Method and tool for quickly screwing double-headed studs into the base of wind turbine gearbox

A technology of wind turbines and studs, which is applied in the manufacture of tools, screwdrivers, wrenches, etc. It can solve the problem of poor assembly of the studs of the reducer, and achieve the effect of easy disassembly and reduced friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

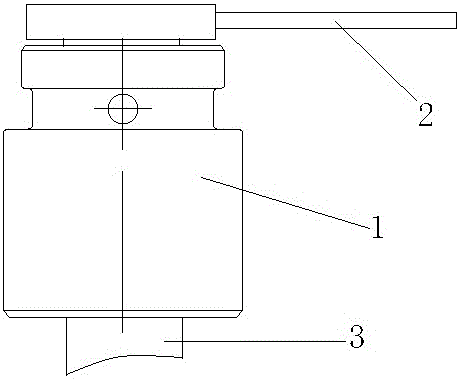

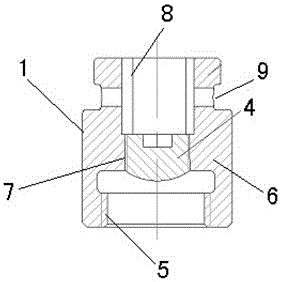

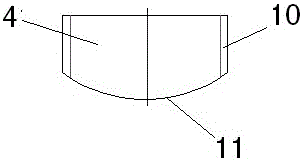

[0032] As shown in the accompanying drawings, an auxiliary working tool 1 for quickly screwing the double-ended studs of the gearbox of a wind power generation unit into the base body. A ratchet wrench 2 is installed on the auxiliary working tool 1. The lower part of the working tool 1; the auxiliary working tool 1 is driven by rotating the ratchet wrench 2, and then the double-ended stud 3 is quickly screwed into the gearbox base of the wind power generating set. The auxiliary operation tool 1 includes a pre-embedded sleeve 6, which is a sleeve with a through hole in the center; one end of the pre-embedded sleeve 6 is provided with an internal thread 5 matched with a double-ended stud. The middle part of the embedded sleeve 6 is provided with a ball head internal thread 7 for installing the sleeve ball head, and the sleeve ball head 4 is installed in the ball head internal thread 7; the other end of the embedded sleeve 6 is provided with a ratchet wrench Square counterbore 8,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com