A top-mounted gas storage metal hard-sealed ball valve that can be maintained online

A gas storage and hard seal technology, applied in valve details, valve devices, valve housing structures, etc., can solve the problems of upstream seal failure and unreliability, achieve the goal of reducing the total torque of the valve, stabilizing the sealing performance, and increasing the sealing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

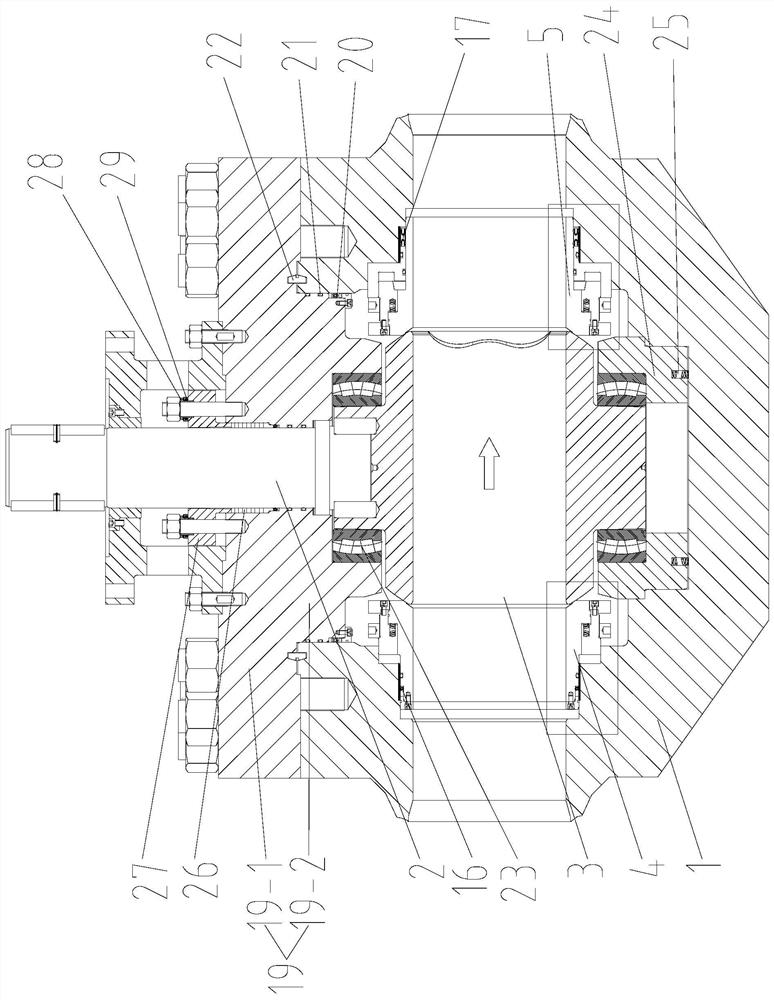

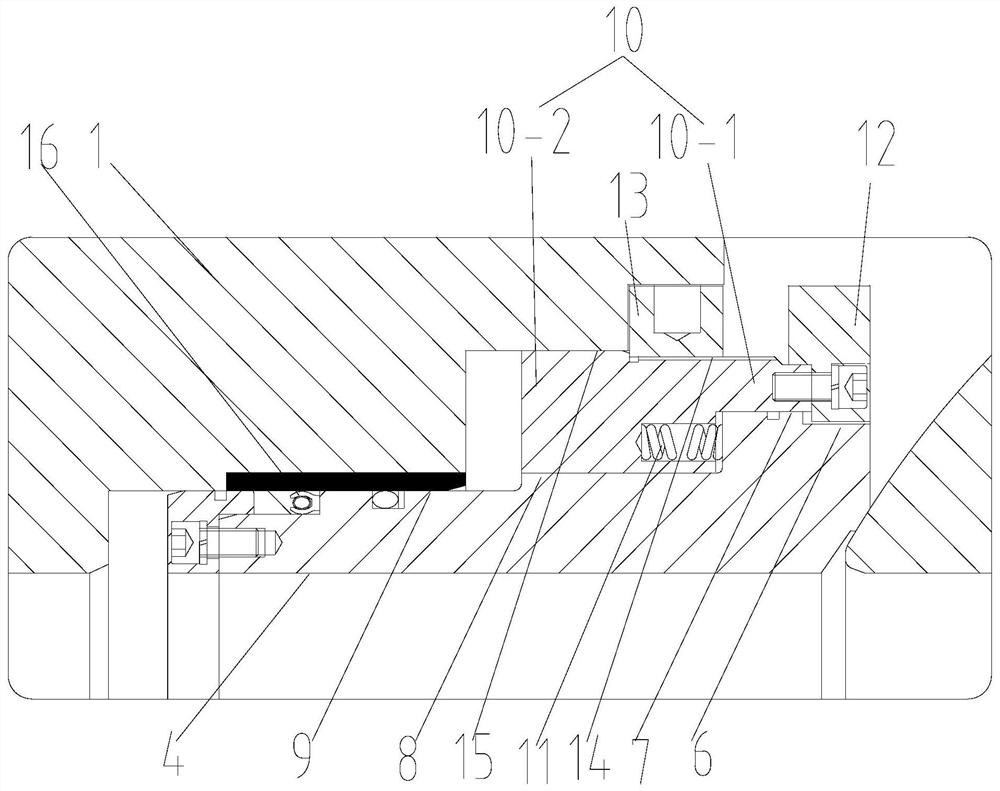

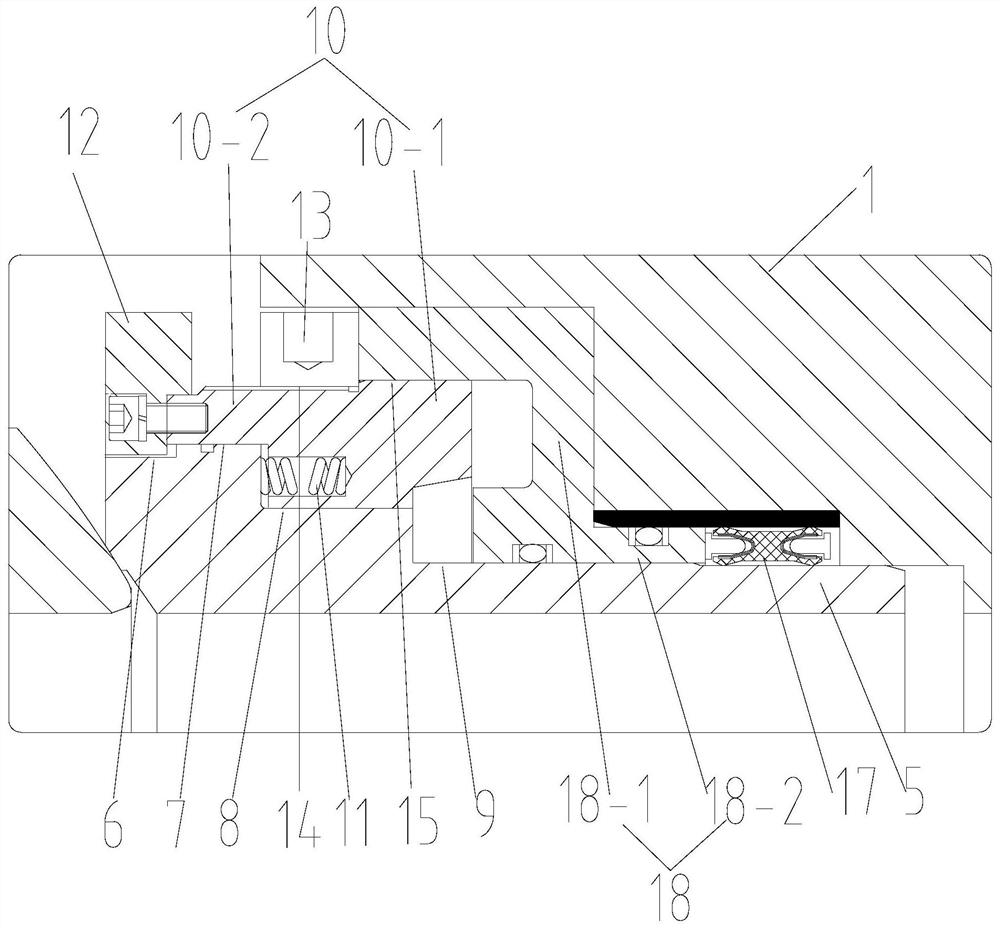

[0028] Below in conjunction with the accompanying drawings in the embodiments of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely

[0033] It should also be noted that, using this structure, the relative distance between the valve seats on both sides is adjustable. need to be disassembled or

[0038] Due to the material limitations of the third spring energy storage seal ring 20 and the O-ring seal 21, there may be flushing by the medium

[0040] Further, the diameter of the upper mandrel is reduced upward, and the diameter of the lower mandrel is reduced downward. Such a setup makes the sphere

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap