Device and method for measuring overhead stranded wire resistance temperature coefficient

A technology of temperature coefficient of resistance and stranded wire, which is applied in the field of devices for measuring the temperature coefficient of resistance of overhead stranded wire, can solve problems such as temperature differences, affecting the accuracy of the temperature coefficient of resistance of stranded wires, and difficulty in accurately controlling the heat of wires, so as to ensure that the engine oil The effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

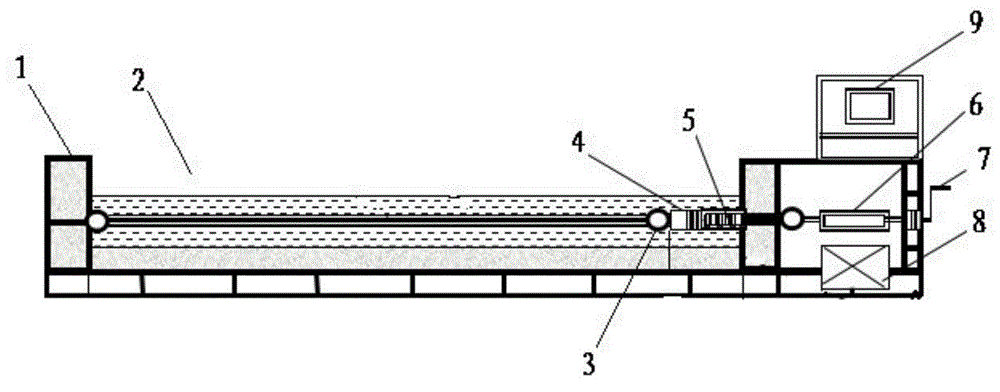

[0012] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0013] like figure 1 As shown, a device for measuring the temperature coefficient of resistance of an overhead stranded wire includes a box body 1, the box body 1 is a steel frame structure, and a cavity 2 for accommodating engine oil is arranged in it, and the oil level of the engine oil is located at the The middle and upper part of the cavity 2, and the boiling point of the engine oil is 200-400°C; the cavity 2 is connected to the circulation pump 8 through a circulation pipeline, and a clamping device 3 is oppositely provided in the middle of the cavity inner wall, so The clamping device 3 is preferably a hook structure, and one end of the clamping device 3 on the same axis is connected with an insulator 4, a bellows 5, a digital tension gauge 6 and a loading handle 7 in sequence, and the bellows 5 and The loading r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com