Plastic steel winding pipe

A technology of plastic-steel winding pipe and pipe section, which is applied in the direction of pipes, rigid pipes, pipeline connection arrangement, etc., can solve the problems of large water resistance, large proportion of plastic-steel pipes, difficult engineering construction, etc., and achieve the effect of small resistance to water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In conjunction with the accompanying drawings, the present invention is described in detail, but the scope of protection of the present invention is not limited to the following examples, that is, all simple equivalent changes and modifications made with the patent scope of the present invention and the content of the specification are still patents of the present invention. covered.

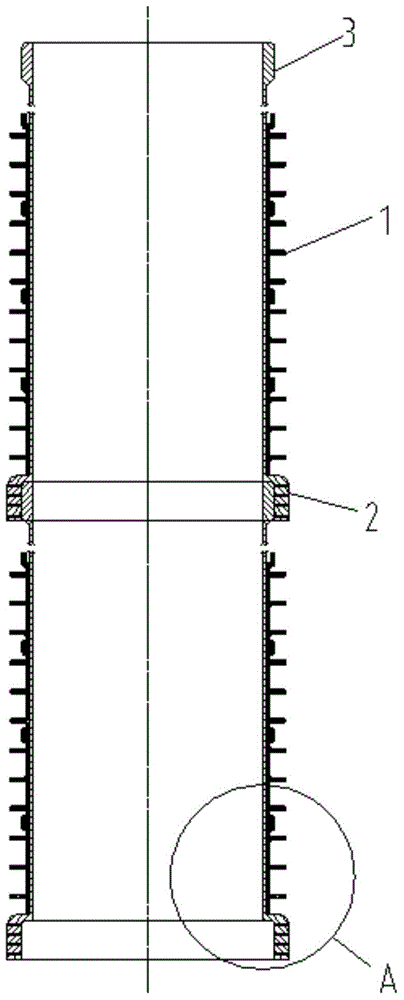

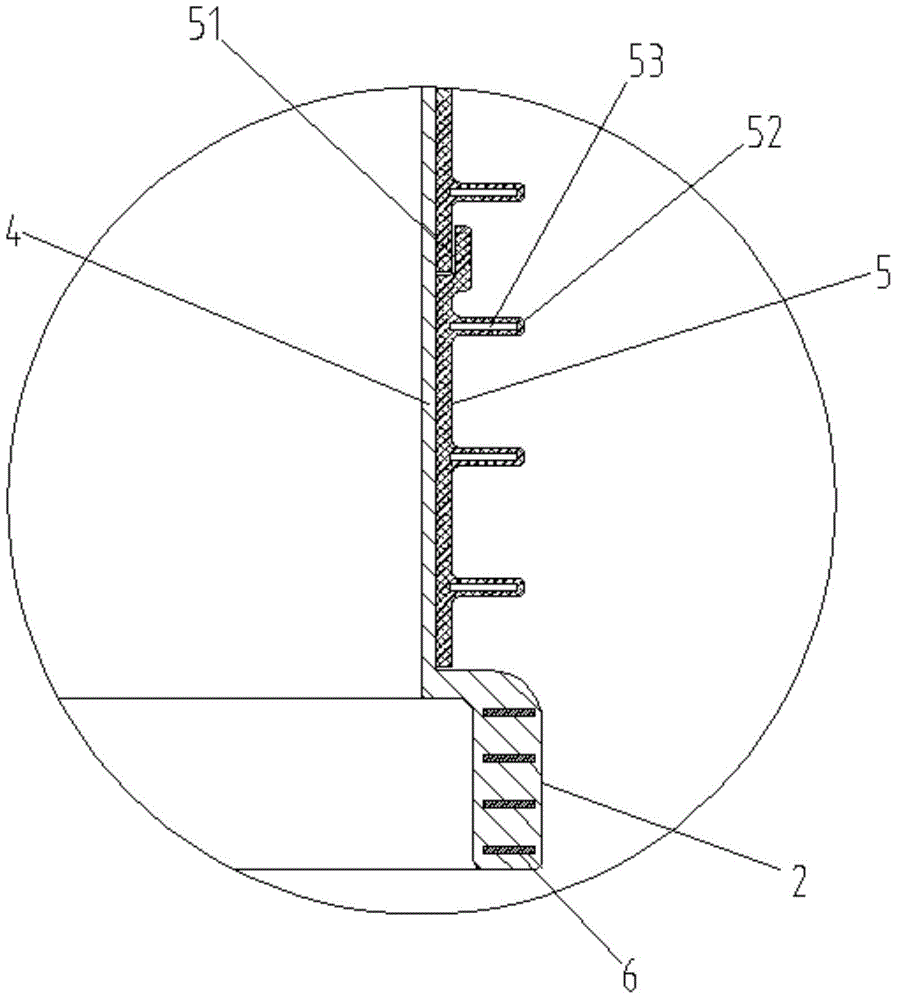

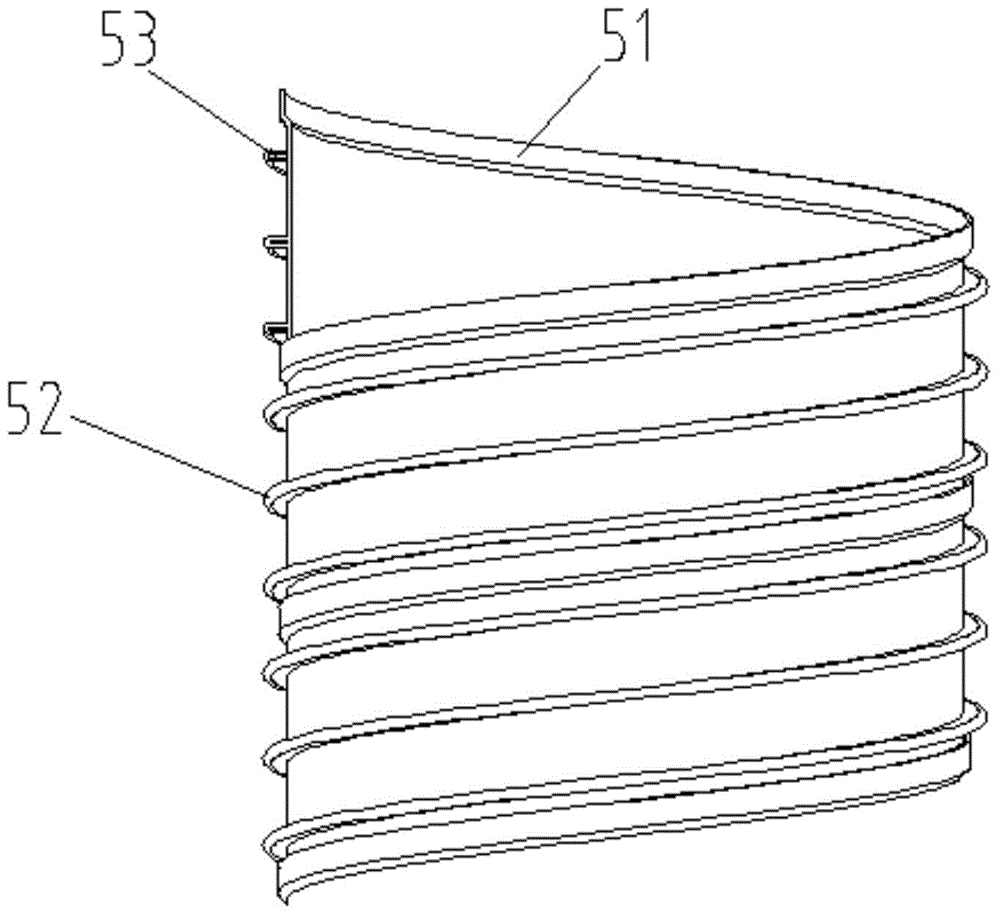

[0021] A plastic-steel winding pipe, such as figure 1 As shown, it includes several sections of pipe 1, and the two ports of each section of pipe are respectively formed with a female interface 2 and a male interface 3 that can be engaged with each other, such as figure 2 As shown, each joint pipe includes an inner pipe 4 and a strip profile 5 spirally wound on the inner pipe, such as image 3 As shown, a notch 51 is formed on one side of the strip-shaped profile along its length direction, and when the strip-shaped profile is wound around the inner tube, the notch is engaged and covere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com