Fabricated reinforced concrete and wood composite floor

A reinforced concrete and composite floor technology, applied in floors, building components, buildings, etc., can solve the problems of low strength, low rigidity, poor sound insulation and fireproof performance, and small applicable span, so as to improve fireproof performance and enhance floor load bearing Capacity and rigidity, the effect of speeding up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

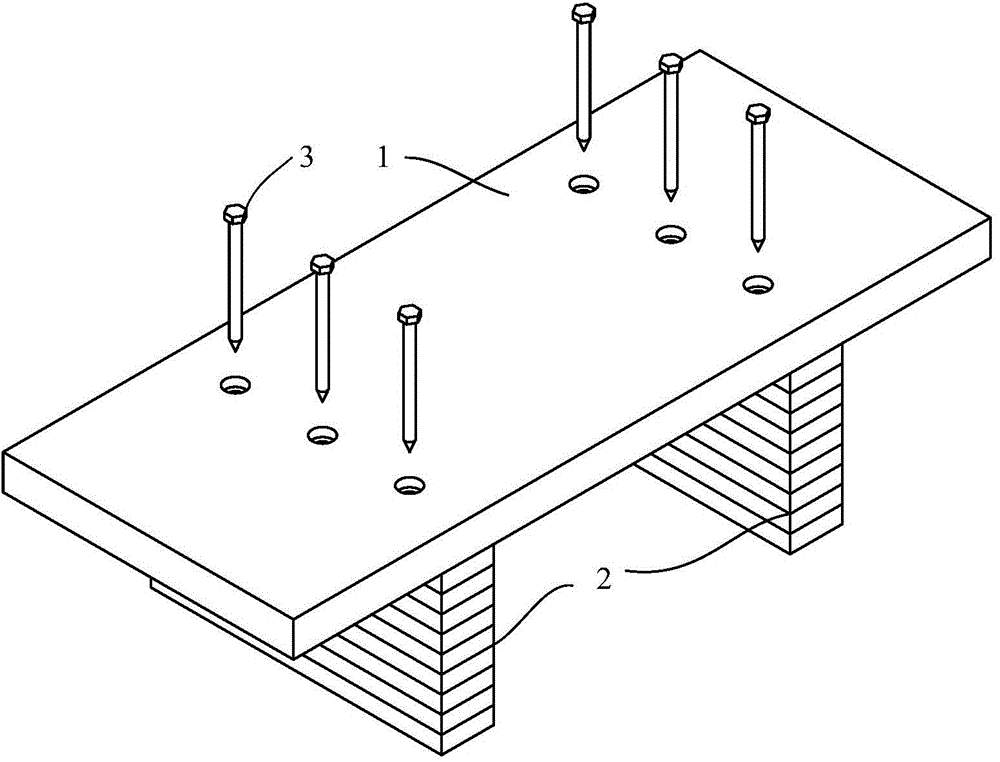

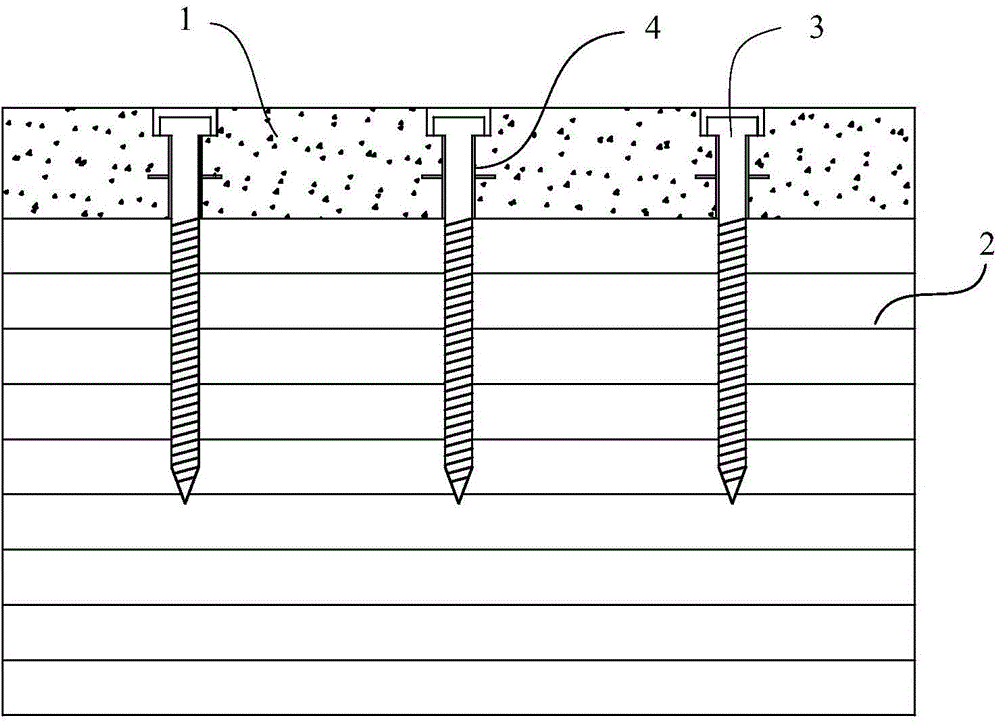

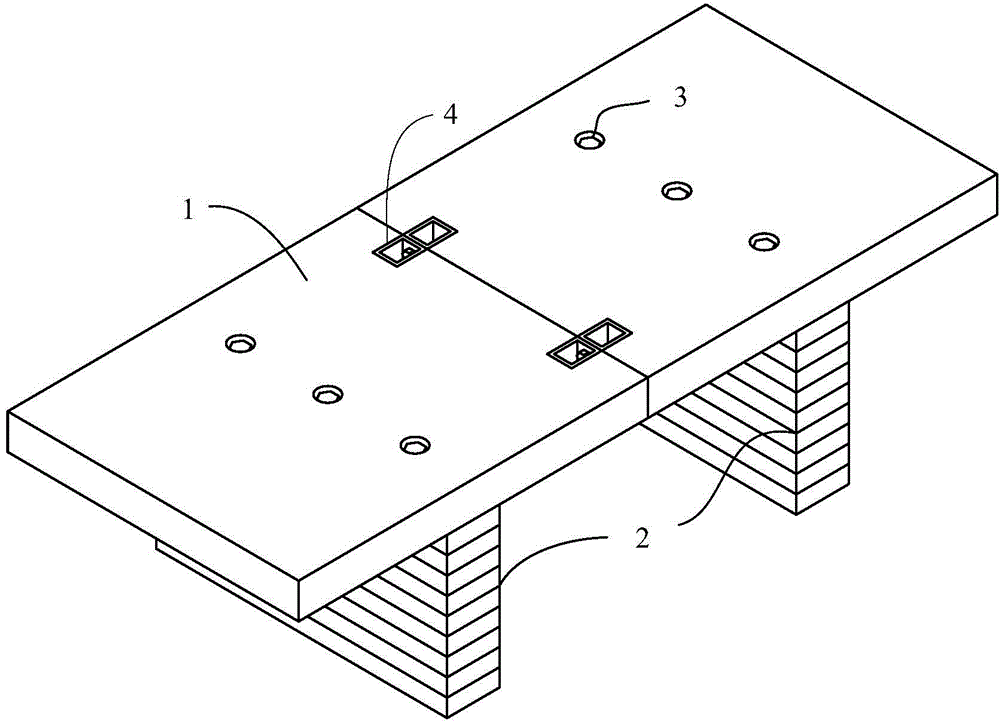

[0020] Such as Figure 1-3 As shown, an assembled reinforced concrete-wood composite floor is composed of a prefabricated reinforced concrete floor 1, wooden joists 2, lag wood screws 3, steel pipe embedded parts 4, and floor edge embedded parts 5.

[0021] The prefabricated reinforced concrete floor 1 is provided with a steel pipe embedded part 4, and the side of the prefabricated reinforced concrete floor 1 is provided with a floor edge embedded part 5; The joists 2 are connected, the lag wood screws 3 pass through the steel pipe embedded parts 4, and the adjacent prefabricated reinforced concrete floors 1 are connected by bolts through the floor edge embedded parts 5.

[0022] The wood used for the wooden joists is logs, laminated lumber (Glulam) or peeled glulam (LVL). The cross-sectional shape of the wooden joists is rectangular or inverted T-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap