Structurally-modified chemical fiber paper bobbin

A paper tube and chemical fiber technology, which is applied in the field of improving the structure of chemical fiber paper tubes, can solve the problems of low efficiency and unsatisfactory use effect of the silk catcher structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below according to the drawings and embodiments.

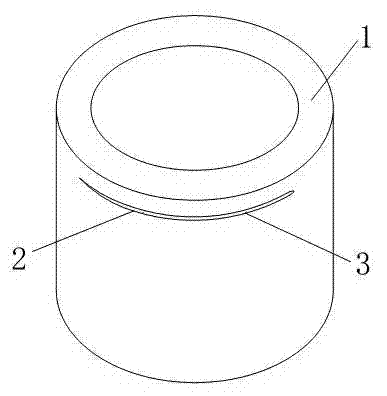

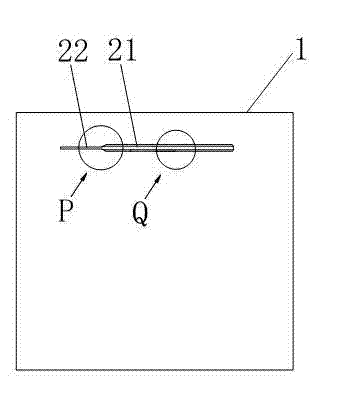

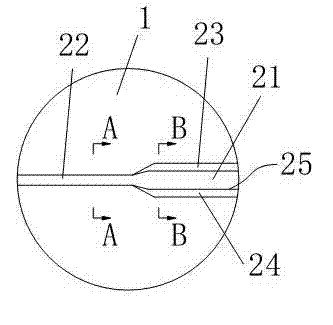

[0018] Such as Figure 1 to Figure 6 As shown, the improved structure of a chemical fiber paper cylinder described in the embodiment of the present invention includes a cylinder body 1, and a thread catching groove 2 is provided on the outer surface of the top circumference of the cylinder body 1, and the silk catching groove 2 includes a guide The wire groove 21 and the wire holding groove 22, the two sides of the notch of the wire guiding groove 21 are respectively provided with an upper slope 23 and a lower slope 24, and the lower groove wall 211 of the wire guiding groove 21 meets the lower slope 24 to form The lower edge 25 , the lower groove wall 211 and the lower slope 24 are inclined along the length extension direction of the lower edge 25 to form a hanging thread portion 3 . The thread catcher 2 has two thread hanging parts 3 .

[0019] combine Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com