A pipe jacking construction method

A construction method and pipe jacking technology, which is applied to sewer systems, waterway systems, buildings, etc., can solve problems such as many hidden dangers, large safety hazards, and short jacking length, and achieve the goals of saving investment, avoiding leakage, and facilitating construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

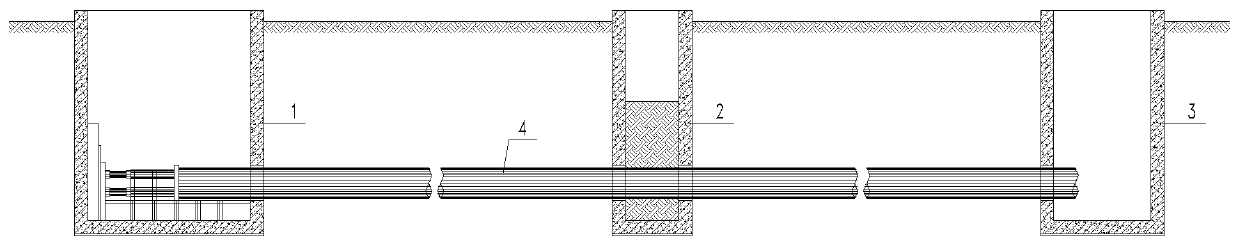

[0019] A pipe jacking construction method, comprising the steps of:

