Magnetic confinement device and method of CO2 laser beam bunching

A magnetic confinement and laser technology, applied to lasers, laser parts, phonon exciters, etc., can solve problems such as difficult cutting and poor quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

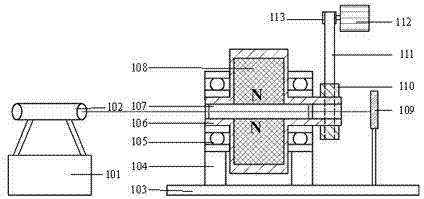

[0019] The high-energy CO of the present invention will be discussed below in conjunction with the accompanying drawings 2 A magnetic confinement method and device for laser beam focusing will be described.

[0020] Such as figure 1 As shown, the CO of the present invention 2 Magnetic confinement methods and devices for laser beamforming include:

[0021] The four-dimensional motion platform 101, on which the laser is installed, realizes the control and adjustment of the position and posture of the laser, and ensures that the laser beam passes through the center of the magnetic cavity;

[0022] CO 2 Laser 102, emitting CO 2 Devices for high-power lasers;

[0023] Precision rail 103, adjust mutually exclusive magnetic confinement body and CO 2 The position between the lasers, choose the most suitable distance for focusing the laser beam;

[0024] Bearing bracket 104 supports the bearing and is connected to the precision guide rail at the same time to ensure that the bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com