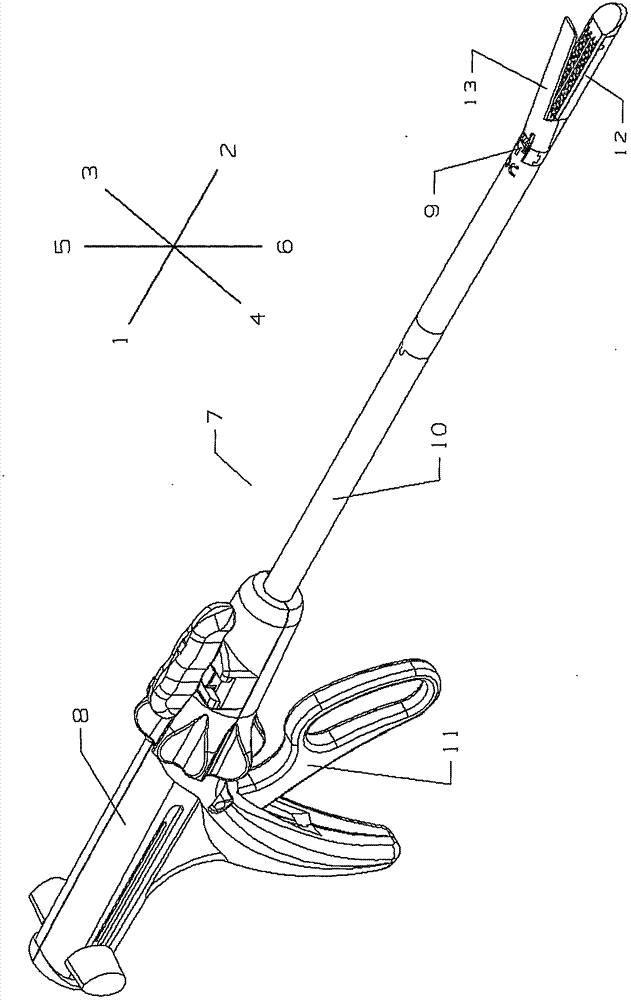

Endoscope cutting stapler with stapler anvil capable of moving and rotating up and down

A stapler and anvil technology, applied in the field of laparoscopic cutting staplers, can solve problems such as damage to instrument parts, affecting surgical quality, and increasing operational resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

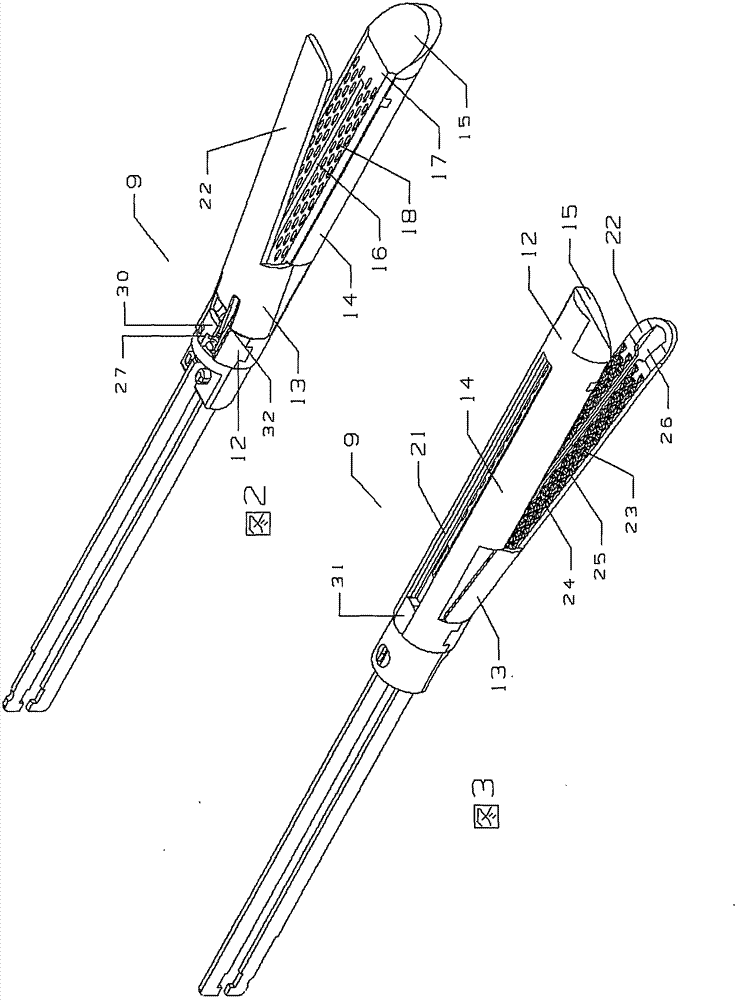

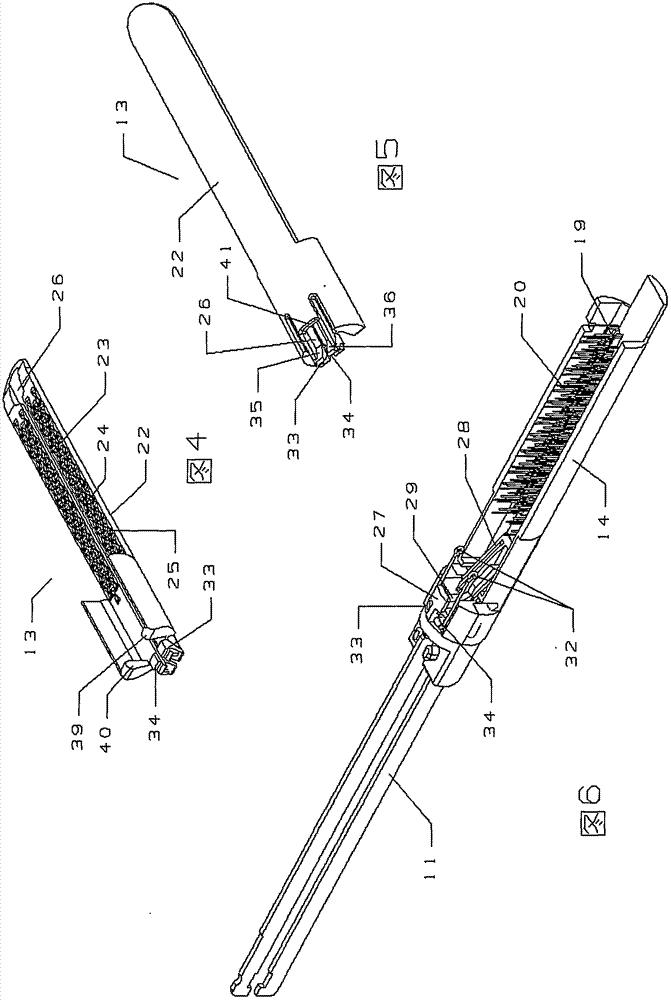

[0075] By way of example, the best embodiment of the endoscopic cutting stapler that the nail anvil of the present invention can move up and down and rotate is set forth below in conjunction with the accompanying drawings. The scope of the invention will be indicated in the claims. It should be recognized that some or all of the drawings are illustrative diagrams illustrating preferred embodiments of the invention and do not depict the true dimensions of the parts shown. The practical manner in which these and other objects and advantages of the invention are achieved will become more clearly understood by reference to the detailed description of the preferred embodiment.

[0076] In order to highlight the figure of the elastic collar and its description, except for the execution head of the laparoscopic cutting stapler, other components are not introduced in detail in the drawings. For the structure, installation, use and action process of other parts of various laparoscopic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com