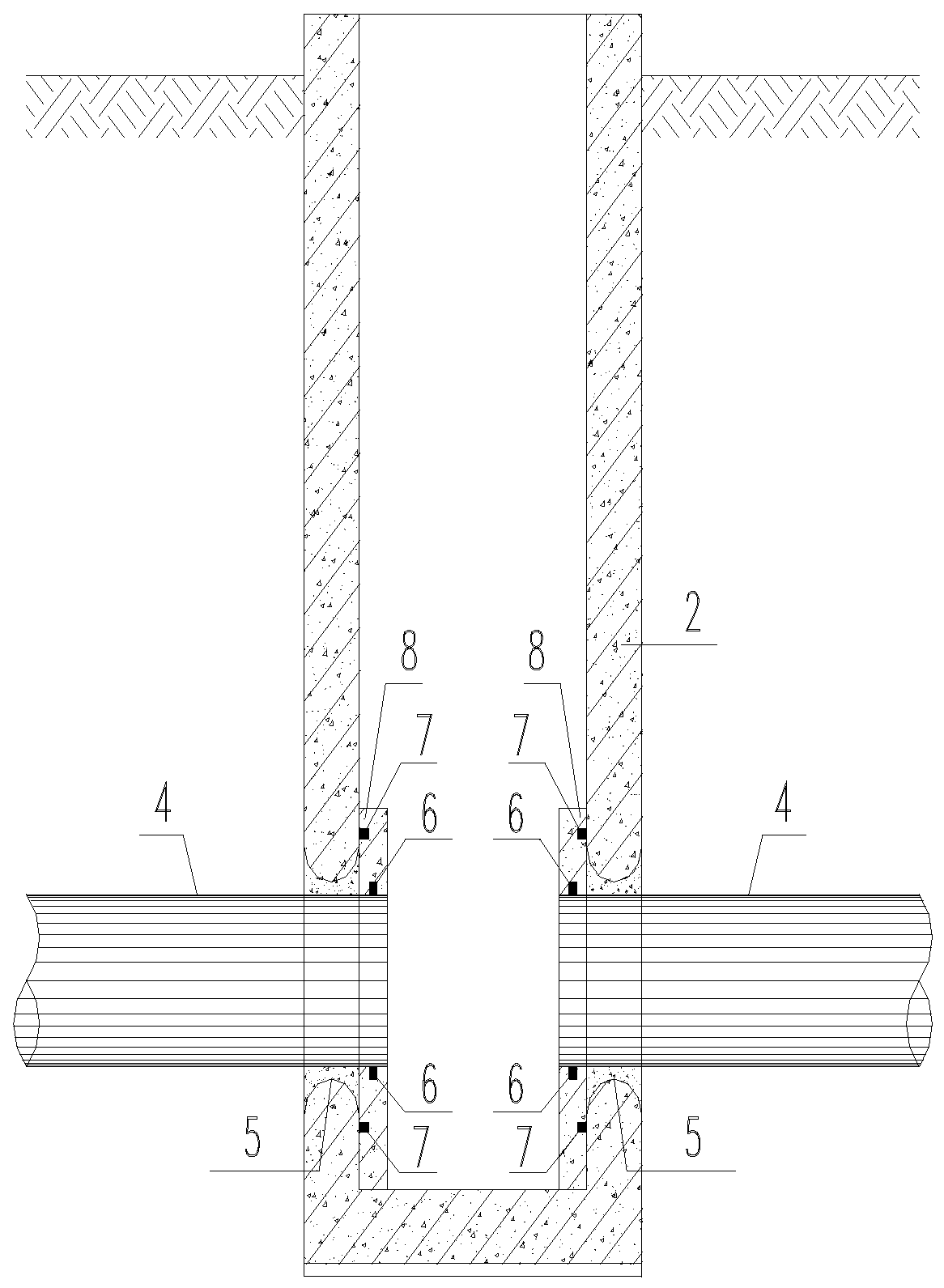

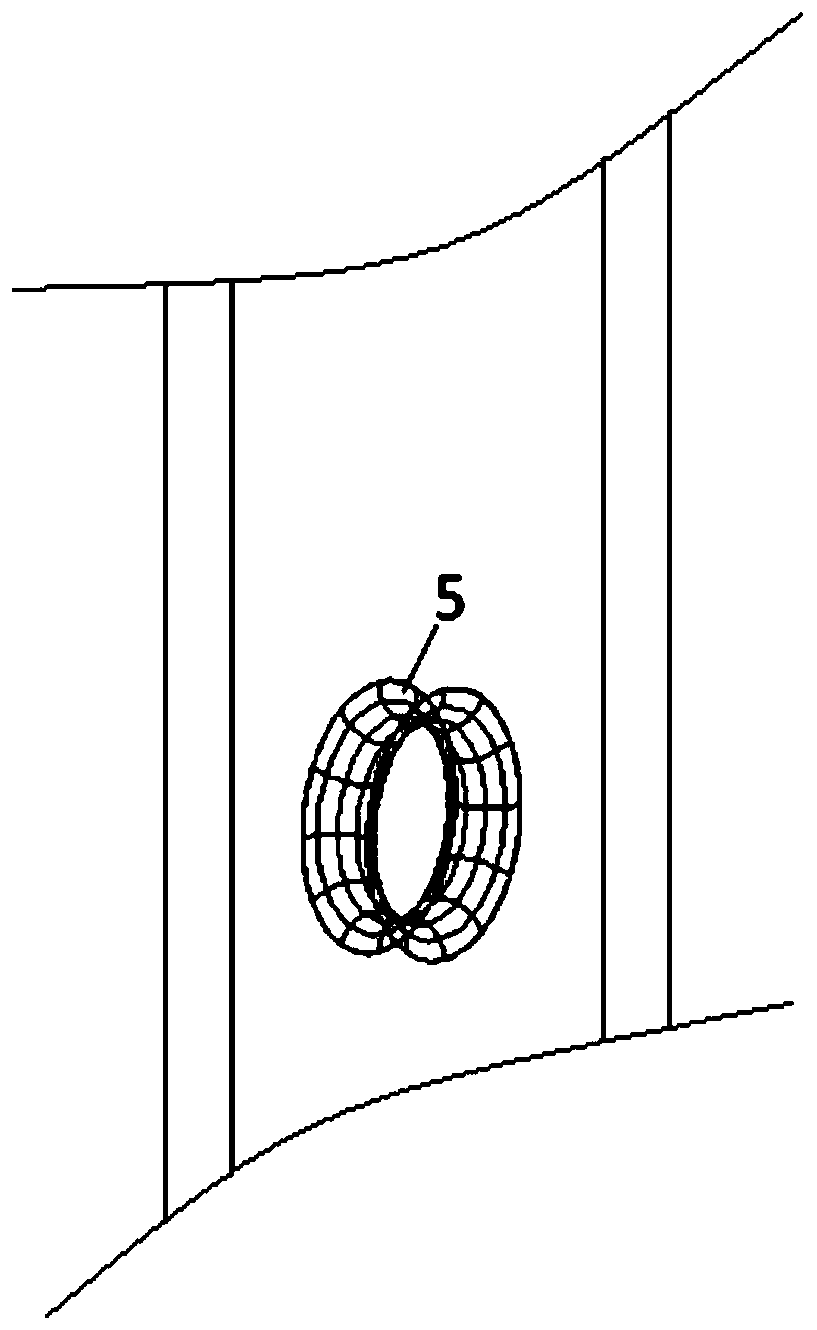

[0020] S1. According to the center line of the design pipeline, release the position of the excavation line at the selected construction position. According to the position and direction of the excavation line, simultaneously construct the pipe jacking working well 1, the pipe jacking receiving well 3, and the pipe jacking working well 1, top pipe jacking well 1 The pipe jacking well 2 between the pipe receiving wells 3; wherein, when constructing the pipe jacking well 2, holes 5 are reserved at the corresponding positions where the pipe passes through the wall plate in the pipe jacking well 2, and then the pipe jacking Compact and backfill the plain soil in the line-crossing well 2;

[0021] Preferably, the pipe jacking working well 1 and the pipe jacking receiving well 3 are all poured with reinforced concrete on the surrounding side walls, and a concrete bottom is laid at the bottom of the well and the re...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap