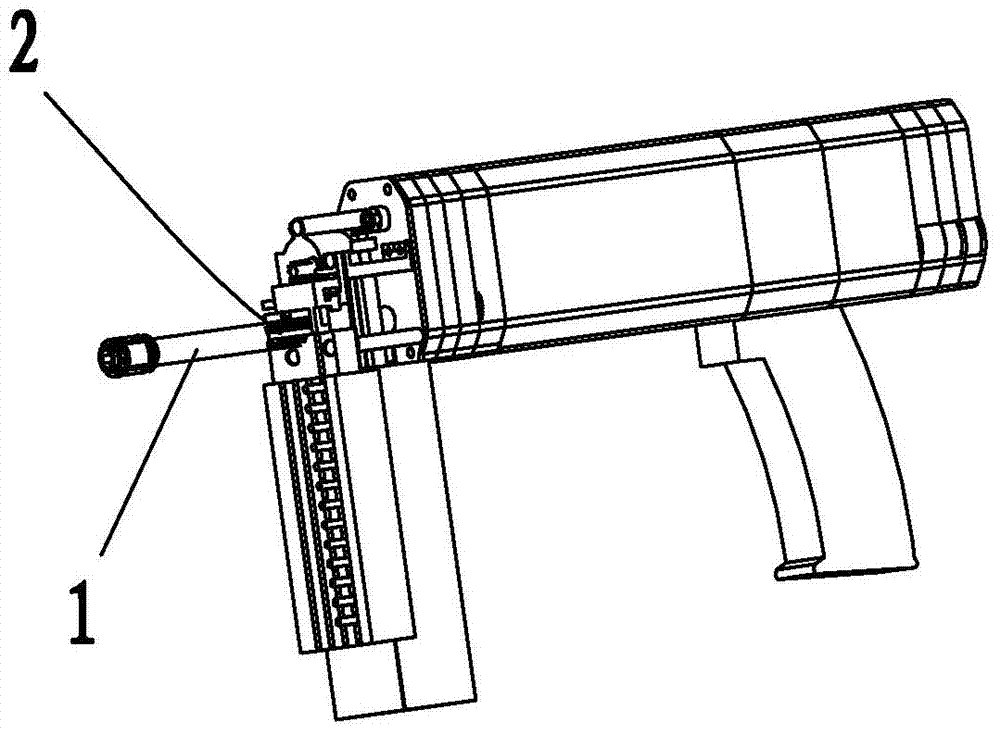

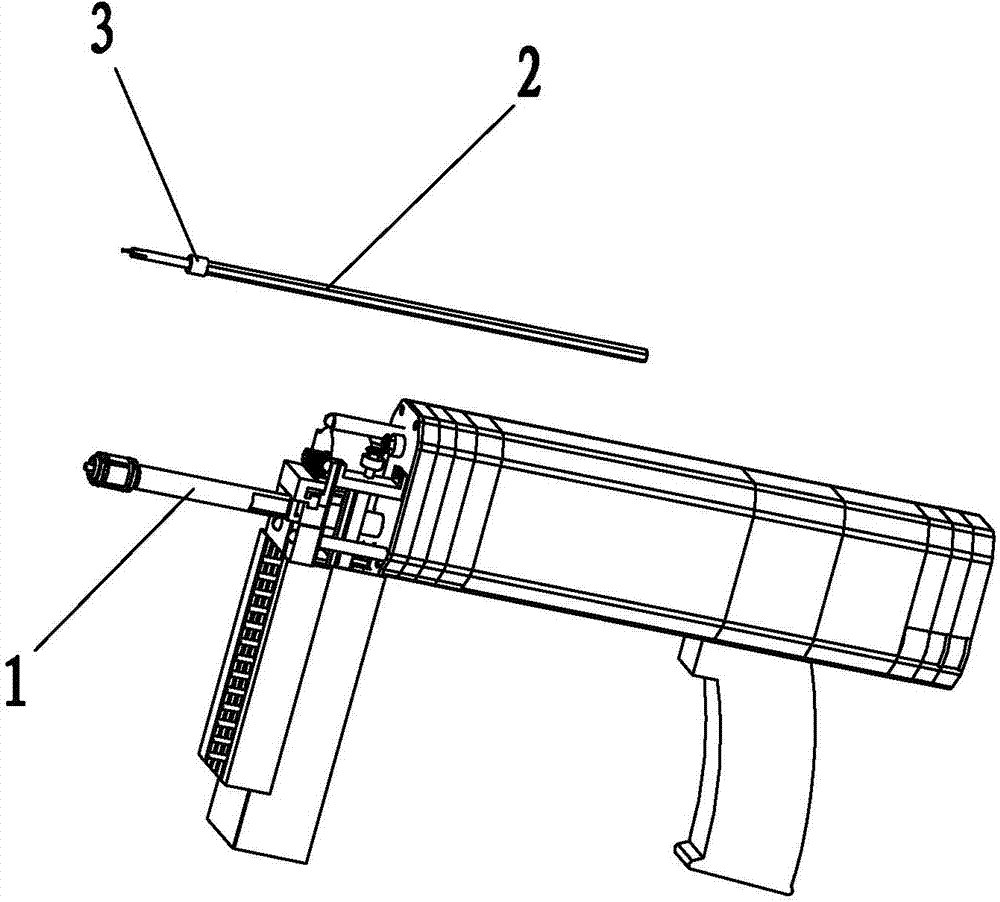

[0012] Such as figure 1 , figure 2 As shown, the position of the knife bar 2 is suitable for the connection of the driving device during use, and there will not be too much shaking, but small vibrations may still occur, which reduces the stability of the knife bar 2 .

[0013] The stable structure of the knife bar in the automatic screwdriver of the present invention includes a sleeve 1 and a knife bar 2. The knife bar 2 is inserted in the sleeve 1 and can freely move along the axial direction of the sleeve 1. The knife bar 2 is provided with The limiting part 3 for limiting the radial movement of the tool rod 2 is located in the casing 1 and is slidingly fitted with the casing 1 . Specifically, the limiting member 3 is a copper collar, and the collar is fixedly mounted on the cutter bar 2, and the collar is in sliding fit with the casing 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com