A method for controlling the welding deformation of a hollow stationary vane and a special cavity supporting device

A hollow vane and support device technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of irregular deformation of the blade surface, difficult correction and irregularity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

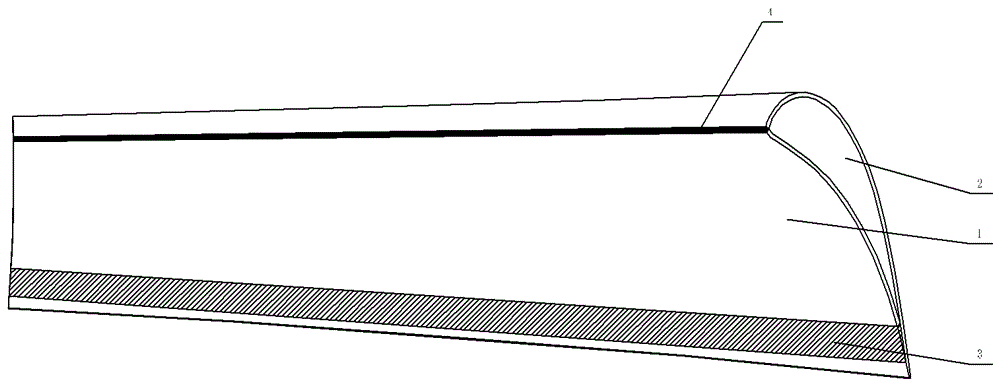

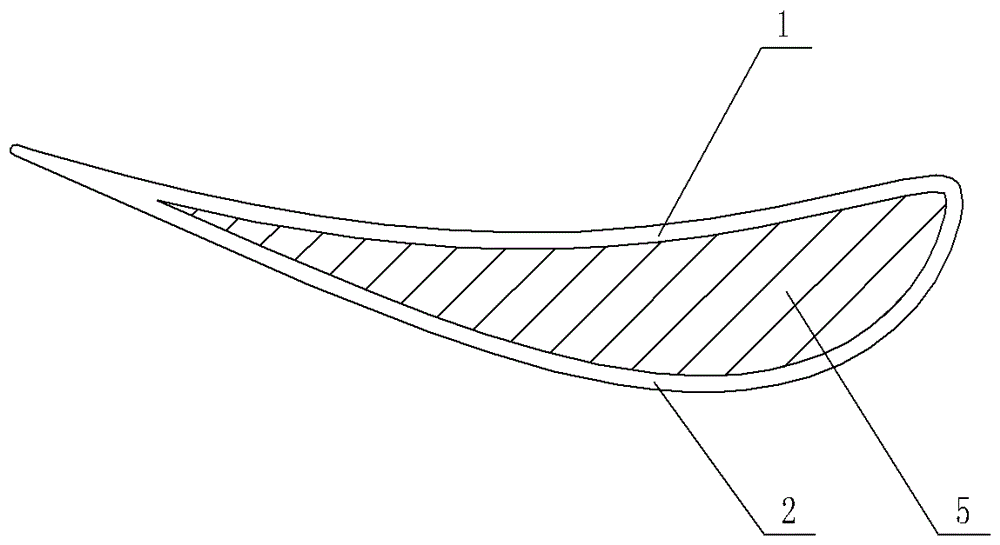

[0011] A method for controlling the welding deformation of a hollow static blade, firstly spot welding and positioning the steam inlet and outlet sides of the inner arc plate 1 and the back arc plate 2 of the blade, and then installing a special cavity support device 5 in the hollow cavity of the blade, See figure 2 , and then put the whole blade into the welding fixture to carry out the welding operation of the blade inlet and outlet sides, after the welding is completed, take off the blade after it is fully cooled, and finally take out the cavity support device from the blade cavity.

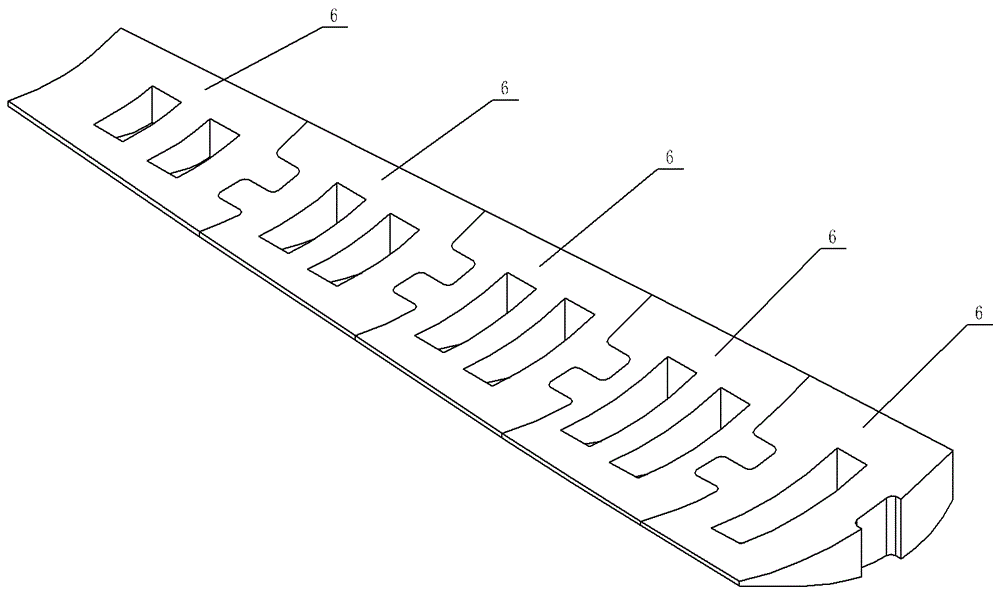

[0012] The special cavity support device in the present invention is composed of a plurality of cavity support blocks 6. The number of cavity support blocks 6 is determined according to the total effective length of the blades. In this embodiment, there are five cavity support blocks 6. block, see image 3 , the combined outer profile of the five cavity support blocks fits the inner profile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com