Automobile heat shield

A technology for heat shields and automobiles, which is applied to mufflers, engine components, machines/engines, etc., can solve problems such as insufficient sealing performance of heat shield connections, and achieve the effect of ensuring sealing performance, easy absorption, and strong strain performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

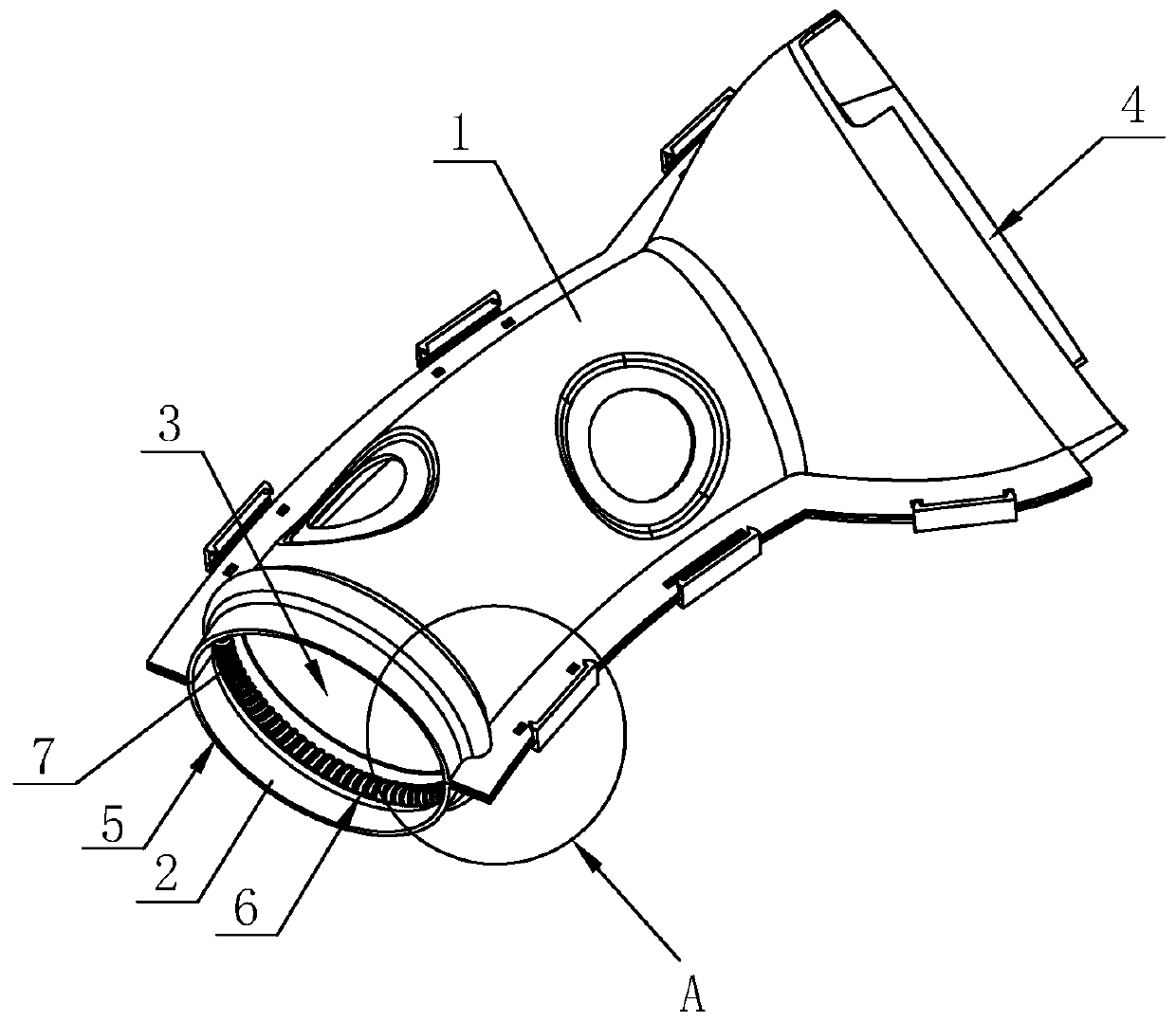

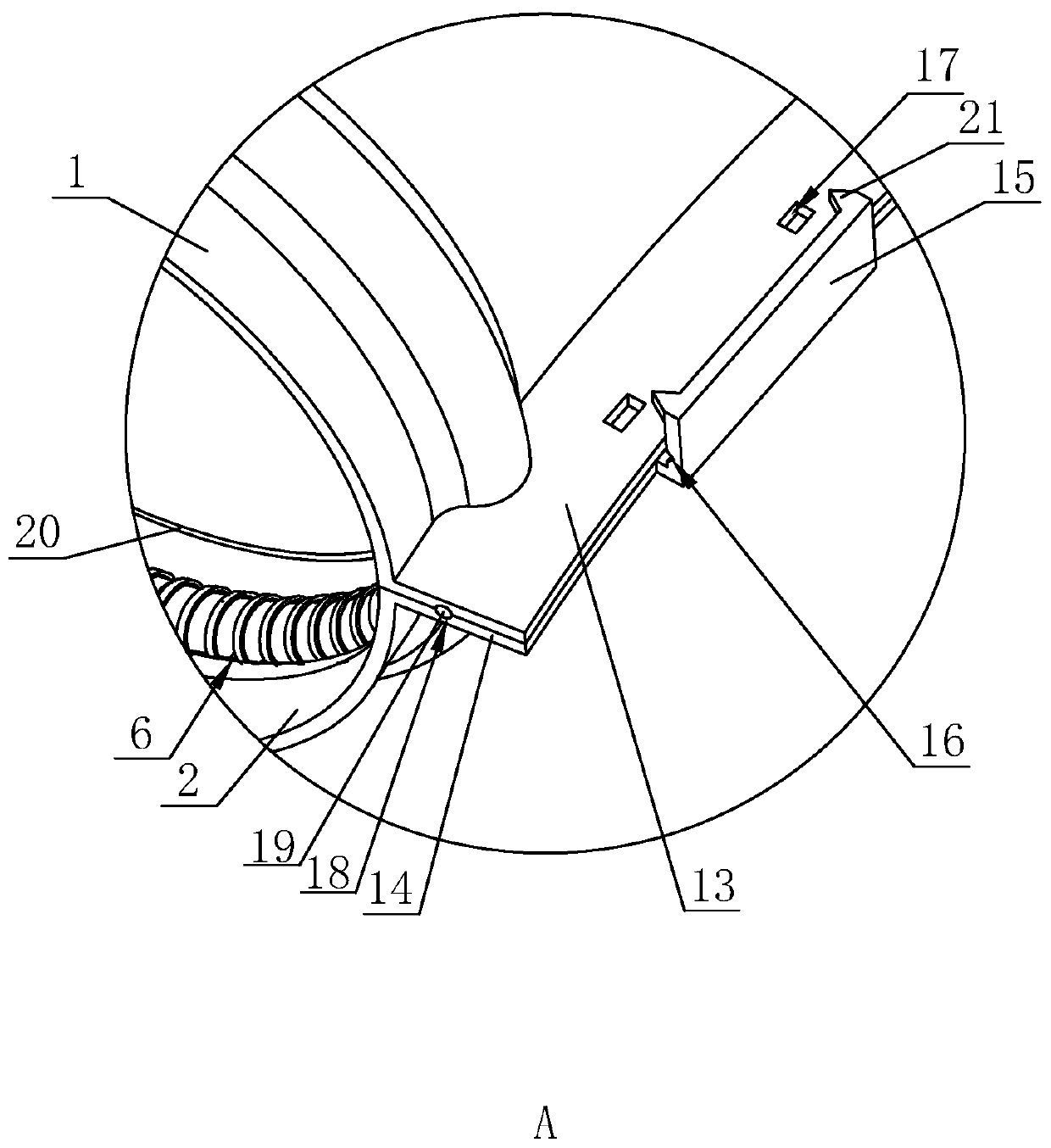

[0037] A car heat shield such as figure 1 and figure 2 As shown, it includes an upper half cover 1 and a lower half cover 2 fixed to each other. Both the upper half cover 1 and the lower half cover 2 are sheet metal parts. An exhaust channel 3 for penetrating the exhaust pipe is formed between the cover 1 and the lower half cover 2, a large port 4 and a small port 5 are respectively formed at both ends of the exhaust channel 3, and the upper half cover 1 and the lower half cover 2 are connected to each other. A snap ring groove 6 is formed by stamping at the small port 5, and a metal mesh roll 7 for enhancing connection sealing is fixed in the snap ring groove 6. The use of metal mesh to make the seal has the following advantages: First, the material of the metal mesh is similar to that of the upper half cover 1 and the lower half cover 2, so their thermal expansion and contraction properties are also similar, thereby avoiding the small port 5 and the inlet port 5 during use...

