Image capturing system group

一种影像撷取、像侧的技术,应用在光学、仪器、光学元件等方向,能够解决不利生产制造、成本提高、拓展景深范围功能不佳等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example 》

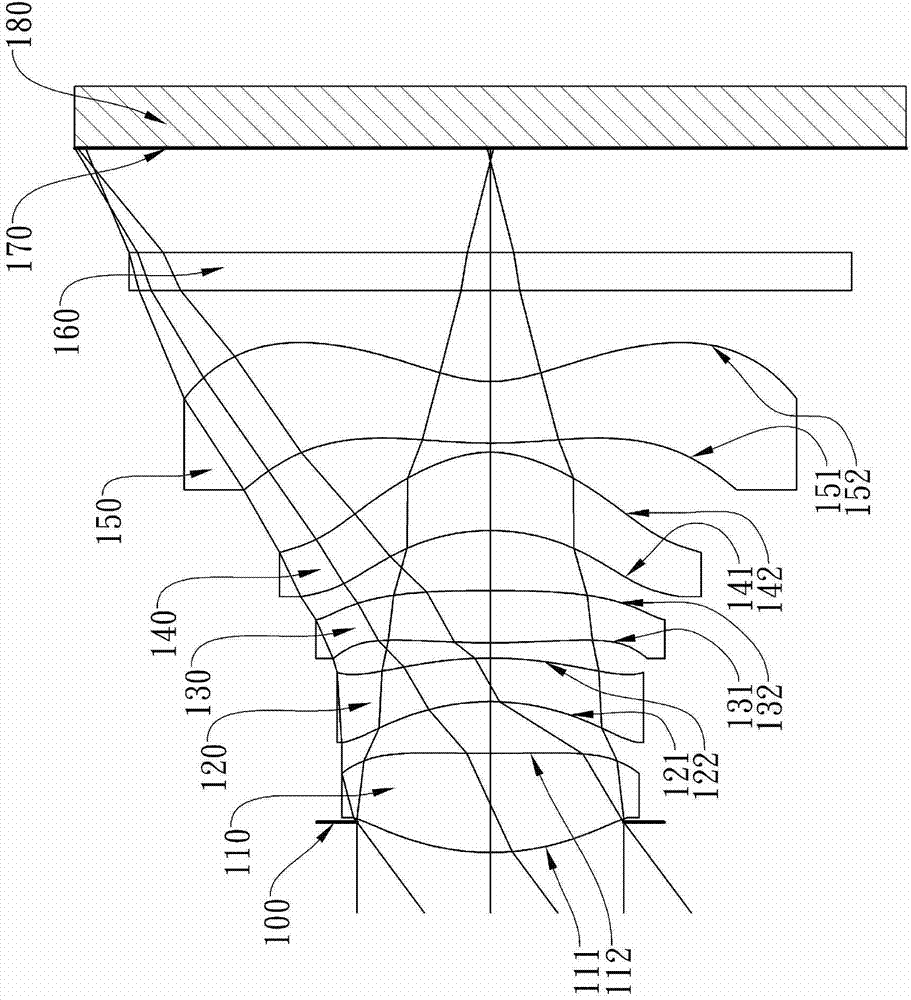

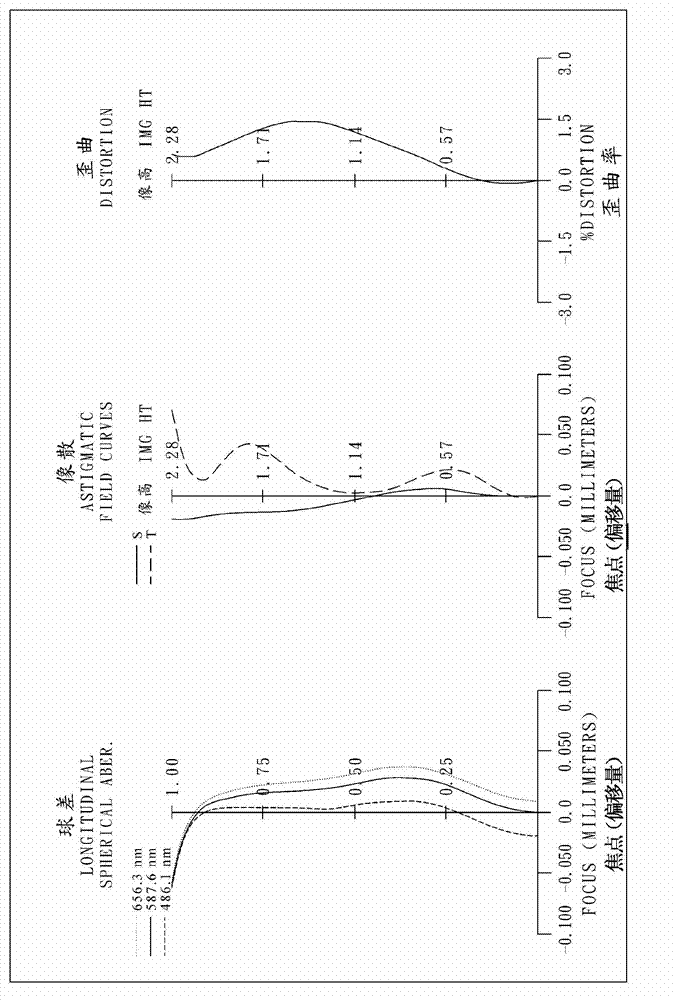

[0111] Please refer to the first embodiment of the present invention Figure 1A , for the aberration curve of the first embodiment, please refer to Figure 1B . The image capture system group of the first embodiment is mainly composed of five lenses with refractive power, which sequentially include from the object side to the image side:

