Heterogeneous photovoltaic welding strip and machining method thereof

A photovoltaic ribbon and heterogeneous technology, applied in the field of solar energy, can solve the problems of bending the ribbon, disconnection of the transmission circuit, and large thickness of the envelope of the ribbon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

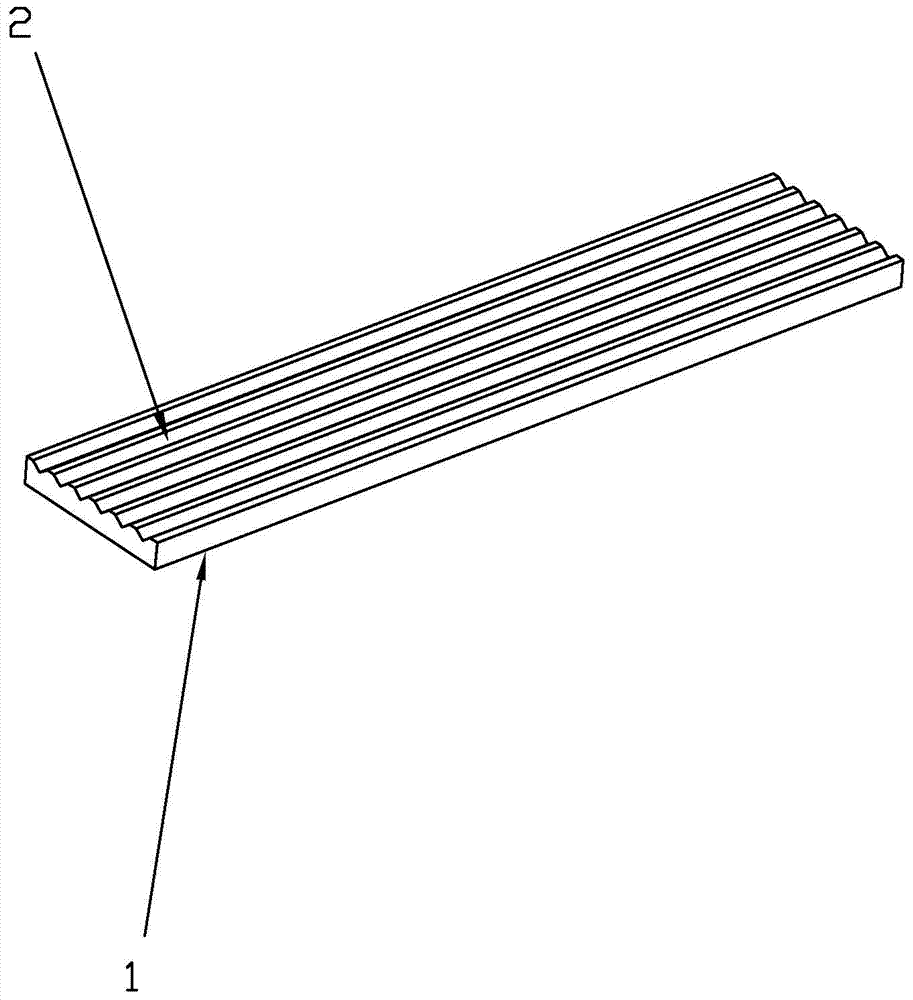

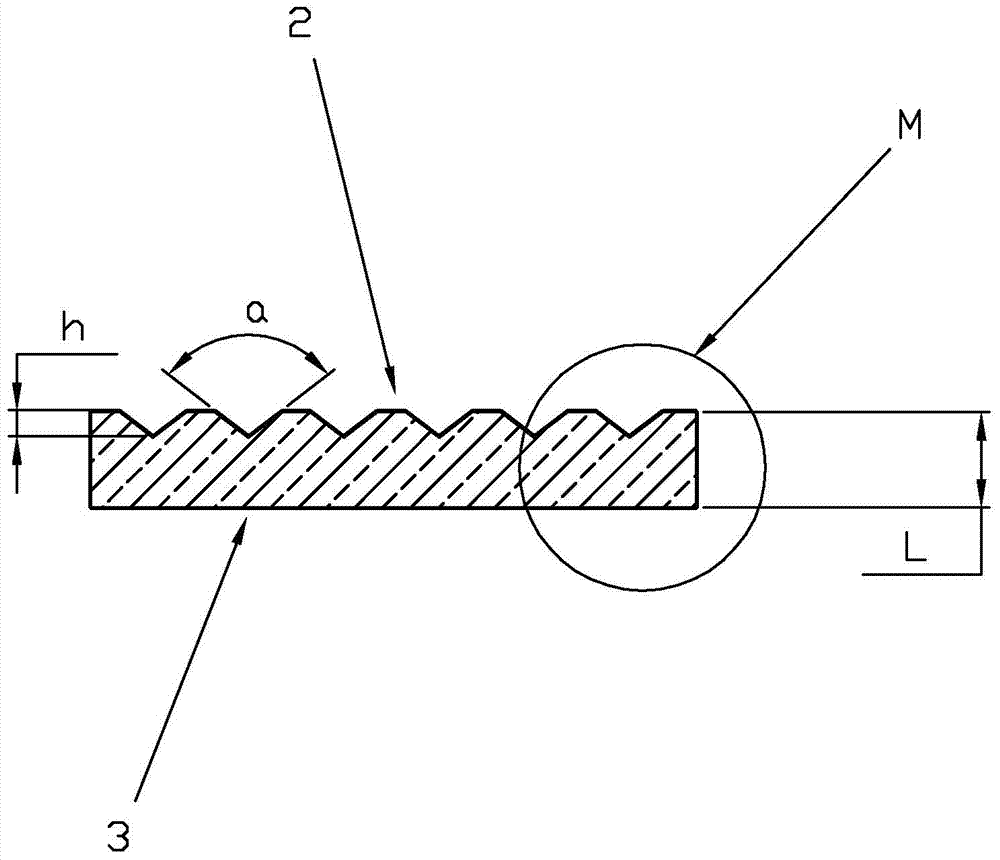

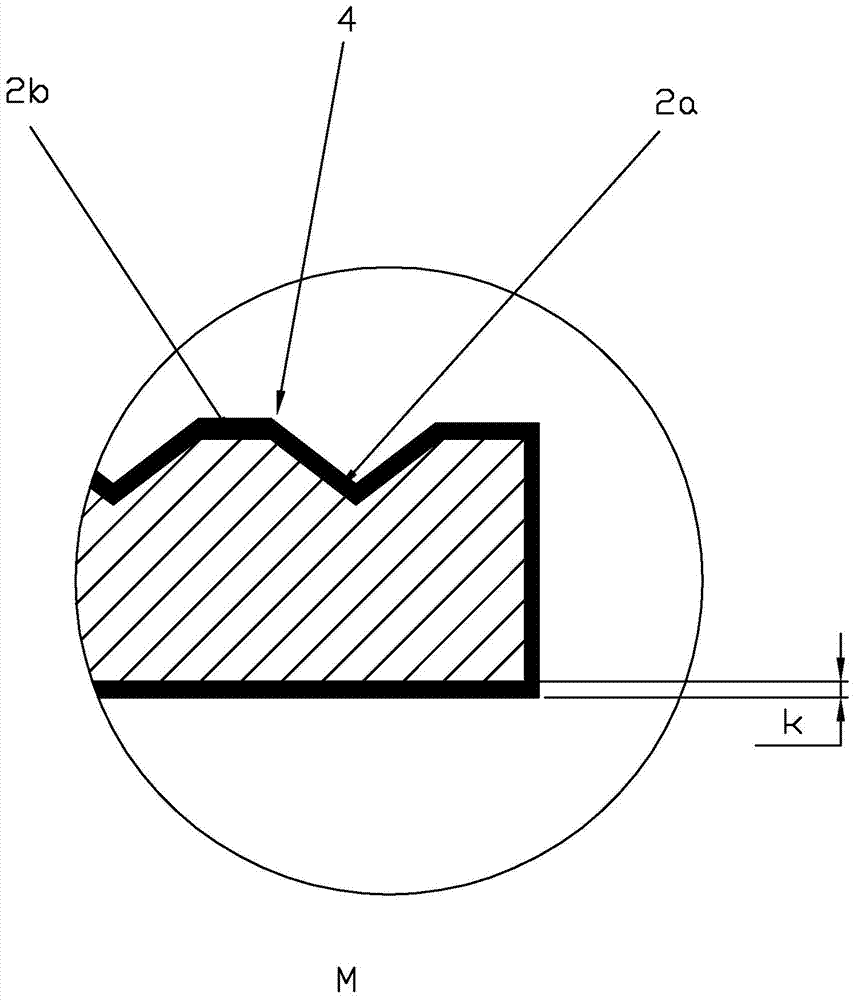

[0024] A heterogeneous photovoltaic ribbon, comprising a conductive base strip 1, the conductive base strip 1 has a lower bonding surface 3 and an upper reflecting surface 2, the lower bonding surface 3 is a flat surface, and the upper reflecting surface 2 is distributed with V-shaped grooves 2A, adjacent A coupling platform 2b is formed between the V-shaped grooves 2A, the V-shaped grooves 2A extend in parallel along the length direction of the conductive base strip 1, and the depth of the V-shaped grooves 2A is 25%-30% (preferably 25.5%, 26%) of the thickness L of the conductive base strip. %, 28% these three endpoints, such as Figure 4 As shown, when the angle A of the V-shaped groove is 80°, the light utilization rate A of the three endpoints is at the peak), and the angle A of the V-shaped groove 2A is between 77°-95° (preferably 80°, 83° , 90°, such as Figure 5 As shown, when the reading H of the V-shaped groove is at 26%, the light utilization rate A of the three e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com