Automatic robotic graphite deep-processed product sintering line

A technology of deep processing and robotics, applied in the direction of conveyor control devices, conveyors, writing utensils, etc., can solve the problems of poor working environment, low manual efficiency, low operating efficiency, etc., achieve continuous firing methods, improve efficiency, Effect of reducing heating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to better understand the shape, structure and characteristics of the present invention, preferred embodiments will be listed below and described in detail with reference to the accompanying drawings.

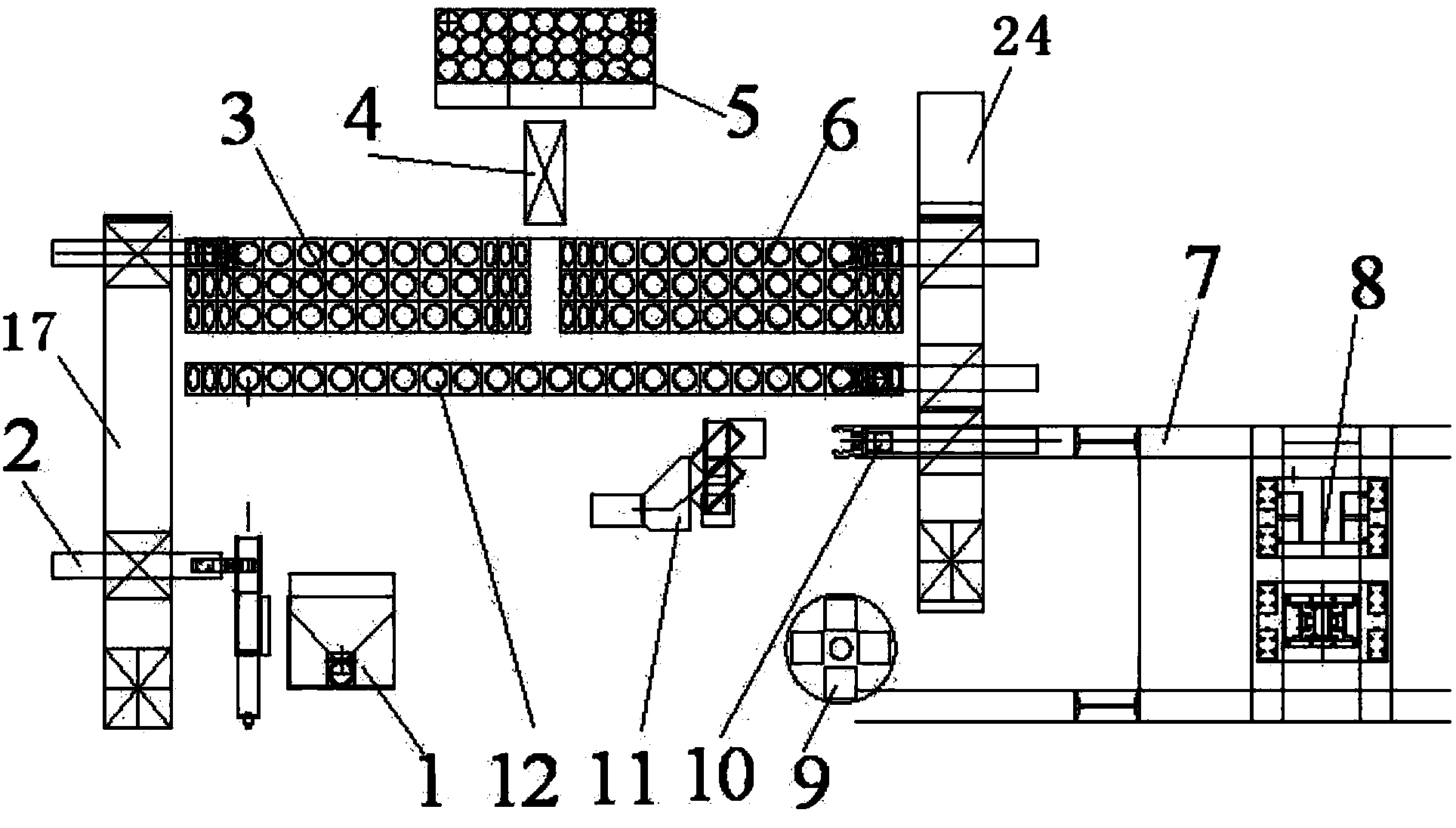

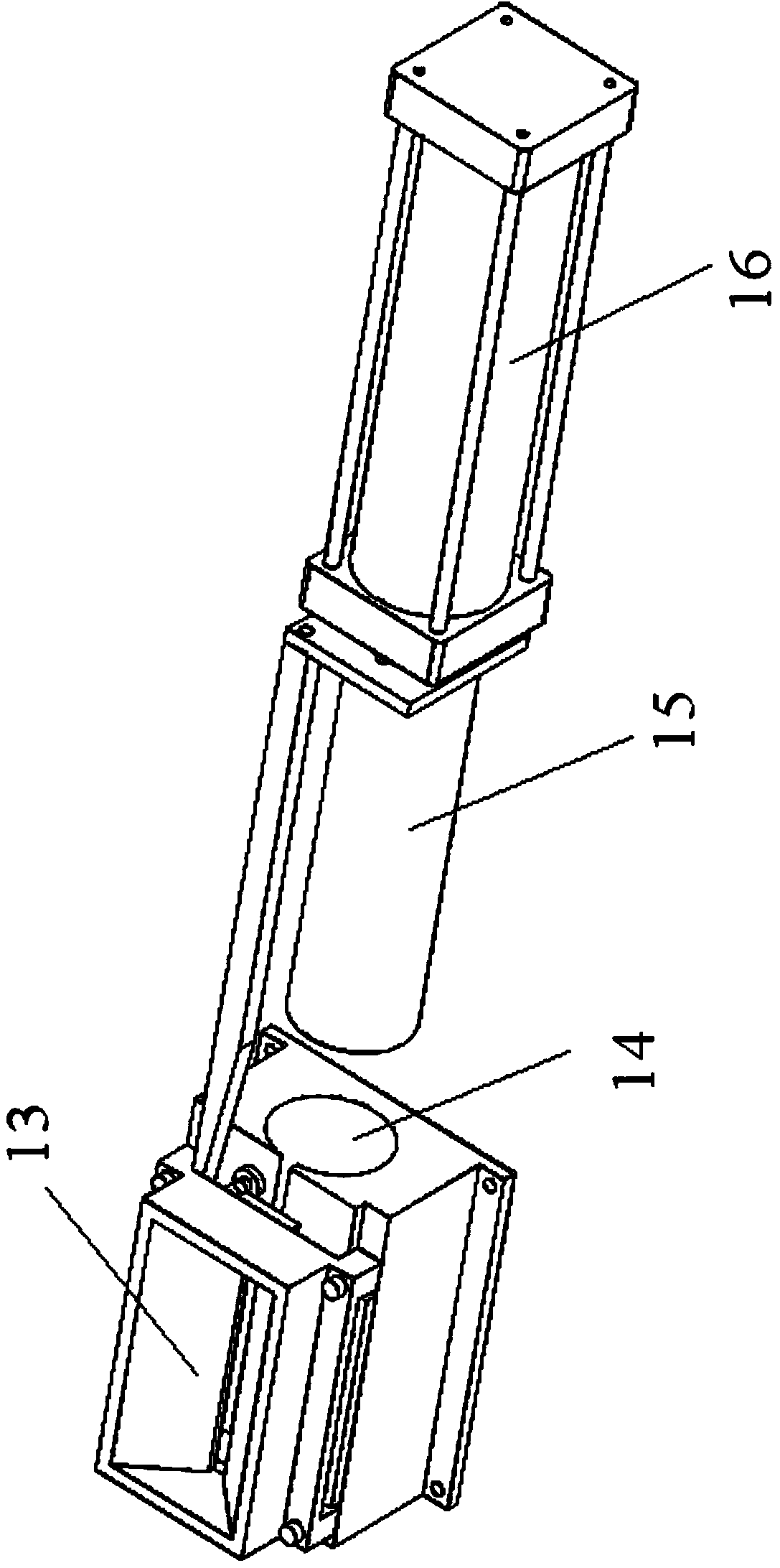

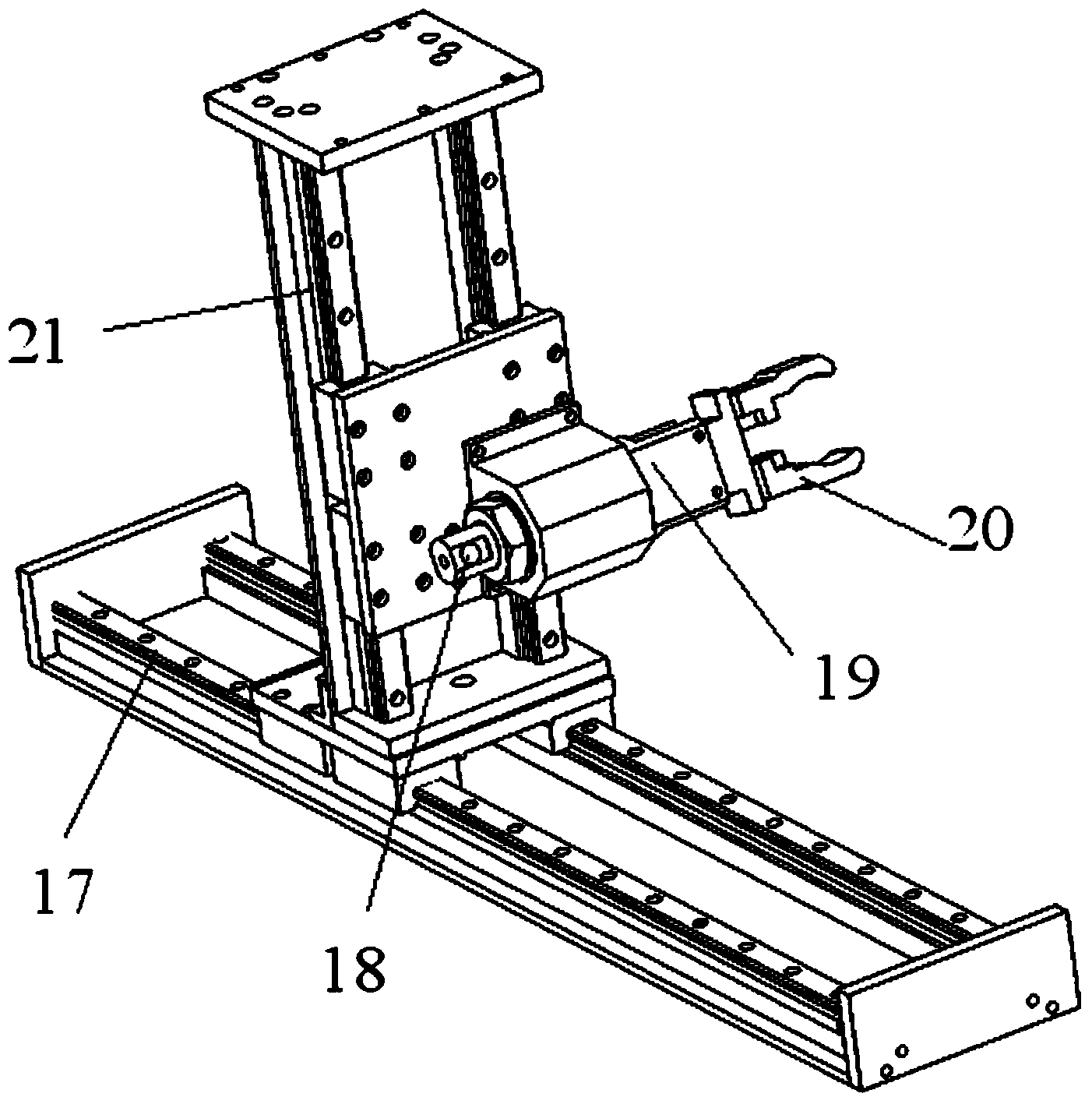

[0034] An automatic robot graphite deep-processing product (pencil lead) firing production line of the present invention comprises: a normal temperature lead can conveyor belt 3 and a sintered lead can conveyor belt 6 arranged side by side on the same straight line, the end of the normal temperature lead can conveyor belt 3 and The head end of sintered lead can conveyor belt 6 links to each other. A sintering furnace 5 and a sintering manipulator 4 are installed at the intermediate connection between the normal temperature lead can conveyor belt 3 and the sintered lead can conveyor belt 6 .

[0035] Empty can conveyor belt 12 is arranged in parallel with room temperature lead can conveyor belt 3 and sintered lead can conveyor belt 6. The head end place of room t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com