[0112] A first lens (110) with positive refractive power, its object side (111) is convex and image side (112) is concave, its material is plastic, the object side (111) and image of the first lens (110) The side surfaces (112) are all aspherical surfaces;

[0113] A second lens (120) with negative refractive power, its object side (121) is concave and image side (122) is convex, its material is plastic, the object side (121) and image of the second lens (120) The side surfaces (122) are all aspherical surfaces;

[0114] A third lens (130) with positive refractive power, its object side (131) is convex and its image side (132) is convex, ...

no. 2 example 》

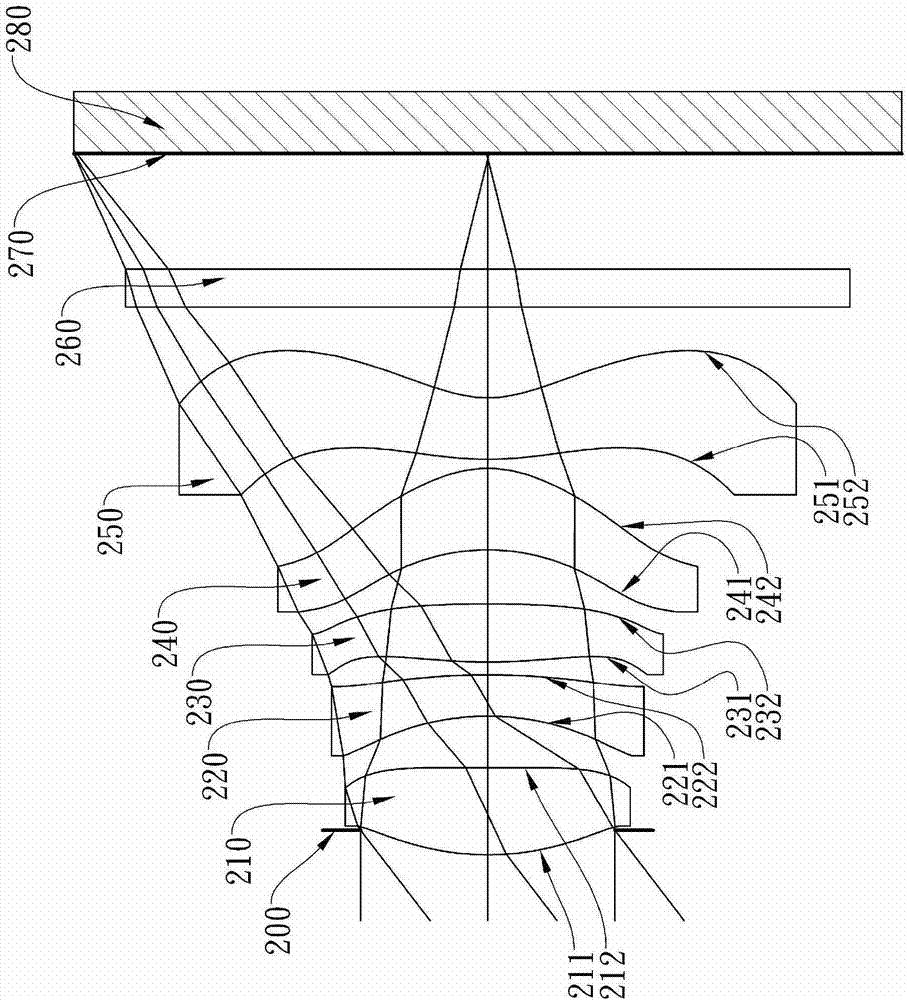

[0146] Please refer to the second embodiment of the present invention Figure 2A , for the aberration curve of the second embodiment, please refer to Figure 2B . The image capture system group of the second embodiment is mainly composed of five lenses with refractive power, which sequentially include from the object side to the image side:

[0147] A first lens (210) with positive refractive power, its object side (211) is convex and image side (212) is concave, its material is plastic, the object side (211) and image of the first lens (210) The side surfaces (212) are all aspheric surfaces;

[0148] A second lens (220) with negative refractive power, its object side (221) is concave and image side (222) is convex, its material is plastic, the object side (221) and image of the second lens (220) The side surfaces (222) are all aspheric surfaces;

[0149] A third lens (230) with positive refractive power, its object side (231) is convex and its image side (232) is convex, ...

no. 3 example 》

[0160] Please refer to the third embodiment of the present invention Figure 3A , for the aberration curve of the third embodiment, please refer to Figure 3B . The image capture system group of the third embodiment is mainly composed of five lenses with refractive power, which sequentially include from the object side to the image side:

[0161] A first lens (310) with positive refractive power, its object side (311) is convex and image side (312) is concave, its material is plastic, the object side (311) and image of the first lens (310) The side surfaces (312) are all aspherical surfaces;

[0162] A second lens (320) with negative refractive power, its object side (321) is concave and image side (322) is convex, its material is plastic, the object side (321) and image of the second lens (320) The side surfaces (322) are all aspheric surfaces;

[0163] A third lens (330) with positive refractive power, its object side (331) is convex and image side (332) is concave, its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com