Ultraviolet drying electroluminescent screen ink composition

An ink composition and electroluminescence technology, which can be used in inks, household utensils, applications, etc., can solve the problems of inability to prepare dry, printing stability screen inks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

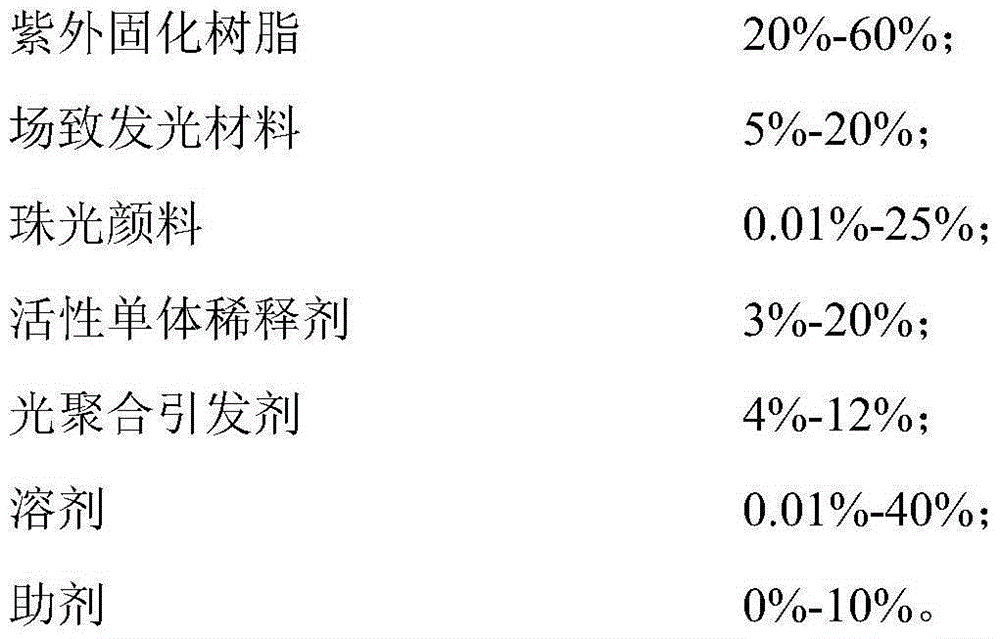

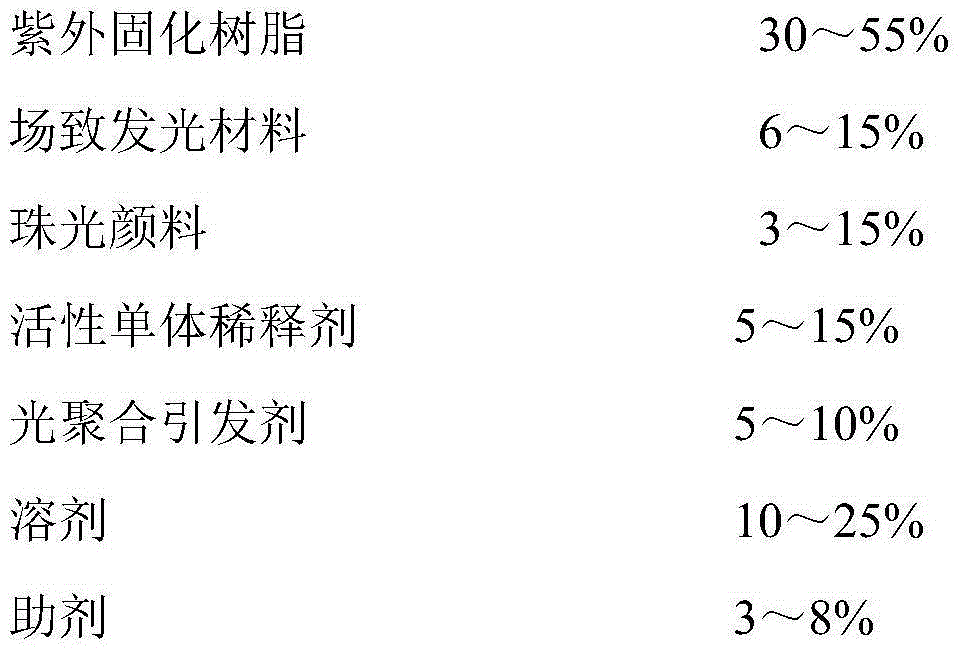

[0055] Formulation (weight percent)

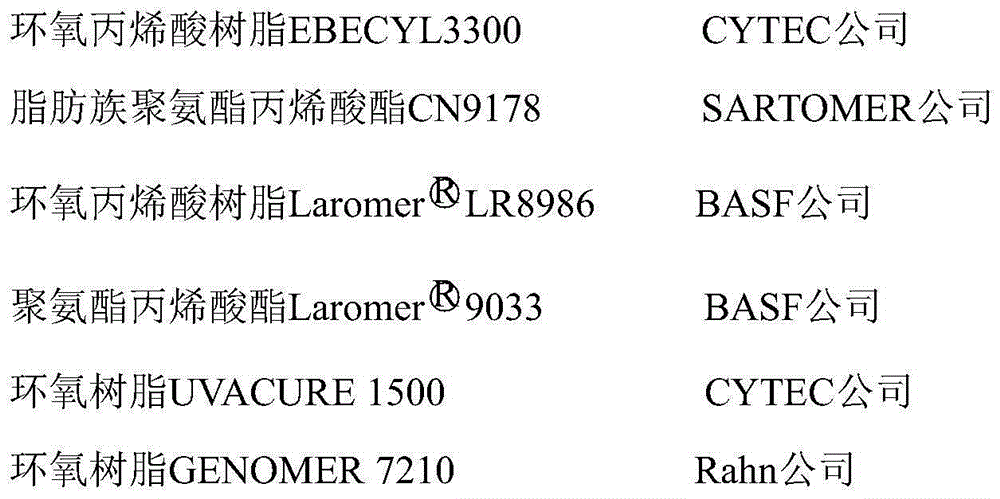

[0056] UV curing resin: epoxy acrylic resin EBECYL330021%

[0057] Aliphatic polyurethane acrylate CN917818%

[0058] Epoxy resin UVACURE150012%

[0059] Reactive diluent: 1,6 hexanediol diacrylate (HDDA) 2%

[0060] Hydroxyl-terminated vinyl ether 5%

[0061] Initiator: Ethyl (2,4,6-trimethylbenzoyl)-phenylphosphonic acid (TPO-L) 4%

[0062] Triarylsulfonium hexafluorophosphate Omincat4323%

[0063] Electroluminescence pigment: Cu-doped ZnS matrix pigment 8%

[0064] Pearlescent pigments: silica-based Green-Gold3%

[0065] Solvent: ethyl ethoxy propionate 19%

[0066] Defoamer: polysiloxane 0.5%

[0067] Silica: Silica TS5301.5%

[0068] Wetting and dispersing agent: polyacrylate-polyacrylic acid block copolymer solution 1.0%

[0069] Leveling agent: polyether modified polydimethylsiloxane 1.0%

[0070] According to the formula, each component is thoroughly mixed until uniform according to the description in the preparation p...

Embodiment 2

[0075] UV Curing Resin: Urethane Acrylate 903318%

[0076] epoxy acrylic resin LR89863%

[0077] Epoxy resin GENOMER721016%

[0078] Reactive diluent: Tripropylene glycol diacrylate (TPGDA) 5%

[0079] Triethylene glycol divinyl ether 6%

[0080] Initiator: Ethyl (2,4,6-trimethylbenzoyl)-phenylphosphonic acid (TPO-L) 3%

[0081] Diaryliodonium salt I-2503%

[0082] Electroluminescence pigment: Cu-doped ZnS matrix pigment 14%

[0083] Pearlescent pigment: mica-based Lumina9T30D12%

[0084] Solvent: ethyl ethoxy propionate 15.5%

[0085] Defoamer: polysiloxane 0.5%

[0086] Wetting and dispersing agent: polyacrylate-polyacrylic acid block copolymer solution 1.0%

[0087] Silica: Silica TS530 2.0%

[0088] Leveling agent: polyether modified polydimethylsiloxane 1.0%

[0089] According to the formulation, each component is thoroughly mixed until uniform as described in the preparation process to obtain the UV-dried electroluminescence screen pearlescent ink compositi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com