Embodiment 2

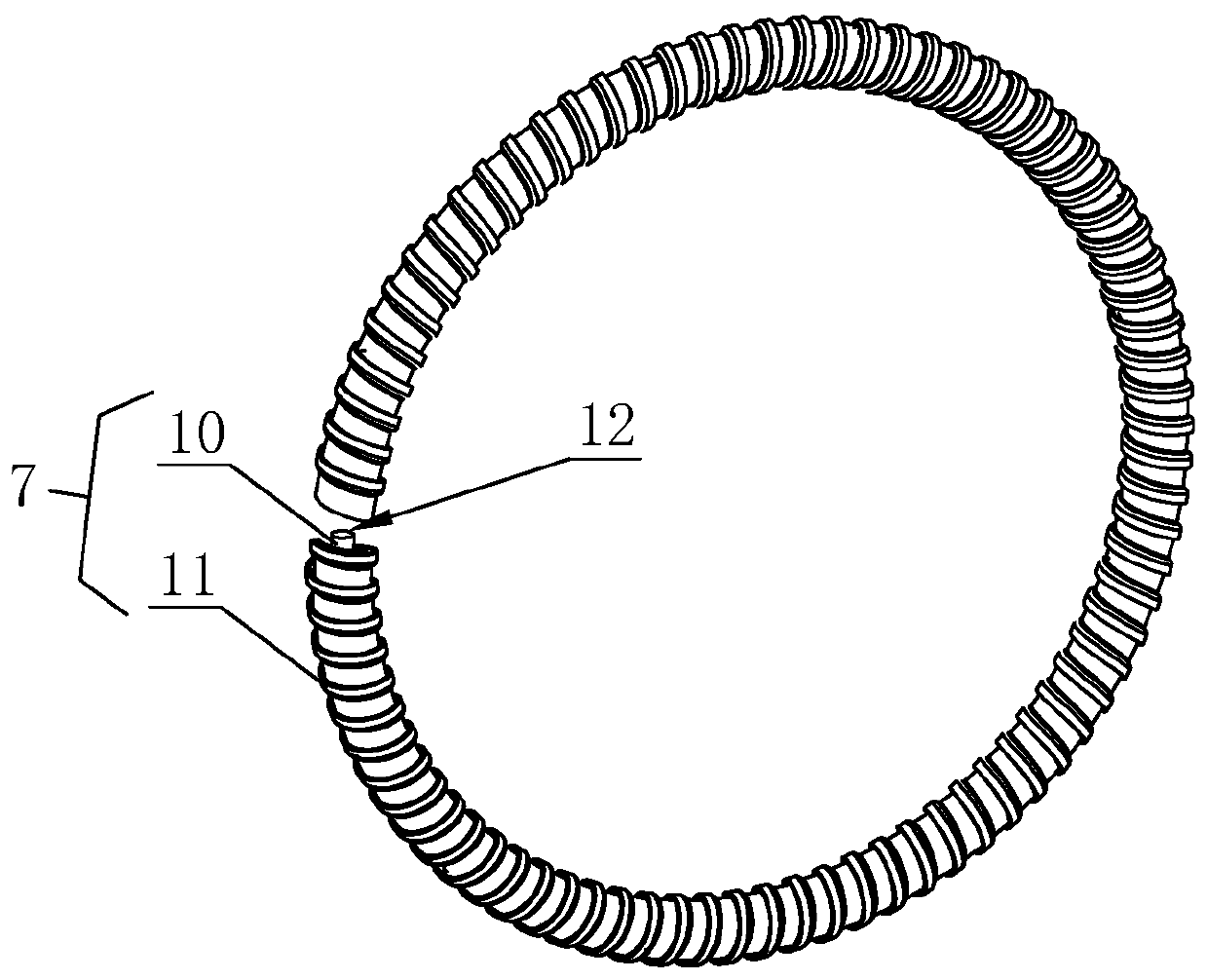

[0041] A car heat shield such as Figure 4 and Figure 5As shown, the difference from Embodiment 1 is that the metal mesh roll 7 includes two half-ring mesh rolls 8 arranged in the snap ring groove 6, and the half-ring mesh roll 8 is helically wound by a metal mesh. There are perforations in the metal mesh, the semi-ring roll 8 is pierced with a shaped half-ring 9, the two ends of the metal mesh are fixed on the shaped half-ring 9 by spot welding, and the two ends of the shaped half-ring 9 are welded and fixed on the On the inner wall of the snap ring groove 6, the semi-ring net roll 8 is fixed, and the semi-ring structure is adopted to facilitate processing and production.

[0042] In summary:

[0043] When the present invention is used, by adopting the metal mesh roll 7 as the sealing member, firstly, the material of the metal mesh is similar to the thermal expansion and contraction performance of the upper half cover 1 and the lower half cover 2, thereby improving the cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com