T iron heading floating die

An internal mold and hollow technology, applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of high cost, unsuitable for mass production and production quality management, and uneven process quality, so as to facilitate mass processing and the effect of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical solution of the present invention will be further described in detail below in conjunction with the specific embodiments, but does not constitute any limitation to the present invention.

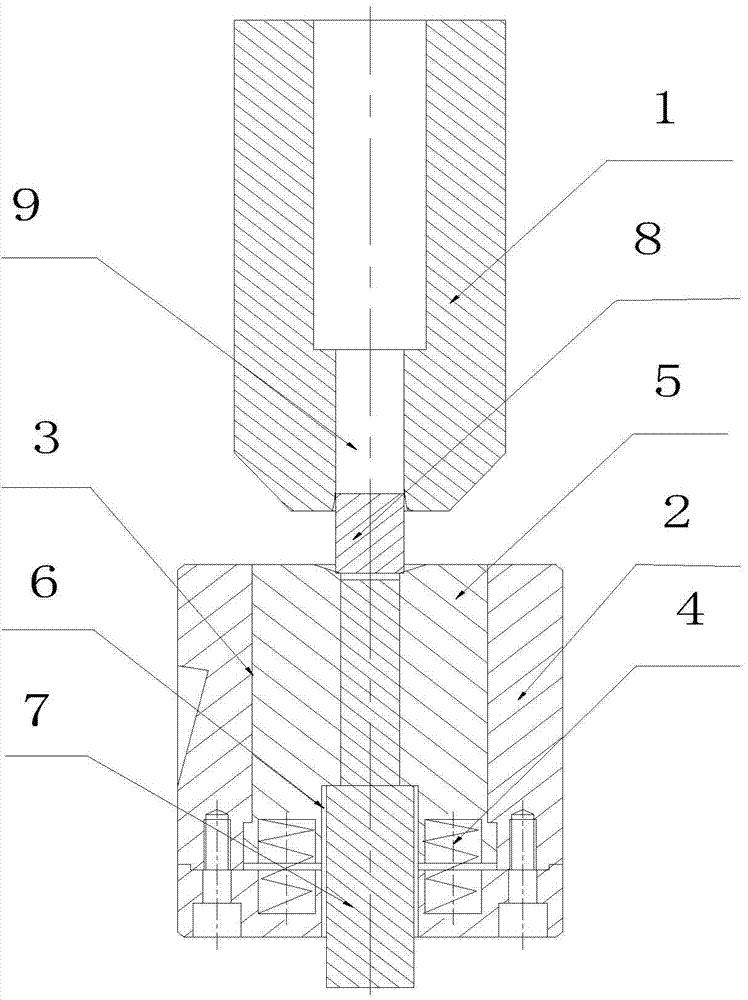

[0011] refer to figure 1 Shown, a kind of T iron head floating die, comprises upper mold 1 and lower mold 2, the upper surface of described lower mold 2 is provided with groove 3, and the bottom of described groove 3 is provided with spring 4, and described The groove 3 is also provided with a hollow cylindrical inner mold 5, the bottom of the inner mold 5 is in contact with the spring 4, the lower surface of the lower mold 2 is provided with a guide hole 6, and the guide hole 6 A thimble 7 extending to the hollow part of the inner mold 5 is provided, and the lower surface of the upper mold 1 is provided with a recess 9 capable of accommodating the bar stock 8, and the recess 9 is arranged opposite to the hollow part of the inner mold 5 , the spring 4 is arranged at bot...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap