Breathing ring anchoring nail

A ring anchor and anchor ring technology, applied in mechanical equipment, connecting components, etc., can solve the problems of anchor ring synchronization, affecting the working life of the wear-resistant layer, etc., to achieve the effect of firm wear-resistant layer, improved service life, and good anchoring function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

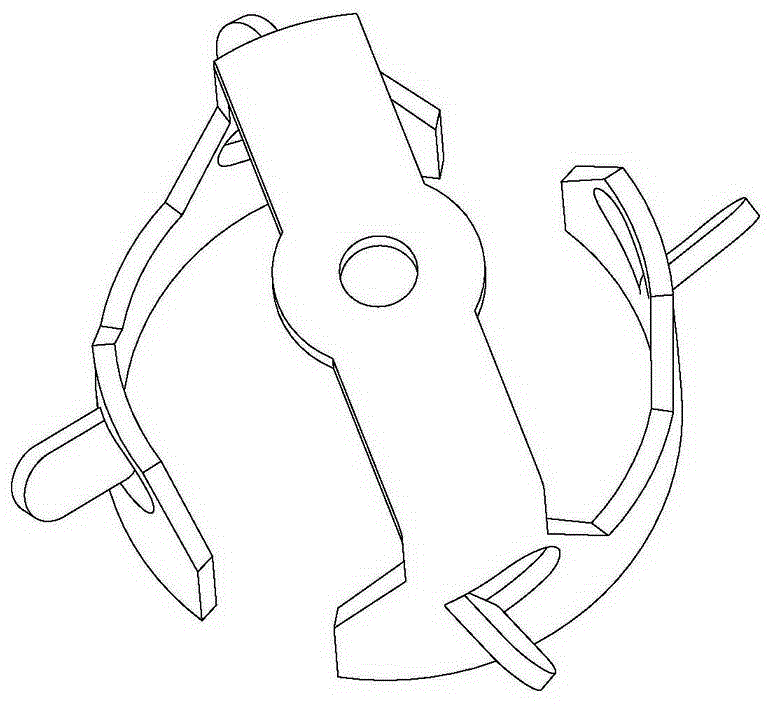

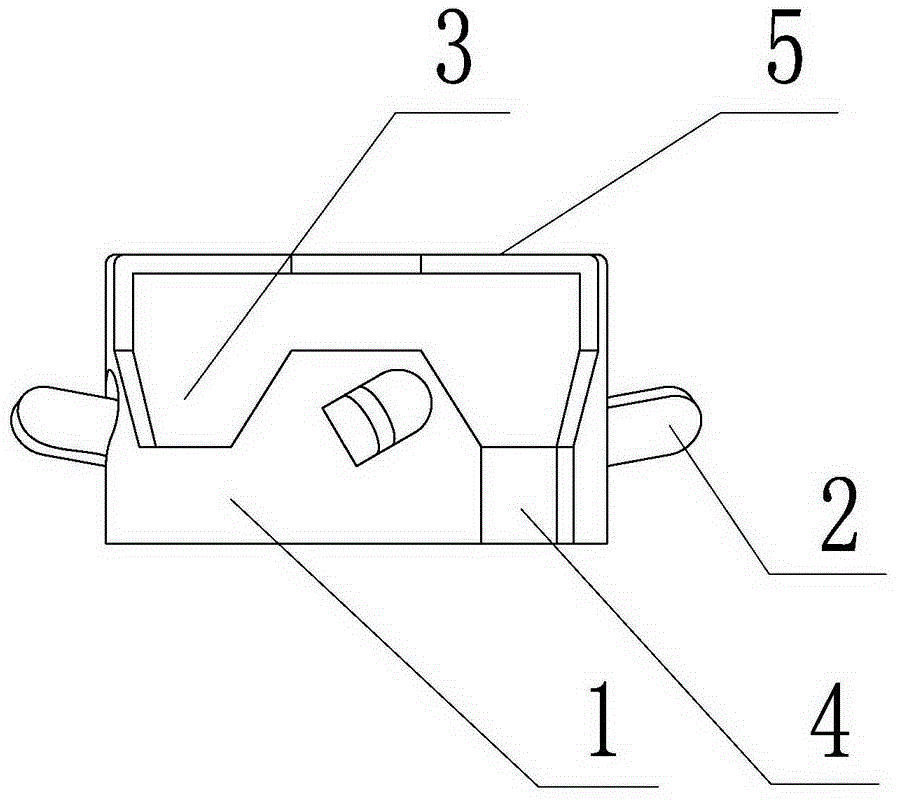

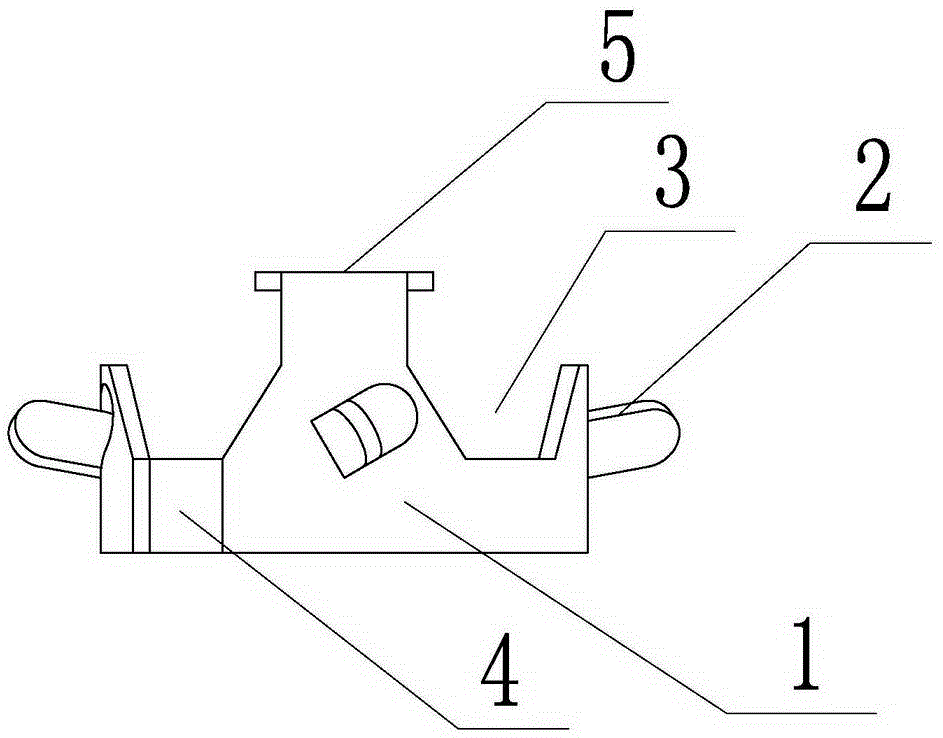

[0010] The breathing ring anchoring nail has a circular anchoring ring, with wings 2 and holes 3 on the wall 1 of the anchoring ring, an opening 4 on the ring wall 1, and a connecting plate 5 on the bottom surface of the anchoring ring. There are more than two symmetrical openings 4 on the ring wall 1 , and the disconnected ring walls 1 are connected into one body through connecting plates 5 . There is a connecting hole in the center of the connecting plate, which is used for screwing with the anchor. The ring wall 1 and the connecting plate 5 are stamped from a whole plate without splicing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com