Liquid spraying bottle

A liquid spray bottle and bottle body technology, applied in the field of liquid spray bottles, can solve the problems of inconvenience to carry and use, and achieve the effects of easy liquid filling operation, easy use and portability, and maintenance-free.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

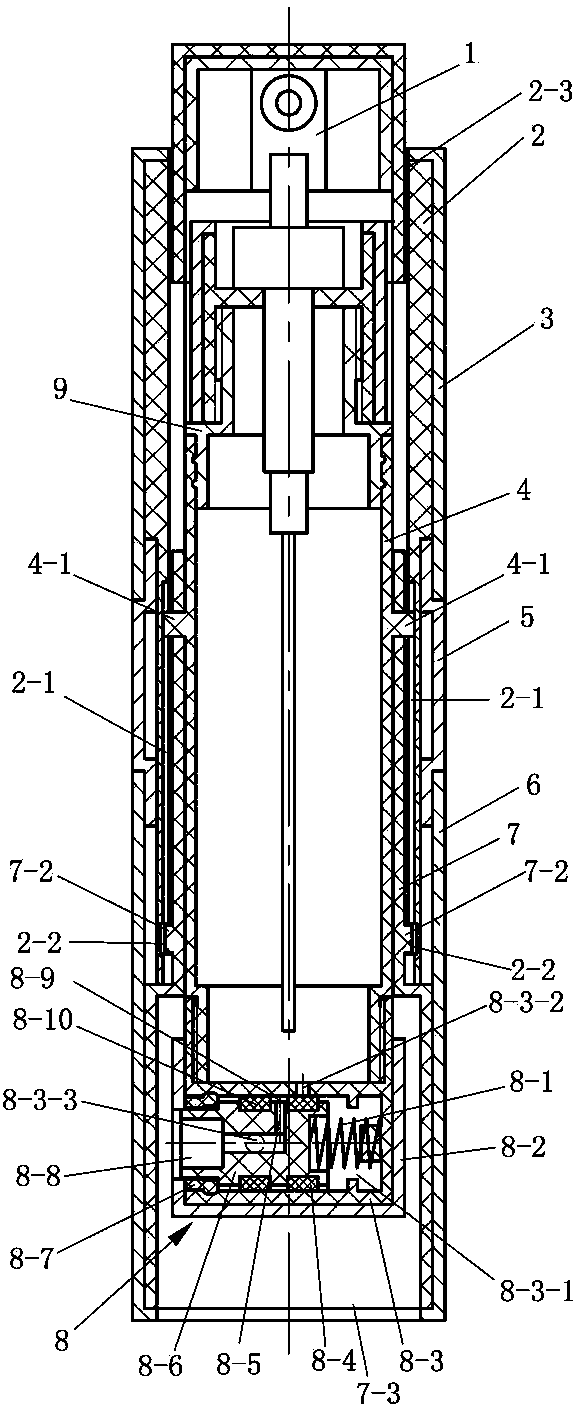

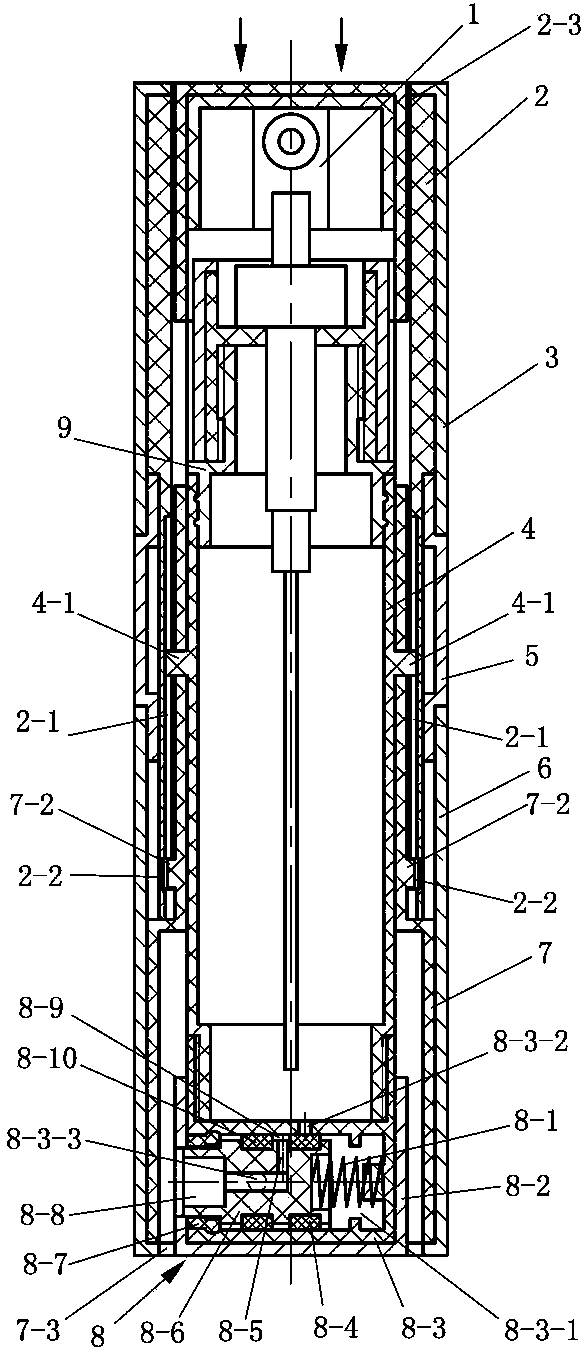

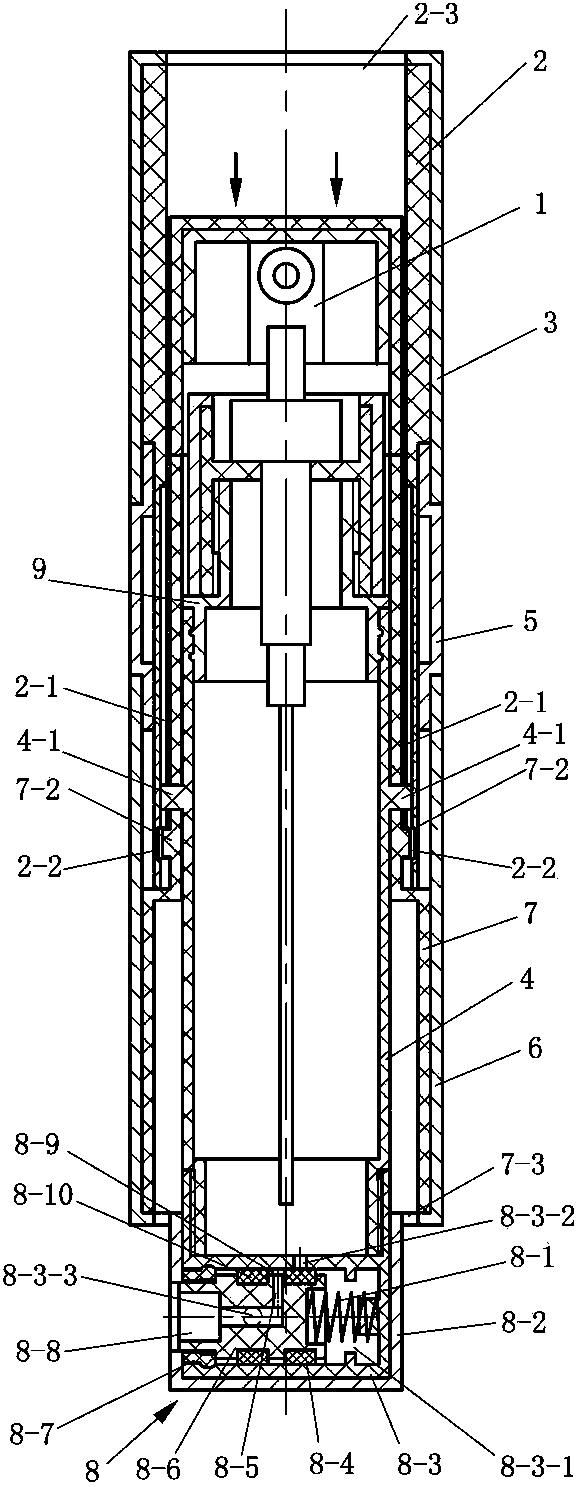

[0046] Such as Figure 1~30 As shown, a liquid spray bottle of the present invention includes a bottle body 4, a nozzle assembly 1 and a liquid filling device 8, the nozzle assembly 1 is installed on the upper end of the bottle body 4, and the liquid filling device 8 is installed on the lower end of the bottle body 1 , also includes upper cover 2 and lower cover 7, the upper end of said upper cover 2 has upper opening 2-3, the lower end of lower cover 7 has lower opening 7-3, the lower part of upper cover 2 and the upper part of lower cover 7 The upper cover 2 and the lower cover 7 are axially limited and rotated in the circumferential direction, and the cover is set outside the bottle body 4. The lower part of the upper cover 2 has an axial guide groove 2-1, so The upper part of the lower cover 7 has a travel chute 7-1, and the outer periphery of the bottle body 4 has a protrusion 4-1, and the protrusion 4-1 passes through the travel chute 7-1 and extends into the axial guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com