Method for machining inner bevel edge of PCB

A technology of PCB board and processing method, which is applied in the field of processing the beveled edge of the PCB board, can solve the problems of difficult processing and waste of board materials, and achieve the effect of saving costs and improving the utilization rate of board materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention provides a method for processing the inner hypotenuse of a PCB board. In order to make the purpose, technical solution and effect of the present invention clearer and clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

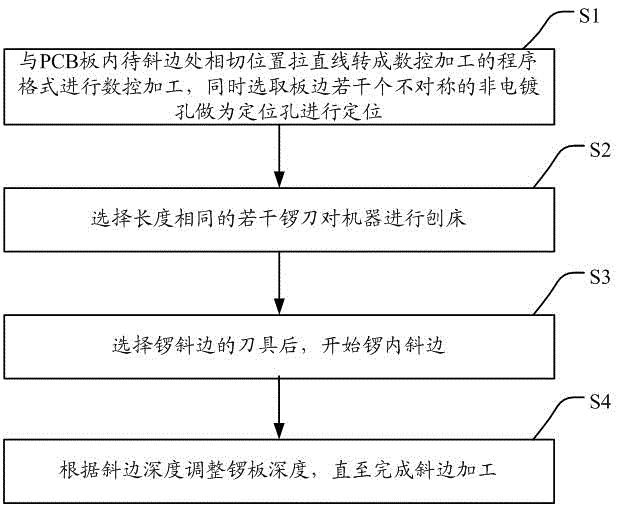

[0027] see figure 1 , which is a flowchart of the method for processing the beveled edge of the PCB board of the present invention. Such as figure 1 As shown, the method includes the following steps;

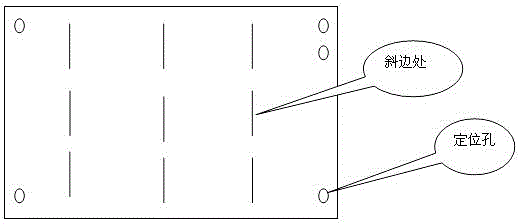

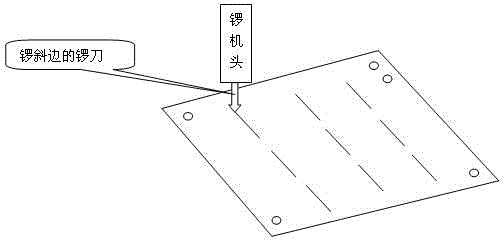

[0028] S1. Draw a straight line at the position tangent to the hypotenuse in the PCB board and convert it into the program format of CNC machining for CNC machining. At the same time, select a number of asymmetric non-plated holes on the edge of the board as positioning holes for positioning;

[0029] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com